Search results for: 'automat'

- Related search terms

- automatic te

- automatic+V''

- Automatic du

- Automatic+4+s

- AUTOMATIC''

-

M-1456 COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATEDREFERENCE NUMBER: M-1456 (660211BTC5R) COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATED QUANTITY AVAILABLE: 1 Learn More

M-1456 COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATEDREFERENCE NUMBER: M-1456 (660211BTC5R) COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATED QUANTITY AVAILABLE: 1 Learn More -

G-2253 PILLOW & CUSHION AUTOMATIC WEIGHING & FILLING LINEREFERENCE NUMBER: G-2253 PILLOW & CUSHION AUTOMATIC WEIGHING & FILLING LINE FOR SALE: (5 PILLOWS PER MINUTE) FIBER OPENING, ACCURATE WEIGHING BY WEIGH PAN WITH LOAD CELL AND HIGH SPEED FILLING SYSTEM TOUCH SCREEN PANEL, FULLY AUTOMATED AND ACCURATE HANDLES WEIGHTS OF PILLOWS: FROM 150g TO 1500g PRODUCTION RATE: 5 PIECES PER MIN, 2400 PIECES PER 8 HOURS METAL DETECTOR AND OVERLOAD ALARM INCLUDES FIBER OPENING MACHINE ONE PERSON CAN RUN WHOLE LINE TWO HEAD FILLING MACHINE WITH PATTING DEVICES OPTIONAL: VACUUM FILLING TABLE QUANTITY AVAILABLE: 1 Learn More

G-2253 PILLOW & CUSHION AUTOMATIC WEIGHING & FILLING LINEREFERENCE NUMBER: G-2253 PILLOW & CUSHION AUTOMATIC WEIGHING & FILLING LINE FOR SALE: (5 PILLOWS PER MINUTE) FIBER OPENING, ACCURATE WEIGHING BY WEIGH PAN WITH LOAD CELL AND HIGH SPEED FILLING SYSTEM TOUCH SCREEN PANEL, FULLY AUTOMATED AND ACCURATE HANDLES WEIGHTS OF PILLOWS: FROM 150g TO 1500g PRODUCTION RATE: 5 PIECES PER MIN, 2400 PIECES PER 8 HOURS METAL DETECTOR AND OVERLOAD ALARM INCLUDES FIBER OPENING MACHINE ONE PERSON CAN RUN WHOLE LINE TWO HEAD FILLING MACHINE WITH PATTING DEVICES OPTIONAL: VACUUM FILLING TABLE QUANTITY AVAILABLE: 1 Learn More -

G-1385 AUTOMATIC CUTTING MACHINEREFERENCE NUMBER: G-1385 AUTOMATIC CUTTING MACHINE MODEL BF45 RIGHT TABLE: 2200mm (86.6") LEFT TABLE: 2000mm (78.7") WORKING CUTTING LENGTH: 2350mm (92.5") WORKING CUTTING HEIGHT: 1300mm (51") QUANTITY AVAILABLE: 1 Learn More

G-1385 AUTOMATIC CUTTING MACHINEREFERENCE NUMBER: G-1385 AUTOMATIC CUTTING MACHINE MODEL BF45 RIGHT TABLE: 2200mm (86.6") LEFT TABLE: 2000mm (78.7") WORKING CUTTING LENGTH: 2350mm (92.5") WORKING CUTTING HEIGHT: 1300mm (51") QUANTITY AVAILABLE: 1 Learn More -

M-0037 AUTOMATIC BOX FOAMING MACHINEREFERENCE NUMBER: M-0037 FOAM BLOCK MACHINE AUTOMATIC BOX FOAMING MACHINE (7 CHEMICAL GROUPS) CHEMICAL: PPG, TDI, MC, AMINE, TIN, SILICONE AND WATER (7 GROUPS) FOAMING SIZE OF MOULD (MAXIMUM): L2440 X W2050 X H1200mm QUANTITY AVAILABLE: 1 Learn More

M-0037 AUTOMATIC BOX FOAMING MACHINEREFERENCE NUMBER: M-0037 FOAM BLOCK MACHINE AUTOMATIC BOX FOAMING MACHINE (7 CHEMICAL GROUPS) CHEMICAL: PPG, TDI, MC, AMINE, TIN, SILICONE AND WATER (7 GROUPS) FOAMING SIZE OF MOULD (MAXIMUM): L2440 X W2050 X H1200mm QUANTITY AVAILABLE: 1 Learn More -

K-9100 HORIZONTAL FOAM CUTTING MACHINE:(FULLY AUTOMATIC) - FOR 60" HIGH BUNSREFERENCE NUMBER: K-9100 HORIZONTAL FOAM CUTTING MACHINE:(FULLY AUTOMATIC) - FOR 60" HIGH BUNS MODEL PQ-2150- 1524MM FOAM BLOCK SIZE W2150 X L3000mm X 1524mm HIGH POWER 7.94 KW CUTTING SPEED 0~25m/MIN (TABLE TRAVEL SPEED) FLOOR SPACE REQUIREMENT L5800 X W3500 X H2400mm CUT THICKNESS FROM 2 mm AND UP BLADE LENGTH 9580mm, BLADE WIDTH 30mm BLADE THICKNESS IS 0.45mm, BLADE GUIDE OPENING IS FIXED OPENING OF 0.55mm BLADE SPEED: 720 METERS/MINUTE MACHINE WEIGHT 2000 KG VERTICAL BLADE MOVEMENT IS BY BALL SCREWS FULLY AUTOMATED PLC NUMERICAL CONTROLS ALLOWING FOR MULTIPLE THICKNESS CUT IN ONE BUN, SEQUENTIALLY TOUCH SCREEN CONTROLS, INVERTER CONTROLS, SIEMENS PLC , all motors 220 volt , 3 phase , 60HZ WITH A PRESSURE ROLLER FOR FINER CUTS.ELECTRICALLY ACTIVATED VACUUM TABLE (3.6 Kw MOTOR) BLADE SHARPENER AND DUST COLLECTOR (1.1 Kw motor) MOVABLE STABILIZER BAR FOR BLADE GUIDE EXTRA SUPPORT PNEUMATIC BLADE GUIDE TENSIONING QUANTITY AVAILABLE: 1 Learn More

K-9100 HORIZONTAL FOAM CUTTING MACHINE:(FULLY AUTOMATIC) - FOR 60" HIGH BUNSREFERENCE NUMBER: K-9100 HORIZONTAL FOAM CUTTING MACHINE:(FULLY AUTOMATIC) - FOR 60" HIGH BUNS MODEL PQ-2150- 1524MM FOAM BLOCK SIZE W2150 X L3000mm X 1524mm HIGH POWER 7.94 KW CUTTING SPEED 0~25m/MIN (TABLE TRAVEL SPEED) FLOOR SPACE REQUIREMENT L5800 X W3500 X H2400mm CUT THICKNESS FROM 2 mm AND UP BLADE LENGTH 9580mm, BLADE WIDTH 30mm BLADE THICKNESS IS 0.45mm, BLADE GUIDE OPENING IS FIXED OPENING OF 0.55mm BLADE SPEED: 720 METERS/MINUTE MACHINE WEIGHT 2000 KG VERTICAL BLADE MOVEMENT IS BY BALL SCREWS FULLY AUTOMATED PLC NUMERICAL CONTROLS ALLOWING FOR MULTIPLE THICKNESS CUT IN ONE BUN, SEQUENTIALLY TOUCH SCREEN CONTROLS, INVERTER CONTROLS, SIEMENS PLC , all motors 220 volt , 3 phase , 60HZ WITH A PRESSURE ROLLER FOR FINER CUTS.ELECTRICALLY ACTIVATED VACUUM TABLE (3.6 Kw MOTOR) BLADE SHARPENER AND DUST COLLECTOR (1.1 Kw motor) MOVABLE STABILIZER BAR FOR BLADE GUIDE EXTRA SUPPORT PNEUMATIC BLADE GUIDE TENSIONING QUANTITY AVAILABLE: 1 Learn More -

G-9015 HORIZONTAL MOVING TABLE FOAM CUTTING MACHINE (WITH AUTOMATIC WINDING SYSTEM)REFERENCE NUMBER: G-9015 HORIZONTAL MOVING TABLE FOAM CUTTING MACHINE (WITH AUTOMATIC WINDING SYSTEM) TABLE IS 16 METERS LONG, TO ACCOMMODATE 50 FOOT LONG BUNS X 51" MAXIMUM HEIGHT. WITH A 2.15 METER CUTTING WIDTH AND 16 METER MOVING TABLE, THE FLOORSPACE OF THE WHOLE MACHINE IS ABOUT L 35 METERS X W 4200mm X H 2400mm (116 FEET LONG; 165" OVERALL WIDTH) QUANTITY AVAILABLE: 1 Learn More

G-9015 HORIZONTAL MOVING TABLE FOAM CUTTING MACHINE (WITH AUTOMATIC WINDING SYSTEM)REFERENCE NUMBER: G-9015 HORIZONTAL MOVING TABLE FOAM CUTTING MACHINE (WITH AUTOMATIC WINDING SYSTEM) TABLE IS 16 METERS LONG, TO ACCOMMODATE 50 FOOT LONG BUNS X 51" MAXIMUM HEIGHT. WITH A 2.15 METER CUTTING WIDTH AND 16 METER MOVING TABLE, THE FLOORSPACE OF THE WHOLE MACHINE IS ABOUT L 35 METERS X W 4200mm X H 2400mm (116 FEET LONG; 165" OVERALL WIDTH) QUANTITY AVAILABLE: 1 Learn More -

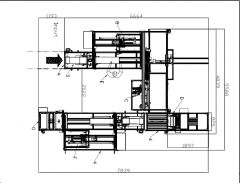

G-5887-A HORIZONTAL AUTOMATIC CONTINUOUS FOAM PROCESSING LINEREFERENCE NUMBER: G-5887-A HORIZONTAL AUTOMATIC CONTINUOUS FOAM PROCESSING LINE OVEN LENGTH: 17.5 METERS FOAMING HEIGHT: <1.25M FOAMING WIDTH: 1.0~2.25M FOAMING DENSITY: 10~50KG/M3 QUANTITY AVAILABLE: 1 LINE Learn More

G-5887-A HORIZONTAL AUTOMATIC CONTINUOUS FOAM PROCESSING LINEREFERENCE NUMBER: G-5887-A HORIZONTAL AUTOMATIC CONTINUOUS FOAM PROCESSING LINE OVEN LENGTH: 17.5 METERS FOAMING HEIGHT: <1.25M FOAMING WIDTH: 1.0~2.25M FOAMING DENSITY: 10~50KG/M3 QUANTITY AVAILABLE: 1 LINE Learn More -

A-1223 DETTIN AUTOMATED HYDRO-EXTRACTOR BERTA 24 YEAR 2001REFERENCE NUMBER: A-1223 (0101GHBXX12) A DETTIN AUTOMATED HYDRO-EXTRACTOR BERTA 24 YEAR 2001 DETTIN AUTOMATIC HYDRO-EXTRAXTOR TYPE BERTA 24 YEAR: 2001 QUANTITY AVAILABLE: 1 Learn More

A-1223 DETTIN AUTOMATED HYDRO-EXTRACTOR BERTA 24 YEAR 2001REFERENCE NUMBER: A-1223 (0101GHBXX12) A DETTIN AUTOMATED HYDRO-EXTRACTOR BERTA 24 YEAR 2001 DETTIN AUTOMATIC HYDRO-EXTRAXTOR TYPE BERTA 24 YEAR: 2001 QUANTITY AVAILABLE: 1 Learn More -

G-6976 AUTOMATIC DOWN FILLING MACHINE (NEW)FOR PILLOWS, COMFORTERS, JACKETS, ETC FOR DOWN OR STANDARD FEATHERS MODEL: 002 POWER: 5.9kw AIR PRESSURE: 0.6 TO 0.8 Mpa CAPACITY: 4-6 s/pc DIMENSIONS: 6800 x 2000 x 2400mm VOLTAGE: PER CUSTOMER REQUEST WEIGHING ABILITY: 1 TO 200 g/pc MATERIAL APPLICATION: DUCK DOWN 50 UP Learn More

G-6976 AUTOMATIC DOWN FILLING MACHINE (NEW)FOR PILLOWS, COMFORTERS, JACKETS, ETC FOR DOWN OR STANDARD FEATHERS MODEL: 002 POWER: 5.9kw AIR PRESSURE: 0.6 TO 0.8 Mpa CAPACITY: 4-6 s/pc DIMENSIONS: 6800 x 2000 x 2400mm VOLTAGE: PER CUSTOMER REQUEST WEIGHING ABILITY: 1 TO 200 g/pc MATERIAL APPLICATION: DUCK DOWN 50 UP Learn More -

G-8448-C DUST-FREE AUTOMATIC FEATHER FILLING MACHINE MODEL S-6CLOSED TYPE WITH SMALL AIR-CONDITIONER (2) COMPUTER AND FILLING SETS RUN BY TWO OPERATORS DIAMETER OF FILLING NOZZLE: 12mm FILLING WEIGHT ≤2 GRAM, FILLING TIME ≤1 SECOND AN AIR COMPRESSOR (THREE-PHASE WITH 5.5KW) AND AN AIR STORAGE TANK (0.6 TO 1 M³) ARE NEEDED THE CAPACITY OF THE COMPRESSED AIR CAN BE USED BY (12) SETS OF FILLING NOZZLES (SIX FILLING MACHINES) DIAMETER OF COMPRESSED AIR PIPE: 1” (FROM AIR STORAGE TANK TO FILLING ROOM) DIAMETER OF COMPRESSED AIR PIPE: ½” (MAIN MACHINE TO FILLING NOZZLE) VOLTAGE: 220V POWER: AIR-CONDITION 500W, AIR-CIRCULATION FAN 370W, FILLING FAN 180W, VARIABLE SPEED MOTOR 200W, LIGHTS 60W AND COMPUTER 50W AIR PRESSURE: 6MPa FLOOR SPACE OF FILLING ROOM: ≥6M² FILLING ERROR RANGE: 1 GRAM FOR ONE PIECE DOWN CONTENT: 50% TO 95% STAINLESS STEEL MAIN FRAME TOUCH SCREEN WITH (1) PRECISE WEIGHING SCALE WITH AIR CIRCULATION SYSTEM AUTOMATICLLY RECYCLE FEATHERS THAT FALL TO THE FLOOR MOVABLE FILLING MACHINE CAN BE DISMOUNTED WITH SPOTLIGHT (2) WORKING TABLE DIMENSIONS OF THE MACHINE: 3000 X 1300 X 1800 (mm) Learn More

G-8448-C DUST-FREE AUTOMATIC FEATHER FILLING MACHINE MODEL S-6CLOSED TYPE WITH SMALL AIR-CONDITIONER (2) COMPUTER AND FILLING SETS RUN BY TWO OPERATORS DIAMETER OF FILLING NOZZLE: 12mm FILLING WEIGHT ≤2 GRAM, FILLING TIME ≤1 SECOND AN AIR COMPRESSOR (THREE-PHASE WITH 5.5KW) AND AN AIR STORAGE TANK (0.6 TO 1 M³) ARE NEEDED THE CAPACITY OF THE COMPRESSED AIR CAN BE USED BY (12) SETS OF FILLING NOZZLES (SIX FILLING MACHINES) DIAMETER OF COMPRESSED AIR PIPE: 1” (FROM AIR STORAGE TANK TO FILLING ROOM) DIAMETER OF COMPRESSED AIR PIPE: ½” (MAIN MACHINE TO FILLING NOZZLE) VOLTAGE: 220V POWER: AIR-CONDITION 500W, AIR-CIRCULATION FAN 370W, FILLING FAN 180W, VARIABLE SPEED MOTOR 200W, LIGHTS 60W AND COMPUTER 50W AIR PRESSURE: 6MPa FLOOR SPACE OF FILLING ROOM: ≥6M² FILLING ERROR RANGE: 1 GRAM FOR ONE PIECE DOWN CONTENT: 50% TO 95% STAINLESS STEEL MAIN FRAME TOUCH SCREEN WITH (1) PRECISE WEIGHING SCALE WITH AIR CIRCULATION SYSTEM AUTOMATICLLY RECYCLE FEATHERS THAT FALL TO THE FLOOR MOVABLE FILLING MACHINE CAN BE DISMOUNTED WITH SPOTLIGHT (2) WORKING TABLE DIMENSIONS OF THE MACHINE: 3000 X 1300 X 1800 (mm) Learn More