Search results for: 'Thi'

- Related search terms

- Thie

- Thies d

- THIBEAU

- thibe

- Thies dyeing

-

T-6337 DISPOSABLE MEDICAL RUBBER INSPECTION GLOVES TESTING INSTRUMENTS

T-6337 DISPOSABLE MEDICAL RUBBER INSPECTION GLOVES TESTING INSTRUMENTSITEM 001

PLASTIC FILM THICKNESS TESTERITEM 002

RUBBER GLOVES TENSILE STRENGTH TESTERITEM 003

RUBBER GLOVES WATERPROOF TESTERITEM 004

RUBBER GLOVES PRETREATMENT AGING BOXEMAIL US FOR PRICE & PICTURES

INCLUDE OUR REFERENCE NUMBER

Learn More -

HPFJ-1111 POLYMAT FOR UPHOLSTERY, MATTRESS TOPPERS, MATS AND SEAT CUSHIONS

HPFJ-1111 POLYMAT FOR UPHOLSTERY, MATTRESS TOPPERS, MATS AND SEAT CUSHIONS• Air permeable

The mesh openings on two sides and the porous structure allow free air flow and vapor emission from all six sides, effectively inhibiting the growth of molds, bacteria and mites and thus preventing skin itches.• Stress-relieving and body-fitting

The hardness is moderate to reduce the body stress so that human body can fully relax without feeling any compression, avoiding blocking blood flow. There are 40 supporting points per square centimeter, providing meticulous support and fitting the material to the natural curve of human body.• Easy-to-wash and fast-dry

The material is made from functional fiber, which neither absorbs moisture nor easily reacts chemically with oil and dirt. Water stays no more than one second on the material, while sweat, dirt, and dust can be washed away easily. Therefore, the surface can be cleaned with minimum effort, preventing the growth of mites and bacteria.• Eco-friendly and non-toxic

The pure fabric can be fully recycled upon disposal. The combustion products of sponge are cyanides, which are highly toxic; on the contrary, the products of complete combustion of 3D spacer material are water and carbon dioxide, which are non-toxic and totally safe.• Rollable and portable.

With superior rollability, it can be easily carried into and out of an elevator, taken to outdoor activities, or stores easily when the seasons change.

Learn More

CONSTRUCTED OF 100% POLYESTER

FEATURES: AIR-PERMEABLE, WATER-PERMEABLE, ECO-FRIENDLY, NON-TOXIC, 100% RECYCLED, ANTI-STATIC, ANTI-MITE, ELASTIC, FLAME-RETARDANT, ETC.

NET “X” STRUCTURE

FOR UPHOLSTERY, MATTRESS TOPPERS, MATS, SEAT CUSHIONS, ETC.

NO# NAME LENGTH x WIDTH DIMENSIONS APPROX. INCHES THICKNESS

1 CUSHION 450x450mm 17.7 x 17.7 8 INCHES

2 BABY BED 600x1200mm 23.6 x 47.2 8 INCHES

3 STUDENT BED 1000x2000mm 39.3 x 78.7 8 INCHES

4 1.2 METER BED 1200x2000mm 47.2 x 78.7 8 INCHES

5 1.5 METER BED 1500x2000mm 59 x 78.7 8 INCHES

6 1.8 METER BED 1800x2000mm 70.8 x 78.7 8 INCHES

7 QUEEN BED 1524 x 2032mm 60 x 80 8 INCHES -

H-2366 MASK AND MEDICAL GOWN LABORATORY EQUIPMENT

H-2366 MASK AND MEDICAL GOWN LABORATORY EQUIPMENTREFERENCE NUMBER: T-6334

Learn More

ALL KINDS OF MASK TESTING INSTRUMENTS

(SURGICAL MASK)

(DISPOSABLE SURGICAL MASK)

(MEDICAL PROTECTIVE MASK)

(DAILY PROTECTIVE MASK)

ITEM 001

COMPREHENSIVE TENSION TESTER FOR SURGICAL MASK

ITEM 002

MASK SYNTHETIC BLOOD PENETRATION DETECTOR

ITEM 003

BACTERIAL PERCOLATION EFFICIENCY (BFE) TESTER

ITEM 004

PARTICLE EFFICIENCY (PFE) TESTER

ITEM 005

RESPIRATOR RESISTANCE TESTER

ITEM 006

MASK FLAME RETARDANT PERFORMANCE TESTER

ITEM 007

FABRIC SURFACE MOISTURE TESTER

ITEM 008

MASK AIR TIGHTNESS TESTER

ITEM 009

TEMPERATURE PRETREATMENT CONSTANT TEMPERATURE AND HUMIDITY CHAMBER

ITEM 010

COLOR FASTNESS TO FRICTION TESTER

ITEM 011

TEXTILE FORMALDEHYDE TESTER

ITEM 012

PH METER

REFERENCE NUMBER: T-6335

RESPIRATORY PROTECTIVE EQUIPMENT & SELF-IMBIBITION FILTER ANTI-PARTICULATE RESPIRATOR TESTING INSTRUMENTS

ITEM 001

FIITRATION EFFICIENCY N CLASS SODIUM CHLORIDE PARTICLES, P CLASS OIL PARTICLES

PARTICLE RATE EFFICIENCY TESTER

ITEM 002

RESPIRATOR RESISTANCE TESTER

ITEM 003

BREATHING VALVE TIGHTNESS TESTER

ITEM 004

AXIAL TENSION TESTER FOR BREATHING BONNET

ITEM 005

AXIAL TENSION TESTER FOR BREATHING BONNET

ITEM 006

MASK FIELD TESTER

ITEM 007

HEADBAND TENSILE TESTING MACHINE

ITEM 008

JOINT PARTS&AXIAL TENSILE TESTING MACHINE

ITEM 009

MASK FLAME RETARDANT PERFORMANCE TESTER

ITEM 010

TEMPERATURE PRETREATMENT CONSTANT TEMPERATURE AND HUMIDITY CHAMBER

REFERENCE NUMBER: T-6336

MEDICAL DISPOSABLE PROTECTIVE CLOTHING TESTING INSTRUMENTS

ITEM 001

WATER PENETRATION RESISTANCE TESTER FOR PROTECTIVE CLOTHING

ITEM 002

MOISTURE PERMEABILITY TESTER FOR PROTECTIVE CLOTHING

ITEM 003

SURFACE MOISTURE RESISTANCE TESTER

ITEM 004

ANTISYNTHETIC BLOOD PENETRANT DETECTOR

ITEM 005

TENSILE TESTER FOR BREAKING STRENGTH AND ELONGATION

ITEM 006

FLAME RETARDANT PERFORMANCE TESTER FOR PROTECTIVE CLOTHING

ITEM 007

FRICTION ELECTRIFICATION TESTER FOR PROTECTIVE CLOTHING (FRENCH LADLE)

REFERENCE NUMBER: T-6337

DISPOSABLE MEDICAL RUBBER INSPECTION GLOVES TESTING INSTRUMENTS

ITEM 001

PLASTIC FILM THICKNESS TESTER

ITEM 002

RUBBER GLOVES TENSILE STRENGTH TESTER

ITEM 003

RUBBER GLOVES WATERPROOF TESTER

ITEM 004

RUBBER GLOVES PRETREATMENT AGING BOX

More information is available upon request.

E-mail us for price, pictures, video, or diagram.

Include our reference number -

J-2007 ULTRASONIC NONWOVEN BONDING MACHINE, WORKING WIDTH 1600mm, 100 METERS PER MINUTE

J-2007 ULTRASONIC NONWOVEN BONDING MACHINE, WORKING WIDTH 1600mm, 100 METERS PER MINUTEFOR NONWOVEN MATERIALS: SPUNBOND, MELTBLOW, SPUNLACE, AIRLAID, PPE, PS, PES, NYLON66, ARAMID ETC.

OIL ABSORBER, WATERPROOF, BREATHABLE COMPOSITES

TOTAL MATERIAL THICKNESS RANGE: 20gsm TO 55gsmWORKING WIDTH: 1600mm

CAPACITY: 10 TO 100 METERS PER MINUTE

ONE PATTERN ROLLER

TITANIUM HORNS

ULTRASONIC SYSTEM 20 KHZ, 2000 WATTS (10 SETS)

PLC CONTROLS WITH TOUCH SCREEN

ELECTRICAL: 380 VOLTS, 3-PHASE, 28 KW

AIR: 6 BAR PER CM2 , 2 LITERS PER HOUR

OPTIONAL EXTRA PATTERN ROLLER AVAILABLE (PRICED SEPERATELY)

WITH CE CERTIFICATE, TOOL BOX, USER MANUALLEAD TIME: 110 DAYS

QUANTITY: 1

Learn More -

V-1724 MATTRESS WRAPPING WITH PRESSING UNIT AND ROLLING UP – NEW

V-1724 MATTRESS WRAPPING WITH PRESSING UNIT AND ROLLING UP – NEWFLATTEN ALL TYPES OF MATTRESSES AND ROLL UP THE FLAT POCKET SPRING MATTRESSES.

FLATTENING AND ROLLING MATTRESSES HAS THE ADVANTAGE OF MINIMIZING THE STORAGE AREA AND

FACILITATE THE TRANSPORTATION AND LOWER TRANSPORTATION COSTS.

PRODUCTION CAPACITY: 3 MATTRESSES PER MINUTE FOR NORMAL PACKING.

MATTRESS SIZE: MIN. 700 X 1900mm TO MAX. 2100 X 2100mm

MATTRESS HEIGHT: 50mm TO 400mm

PRESSING SYSTEM: PNEUMATIC FOR NORMAL PACKING, HYDRAULIC SYSTEM FOR FLATTENING AND ROLL PACKING

PNEUMATIC PRESSURE: 482 KGS (8 BARS)

HYDRAULIC PRESSURE: 65 TON

WIDTH OF FILM ROLLS: MIN. 2200 mm TO MAX. 2650 mm

MAX. DIAMETER OF FILM ROLLS: 320mm

MAX. WEIGHT OF FILM ROLLS: 200 KGS

TYPE OF NYLON: PE FILM

THICKNESS OF FILM: 50 TO 150 MICRON (5 TO 15)

POWER REQUIREMENTS: 3 PHASE 380 V OR AS PER CUSTOMER

TOTAL ELECTRIC DRAW: 20 KW

WEIGHT: APPROX. 10 TONS

NUMBER OF OPERATORS: 1

QUALITY STANDARD: CE

WARRANTY: 2 YEARS

FINAL ROLL PACKING TUBE DIAMETER: 250 TO 400 mm

YouTube Video 1: https://youtu.be/7e3-3FtaQdE

YouTube Video 2: https://youtu.be/LrmcQ18A1zM

QUANTITY: 1

Learn More -

J-1937 LAMINATING MACHINE FOR FOAM TO FABRIC – CONTINUOUS WITH SLITTING, NEW

J-1937 LAMINATING MACHINE FOR FOAM TO FABRIC – CONTINUOUS WITH SLITTING, NEWSILICON COATED NOMEX FELT (ITB BRAND – ITALIAN)

BLANKET THICKNESS: 8mm

PNEUMATICALLY ADJUSTABLE FELT PRESSURE

MAXIMUM WORKING WIDTH: 2100mm (82.6”)

EVA HOT MELT FILM, FILM ROLL MIMIMUM 500 METERS, MAXIMUM 1000 METERS

36 KW HEATER RESISTANCE

MAIN DRUM DIAMETER: 500mm

TEFLON COATED MAIN CYLINDER

PNEUMATIC BLANKET EDGE CONTROL BY PHOTOCELL

WORKING SPEED: 5 TO 10 METERS PER MINUTE, DEPENDING ON FABRIC THICKNESS (THICK FABRIC IS SLOWER, NORMAL FABRIC IS FASTER)

PLC CONTROLLER WITH TOUCH SCREEN OPERATOR PANEL

PROGRAMMABLE HEATING UP AND COOLING DOWN

ROLL TO ROLL WORKING SYSTEM

SLITTING UNIT WITH 3 PIECE PNEUMATIC CUTTER AND DUAL CENTER REWINDING UNIT (OPTIONAL)

440 V 3-PHASE, 60 Hz, 55 AMPLEAD TIME: 6 TO 8 WEEKS AFTER RECEIPT OF DEPOSIT

Learn More -

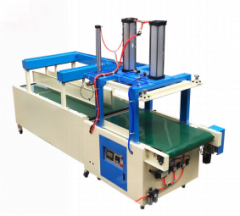

J-1948 PILLOW & CUSHION COMPRESSION PACKING MACHINE- NEW -AUTOMATIC , 12 PILLOWS PER MINUTE

J-1948 PILLOW & CUSHION COMPRESSION PACKING MACHINE- NEW -AUTOMATIC , 12 PILLOWS PER MINUTEREDUCES VOLUME FOR STORAGE AND TRANSPORTATION

USES COMPRESSED AIR AND PLASTIC COMPOSITE FILM BAGS FOR PACKAGING ITEMS AFTER COMPRESSION

EQUIPPED WITH AUTOMATIC TRANSMISSION TO COMPRESS AND FILM ITEMS UNINTERRUPTED

STANDARD MODEL EQUIPPED WITH ONE WORKSTATION WITH SINGLE SEAL (OPTIONAL ONE WORKSTATION WITH DOUBLE SEALS)

PLC TOUCH SCREEN OPERATION, USER FRIENDLY INTERFACE

CONSTANT TEMPERATURE CONTROL FUNCTION TO PREVENT BAG BURNSVOLTAGE AND POWER: 220 V SINGLE-PHASE, 0.5 KW, 50 Hz

AIR PRESSURE: 0.4 – 0.8 MPA

PACKING CAPACITY: : 8 TO 12 ITEMS PER MINUTE

PRESS BOARD SIZE: LENGTH 700mm x WIDTH 900mm

MAXIMUM COMPRESSION THICKNESS: 500mm (AIR CYLINDER TRAVEL)

SEAL LENGTH: 880mm x 10mm

OVERALL DIMENSIONS: LENGTH 3390mm x WIDTH 940mm x HEIGHT 2010mm

POWER: 1.5 KW

NET WEIGHT: 350 KG

GROSS WEIGHT: 400 KGQUANTITY: 1

Learn More -

L-6683 DOUBLE BELT COMPRESSION THERMOBONDING OVEN

L-6683 DOUBLE BELT COMPRESSION THERMOBONDING OVENL-6683 DOUBLE BELT COMPRESSION THERMOBONDING OVEN SYSTEM 6000mm X 3300mm WIDE

INCLUDING:

THERMOBONDING OVEN

- DOUBLE COMPRESSION CONVEYORS SYSTEM SINGLE PASS

- DOUBLE BELT SOFT & HARD WADDING OVEN (6000mm LONG)

WORKING WIDTH: 3300mm

LENGTH OF HEATING CHAMBER: 6000mm

PANELS ARE 100mm THICK

TEMPERATURE INSIDE: UP TO 220 C

GAS BURNER 25 CUBIC METER PER HOUR DEPENDING ON MATERIAL THICKNESS

TWO GAS BURNERS ONE ON EACH SIDE 80 START AND 25 RUN CBM/H WITH MAINLINE 2 INCH

REDUCED TO 1” AT BURNER, PRESSURE 10 TO 15 KPascal

TWO HOT AIR FANS 22 KW EACH

ONE EXHAUST FAN 5.5 KW

WORKING SPEED: 1 TO 8 METERS PER MINUTE

DOUBLE TEFLON BELT WITH SINGLE PASS, WEAVE IS 2mm X 2mm

SUCTION HOOD AT THE ENTRANCE

THICKNESS OF FINAL PRODUCT 20 TO 150mm DEPENDINGCOOLING UNIT

- FOUR COOLING PRESS ROLLERS 200mm diameter , 10mm shell thickness, with chiller

12,000 watt output power , input power 5700 watt , capacity 65 liter per minute

WORKING WIDTH: 3300mm

- LENGTHWISE CUTTER – 7 KNIVES ,pneumatically activated , BLADE DIAMETER 650mm

-SINGLE MOTOR

- MOVABLE SIDEWAYS

- CROSS CUTTER 2.2 KW MOTOR . UP TO 4 CUTS PER MINUTE

MAXIMUM LENGTH 2000mm

WORKING WIDTH: 2800mm

PVC CONVEYOR AT THE EXITELECTRICAL CONTROL SYSTEM

-ELECTRICAL CABINET UL COMPONENTSQUANTITY: 1

Learn More -

J-1825 HIGH SPEED COMPUTERIZED CHAIN STITCH MULTI-NEEDLE QUILTING MACHINE, NEW - 1200 RPM

J-1825 HIGH SPEED COMPUTERIZED CHAIN STITCH MULTI-NEEDLE QUILTING MACHINE, NEW - 1200 RPMREFERENCE NUMBER: J-1825

HIGH SPEED COMPUTERIZED CHAIN STITCH MULTI-NEEDLE QUILTING MACHINE, NEW - 1200 RPMQUILTING WIDTH: 2450mm (96 INCHES)

CAPACITY: 60 TO 300 METERS PER HOUR

STITCH LENGTH: 3 TO 7mm

QUILTING THICKNESS: ≤80mm

NEEDLE BAR DISTANCE: 1 x 3 x 6

NEEDLE DISTANCE SIDEWAYS: 25.4mm (ONE INCH)

X-AXIS MOVEMENT DISPLACEMENT: 304.8mm (12 INCHES)

NEEDLE TYPE: 24/180 23/160 22/140 21/130

MAIN SHAFT SPEED: 500 TO 1200 RPM

VOLTAGE: 380V/50Hz, 220V/60Hz, 3-PHASE

POWER: 7 KW

DIMENSIONS: 5400 x 1650 x 2050mm

WEIGHT: 4800 KGCONTROLS BASED ON WINDOWS, CAD DRAWING

CONTINUOUS PATTERNS AND TACK & JUMP PATTERNS (360° AND 180°) ARE AVAILABLE

DELTA VFD (VARIABLE FREQUENCY DRIVER) DRIVES MAIN SHAFT (Z SHAFT)

PANASONIC SERVO DRIVER & MOTOR CONTROL THE SADDLE (X SHAFT) AND ROLLER (Y SHAFT)

AUTOMATIC STOP WHEN UP OR BOTTOM THREAD IS BROKEN

BOTH UP AND DOWN SAFETY INFRARED PROTECTIONQUANTITY: 1

Learn More