Search results for: 'Continuous t'

- Related search terms

- continuous 20

- continuous+f

- Continuous fo

- Continuous+foam

- Continuous fo'[0]

-

J-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEETJ-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEET SUITABLE FOR FOAM ROLL WRAP FOAM DENSITY: 25 KGS/m3 TO 45 KGS/m3 CAPACITY: 15 SECONDS PER SHEET, CONTINUOUS OPERATION MAXIMUM MATTRESS SIZE: 2200 x 1500 x 150mm ROLL DIAMETER: 50 TO 300mm VOLTAGE: 380 VOLTS, 50 Hz OR 220 VOLTS, 60 Hz TOTAL POWER: 25 KW WEIGHT: 6.5 TONS QUANTITY: 1 Learn More

J-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEETJ-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEET SUITABLE FOR FOAM ROLL WRAP FOAM DENSITY: 25 KGS/m3 TO 45 KGS/m3 CAPACITY: 15 SECONDS PER SHEET, CONTINUOUS OPERATION MAXIMUM MATTRESS SIZE: 2200 x 1500 x 150mm ROLL DIAMETER: 50 TO 300mm VOLTAGE: 380 VOLTS, 50 Hz OR 220 VOLTS, 60 Hz TOTAL POWER: 25 KW WEIGHT: 6.5 TONS QUANTITY: 1 Learn More -

YY-2370 UNUSED WATERMAKERS, CAPACITY 50 M3 PER 24H, QUANTITY 2YY-2370 UNUSED WATERMAKERS, CAPACITY 50 M3 PER 24H, QUANTITY 2 WATERMAKER PRODUCES DRINKING WATER FROM SEA WATER BASED UPON THE REVERSE OSMOSIS MEMBRANE TECHNIQUE. THE CAPACITY IS 50M3/24H FROM SEAWATER (25OC). THE QUALITY OF THE DRINKING WATER IS CONTINUOUSLY MONITORED BY A SALINITY METER. THE DESIGN IS IDEAL FOR SIMPLE SERVICE AND MAINTENANCE. THE UNIT IS SUITABLE FOR: - DRILLING PLATFORMS; - OFFSHORE RIGS AND ACCOMMODATION PLATFORMS; - COMMERCIAL VESSELS; - MILITARY VESSELS; - RESORTS, HOTELS AND COMMUNITIES; - GOLF COURSES. QUANTITY: 2 Learn More

YY-2370 UNUSED WATERMAKERS, CAPACITY 50 M3 PER 24H, QUANTITY 2YY-2370 UNUSED WATERMAKERS, CAPACITY 50 M3 PER 24H, QUANTITY 2 WATERMAKER PRODUCES DRINKING WATER FROM SEA WATER BASED UPON THE REVERSE OSMOSIS MEMBRANE TECHNIQUE. THE CAPACITY IS 50M3/24H FROM SEAWATER (25OC). THE QUALITY OF THE DRINKING WATER IS CONTINUOUSLY MONITORED BY A SALINITY METER. THE DESIGN IS IDEAL FOR SIMPLE SERVICE AND MAINTENANCE. THE UNIT IS SUITABLE FOR: - DRILLING PLATFORMS; - OFFSHORE RIGS AND ACCOMMODATION PLATFORMS; - COMMERCIAL VESSELS; - MILITARY VESSELS; - RESORTS, HOTELS AND COMMUNITIES; - GOLF COURSES. QUANTITY: 2 Learn More -

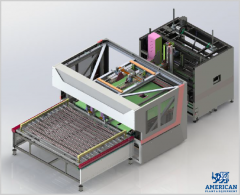

YY-1357 HORIZONTAL CONTINUOUS FOAMING MACHINE, 21000 KG PER HOURYY-1357 HORIZONTAL CONTINUOUS FOAMING MACHINE, 21000 KG PER HOUR MAIN TECHNICAL SPECIFICATION: 1.TOTAL LENGTH: 35000mm × WIDTH 4500mm × HEIGHT 3000mm 2. FOAMING WIDTH 1000mm TO APPROXIMATELY 2300mm 3.FOAMING HEIGHT: 1200mm 4.FOAMING DENSITY: 8 KG PER m3 TO APPROXIMATELY 80 KG PER m3 5.FOAMING SPEED: 0 TO 6.8 METERS PER MINUTE 6.MAX TOTAL OUTPUT: 80 LITERS TO 350 LITERS PER MINUTE 7.MATERIAL SPRAYING METHOD: TROUGH 8.ALL KINDS OF VALVES, PIPES AND SPARE PARTS 9.THE MEMBRANE AUTOMATICALLY RECEIVES THE VOLUME INSTALLMENT (TO USE THE NEWEST INSTALLMENT, TO GUARANTEE THAT IT RECEIVES VOLUME SIDE PAPER SMOOTHLY); 10.USES ENVIRONMENTALLY-FRIENDLY EQUIPMENT TO PURIFY EXHAUST GAS, NO POLLUTION PRESENT 11. RESPONSIBLE FOR ELECTRICAL, MECHANICAL MAINTENANCE PERSONNEL TRAINING 12.THE BLOCK CUTTER MACHINE CUTS THE BUN LENGTH USING ROTARY ENCODER AND THICKNESS GAUGE TO SETUP AND CONTROL 13. MIXING HEAD FRAME PLUS OVERHAUL STAND, LADDER AND BARRICADE 14.MIXING HEAD IS GERMAN PRECISION TECHNOLOGY 15.FOAMING OVEN, DECLINING BOARD AND OVEN INNER CONVEYOR MACHINE PARTS 16. MIXING HEAD SIZE: Φ100mm 18.MIXING HEAD MOTOR: 30 KW 19.TOTAL POWER: ABOUT 80 KW Learn More

YY-1357 HORIZONTAL CONTINUOUS FOAMING MACHINE, 21000 KG PER HOURYY-1357 HORIZONTAL CONTINUOUS FOAMING MACHINE, 21000 KG PER HOUR MAIN TECHNICAL SPECIFICATION: 1.TOTAL LENGTH: 35000mm × WIDTH 4500mm × HEIGHT 3000mm 2. FOAMING WIDTH 1000mm TO APPROXIMATELY 2300mm 3.FOAMING HEIGHT: 1200mm 4.FOAMING DENSITY: 8 KG PER m3 TO APPROXIMATELY 80 KG PER m3 5.FOAMING SPEED: 0 TO 6.8 METERS PER MINUTE 6.MAX TOTAL OUTPUT: 80 LITERS TO 350 LITERS PER MINUTE 7.MATERIAL SPRAYING METHOD: TROUGH 8.ALL KINDS OF VALVES, PIPES AND SPARE PARTS 9.THE MEMBRANE AUTOMATICALLY RECEIVES THE VOLUME INSTALLMENT (TO USE THE NEWEST INSTALLMENT, TO GUARANTEE THAT IT RECEIVES VOLUME SIDE PAPER SMOOTHLY); 10.USES ENVIRONMENTALLY-FRIENDLY EQUIPMENT TO PURIFY EXHAUST GAS, NO POLLUTION PRESENT 11. RESPONSIBLE FOR ELECTRICAL, MECHANICAL MAINTENANCE PERSONNEL TRAINING 12.THE BLOCK CUTTER MACHINE CUTS THE BUN LENGTH USING ROTARY ENCODER AND THICKNESS GAUGE TO SETUP AND CONTROL 13. MIXING HEAD FRAME PLUS OVERHAUL STAND, LADDER AND BARRICADE 14.MIXING HEAD IS GERMAN PRECISION TECHNOLOGY 15.FOAMING OVEN, DECLINING BOARD AND OVEN INNER CONVEYOR MACHINE PARTS 16. MIXING HEAD SIZE: Φ100mm 18.MIXING HEAD MOTOR: 30 KW 19.TOTAL POWER: ABOUT 80 KW Learn More -

YY-1285 COMPUTERIZED CONTINUOUS EDGE FOLDING & SEWING MACHINE, PRODUCT WIDTH 1800 TO 2000mmYY-1285 COMPUTERIZED CONTINUOUS EDGE FOLDING & SEWING MACHINE, PRODUCT WIDTH 1800 TO 2000mm SUITABLE FOR CURTAIN OR OTHER HOME TEXTILES WHERE THERE IS A NEED TO SEW EDGES CONTINUOUSLY. QUANTITY: 1 Learn More

YY-1285 COMPUTERIZED CONTINUOUS EDGE FOLDING & SEWING MACHINE, PRODUCT WIDTH 1800 TO 2000mmYY-1285 COMPUTERIZED CONTINUOUS EDGE FOLDING & SEWING MACHINE, PRODUCT WIDTH 1800 TO 2000mm SUITABLE FOR CURTAIN OR OTHER HOME TEXTILES WHERE THERE IS A NEED TO SEW EDGES CONTINUOUSLY. QUANTITY: 1 Learn More -

M-6063 AIRLAY / THERMOBONDING PRODUCTION LINE, WIDTH 2500mm TO 2700mm, YEAR 1975 TO 2012

M-6063 AIRLAY / THERMOBONDING PRODUCTION LINE, WIDTH 2500mm TO 2700mm, YEAR 1975 TO 2012M-6063 AIRLAY / THERMOBONDING PRODUCTION LINE, WIDTH 2500mm TO 2700mm, YEAR 1975 TO 2012

OFFER 001

AIRLAY / THERMOBONDING PRODUCTION LINE

WORKING WIDTH: 2500mmOFFER 002

CROSA PERINO BLENDING BOXES

YEAR: 1990 (OVERHAULED 2011)

CAPACITY: 750 KG EACHOFFER 003

HDB CARDING WILLOW

YEAR: 1975OFFER 004

MESUTRONIC METAL DETECTOR

YEAR: 2007OFFER 005

MESUTRONIC METAL SEPARATOR

YEAR: 2007OFFER 006

FALLGARTER HOPPER FEEDER

YEAR: 1975OFFER 007

ROLANDO HOPPER FEEDER

YEAR: 1985 (OVERHAULED 2003)OFFER 008

HERGETH HOLLINGSWORTH FINE OPENER

YEAR: 1981OFFER 009

STUMMER CONTINUOUS CLEANER

YEAR: 2007OFFER 010

HERGETH HOLLINGSWORTH AIRLAY FEEDING

YEAR: 1981 (OVERHAULED 2012)

WORKING WIDTH: 2500mmOFFER 011

OLBRICH AIRLAY CARD

YEAR: 2010

WORKING WIDTH: 2500mmOFFER 012

STRAHM OVEN

YEAR: 2008

WORKING WIDTH: 2700mmOFFER 013

OLBRICH LONGITUDINAL CUTTING

YEAR: 2004

WORKING WIDTH: 2600mmOFFER 014

KZE CROSSCUTTING

YEAR: 2012

WORKING WIDTH: 2600mmQUANTITY: 1 LINE

Learn More -

G-6521 POTATO CHIPS PRODUCTION LINE 200KG/HREFERENCE NUMBER: G-6521 POTATO CHIPS PRODUCTION LINE 200KG/H 1. WASHING MACHINE 2. PEELING MACHINE 3. TRIMMING MACHINE 4. SLICER FEEDER 5. SLICER 6. WASHING MACHINE 7. BLANCHING MACHINE 8. GAS TYPE CONTINUOUS FRYING MACHINE 9. FLAVORING MACHINE QUANTITY AVAILABLE: 1 Learn More

G-6521 POTATO CHIPS PRODUCTION LINE 200KG/HREFERENCE NUMBER: G-6521 POTATO CHIPS PRODUCTION LINE 200KG/H 1. WASHING MACHINE 2. PEELING MACHINE 3. TRIMMING MACHINE 4. SLICER FEEDER 5. SLICER 6. WASHING MACHINE 7. BLANCHING MACHINE 8. GAS TYPE CONTINUOUS FRYING MACHINE 9. FLAVORING MACHINE QUANTITY AVAILABLE: 1 Learn More -

TT-7967 KATO/WAUKESHA GENERATOR SETS, 4.3 MW, 60 Hz, YEAR 2001TT-7967 KATO/WAUKESHA GENERATOR SETS, 4.3 MW, 60 Hz, YEAR 2001 1. NATURAL GAS 2. NEW AND NEVER INSTALLED Learn More

TT-7967 KATO/WAUKESHA GENERATOR SETS, 4.3 MW, 60 Hz, YEAR 2001TT-7967 KATO/WAUKESHA GENERATOR SETS, 4.3 MW, 60 Hz, YEAR 2001 1. NATURAL GAS 2. NEW AND NEVER INSTALLED Learn More -

TT-3122 WAUKESHA GAS GENERATOR SETS, 3360.8 KW (4201 KVA), 50 HzTT-3122 WAUKESHA GAS GENERATOR SETS, 3360.8 KW (4201 KVA), 50 Hz ITEM 001 WAUKESHA GAS GENERATOR 3360.8 KW (4201 KVA), 11000 VOLT, 220.5 AMP, 3 PHASE, 50 Hz GAS ENGINE DRIVEN ELECTRICAL GENERATOR ENGINE MANUFACTURED BY WAUKESHA (DRESSER) MODEL #16VAT27GL ITEM 002 WAUKESHA GAS GENERATOR 3360.8 KW (4201 KVA), 11000 VOLT, 220.5 AMP, 3 PHASE, 50 Hz GAS ENGINE DRIVEN ELECTRICAL GENERATOR ENGINE MANUFACTURED BY WAUKESHA (DRESSER) MODEL #16VAT27GL Learn More

TT-3122 WAUKESHA GAS GENERATOR SETS, 3360.8 KW (4201 KVA), 50 HzTT-3122 WAUKESHA GAS GENERATOR SETS, 3360.8 KW (4201 KVA), 50 Hz ITEM 001 WAUKESHA GAS GENERATOR 3360.8 KW (4201 KVA), 11000 VOLT, 220.5 AMP, 3 PHASE, 50 Hz GAS ENGINE DRIVEN ELECTRICAL GENERATOR ENGINE MANUFACTURED BY WAUKESHA (DRESSER) MODEL #16VAT27GL ITEM 002 WAUKESHA GAS GENERATOR 3360.8 KW (4201 KVA), 11000 VOLT, 220.5 AMP, 3 PHASE, 50 Hz GAS ENGINE DRIVEN ELECTRICAL GENERATOR ENGINE MANUFACTURED BY WAUKESHA (DRESSER) MODEL #16VAT27GL Learn More -

X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MOREREFERENCE NUMBER: X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MORE THIS MACHINE IS A STAND-ALONE AND VERY VERSATILE PILLOW STUFFING AND BAGGING MACHINE. ITS SIMPLE OPERATION ALLOWS TO USE THE SAME EQUIPMENT TO ACCOMPLISH THE TWO PROCESSES: STUFFING A BATT OR A FOAM CORE IN A COVER (OR AN INSERT IN THE FINAL DEC COVER / A PILLOW IN THE FINAL ZIPPERED COVER) AND/OR PUT A FINISHED PILLOW IN A BAG (INDIVIDUAL PE BAG, TWIN-PACK BAG, ZIPPERED VINYL BAG, ETC). THE MACHINE CAN BE LOADED MANUALLY OR WITH A CONVEYOR ON THE REAR PART, WHILE AN OPERATOR IS NEEDED IN THE FRONT: HE PUTS THE COVER/BAG ONTO THE STUFFING BELTS, ACTIVATES THE TENSIONING FORKS WITH THE PEDAL AND HOLDING THE COVER/BAG FACILITATES THE PILLOW STUFFING. POWER SUPPLY IS 400 VOLTS, WILL NEED A TRANSFORMER TO OPERATE ON 480 VOLTS, INQUIRE IF NEEDED Learn More

X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MOREREFERENCE NUMBER: X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MORE THIS MACHINE IS A STAND-ALONE AND VERY VERSATILE PILLOW STUFFING AND BAGGING MACHINE. ITS SIMPLE OPERATION ALLOWS TO USE THE SAME EQUIPMENT TO ACCOMPLISH THE TWO PROCESSES: STUFFING A BATT OR A FOAM CORE IN A COVER (OR AN INSERT IN THE FINAL DEC COVER / A PILLOW IN THE FINAL ZIPPERED COVER) AND/OR PUT A FINISHED PILLOW IN A BAG (INDIVIDUAL PE BAG, TWIN-PACK BAG, ZIPPERED VINYL BAG, ETC). THE MACHINE CAN BE LOADED MANUALLY OR WITH A CONVEYOR ON THE REAR PART, WHILE AN OPERATOR IS NEEDED IN THE FRONT: HE PUTS THE COVER/BAG ONTO THE STUFFING BELTS, ACTIVATES THE TENSIONING FORKS WITH THE PEDAL AND HOLDING THE COVER/BAG FACILITATES THE PILLOW STUFFING. POWER SUPPLY IS 400 VOLTS, WILL NEED A TRANSFORMER TO OPERATE ON 480 VOLTS, INQUIRE IF NEEDED Learn More -

V-1041 AIRLAY- FELT LINE 2400mmINDEX 1. Technical specification pag.2 2. Line composition pag.3 3. Machines description pag.4 4. Total price of the turn-key plant pag.25 5. Sale terms pag.26 6. Payment terms pag.28 7. General selling terms and conditions pag.29 Learn More

V-1041 AIRLAY- FELT LINE 2400mmINDEX 1. Technical specification pag.2 2. Line composition pag.3 3. Machines description pag.4 4. Total price of the turn-key plant pag.25 5. Sale terms pag.26 6. Payment terms pag.28 7. General selling terms and conditions pag.29 Learn More