Search results for: 'Part's t'

- Related search terms

- Part's

- Part's ta

- Part's tap

- Part's tape e

- Part's tape ed

-

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More -

T-8260 ALBRECHT BAUMER IS-M, 40 METERS PER MINUTE, CUT HEIGHT 1300mm, YEAR 1987T-8260 ALBRECHT BAUMER IS-M, 40 METERS PER MINUTE, CUT HEIGHT 1300mm, YEAR 1987 MAKE: ALBRECHT BAUMER MODEL: IS-M SPEED: 0 TO 40 METERS PER MINUTE CUTTING HEIGHT: 1300mm KNIFE MEASUREMENTS: 10 x 0.45 x 10350mm POWER SUPPLY: 380 VOLTS, 3-PHASE, 50 Hz POWER REQUIREMENT: 4 KW YEAR: 1987 RIGHT TABLE: 2435mm BUN WIDTH (RIGHT TABLE): 2200mm BUN LENGTH: 2580mm LEFT TABLE: 2435mm BUN WIDTH (LEFT TABLE): 2200mm BUN LENGTH: 2580mm) QUANTITY: 1 Learn More

T-8260 ALBRECHT BAUMER IS-M, 40 METERS PER MINUTE, CUT HEIGHT 1300mm, YEAR 1987T-8260 ALBRECHT BAUMER IS-M, 40 METERS PER MINUTE, CUT HEIGHT 1300mm, YEAR 1987 MAKE: ALBRECHT BAUMER MODEL: IS-M SPEED: 0 TO 40 METERS PER MINUTE CUTTING HEIGHT: 1300mm KNIFE MEASUREMENTS: 10 x 0.45 x 10350mm POWER SUPPLY: 380 VOLTS, 3-PHASE, 50 Hz POWER REQUIREMENT: 4 KW YEAR: 1987 RIGHT TABLE: 2435mm BUN WIDTH (RIGHT TABLE): 2200mm BUN LENGTH: 2580mm LEFT TABLE: 2435mm BUN WIDTH (LEFT TABLE): 2200mm BUN LENGTH: 2580mm) QUANTITY: 1 Learn More -

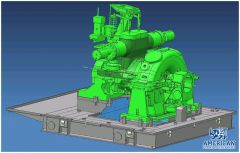

TT-7052 ELLIOT STEAM TURBINES W/ HYUNDAI-IDEAL ELECTRIC GENERATOR SET, YEAR 2016, 60 Hz, 6.5 MW, 6600 VOLTSTT-7052 ELLIOT STEAM TURBINES W/ HYUNDAI-IDEAL ELECTRIC GENERATOR SET, YEAR 2016, 60 Hz, 6.5 MW, 6600 VOLTS ITEM 001 1. STEAM TURBINE "ELLIOT" WITH GENERATOR SET "HYUNDAI-IDEAL ELECTRIC" 2. BRAND: ELLIOT-HYUNDAI-IDEAL ELECTRIC 3. MODEL: 2 DYR6 ITEM 002 1. MULTI-STAGE STEAM TURBINE “ ELLIOTT”. 2. MODEL 2DYR6 3. YEAR 2016 ITEM 003 1. BRUSHLESS SYNCHRONOUS GENERATOR “HYUNDAI-IDEAL ELECTRIC” 2. OUTPUT 6.595 KW-4P- 6600 VOLT; 60 Hz 3. WEIGHT 20,000 KG 4. WITH START-UP AND 2 YEAR SPARE PARTS Learn More

TT-7052 ELLIOT STEAM TURBINES W/ HYUNDAI-IDEAL ELECTRIC GENERATOR SET, YEAR 2016, 60 Hz, 6.5 MW, 6600 VOLTSTT-7052 ELLIOT STEAM TURBINES W/ HYUNDAI-IDEAL ELECTRIC GENERATOR SET, YEAR 2016, 60 Hz, 6.5 MW, 6600 VOLTS ITEM 001 1. STEAM TURBINE "ELLIOT" WITH GENERATOR SET "HYUNDAI-IDEAL ELECTRIC" 2. BRAND: ELLIOT-HYUNDAI-IDEAL ELECTRIC 3. MODEL: 2 DYR6 ITEM 002 1. MULTI-STAGE STEAM TURBINE “ ELLIOTT”. 2. MODEL 2DYR6 3. YEAR 2016 ITEM 003 1. BRUSHLESS SYNCHRONOUS GENERATOR “HYUNDAI-IDEAL ELECTRIC” 2. OUTPUT 6.595 KW-4P- 6600 VOLT; 60 Hz 3. WEIGHT 20,000 KG 4. WITH START-UP AND 2 YEAR SPARE PARTS Learn More -

E-9456-A FOAM BUN COMPRESSION AND PACKAGING MACHINE 10 METERS LONGINVENTORY NUMBER: E-9456-A FOAM BUN COMPRESSION AND PACKAGING MACHINE 10 METERS LONG BUILT OF RIGID STEEL BEAMS AND HEAVY PLATE MAXIMUM OIL PRESSURE: 60 TONS COMPRESSION UNIT WITH TWO HYDRAULIC CYLINDERS QUANTITY AVAILABLE: 1 Learn More

E-9456-A FOAM BUN COMPRESSION AND PACKAGING MACHINE 10 METERS LONGINVENTORY NUMBER: E-9456-A FOAM BUN COMPRESSION AND PACKAGING MACHINE 10 METERS LONG BUILT OF RIGID STEEL BEAMS AND HEAVY PLATE MAXIMUM OIL PRESSURE: 60 TONS COMPRESSION UNIT WITH TWO HYDRAULIC CYLINDERS QUANTITY AVAILABLE: 1 Learn More -

TT-5615 SOLLICH CHOCOLATE ENROBER IC 620, WIDTH 600mm, YEAR 2003TT-5615 SOLLICH CHOCOLATE ENROBER IC 620, WIDTH 600mm, YEAR 2003 SOLLICH ENROBER IC 620 CHOCOLATE ENROBER PRODUCTS COATING OF: -WAFER -CEREAL BAR -BISCUIT -BAKERY -OTHER INDUSTRIES DESCRIPTION THE SOLLICH-BRANDED COATING MACHINE IC 620 IS APPROPRIATE FOR FULL, PARTIAL, AND STRIP COATING WITH OR WITHOUT CHOPPED NUTS. ADVANCED TECHNOLOGY AND BELT SPEEDS GUARANTEE HIGH EFFICIENCY AND LOW ENERGY USAGE. QUANTITY: 1 Learn More

TT-5615 SOLLICH CHOCOLATE ENROBER IC 620, WIDTH 600mm, YEAR 2003TT-5615 SOLLICH CHOCOLATE ENROBER IC 620, WIDTH 600mm, YEAR 2003 SOLLICH ENROBER IC 620 CHOCOLATE ENROBER PRODUCTS COATING OF: -WAFER -CEREAL BAR -BISCUIT -BAKERY -OTHER INDUSTRIES DESCRIPTION THE SOLLICH-BRANDED COATING MACHINE IC 620 IS APPROPRIATE FOR FULL, PARTIAL, AND STRIP COATING WITH OR WITHOUT CHOPPED NUTS. ADVANCED TECHNOLOGY AND BELT SPEEDS GUARANTEE HIGH EFFICIENCY AND LOW ENERGY USAGE. QUANTITY: 1 Learn More -

TT-8063 LATEX FINISHING COATING LINE, YEAR 1996 TO 2014TT-8063 LATEX FINISHING COATING LINE, YEAR 1996 TO 2014 1. LATEX FINISHING COATING LINE 2. ETF PART 1996 3. BABCOCK PART 1998 4. KUSTERS PART 1998 QUANTITY: 1 Learn More

TT-8063 LATEX FINISHING COATING LINE, YEAR 1996 TO 2014TT-8063 LATEX FINISHING COATING LINE, YEAR 1996 TO 2014 1. LATEX FINISHING COATING LINE 2. ETF PART 1996 3. BABCOCK PART 1998 4. KUSTERS PART 1998 QUANTITY: 1 Learn More -

TT-7736 GERMAN 32/6 MONOBLOCK CAN FILLER-SEAMER, MECHANICAL-LEVEL (BEER & CSD), 15 K CPH, YEAR 1988TT-7736 GERMAN 32/6 MONOBLOCK CAN FILLER-SEAMER, MECHANICAL-LEVEL (BEER & CSD), 15 K CPH, YEAR 1988 THIS REFURBISHED FILLER-SEAMER MONOBLOCK, BUILT BY A RESPECTED GERMAN OEM IN THE SEN SERIES, IS DESIGNED FOR BEER AND CARBONATED SOFT DRINKS. IT HANDLES ROUGHLY FIFTEEN THOUSAND CANS PER HOUR AND OFFERS SECURE REMOTE-ACCESS DIAGNOSTICS. THE UNIT WAS REMOVED FROM A BALTIC BREWERY AND FULLY SERVICED WITH NEW WEAR PARTS. QUANTITY: 1 Learn More

TT-7736 GERMAN 32/6 MONOBLOCK CAN FILLER-SEAMER, MECHANICAL-LEVEL (BEER & CSD), 15 K CPH, YEAR 1988TT-7736 GERMAN 32/6 MONOBLOCK CAN FILLER-SEAMER, MECHANICAL-LEVEL (BEER & CSD), 15 K CPH, YEAR 1988 THIS REFURBISHED FILLER-SEAMER MONOBLOCK, BUILT BY A RESPECTED GERMAN OEM IN THE SEN SERIES, IS DESIGNED FOR BEER AND CARBONATED SOFT DRINKS. IT HANDLES ROUGHLY FIFTEEN THOUSAND CANS PER HOUR AND OFFERS SECURE REMOTE-ACCESS DIAGNOSTICS. THE UNIT WAS REMOVED FROM A BALTIC BREWERY AND FULLY SERVICED WITH NEW WEAR PARTS. QUANTITY: 1 Learn More -

YY-2230 CONVERTING MACHINES, EXTRUSION LAMINATIONYY-2230 CONVERTING MACHINES, EXTRUSION LAMINATION STATUS: DISMANTLED Learn More

YY-2230 CONVERTING MACHINES, EXTRUSION LAMINATIONYY-2230 CONVERTING MACHINES, EXTRUSION LAMINATION STATUS: DISMANTLED Learn More -

L-1177 TRUTZSCHLER/RIETER COMPLETE SPINNING MILL

L-1177 TRUTZSCHLER/RIETER COMPLETE SPINNING MILLL-1177 TRUTZSCHLER/RIETER COMPLETE SPINNING MILL

BLOW ROOM TRÜTZSCHLER

1 MONOTAMBOUR B4/1, YEAR 1989

1 MULTIMIXER MCM 6 /1200 YEAR 1997 + 1 CVT-4 / 1200 YEAR 1997

1 JOSSI THE VISION SHIELD FIBER DETECTOR EA-33-S YEAR 2002

1 DUSTEX DX 385 YEAR 1997

1 JOSSI THE SHIELD HIGH PERFORMANCE FIRE DETECTOR

TYPE D-11-250, YEAR 2005

3 TRÜTZSCHLER FAN

1 UNIMIX RIETER + ERM CLEANER RIETER

QUANTITY: 1BLOW ROOM RIETER

2 ERM B 5/5 YEAR 1989

1 ERM B 5/5 YEAR 1987

1 ERM B 5/5 YEAR 1988

2 JOSSI FIRE DETECTOR D-11-250 YEAR 2005

1 JOSSI FIBRE DETECTOR EA-33-S, YEAR 2002

3 BALE PRESS RIETER B3/4S, YEAR 1990-1991

QUANTITY: 1

CARDS TRÜTZSCHLER DK-803, YEAR 1996/ 1997 (3) COILER KH 950-1200,

AUTOMATIC REVOLVER, FEEDING FBK-533

QUANTITY: 3

CARDS TRÜTZSCHLER DK-903, YEAR 2002/2003 (1) COILER KH 600-1200, (2) COILER KH 450-1200

AUTOMATIC REVOLVER, FEEDING DKF

QUANTITY: 3

DRAWING FRAME TRÜTZSCHLER HSR-1000X2 , YEAR 2003, 1 DELIVERY 18” (450X1000), CREEL 8 CANS,

SLIVER MONITOR, AUTOLEVELLER

QUANTITY: 2

2 ROVING FRAME SIMPLEX ZINZER 670, YEAR 2003, DRAFT PK 1500, 120 SPINDLES,

CAPACITY BOBBIN 16”X6”, DRIVER CREEL, COLLECTIVE ASPIRATION,

INDIVIDUAL BLOWER ELECTRO-JET

2 AUTOMATIC TRANSPORT INSTALLATION FOR BOBBINS ELECTRO-JET

FOR 8 RING SPINNING FRAME OF 1.200 SPINDLES, YEAR 2003

QUANTITY: 1

5 RING SPINNING FRAME ZINZER RM 351, YEAR 2002 (4), YEAR 2003 (1), 1200 SPINDLES,

GAUGE 70 MM

DRAFT PK 2500, RING 42 MM, TUBE 220 MM, COWEMAT, COLLECTIVE ASPIRATION, INDIVIDUAL BLOWER

ELECTRO-JET WITH AUTOMATIC UNLOADING, TOTAL LENGTH 47 M

4 WINDER SCHLAFHORST 338 RM, 2 X YEAR 2002, COLOUR GREEN, 2 X YEAR 2003, COLOUR WHITE, 60 POSITIONS

MAGAZINE FEEDING 6 TUBES, 2 ROBOTS, WAXING, AUTOMATIC CONE CHANGE, TK-840,

CLEARER LOEPFE, DELIVERY 4.20 X 6”, INDIVIDUAL BLOWER

QUANTITY: 1

1 AUTOCORO SCHLAFHORST SE-11 ACO-288, YEAR 2001, 216 ROTORS, INFORMATOR,

DELIVERY CYLINDRICAL SLUBIER PINTER, ROTOR Ø 28-36-40 MM , ROLLERS B-174, CLEARERS COROLAB,

WAXING, 2 ROBOTS CONE CHANGE ROBOTS PIECERS

QUANTITY: 1

1 AUTOCORO SCHLAFHORST SE-9, 216 ROTORS, 2 ROBOTS, WAXING, COROLAB

INFORMATOR, YEAR 1998

QUANTITY: 1

1 INSTALLATION LTG, YEAR 2003, 5 PARTS, WASTE COLLECTING, AIR SYSTEM

1 INSTALLATION LTG, YEAR 2003, 3 PARTS, WASTE COLLECTING, AIR SYSTEM

1 INSTALLATION LTG, YEAR 2003, 5 PARTS, WASTE COLLECTING, CARDING FILTRATION

- POWER 380V/50HZ

- CONDITION COMPLETED

QUANTITY: 1

RIETER SPINNING COMBING PLANT

BLOW ROOM RIETER

UNIFLOC RIETER, A1/2, YEAR 2000

UNIMIX RIETER , B7/3, YEAR 2000

UNILEX B60, YEAR 2000

JOSSI , D-21-370-01, YEAR 2000

QUANTITY: 1

CARDS RIETER

10 X CARD RIETER C51, YEAR 2000, WITH IGS

WITH LUWA WASTE SYSTEM

QUANTITY: 10

1 X CARD RIETER C60 WITH MODUL IGS

YEAR :

QUANTITY: 1

DRAWING FRAMES RIETER

2 X DRAWING FRAME RIETER, SB-D10, YEAR 2000

QUANTITY: 2

1 X DRAW FRAME RIETER, RSB-D30C, YEAR 2000

QUANTITY: 1

2 X DRAWING FRAME RIETER, D-30QUANTITY: 2

1 X DRAWING FRAME RIETER, D-35QUANTITY: 1

COMBERS RIETER

1 X UNILAP RIETER E33, YEAR 2000

WITH TRANSPORT SYSTEM SCHONENBERGER , ARS-N2, 2000

5 X COMBING MACHINE RIETER , E72, YEAR 2000

1 X COMBING MACHINE RIETER, E75, YEAR 2006

1 X SERVOLAP RIETER , E25, YEAR 2000

WITH WASTE COLLECT SYSTEM AND PRESS

QUANTITY: 1

FLYERS RIETER

3 X ROVING FRAME RIETER, F33/120POS, YEAR 2000

AUTOMATIC BOBINES TRANSPORT , SCHONENBERGER , YEAR 2000

QUANTITY: 1

RING SPINNING MACHINES RIETER

6 X SPINNING FRAME RIETER G33

6 RIETER RINGFRAMES, TYPE G33, BUILT 1999, EACH WITH 1200 SPINDLES, RING DIAMETER 38 MM, TYPE SFB-TITAN, GAUGE 70 MM, LIFT 187 MM, SPINDLE TYPE HPS 25, AUTOMATIC DRAFTING SYSTEM, WITH AUTODOFFER AND MAGITEX OVERHEAD CLEANER, LINKED WITH MURATA CONER, TYPE 7V-II, BUILT 1999, EACH WITH 32 WINDING HEADS, AUTOMATIC FEEDING, AUTOMATIC PACKAGE CONVEYOR, YARN CLEARERS USTER QUANTUM WITH FIBER DETECTOR, MK-C-15F23, WITH WAXING, INFORMATOR MMC/3, CONICITY 4 DEG. 20 , VOLTAGE : 380V, 50HZ

QUANTITY: 61 X MURATA MINICONER

Learn More

LUWA AIRCONDITION, YEAR 2005

LUWA FILTER FOR CADING, YEAR 2005

LUWA FILTER FOR COMBING, YEAR 2005

LUWA FILTER FOR SPINNING AND WINDING, YEAR 2005

QUANTITY: 1 -

YY-3080 SIEMENS EQUIPMENT FOR SALEYY-3080 SIEMENS EQUIPMENT FOR SALE FOR SALE 2013 IN FACTORY PACKAGING Learn More

YY-3080 SIEMENS EQUIPMENT FOR SALEYY-3080 SIEMENS EQUIPMENT FOR SALE FOR SALE 2013 IN FACTORY PACKAGING Learn More