Search results for: 'Steam+Turbine+generator'

-

TT-4546 SIEMENS STEAM TURBINE TYPE SST-600 – NEW, 22MW, YEAR 2013TT-4546 SIEMENS STEAM TURBINE TYPE SST-600 – NEW, 22MW, YEAR 2013 SIEMENS 60 Hz 22 MW STEAM GAS TURBINE SST-600 COMPOSED OF 12 MW COMPRESSOR AND 10 MW GENERATOR: NEW SIEMENS 60 Hz 12 MW COMPRESSOR STC GV 40-6 NEW SIEMENS 60 Hz, 10 MW 3 GENERATOR ALSO INCLUDED: SPARE PARTS FOR COMP AND TURBINE WORTH ABOUT $120,000 Learn More

TT-4546 SIEMENS STEAM TURBINE TYPE SST-600 – NEW, 22MW, YEAR 2013TT-4546 SIEMENS STEAM TURBINE TYPE SST-600 – NEW, 22MW, YEAR 2013 SIEMENS 60 Hz 22 MW STEAM GAS TURBINE SST-600 COMPOSED OF 12 MW COMPRESSOR AND 10 MW GENERATOR: NEW SIEMENS 60 Hz 12 MW COMPRESSOR STC GV 40-6 NEW SIEMENS 60 Hz, 10 MW 3 GENERATOR ALSO INCLUDED: SPARE PARTS FOR COMP AND TURBINE WORTH ABOUT $120,000 Learn More -

SUGAR AND ALCOHOL PLANTREFERENCE NUMBER: A-2511 SUGAR AND ALCOHOL PLANT CANE UNLOAD SECTOR THE CANE UNLOADING SECTOR IS EQUIPPED WITH THE EQUIPMENT LISTED BELOW IN THE CONDITION TO CARRY OUT A GRINDING OF 8400 TCD WHICH CORRESPONDS TO A HARVEST OF 1800000 TONNES OF CANE / YEAR • 01 HILO UNLOADER OF STORAGE • 01 HILO UNLOADER OF MILLING • 01 FEEDER SUGARCANE TABLE WITH INCLINATION OF 25 INCHES • 01 FEEDER SUGARCANE TABLE WITH INCLINATION OF 45 INCHES • 02 CRANES WITH CAPACITY OF 20 TONNES • 01 TRANSPORTER TYPE CUSCH - CUSH OF 40 INCHES • 02 MOTOR PUMP WITH CAPACITY OF 1000 M³/H TO 50 MCW FOR CANE WASHING • 01 CONTAMINATED FLUID TREATMENT SYSTEM • 01 METAL STRUCTURE BUILDING MEASURING 20000 X 100000 mm CANE PREPARATION SECTOR THE SUGARCANE PREPARATION SECTOR IS EQUIPPED WITH THE FOLLOWING AUTOMATED EQUIPMENT WITH THE CONTROL BY THE SUPERVISORY INSTALLED IN THE CONTROL ROOM AS SHOWN BELOW TO PERFORM A CRUSHING OF 7200 TCD WHICH CORRESPONDS TO A CROP OF 1600000 TONS OF SUGARCANE / YEAR • 01 METALLIC CONVEYOR OF 60 INCHES • 01 LEVELING OF CANE OF 60 INCHES • 01 CANE KNIVES SET TYPE COP-8 OF 60 INCHES • 01 CAN SHREDDER SET TYPE COP-5 OF 60 INCHES • 01 FEEDER ROLL 60 IINCHES • 01 RUBBER TRANSPORTER FOR CANE SHREDDED OF 60 INCHES • 01 TGM TURBINE FOR KNIVES SET • 01 TGM TURBINE FOR SHREDDER SET • 01 HIGH AND LOWER SPEED REDUCER OF KNIVES SET • 01 HIGH AND LOWER SPEED REDUCER OF SHREDDER SET • 01 REDUCER FOR METALLIC CONVEYOR • 01 REDUCER FOR FEEDER ROLL • 01 REDUCER OF SHREDDED CANE TRANSPORTER TYPE BELT MILLING CANE SECTOR THE CANE MILLING SECTOR OF THE PLANT IS EQUIPPED WITH THE FOLLOWING AUTOMATED EQUIPMENT WITH THE CONTROL BY THE SUPERVISORY INSTALLED IN THE CONTROL ROOM TO CARRY OUT A GRINDING OF 7200 TCD CORRESPONDING TO A 222 - DAY HARVEST TO GRIND 1600000 TONS. CANE / YEAR • 04 MILLS OF 32 X 60 INCHES • 03 INTERMIDIATE TRANSPORTER OF 60 INCHES • 01 ROTARY SIEVE FOR MILLING 300 TCD • 01 TGM TURBINE OF DRIVING THE 1º / 2º MILLS • 01 TGM TURBINE OF DRIVING OF 3º / 4º MILLS • 01 REDUCER OF HIGH AND LOW SPEED OF DRIVING THE 1º / 2º MILLS • 01 REDUCER OF HIGH AND LOW SPEED OF DRIVING THE 3º / 4º MILLS • 03 REDUCER INTERMEDIATE TRANSPORTER OF 60 INCHES • 02 PUMPS OF 1ST JUICE • 02 PUMPS OF JUICE IMBIBITION OF 3RD FOR 2ND MILL • 02 PUMPS OF JUICE IMBIBITION OF 4TH FOR 3RD MILLS • 02 PUMPS OF MIXED JUICE OF MILL FOR JUICE TREATMENT STEAM GENERATION SECTOR THE STEAM GENERATION SECTOR OF THE PLANT IS PREPARED TODAY TO PERFORM A 7200 TCD GRINDING CORRESPONDING TO A 220 - DAY HARVEST TO GRIND 1600000 TON. CANE / YEAR WITH THE FOLLOWING AUTOMATED EQUIPMENT WITH CONTROL BY THE SUPERVISORY INSTALLED IN THE CONTROL ROOM AS SHOWN BELOW • 01 BOILER N ° 01, MODEL: TS-3-150 MODIFIED FOR CBS-120-21 KG / CM² TODAY GENERATES AN AVERAGE OF 11000 KG / HR OF STEAM AT A PRESSURE OF 21 KG / CM² • 01 BOILER N ° 02, MODEL: TS-3-150-21 KG / CM² TODAY GENERATES AN AVERAGE OF 55000 KG / HR OF STEAM AT A PRESSURE OF 21 KG / CM² • 01 DEAERATOR WITH A CAPACITY OF 70 M³ • 01 78 INCHES BAGASSE METALLIC TRANSPORTER OF 32000 mm LENGTH • 01 48 INCHES BAGASSE TRANSPORTER FROM MILL TO BOILER • 01 48 INCHES BAGASSE RETURN TRANSPORTER FOR BOILER • 01 REDUCER OF BAGASSE TRANSPORTER FROM MILL TOBOILER • 01 REDUCER OF BAGASSE RETURN TRANSPORTER TOBOILER • 02 MOTO - PUMPS OF WATER FEEDING OF DEAERATOR • 02 MOTO - PUMPS OF WATER TREATMENT OF BOILER • 01 MOTO - PUMP WITH CAPACITY OF 300 M³/H TO 350 MCW FOR WATER FEEDING OF BOILER • 01 TURBO-PUMP WITH CAPACITY OF 300 M³/H TO 350 MCW FOR WATER FEEDING OF BOILER • 02 MOTO-PUMPS WITH CAPACITY OF 220 M³/H TO 50 MCW FOR WET SCRUBBER OF BOILER NO. 2 • 03 MOTO - PUMPS OF 40 M³/H TO 300 MCW • 01 METALLIC RESERVOIR WITH 200 M³ OF CONDENSED WATER CAPACITY POWER GENERATION SECTOR THE POWER GENERATION SECTOR IS EQUIPPED WITH THE FOLLOWING MODERN AND AUTOMATED EQUIPMENT LISTED BELOW TO MEET A GRINDING OF 8400 TCD • 01 THREE - PHASE GENERATOR OF 6250 KVA – 13800 VOLTS – 60Hz • 01 TGM STEAM TURBINE MODEL TM - 5000 • 01 REDUCER RENK - ZANINI WITH CAPACITY OF 5000 KW • SEVERAL ELECTRICALS PANELS OF THE GENERATOR • 01 TURBO GENERATOR HOUSE BUILDING • 02 WATER COOLING TOWERS FOR THE TURBO-GENERATOR • 02 MOTO - PUMPS OF 100 M³/H TO 30 MCW SUGAR FACTORY THE SUGAR FACTORY WAS SET UP BETWEEN 2007 / 2008 AND COMPLETELY AUTOMATED WITH THE CONTROL BY THE SUPERVISORY INSTALLED IN THE CONTROL ROOM, PRODUCING AN AVERAGE OF 500000 KG OF VHP SUGAR PER DAY, A VALUE CORRESPONDING TO A MILLING OF 5000 TCD. THE TRANSPORT OF THIS SUGAR MANUFACTURED AT THE DECASA PLANT IS BEING TRANSPORTED BY MEANS OF A BUCKET VEHICLE WITH A DESTINATION INFORMED BY THE CUSTOMER. FOR THIS PLANT TO PRODUCE CRYSTAL SUGAR IC - 150, WE WILL NEED TO ACQUIRE AND ASSEMBLE THE FOLLOWING EQUIPMENT • SULFITATION EQUIPAMENT • BAGGING EQUIPMENT OF 50 KG BAGS • BUILD OR RENT AN INFLATABLE WAREHOUSE TO STORE SUGAR WITH THE INSTALLATION OF THIS EQUIPMENT, THE SUGAR FACTORY IS PREPARED TO RECEIVE A MILLING OF 5000 TCD CORRESPONDING TO A DAILY PRODUCTION OF 500000 KG OF CRYSTAL SUGAR IC - 150 PER DAY ALCOHOL DISTILLERY THE DISTILLERY WAS INSTALLED IN 1982 WITH A CAPACITY OF 300000 LITERS OF HYDRATED ALCOHOL PER DAY. WHEN THE FORMER OWNER'S UNIT WAS SOLD TO THE OLIVAL TENÓRIO GROUP IN 2003, THE NEW ENTREPRENEUR INVESTED IN THE MANUFACTURE OF ALCOHOL IN 2006 BY INSTALLING ANOTHER COLUMN OF DISTILLATION WITH A CAPACITY OF 300,000 LITERS AND AUTOMATED 100% INCREASING ITS PRODUCTION CAPACITY TO 600,000 LITERS OF HYDRATED ALCOHOL PER DAY • 02 TYPE “A” DISTILLATION COLUMNS WITH CAPACITY TO PRODUCE 300 M³ OF ALCOHOL / DAY • 02 TYPE “B” RECTIFICATION COLUMNS WITH CAPACITY FOR PRODUCTION OF 300 M³ OF ALCOHOL / DAY • 01 TYPE “A” DISTILLATION COLUMN WITH CAPACITY FOR PRODUCTION OF 300 M³ OF ALCOHOL / DAY • 01 TYPE “B” RECTIFICATION COLUMN WITH CAPACITY FOR PRODUCTION OF 300 M³ OF ALCOHOL / DAY • 09 TUBULAR HEAT EXCHANGERS TYPE “K” • 02 TUBULAR HEAT EXCHANGERS TYPE “J” • 02 TUBULAR HEAT EXCHANGERS TYPE “E” • 02 TUBULAR HEAT EXCHANGERS TYPE “E1” • 02 TUBULAR HEAT EXCHANGERS TYPE “E2” • 02 TUBULAR HEAT EXCHANGERS TYPE “R” • 02 TUBULAR HEAT EXCHANGERS TYPE “R1” • 11 NEW FERMENTATION VATS WITH A CAPACITY OF 300 M³ • 03 PLATE HEAT EXCHANGERS FOR THE WORT • 05 PLATE TYPE HEAT EXCHANGERS FOR VATS • 01 VAT FOR WINE • 01 CO₂ RECOVERY COLUMN • 02 PUMPS WITH A CAPACITY OF 600 M³ / H - 50 MCA FOR THE COOLING SYSTEM OF THE PLATE HEAT EXCHANGERS • 01 PUMP WITH A CAPACITY OF 800 M³ / H FOR THE COOLING SYSTEM OF THE PLATE HEAT EXCHANGERS • 02 CENTRÍFUGES HAD - 90 • 04 CENTRÍFUGES HAD - 60 WITH THE INSTALLATION OF THIS EQUIPMENT, THE ALCOHOL DISTILLERY IS PREPARED TO PRODUCE 600000 LITERS OF ALCOHOL PER DAY, RECEIVING A MILLING OF 6500 TCD CORRESPONDING TO 2500000 TONS OF CANE / YEAR Learn More

SUGAR AND ALCOHOL PLANTREFERENCE NUMBER: A-2511 SUGAR AND ALCOHOL PLANT CANE UNLOAD SECTOR THE CANE UNLOADING SECTOR IS EQUIPPED WITH THE EQUIPMENT LISTED BELOW IN THE CONDITION TO CARRY OUT A GRINDING OF 8400 TCD WHICH CORRESPONDS TO A HARVEST OF 1800000 TONNES OF CANE / YEAR • 01 HILO UNLOADER OF STORAGE • 01 HILO UNLOADER OF MILLING • 01 FEEDER SUGARCANE TABLE WITH INCLINATION OF 25 INCHES • 01 FEEDER SUGARCANE TABLE WITH INCLINATION OF 45 INCHES • 02 CRANES WITH CAPACITY OF 20 TONNES • 01 TRANSPORTER TYPE CUSCH - CUSH OF 40 INCHES • 02 MOTOR PUMP WITH CAPACITY OF 1000 M³/H TO 50 MCW FOR CANE WASHING • 01 CONTAMINATED FLUID TREATMENT SYSTEM • 01 METAL STRUCTURE BUILDING MEASURING 20000 X 100000 mm CANE PREPARATION SECTOR THE SUGARCANE PREPARATION SECTOR IS EQUIPPED WITH THE FOLLOWING AUTOMATED EQUIPMENT WITH THE CONTROL BY THE SUPERVISORY INSTALLED IN THE CONTROL ROOM AS SHOWN BELOW TO PERFORM A CRUSHING OF 7200 TCD WHICH CORRESPONDS TO A CROP OF 1600000 TONS OF SUGARCANE / YEAR • 01 METALLIC CONVEYOR OF 60 INCHES • 01 LEVELING OF CANE OF 60 INCHES • 01 CANE KNIVES SET TYPE COP-8 OF 60 INCHES • 01 CAN SHREDDER SET TYPE COP-5 OF 60 INCHES • 01 FEEDER ROLL 60 IINCHES • 01 RUBBER TRANSPORTER FOR CANE SHREDDED OF 60 INCHES • 01 TGM TURBINE FOR KNIVES SET • 01 TGM TURBINE FOR SHREDDER SET • 01 HIGH AND LOWER SPEED REDUCER OF KNIVES SET • 01 HIGH AND LOWER SPEED REDUCER OF SHREDDER SET • 01 REDUCER FOR METALLIC CONVEYOR • 01 REDUCER FOR FEEDER ROLL • 01 REDUCER OF SHREDDED CANE TRANSPORTER TYPE BELT MILLING CANE SECTOR THE CANE MILLING SECTOR OF THE PLANT IS EQUIPPED WITH THE FOLLOWING AUTOMATED EQUIPMENT WITH THE CONTROL BY THE SUPERVISORY INSTALLED IN THE CONTROL ROOM TO CARRY OUT A GRINDING OF 7200 TCD CORRESPONDING TO A 222 - DAY HARVEST TO GRIND 1600000 TONS. CANE / YEAR • 04 MILLS OF 32 X 60 INCHES • 03 INTERMIDIATE TRANSPORTER OF 60 INCHES • 01 ROTARY SIEVE FOR MILLING 300 TCD • 01 TGM TURBINE OF DRIVING THE 1º / 2º MILLS • 01 TGM TURBINE OF DRIVING OF 3º / 4º MILLS • 01 REDUCER OF HIGH AND LOW SPEED OF DRIVING THE 1º / 2º MILLS • 01 REDUCER OF HIGH AND LOW SPEED OF DRIVING THE 3º / 4º MILLS • 03 REDUCER INTERMEDIATE TRANSPORTER OF 60 INCHES • 02 PUMPS OF 1ST JUICE • 02 PUMPS OF JUICE IMBIBITION OF 3RD FOR 2ND MILL • 02 PUMPS OF JUICE IMBIBITION OF 4TH FOR 3RD MILLS • 02 PUMPS OF MIXED JUICE OF MILL FOR JUICE TREATMENT STEAM GENERATION SECTOR THE STEAM GENERATION SECTOR OF THE PLANT IS PREPARED TODAY TO PERFORM A 7200 TCD GRINDING CORRESPONDING TO A 220 - DAY HARVEST TO GRIND 1600000 TON. CANE / YEAR WITH THE FOLLOWING AUTOMATED EQUIPMENT WITH CONTROL BY THE SUPERVISORY INSTALLED IN THE CONTROL ROOM AS SHOWN BELOW • 01 BOILER N ° 01, MODEL: TS-3-150 MODIFIED FOR CBS-120-21 KG / CM² TODAY GENERATES AN AVERAGE OF 11000 KG / HR OF STEAM AT A PRESSURE OF 21 KG / CM² • 01 BOILER N ° 02, MODEL: TS-3-150-21 KG / CM² TODAY GENERATES AN AVERAGE OF 55000 KG / HR OF STEAM AT A PRESSURE OF 21 KG / CM² • 01 DEAERATOR WITH A CAPACITY OF 70 M³ • 01 78 INCHES BAGASSE METALLIC TRANSPORTER OF 32000 mm LENGTH • 01 48 INCHES BAGASSE TRANSPORTER FROM MILL TO BOILER • 01 48 INCHES BAGASSE RETURN TRANSPORTER FOR BOILER • 01 REDUCER OF BAGASSE TRANSPORTER FROM MILL TOBOILER • 01 REDUCER OF BAGASSE RETURN TRANSPORTER TOBOILER • 02 MOTO - PUMPS OF WATER FEEDING OF DEAERATOR • 02 MOTO - PUMPS OF WATER TREATMENT OF BOILER • 01 MOTO - PUMP WITH CAPACITY OF 300 M³/H TO 350 MCW FOR WATER FEEDING OF BOILER • 01 TURBO-PUMP WITH CAPACITY OF 300 M³/H TO 350 MCW FOR WATER FEEDING OF BOILER • 02 MOTO-PUMPS WITH CAPACITY OF 220 M³/H TO 50 MCW FOR WET SCRUBBER OF BOILER NO. 2 • 03 MOTO - PUMPS OF 40 M³/H TO 300 MCW • 01 METALLIC RESERVOIR WITH 200 M³ OF CONDENSED WATER CAPACITY POWER GENERATION SECTOR THE POWER GENERATION SECTOR IS EQUIPPED WITH THE FOLLOWING MODERN AND AUTOMATED EQUIPMENT LISTED BELOW TO MEET A GRINDING OF 8400 TCD • 01 THREE - PHASE GENERATOR OF 6250 KVA – 13800 VOLTS – 60Hz • 01 TGM STEAM TURBINE MODEL TM - 5000 • 01 REDUCER RENK - ZANINI WITH CAPACITY OF 5000 KW • SEVERAL ELECTRICALS PANELS OF THE GENERATOR • 01 TURBO GENERATOR HOUSE BUILDING • 02 WATER COOLING TOWERS FOR THE TURBO-GENERATOR • 02 MOTO - PUMPS OF 100 M³/H TO 30 MCW SUGAR FACTORY THE SUGAR FACTORY WAS SET UP BETWEEN 2007 / 2008 AND COMPLETELY AUTOMATED WITH THE CONTROL BY THE SUPERVISORY INSTALLED IN THE CONTROL ROOM, PRODUCING AN AVERAGE OF 500000 KG OF VHP SUGAR PER DAY, A VALUE CORRESPONDING TO A MILLING OF 5000 TCD. THE TRANSPORT OF THIS SUGAR MANUFACTURED AT THE DECASA PLANT IS BEING TRANSPORTED BY MEANS OF A BUCKET VEHICLE WITH A DESTINATION INFORMED BY THE CUSTOMER. FOR THIS PLANT TO PRODUCE CRYSTAL SUGAR IC - 150, WE WILL NEED TO ACQUIRE AND ASSEMBLE THE FOLLOWING EQUIPMENT • SULFITATION EQUIPAMENT • BAGGING EQUIPMENT OF 50 KG BAGS • BUILD OR RENT AN INFLATABLE WAREHOUSE TO STORE SUGAR WITH THE INSTALLATION OF THIS EQUIPMENT, THE SUGAR FACTORY IS PREPARED TO RECEIVE A MILLING OF 5000 TCD CORRESPONDING TO A DAILY PRODUCTION OF 500000 KG OF CRYSTAL SUGAR IC - 150 PER DAY ALCOHOL DISTILLERY THE DISTILLERY WAS INSTALLED IN 1982 WITH A CAPACITY OF 300000 LITERS OF HYDRATED ALCOHOL PER DAY. WHEN THE FORMER OWNER'S UNIT WAS SOLD TO THE OLIVAL TENÓRIO GROUP IN 2003, THE NEW ENTREPRENEUR INVESTED IN THE MANUFACTURE OF ALCOHOL IN 2006 BY INSTALLING ANOTHER COLUMN OF DISTILLATION WITH A CAPACITY OF 300,000 LITERS AND AUTOMATED 100% INCREASING ITS PRODUCTION CAPACITY TO 600,000 LITERS OF HYDRATED ALCOHOL PER DAY • 02 TYPE “A” DISTILLATION COLUMNS WITH CAPACITY TO PRODUCE 300 M³ OF ALCOHOL / DAY • 02 TYPE “B” RECTIFICATION COLUMNS WITH CAPACITY FOR PRODUCTION OF 300 M³ OF ALCOHOL / DAY • 01 TYPE “A” DISTILLATION COLUMN WITH CAPACITY FOR PRODUCTION OF 300 M³ OF ALCOHOL / DAY • 01 TYPE “B” RECTIFICATION COLUMN WITH CAPACITY FOR PRODUCTION OF 300 M³ OF ALCOHOL / DAY • 09 TUBULAR HEAT EXCHANGERS TYPE “K” • 02 TUBULAR HEAT EXCHANGERS TYPE “J” • 02 TUBULAR HEAT EXCHANGERS TYPE “E” • 02 TUBULAR HEAT EXCHANGERS TYPE “E1” • 02 TUBULAR HEAT EXCHANGERS TYPE “E2” • 02 TUBULAR HEAT EXCHANGERS TYPE “R” • 02 TUBULAR HEAT EXCHANGERS TYPE “R1” • 11 NEW FERMENTATION VATS WITH A CAPACITY OF 300 M³ • 03 PLATE HEAT EXCHANGERS FOR THE WORT • 05 PLATE TYPE HEAT EXCHANGERS FOR VATS • 01 VAT FOR WINE • 01 CO₂ RECOVERY COLUMN • 02 PUMPS WITH A CAPACITY OF 600 M³ / H - 50 MCA FOR THE COOLING SYSTEM OF THE PLATE HEAT EXCHANGERS • 01 PUMP WITH A CAPACITY OF 800 M³ / H FOR THE COOLING SYSTEM OF THE PLATE HEAT EXCHANGERS • 02 CENTRÍFUGES HAD - 90 • 04 CENTRÍFUGES HAD - 60 WITH THE INSTALLATION OF THIS EQUIPMENT, THE ALCOHOL DISTILLERY IS PREPARED TO PRODUCE 600000 LITERS OF ALCOHOL PER DAY, RECEIVING A MILLING OF 6500 TCD CORRESPONDING TO 2500000 TONS OF CANE / YEAR Learn More -

TT-7760 GE MODEL 7EA 62,480 KW BASE RATED, 80,000 KW ISO RATED, COMBUSTION TURBINE GENERATOR SET, 60 Hz, YEAR 2007TT-7760 GE MODEL 7EA 62,480 KW BASE RATED, 80,000 KW ISO RATED, COMBUSTION TURBINE GENERATOR SET, 60 Hz, YEAR 2007 SCOPE OF SUPPLY 1. HP/LP STEAM DRUMS 2. HEAT TRANSFORMER MODULES 3. DEAERATOR SYSTEM 4. DUCT BURNER SYSTEM 5. ISOLATION, VENT & DRAIN VALVES 6. HP/LP FLOW ELEMENTS 7. LADDERS AND WALKWAYS 8. FIELD ASSEMBLY FITTINGS 9. EXCLUDED 10. EMISSIONS CONTROL 11. BOILER FEED WATER PUMP 12. EXHAUST STACK 13. TRANSITION DUCTS QUANTITY: 1 Learn More

TT-7760 GE MODEL 7EA 62,480 KW BASE RATED, 80,000 KW ISO RATED, COMBUSTION TURBINE GENERATOR SET, 60 Hz, YEAR 2007TT-7760 GE MODEL 7EA 62,480 KW BASE RATED, 80,000 KW ISO RATED, COMBUSTION TURBINE GENERATOR SET, 60 Hz, YEAR 2007 SCOPE OF SUPPLY 1. HP/LP STEAM DRUMS 2. HEAT TRANSFORMER MODULES 3. DEAERATOR SYSTEM 4. DUCT BURNER SYSTEM 5. ISOLATION, VENT & DRAIN VALVES 6. HP/LP FLOW ELEMENTS 7. LADDERS AND WALKWAYS 8. FIELD ASSEMBLY FITTINGS 9. EXCLUDED 10. EMISSIONS CONTROL 11. BOILER FEED WATER PUMP 12. EXHAUST STACK 13. TRANSITION DUCTS QUANTITY: 1 Learn More -

YY-3080 SIEMENS EQUIPMENT FOR SALEYY-3080 SIEMENS EQUIPMENT FOR SALE FOR SALE 2013 IN FACTORY PACKAGING Learn More

YY-3080 SIEMENS EQUIPMENT FOR SALEYY-3080 SIEMENS EQUIPMENT FOR SALE FOR SALE 2013 IN FACTORY PACKAGING Learn More -

TT-1418 SOLAR TITAN 130 GAS TURBINE, 50Hz / 60Hz, YEAR 2007TT-1418 SOLAR TITAN 130 GAS TURBINE, 50Hz / 60Hz, YEAR 2007 SOLAR TITAN 130 GAS TURBINE 15,000KWE 11,170 RPM / 60Hz 11,197 RPM / 50Hz FUEL GAS QUANTITY: 1 Learn More

TT-1418 SOLAR TITAN 130 GAS TURBINE, 50Hz / 60Hz, YEAR 2007TT-1418 SOLAR TITAN 130 GAS TURBINE, 50Hz / 60Hz, YEAR 2007 SOLAR TITAN 130 GAS TURBINE 15,000KWE 11,170 RPM / 60Hz 11,197 RPM / 50Hz FUEL GAS QUANTITY: 1 Learn More -

YY-3186 82MW (ROLLS ROYCE TRENT 60 +SST600) CCPP FOR SALE (50Hz)YY-3186 82MW (ROLLS ROYCE TRENT 60 +SST600) CCPP FOR SALE (50Hz) AN UNUSED 82MW ISO RATED COMBINED CYCLE POWER PLANT. THE PLANT’S MAIN EQUIPMENT IS COMPOSED OF A ROLLS ROYCE TRENT 60 DLE GAS TURBINE (ALSO KNOWN AS THE SGT-A65), A NOOTER/ERIKSEN HRSG, AND A SIEMENS SST-300 STEAM TURBINE. QUANTITY: 1 Learn More

YY-3186 82MW (ROLLS ROYCE TRENT 60 +SST600) CCPP FOR SALE (50Hz)YY-3186 82MW (ROLLS ROYCE TRENT 60 +SST600) CCPP FOR SALE (50Hz) AN UNUSED 82MW ISO RATED COMBINED CYCLE POWER PLANT. THE PLANT’S MAIN EQUIPMENT IS COMPOSED OF A ROLLS ROYCE TRENT 60 DLE GAS TURBINE (ALSO KNOWN AS THE SGT-A65), A NOOTER/ERIKSEN HRSG, AND A SIEMENS SST-300 STEAM TURBINE. QUANTITY: 1 Learn More -

TT-5150 ALSTOM GAS TURBINE WITH GENERATOR, 300MW, 50 HzTT-5150 ALSTOM GAS TURBINE WITH GENERATOR, 300MW, 50 Hz 300 MW GAS TURBINE 50 Hz GAS TURBINE WITH GENERATOR GEARBOX: GT13E2, DUAL FUEL, 5 ALSTOM STAGE, 148.85MW GENERATOR: 50WY21Z-078 WITH STATIC EXCITATION ALSTOM/ZUILEMAE RB FUEL GAS STARTING SYSTEM ALSTOM/ALLWEILER LUBRICATION SYSTEM GTEXHAUST ALSTOM DUCT+DAMPER ALSTOM STACK ALSTOM CO2 FLOODING: 56 CYLINDERS, 28 GINGEKERR SYSTEM: STANDBY Learn More

TT-5150 ALSTOM GAS TURBINE WITH GENERATOR, 300MW, 50 HzTT-5150 ALSTOM GAS TURBINE WITH GENERATOR, 300MW, 50 Hz 300 MW GAS TURBINE 50 Hz GAS TURBINE WITH GENERATOR GEARBOX: GT13E2, DUAL FUEL, 5 ALSTOM STAGE, 148.85MW GENERATOR: 50WY21Z-078 WITH STATIC EXCITATION ALSTOM/ZUILEMAE RB FUEL GAS STARTING SYSTEM ALSTOM/ALLWEILER LUBRICATION SYSTEM GTEXHAUST ALSTOM DUCT+DAMPER ALSTOM STACK ALSTOM CO2 FLOODING: 56 CYLINDERS, 28 GINGEKERR SYSTEM: STANDBY Learn More -

TT-7913 SIEMENS SST-300 COMPLETE STEAM POWER GENERATOR, 20.29 MW, YEAR 2021, 50HzTT-7913 SIEMENS SST-300 COMPLETE STEAM POWER GENERATOR, 20.29 MW, YEAR 2021, 50Hz 1. UNPACKED - STILL BOXED AND CRATED - COMPLETE PLANT 2. NEW UNUSED 3. MODEL: SIEMENS SST-300 4. YEAR OF MANUFACTURE: 2021 Learn More

TT-7913 SIEMENS SST-300 COMPLETE STEAM POWER GENERATOR, 20.29 MW, YEAR 2021, 50HzTT-7913 SIEMENS SST-300 COMPLETE STEAM POWER GENERATOR, 20.29 MW, YEAR 2021, 50Hz 1. UNPACKED - STILL BOXED AND CRATED - COMPLETE PLANT 2. NEW UNUSED 3. MODEL: SIEMENS SST-300 4. YEAR OF MANUFACTURE: 2021 Learn More -

M-4010 10 MW BIOGAS TO STEAM CONGENERATION PLANT – 10 MEGAWATTS

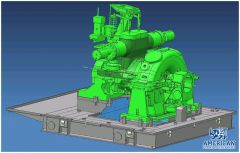

M-4010 10 MW BIOGAS TO STEAM CONGENERATION PLANT – 10 MEGAWATTSREFERENCE NUMBER: M-4010

10 MW BIOGAS TO STEAM CONGENERATION PLANT – 10 MEGAWATTS

10 MW BIOGAS-FIRED COGENERATION PLANT

LATE MODEL, EXCELLENT CONDITION

INCLUDES BOILER, STEAM TURBINE, GENERATOR AND CONDENSER

CAPABLE OF CONVERTING METHANE, LANDFILL GAS, BIOGAS OR NATURAL GAS INTO ELECTRICITY

COMPLETE WITH ALL SUPPORT EQUIPMENT, INCLUDING PUMPS, WATER SYSTEMS, BLOWERS, ETC.

COMPLETE CONTROL ROOM AVAILABLE WITH OPERATIONAL CONTROL PANELS FEATURING CONTROLS BY PANALARM, FOXBORO, BENTLY NEVADA AND BASLER

STARTERS AND SWITCH GEAR BY SIEMENS

BOILER:

125,000 LBS/HR @ 725 PSI DELTAK FIRE TUBE STEAM BOILER

16,189 SQ. FT. HEATING SURFACE

STEAM TURBINE:

101,000 LBS/HR @ 600 PSI TERRY MULTI-STAGE CONDENSING STEAM TURBINE

INCLUDES WOODWARD GOVERNOR AND TACKE GEAR REDUCER

GENERATOR:

10,200 KW IDEAL ELECTRIC

1,800 RPM, 60 HZ

INCLUDES BRUSHLESS EXCITER

CONDENSER:

7,809 SQ. FT. GRAHAM SHELL AND TUBE HEAT EXCHANGER

CS AND ADMIRALTY BRASS CONSTRUCTION

88,100 LBS/HR EXHAUST

86 MM BTU/HR DUTY

Learn More -

M-4798 POWER PLANT 35,000KW YEAR 2008REFERENCE NUMBER: M-4798 (1111BBTLXX10) L POWER PLANT 35,000KW YEAR 2008 POWER PLANT, 35,000KW INCLUDES GENERAL ELECTRIC CONDENSING STEAM TURBINE BRUSH SYNCHRONOUS GENERATOR AIR COOLED CONDENSER SWITCHGEAR TRANSFORMERS CRANE & BUILDING YEAR 2008, UNUSED, 1 LOT QUANTITY AVAILABLE: 1 Learn More

M-4798 POWER PLANT 35,000KW YEAR 2008REFERENCE NUMBER: M-4798 (1111BBTLXX10) L POWER PLANT 35,000KW YEAR 2008 POWER PLANT, 35,000KW INCLUDES GENERAL ELECTRIC CONDENSING STEAM TURBINE BRUSH SYNCHRONOUS GENERATOR AIR COOLED CONDENSER SWITCHGEAR TRANSFORMERS CRANE & BUILDING YEAR 2008, UNUSED, 1 LOT QUANTITY AVAILABLE: 1 Learn More