Search results for: 'Combined'

- Related search terms

- combined o

- combined+o

- combined c

- combined cycle

- combined+heat+and+power

-

TT-4871 COMPLETE BABCOCK STENTER LINE FOR IMPREGNATION AND HEATSETTING, WORKING WIDTH 3200mm, YEAR 1989 TO 2019TT-4871 COMPLETE BABCOCK STENTER LINE FOR IMPREGNATION AND HEATSETTING, WORKING WIDTH 3200mm, YEAR 1989 TO 2019 COMPLETE STENTER LINE FOR IMPREGNATION AND HEATSETTING BRAND BABCOCK MODEL: 5000 -1700 WORKING WIDTH: 3200mm QUANTITY: 1 Learn More

TT-4871 COMPLETE BABCOCK STENTER LINE FOR IMPREGNATION AND HEATSETTING, WORKING WIDTH 3200mm, YEAR 1989 TO 2019TT-4871 COMPLETE BABCOCK STENTER LINE FOR IMPREGNATION AND HEATSETTING, WORKING WIDTH 3200mm, YEAR 1989 TO 2019 COMPLETE STENTER LINE FOR IMPREGNATION AND HEATSETTING BRAND BABCOCK MODEL: 5000 -1700 WORKING WIDTH: 3200mm QUANTITY: 1 Learn More -

TT-4548 BABCOCK COMPLETE STENTER LINE FOR IMPREGNATION AND HEATSETTING, WORKING WIDTH 3200mm, YEAR 1989TT-4548 BABCOCK COMPLETE STENTER LINE FOR IMPREGNATION AND HEATSETTING, WORKING WIDTH 3200mm, YEAR 1989 COMPLETE STENTER LINE FOR IMPREGNATION AND HEATSETTING BRAND: BABCOCK MODEL: 5300 ECONAIR WORKING WIDTH: 3200mm YEAR: 1989 QUANTITY: 1 Learn More

TT-4548 BABCOCK COMPLETE STENTER LINE FOR IMPREGNATION AND HEATSETTING, WORKING WIDTH 3200mm, YEAR 1989TT-4548 BABCOCK COMPLETE STENTER LINE FOR IMPREGNATION AND HEATSETTING, WORKING WIDTH 3200mm, YEAR 1989 COMPLETE STENTER LINE FOR IMPREGNATION AND HEATSETTING BRAND: BABCOCK MODEL: 5300 ECONAIR WORKING WIDTH: 3200mm YEAR: 1989 QUANTITY: 1 Learn More -

TT-4547 BABCOCK COMPLETE STENTER LINE FOR IMPREGNATION AND HEATSETTING, WORKING WIDTH 3200mm, YEAR 1989 TO 2019TT-4547 BABCOCK COMPLETE STENTER LINE FOR IMPREGNATION AND HEATSETTING, WORKING WIDTH 3200mm, YEAR 1989 TO 2019 COMPLETE STENTER LINE FOR IMPREGNATION AND HEATSETTING BRAND: BABCOCK MODEL: 5000 -1700 WORKING WIDTH: 3200mm YEAR: 1989 TO 2019 QUANTITY: 1 Learn More

TT-4547 BABCOCK COMPLETE STENTER LINE FOR IMPREGNATION AND HEATSETTING, WORKING WIDTH 3200mm, YEAR 1989 TO 2019TT-4547 BABCOCK COMPLETE STENTER LINE FOR IMPREGNATION AND HEATSETTING, WORKING WIDTH 3200mm, YEAR 1989 TO 2019 COMPLETE STENTER LINE FOR IMPREGNATION AND HEATSETTING BRAND: BABCOCK MODEL: 5000 -1700 WORKING WIDTH: 3200mm YEAR: 1989 TO 2019 QUANTITY: 1 Learn More -

TT-4060-B GENERAL ELECTRIC LM2500 SAC COMPLETE POWER PLANT, 22MW, YEAR 2022, 5000 HOURS, 50HzTT-4060-B GENERAL ELECTRIC LM2500 SAC COMPLETE POWER PLANT, 22MW, YEAR 2022, 5000 HOURS, 50Hz WE OFFER TWO TURBINES AND GENERATOR ALONE OR THE TURBINE ALONE, GENERATION 2 QUANTITY: 2 Learn More

TT-4060-B GENERAL ELECTRIC LM2500 SAC COMPLETE POWER PLANT, 22MW, YEAR 2022, 5000 HOURS, 50HzTT-4060-B GENERAL ELECTRIC LM2500 SAC COMPLETE POWER PLANT, 22MW, YEAR 2022, 5000 HOURS, 50Hz WE OFFER TWO TURBINES AND GENERATOR ALONE OR THE TURBINE ALONE, GENERATION 2 QUANTITY: 2 Learn More -

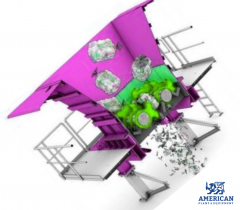

YY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCINGYY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCING WORKING PRINCIPLE OF THE FOUR SHAFT SHREDDER: THE FOUR SHAFT SHREDDER IS A SLOW RUNNING, HIGH TORQUE TWIN SHAFT CRUSHER. THE MATERIAL ENTERS THE INSIDE OF THE BOX THROUGH THE FEED SYSTEM AND HAS TWO ROTOR SHAFTS CARRIED ON THE BOX TO COLLECT IT, WHICH ALTERNATELY ROTATE INWARDS OR OUTWARDS. EACH SHAFT IS EQUIPPED WITH A ROW OF SPECIAL GEOMETRICAL SHREDDING BLADES. THE MATERIAL IS SHREDDED INTO SMALL PIECES BY THE COMBINED EFFECT OF SHEARING, SQUEEZING AND TEARING OF THE SHREDDING BLADES AND IS REMOVED FROM THE LOWER PART OF THE BOX. Learn More

YY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCINGYY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCING WORKING PRINCIPLE OF THE FOUR SHAFT SHREDDER: THE FOUR SHAFT SHREDDER IS A SLOW RUNNING, HIGH TORQUE TWIN SHAFT CRUSHER. THE MATERIAL ENTERS THE INSIDE OF THE BOX THROUGH THE FEED SYSTEM AND HAS TWO ROTOR SHAFTS CARRIED ON THE BOX TO COLLECT IT, WHICH ALTERNATELY ROTATE INWARDS OR OUTWARDS. EACH SHAFT IS EQUIPPED WITH A ROW OF SPECIAL GEOMETRICAL SHREDDING BLADES. THE MATERIAL IS SHREDDED INTO SMALL PIECES BY THE COMBINED EFFECT OF SHEARING, SQUEEZING AND TEARING OF THE SHREDDING BLADES AND IS REMOVED FROM THE LOWER PART OF THE BOX. Learn More -

TT-3472 NEEDLE PUNCHING FELT MACHINE SIMILAR DESIGN AS DILO NEEDLE PUNCHING MACHINE, WORKING WIDTH: 2000mm TO 9000mmTT-3472 NEEDLE PUNCHING FELT MACHINE SIMILAR DESIGN AS DILO NEEDLE PUNCHING MACHINE, WORKING WIDTH: 2000mm TO 9000mm MANUFACTURER: DILO NON WOVEN CONDITION: NEW MIN. ORDER: 1 PIECE APPLICATION: CARDING FIBER AUTOMATIC GRADE: AUTOMATIC QUANTITY: 1 Learn More

TT-3472 NEEDLE PUNCHING FELT MACHINE SIMILAR DESIGN AS DILO NEEDLE PUNCHING MACHINE, WORKING WIDTH: 2000mm TO 9000mmTT-3472 NEEDLE PUNCHING FELT MACHINE SIMILAR DESIGN AS DILO NEEDLE PUNCHING MACHINE, WORKING WIDTH: 2000mm TO 9000mm MANUFACTURER: DILO NON WOVEN CONDITION: NEW MIN. ORDER: 1 PIECE APPLICATION: CARDING FIBER AUTOMATIC GRADE: AUTOMATIC QUANTITY: 1 Learn More -

TT-2821 KUSTERS/RAMISCH DYEING PADDER MACHINES, YEAR 1968 TO 1996TT-2821 KUSTERS/RAMISCH DYEING PADDER MACHINES, YEAR 1968 TO 1996 ITEM 001 DYEING PADDER WITH TWO ROLLERS (FOR DYEING SAMPLES) QUANTITY: 1 ITEM 002 DYEING PADDER KUSTERS WITH TWO ROLLERS QUANTITY: 1 ITEM 003 DYEING PADDER RAMISCH KLEINEWEFERS QUANTITY: 1 ITEM 004 DYEING PADDER KUSTERS QUANTITY: 1 ITEM 005 DYEING PADDER KUSTERS QUANTITY: 1 Learn More

TT-2821 KUSTERS/RAMISCH DYEING PADDER MACHINES, YEAR 1968 TO 1996TT-2821 KUSTERS/RAMISCH DYEING PADDER MACHINES, YEAR 1968 TO 1996 ITEM 001 DYEING PADDER WITH TWO ROLLERS (FOR DYEING SAMPLES) QUANTITY: 1 ITEM 002 DYEING PADDER KUSTERS WITH TWO ROLLERS QUANTITY: 1 ITEM 003 DYEING PADDER RAMISCH KLEINEWEFERS QUANTITY: 1 ITEM 004 DYEING PADDER KUSTERS QUANTITY: 1 ITEM 005 DYEING PADDER KUSTERS QUANTITY: 1 Learn More -

T-9509 MENZEL COATING RANGE, WORKING WIDTH 2600mm, 35 METERS PER MINUTET-9509 MENZEL COATING RANGE, WORKING WIDTH 2600mm, 35 METERS PER MINUTE GENERAL DESCRIPTION: DIFFERENT METHODS OF PRODUCTION CAN BE REALIZED, MACHINE IS DESIGNED FOR COATING ON A PRECISELY HIGH COATING ROLLER OR AS AN AIR DOCTOR BLADE. EQUIPPED WITH A COLLISION CONTROL SYSTEM AVAILABLE IMMEDIATELY Learn More

T-9509 MENZEL COATING RANGE, WORKING WIDTH 2600mm, 35 METERS PER MINUTET-9509 MENZEL COATING RANGE, WORKING WIDTH 2600mm, 35 METERS PER MINUTE GENERAL DESCRIPTION: DIFFERENT METHODS OF PRODUCTION CAN BE REALIZED, MACHINE IS DESIGNED FOR COATING ON A PRECISELY HIGH COATING ROLLER OR AS AN AIR DOCTOR BLADE. EQUIPPED WITH A COLLISION CONTROL SYSTEM AVAILABLE IMMEDIATELY Learn More -

TT-2747 MANROLAND 708, YEAR 2009, 8 COLORSTT-2747 MANROLAND 708, YEAR 2009, 8 COLORS YEAR: 2009 COLORS: 8 IMPRESSIONS: 240 MILL QUANTITY: 1 Learn More

TT-2747 MANROLAND 708, YEAR 2009, 8 COLORSTT-2747 MANROLAND 708, YEAR 2009, 8 COLORS YEAR: 2009 COLORS: 8 IMPRESSIONS: 240 MILL QUANTITY: 1 Learn More -

YY-2535 GE LM6000PA 42+7MW CHP PLANTYY-2535 GE LM6000PA 42+7MW CHP PLANT THE EXTENSIVE LIST OF ACCOMPANYING EQUIPMENT INCLUDES: 1. GE LM6000PA GAS TURBINE EQUIPPED WITH WATER INJECTION, PAIRED WITH A BRUSH ALTERNATOR WITH 42 MW OUTPUT CAPACITY. THIS GAS TURBINE SUPPORTS NATURAL GAS OR DISTILLATE FUEL. 2. GT MK V CONTROL UNIT WITH AUXILIARY SYSTEMS. 3. SIEMENS BACK PRESSURE STEAM TURBINE WITH 7MW OUTPUT CAPACITY. 4. NOOTER ERIKSON HRSG CAPABLE OF SUPPLEMENTARY FIRING WITH NATURAL GAS OR DISTILLATE FUEL. 5. DUAL BELLIS AND MORCOM THREE-STAGE RECIPROCATING NATURAL GAS COMPRESSORS. 6. WATER TREATMENT PLANT COMPOSED OF TWIN BED RESIN EXCHANGE UNITS AND MIXED BED UNITS. 7. MASSIVE STORAGE TANKS FOR DISTILLATE OIL AND HEAVY FUEL OIL, COMPLETE WITH NECESSARY PIPING AND PUMPS. 8. TWO 11/132 KV TRANSFORMERS RATED AT 40 MVA EACH. 9. STANDBY DIESEL GENERATOR FOR BACKUP POWER. 10. SERCK DISTRIBUTED CONTROL SYSTEM (DCS) FOR INTEGRATED CONTROL AND MONITORING. 11. THREE CONTROL AND GENERAL SERVICE AIR COMPRESSORS. 12. AN EXTENSIVE FIRE DETECTION AND SUPPRESSION SYSTEM, SECURITY CAMERAS, AND GAS DETECTION SYSTEM FOR SAFETY AND SECURITY. 13. A CBISS CONTINUOUS EMISSIONS MONITORING SYSTEM (CEMS) TO ENSURE ADHERENCE TO ENVIRONMENTAL STANDARDS. ALL THE NECESSARY CABLING, TRANSFORMERS, SWITCHGEAR, AND PRESSURE-REDUCING STATIONS ASSOCIATED WITH THE ABOVE-MENTIONED PLANT ARE INCLUDED. A BONUS OF UNIQUE SPARE PARTS, EXTENSIVE MANUALS, RECORDS, AND DRAWINGS ARE ALSO PART OF THE PACKAGE, ENSURING SMOOTH OPERATION AND MAINTENANCE. A GE LM6000PA CHP PLANT REPRESENTS A ROBUST, EFFICIENT SOLUTION TO YOUR POWER AND HEATING NEEDS, OFFERING THE RELIABILITY AND FLEXIBILITY NEEDED FOR YOUR OPERATIONS. QUANTITY: 1 UNIT AVAILABLE FOR PURCHASE Learn More

YY-2535 GE LM6000PA 42+7MW CHP PLANTYY-2535 GE LM6000PA 42+7MW CHP PLANT THE EXTENSIVE LIST OF ACCOMPANYING EQUIPMENT INCLUDES: 1. GE LM6000PA GAS TURBINE EQUIPPED WITH WATER INJECTION, PAIRED WITH A BRUSH ALTERNATOR WITH 42 MW OUTPUT CAPACITY. THIS GAS TURBINE SUPPORTS NATURAL GAS OR DISTILLATE FUEL. 2. GT MK V CONTROL UNIT WITH AUXILIARY SYSTEMS. 3. SIEMENS BACK PRESSURE STEAM TURBINE WITH 7MW OUTPUT CAPACITY. 4. NOOTER ERIKSON HRSG CAPABLE OF SUPPLEMENTARY FIRING WITH NATURAL GAS OR DISTILLATE FUEL. 5. DUAL BELLIS AND MORCOM THREE-STAGE RECIPROCATING NATURAL GAS COMPRESSORS. 6. WATER TREATMENT PLANT COMPOSED OF TWIN BED RESIN EXCHANGE UNITS AND MIXED BED UNITS. 7. MASSIVE STORAGE TANKS FOR DISTILLATE OIL AND HEAVY FUEL OIL, COMPLETE WITH NECESSARY PIPING AND PUMPS. 8. TWO 11/132 KV TRANSFORMERS RATED AT 40 MVA EACH. 9. STANDBY DIESEL GENERATOR FOR BACKUP POWER. 10. SERCK DISTRIBUTED CONTROL SYSTEM (DCS) FOR INTEGRATED CONTROL AND MONITORING. 11. THREE CONTROL AND GENERAL SERVICE AIR COMPRESSORS. 12. AN EXTENSIVE FIRE DETECTION AND SUPPRESSION SYSTEM, SECURITY CAMERAS, AND GAS DETECTION SYSTEM FOR SAFETY AND SECURITY. 13. A CBISS CONTINUOUS EMISSIONS MONITORING SYSTEM (CEMS) TO ENSURE ADHERENCE TO ENVIRONMENTAL STANDARDS. ALL THE NECESSARY CABLING, TRANSFORMERS, SWITCHGEAR, AND PRESSURE-REDUCING STATIONS ASSOCIATED WITH THE ABOVE-MENTIONED PLANT ARE INCLUDED. A BONUS OF UNIQUE SPARE PARTS, EXTENSIVE MANUALS, RECORDS, AND DRAWINGS ARE ALSO PART OF THE PACKAGE, ENSURING SMOOTH OPERATION AND MAINTENANCE. A GE LM6000PA CHP PLANT REPRESENTS A ROBUST, EFFICIENT SOLUTION TO YOUR POWER AND HEATING NEEDS, OFFERING THE RELIABILITY AND FLEXIBILITY NEEDED FOR YOUR OPERATIONS. QUANTITY: 1 UNIT AVAILABLE FOR PURCHASE Learn More