Search results for: 'air pressure'

- Related search terms

- Air))),),"')(

- air compr

- air+com'[0]

- air cond

- air+con

-

TT-7003 WARTSILA 18V32D HFO FIRED GENERATOR SET, 6 MW, YEAR 1995TT-7003 WARTSILA 18V32D HFO FIRED GENERATOR SET, 6 MW, YEAR 1995 1. WARTSILA 18V32D HFO FIRED GENERATOR SET 2. YEAR 1995 3. TYPE 18V32D 4. HFO FIRED GENERATOR SET 5. 6 MW 6. VOLTAGE OF 6.6 KV 7. IMMEDIATE DELIVERY 8. EXCELLENT CONDITION QUANTITY: 2 Learn More

TT-7003 WARTSILA 18V32D HFO FIRED GENERATOR SET, 6 MW, YEAR 1995TT-7003 WARTSILA 18V32D HFO FIRED GENERATOR SET, 6 MW, YEAR 1995 1. WARTSILA 18V32D HFO FIRED GENERATOR SET 2. YEAR 1995 3. TYPE 18V32D 4. HFO FIRED GENERATOR SET 5. 6 MW 6. VOLTAGE OF 6.6 KV 7. IMMEDIATE DELIVERY 8. EXCELLENT CONDITION QUANTITY: 2 Learn More -

AA-1120 BASE SHOP COFFEE ROASTERAA-1120 –SALE BASE SHOP COFFEE ROASTER TECHNICAL SPECIFICATIONS: GREEN COFFEE BATCH CAPACITY (MAX): 1.2KG BATCH CAPACITY (MINIMUM ADVISED): 0.5KG CAPACITY PER HOUR: 4KG OPERATION CONTROL TYPE: MANUAL AIRFLOW CONTROL (DAMPER): MANUAL ROASTING TIME: 12 TO 15MIN TEMPERATURE SENSORS: 2 (BEAN AND EXHAUST AIR TEMPERATURE) COOLING TIME: 3MIN TYPE OF COOLING: AIR AMBIENT SAFETY DEVICE: YES OPERATION TYPE BURNER: MANUAL FUEL TYPE: NATURAL GAS(LNG)/PROPANE GAS(LPG) BURNER POWER LPG (G30): LPG 7 TO 23.885KW - BTU/H BURNER POWER LNG (G20): LNG 12 TO 40.945KW - BTU/H INLET PRESSURE LNG: 20MBAR INLET PRESSURE LPG: 37MBAR POWER: 2200W VOLTAGE: 220V/60HZ EXHAUST CHIMNEY (ROASTER CYCLONE): 100mm EXHAUST CHIMNEY (COOLER): 80mm ROASTER FAN MOTOR: 0.33HP COOLER FAN MOTOR: 0.33HP DRUM GEARBOX: 0.17HP COOLER GEARBOX: 170/374HP DIMENSIONS (L X W X H): 1465X940X1180mm NET WEIGHT (ROASTER + CYCLONE): 170KG SHIPPING BOX (L X W X H): 1560X1150X1410mm SHIPPING WEIGHT: 410KG Learn More

AA-1120 BASE SHOP COFFEE ROASTERAA-1120 –SALE BASE SHOP COFFEE ROASTER TECHNICAL SPECIFICATIONS: GREEN COFFEE BATCH CAPACITY (MAX): 1.2KG BATCH CAPACITY (MINIMUM ADVISED): 0.5KG CAPACITY PER HOUR: 4KG OPERATION CONTROL TYPE: MANUAL AIRFLOW CONTROL (DAMPER): MANUAL ROASTING TIME: 12 TO 15MIN TEMPERATURE SENSORS: 2 (BEAN AND EXHAUST AIR TEMPERATURE) COOLING TIME: 3MIN TYPE OF COOLING: AIR AMBIENT SAFETY DEVICE: YES OPERATION TYPE BURNER: MANUAL FUEL TYPE: NATURAL GAS(LNG)/PROPANE GAS(LPG) BURNER POWER LPG (G30): LPG 7 TO 23.885KW - BTU/H BURNER POWER LNG (G20): LNG 12 TO 40.945KW - BTU/H INLET PRESSURE LNG: 20MBAR INLET PRESSURE LPG: 37MBAR POWER: 2200W VOLTAGE: 220V/60HZ EXHAUST CHIMNEY (ROASTER CYCLONE): 100mm EXHAUST CHIMNEY (COOLER): 80mm ROASTER FAN MOTOR: 0.33HP COOLER FAN MOTOR: 0.33HP DRUM GEARBOX: 0.17HP COOLER GEARBOX: 170/374HP DIMENSIONS (L X W X H): 1465X940X1180mm NET WEIGHT (ROASTER + CYCLONE): 170KG SHIPPING BOX (L X W X H): 1560X1150X1410mm SHIPPING WEIGHT: 410KG Learn More -

TT-8545 CATERPILLAR 772G ROCK TRUCK, YEAR 2017, 9930 HOURSTT-8545 CATERPILLAR 772G ROCK TRUCK, YEAR 2017, 9930 HOURS 1. MACHINE HOURS: 9930 - LOAD FACTOR: 22% - NEUTRAL HOURS: 2694 2. CATERPILLAR 772 ROCK TRUCK 3. CATERPILLAR C18 ACERT ENGINE QUANTITY: 1 Learn More

TT-8545 CATERPILLAR 772G ROCK TRUCK, YEAR 2017, 9930 HOURSTT-8545 CATERPILLAR 772G ROCK TRUCK, YEAR 2017, 9930 HOURS 1. MACHINE HOURS: 9930 - LOAD FACTOR: 22% - NEUTRAL HOURS: 2694 2. CATERPILLAR 772 ROCK TRUCK 3. CATERPILLAR C18 ACERT ENGINE QUANTITY: 1 Learn More -

V-2068 WRINKLE TYPE BANDAGE ROLLS PRODUCTION LINE INCLUDING PREFOLDING, BANDAGE DRYING, FOLDING, AND ROLLING MACHINERY (PRODUCT IS LIKE KENDALL “KERLIX”)V-2068 WRINKLE TYPE BANDAGE ROLLS PRODUCTION LINE INCLUDING PREFOLDING, BANDAGE DRYING, FOLDING, AND ROLLING MACHINERY (PRODUCT IS LIKE KENDALL “KERLIX”) THIS LINE INCLUDES PREFOLDING MACHINE, BANDAGE DRYING MACHINE, FOLDING MACHINE, AND WINDING MACHINE. FINAL PRODUCT IS 6 PLY USES 4 OUTPUT LINES, OUTPUT IS APPROXIMATELY 48 PIECES PER MINUTE FINAL WIDTH OF FABRIC: USUALLY CUSTOMERS USE 780mm WIDTH, MACHINE CAN BE MADE ACCORDING TO DIFFERENT REQUESTS MACHINE TOTAL LENGTH: 19 METERS (62.3 FEET) TOTAL QUANTITY: 1 COMPLETE PRODUCTION LINE Learn More

V-2068 WRINKLE TYPE BANDAGE ROLLS PRODUCTION LINE INCLUDING PREFOLDING, BANDAGE DRYING, FOLDING, AND ROLLING MACHINERY (PRODUCT IS LIKE KENDALL “KERLIX”)V-2068 WRINKLE TYPE BANDAGE ROLLS PRODUCTION LINE INCLUDING PREFOLDING, BANDAGE DRYING, FOLDING, AND ROLLING MACHINERY (PRODUCT IS LIKE KENDALL “KERLIX”) THIS LINE INCLUDES PREFOLDING MACHINE, BANDAGE DRYING MACHINE, FOLDING MACHINE, AND WINDING MACHINE. FINAL PRODUCT IS 6 PLY USES 4 OUTPUT LINES, OUTPUT IS APPROXIMATELY 48 PIECES PER MINUTE FINAL WIDTH OF FABRIC: USUALLY CUSTOMERS USE 780mm WIDTH, MACHINE CAN BE MADE ACCORDING TO DIFFERENT REQUESTS MACHINE TOTAL LENGTH: 19 METERS (62.3 FEET) TOTAL QUANTITY: 1 COMPLETE PRODUCTION LINE Learn More -

TT-4374 BACK PRESSURE TURBINE – NEW, 8 MW, 60 HzTT-4374 BACK PRESSURE TURBINE – NEW, 8 MW, 60 Hz STEAM TURBINE GENERATOR 8.0 MW NEW NEVER USED SURPLUS SHIN-NIPPON - ABB ALTERNATOR 8.0 MW - 60 Hz, 13.8 KV, SPEED - 7800 / 1800 RPM INLET PRESSURE - 32 BAR A = 465 PSIG TEMPERATURE - 342 DEG. C. = 647.6 DEF. F. EXHAUST STEAM PRESSURE - 0.12 BAR. A = 1.74 PSIG EXTRACTION STEAM PRESS. - 8 BAR. A = 116.03 PSID WITH ABB - 8.0 MW - BACK-END ALTERNATOR, 1800 RPM, 60 Hz, 13.8 KV Learn More

TT-4374 BACK PRESSURE TURBINE – NEW, 8 MW, 60 HzTT-4374 BACK PRESSURE TURBINE – NEW, 8 MW, 60 Hz STEAM TURBINE GENERATOR 8.0 MW NEW NEVER USED SURPLUS SHIN-NIPPON - ABB ALTERNATOR 8.0 MW - 60 Hz, 13.8 KV, SPEED - 7800 / 1800 RPM INLET PRESSURE - 32 BAR A = 465 PSIG TEMPERATURE - 342 DEG. C. = 647.6 DEF. F. EXHAUST STEAM PRESSURE - 0.12 BAR. A = 1.74 PSIG EXTRACTION STEAM PRESS. - 8 BAR. A = 116.03 PSID WITH ABB - 8.0 MW - BACK-END ALTERNATOR, 1800 RPM, 60 Hz, 13.8 KV Learn More -

TT-5908 JENBACHER JMS620-GS-S.L GAS GENSET, 3.35MW, YEAR 2019, 50HzTT-5908 JENBACHER JMS620-GS-S.L GAS GENSET, 3.35MW, YEAR 2019, 50Hz JENBACHER JMS620-GS-S.L GAS GENSET FUEL: NATURAL GAS, COAL BED GAS 8 X 3.35MW, TOTAL 26.8MW YEAR: 2019 QUANTITY: 8 Learn More

TT-5908 JENBACHER JMS620-GS-S.L GAS GENSET, 3.35MW, YEAR 2019, 50HzTT-5908 JENBACHER JMS620-GS-S.L GAS GENSET, 3.35MW, YEAR 2019, 50Hz JENBACHER JMS620-GS-S.L GAS GENSET FUEL: NATURAL GAS, COAL BED GAS 8 X 3.35MW, TOTAL 26.8MW YEAR: 2019 QUANTITY: 8 Learn More -

G-8230 HIGH-TEMPERATURE AND HIGH-PRESSURE YARN DYEING MACHINE 40KG

G-8230 HIGH-TEMPERATURE AND HIGH-PRESSURE YARN DYEING MACHINE 40KGREFERENCE NUMBER: G-8230

HIGH-TEMPERETURE AND HIGH-PRESSURE YARN DYEING MACHINE 40KG

DESIGNED FOR DYEING, BOILING OFF, BLEACHING, AND WATER WASHING, ETC. SUITABLE FOR HANK YARN, BOBBIN OR RAW STOCK FIBER

MACHINE TYPE: VERTICAL CYLINDER

VAT DIAMETER: Ф600mm

CONE QUANTITY: 7 X 7 = 49 CONES

WORKING TEMPERATURE: 130C

MAX WORKING PRESSURE: 0.4MPA

BOTH RATIO: 1:7 TO 9

WITH COMPUTERIZED CONTROL SYSTEM

HEAT EXCHANGING: COIL TYPE HEAT EXCHANGER, WHICH CAN BE USED FOR EITHER HEATING OR COOLING.

HEAT EXCHANGING SPEED: WHEN THE HEATED STEAM PRESSURE IS 0.4MPA, 40MINUTES WILL BE REQUIRED FOR THE LIQUID INSIDE THE DYEING BARREL RAISING FROM 20OC TO 130OC. WHEN THE COOLING WATER PRESSURE IS 0. 3MPA AND THE WATER TEMPERATURE IS 20 OC, 40 MINUTES WILL BE REQUIRED FOR THE LIQUID INSIDE THE DYEING BECK TO LOWER FROM 130OC TO 80OC.

RECYCLING OF DYEING LIQUID: THE POSITIVE AND NEGATIVE RECYCLING OF DYEING LIQUID WILL BE ADJUSTED BY THE CYLINDER THROUGH THE SWITCHING DEVICE INSIDE THE CENTRIFUGAL PUMP.

SEALING OF BOILER: RUBBER ADHESIVE

THE WORKING PRESSURE INSIDE THE TANK WILL MAKE THE RUBBER SEAL CLOSELY TO ATTACH THE FLANGE. THE CONICAL SURFACE OF THE TANK MOUTH IS TO ENHANCE THE SEALING.

OPENING OF TANK COVER: FIRST OPEN THE AIR VALVE TO RELEASE THE PRESSURE INSIDE THE BOILER. WAIT UNTIL NO EXHAUSTED AIR GOING THRU THE EXHAUST VALVE AND THE READING OF PRESSURE GAUGE IS ZERO, WITHDRAW THE WRENCH HANDLE, OPEN THE CLAMPING HOOP TO REMOVE THE FLANGE; AND THEN OPEN THE COVER WITH DRAG WEIGHT. THE COVER WILL BE CLOSED.

CONFIGURATION:

1. ELECTRICAL CABINET: STAINLESS STEEL CABINET, PLASTIC COATING

2. ELECTRICAL COMPONENTS: SIEMENS, OMRON

3. COMPUTER: HG COMPUTER (MADE IN CHINA)

4. ELECTROMAGNETIC VALVE: TAIWAN YADEKE

5. PUMP: CENTRIFUGAL PUMP

6. MOTOR: WANNAN MOTOR

7. TEMPERATURE CONTROL: COMPUTER CONTROL, WITH HEATING, COOLING, KEEPING WARM, ETC. FUNCTION.

8. HEAT EXCHANGER: INTERNAL COIL HEATING

9. VALVE: STAINLESS ANGLE VALVES, PNEUMATIC BUTTERFLY VALVES

10. ONE CARRIER BASKET

11. MACHINE BODY MATERIAL: STAINLESS STEEL, 316 LITERS

12. ACCESSORIES: SEAL RING FOR DYE VAT, SEAL FOR MAIN PUMP, SEAL FOR REVERSING SHAFT

QUANTITY: 1

Learn More -

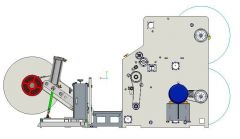

TT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEWTT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEW SUITABLE FOR ROLLS OF PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0-400M/MIN SLITTING WIDTH: 30 TO 1900mm UNWINDING DIAMETER MAXIMUM ø1400mm WINDING DIAMETER: ø610mm MACHINE WEIGHT: 5000KG TOTAL MOTOR POWER: 31KW DIMENSIONS: W3500 X L3500 X H1900 (mm) PAPER CORE 3" (DIAMETER φ76mm DIAMETER φ92mm) OR 3.6” CORE ACCURACY: ≤ 0.30mm TENSION SETTING RANGE: 2 ~ 30KG WINDING MOTOR POWER: 11KW X 2 TRACTION MOTOR: 11KW MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED) QUANTITY: 1 SET Learn More

TT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEWTT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEW SUITABLE FOR ROLLS OF PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0-400M/MIN SLITTING WIDTH: 30 TO 1900mm UNWINDING DIAMETER MAXIMUM ø1400mm WINDING DIAMETER: ø610mm MACHINE WEIGHT: 5000KG TOTAL MOTOR POWER: 31KW DIMENSIONS: W3500 X L3500 X H1900 (mm) PAPER CORE 3" (DIAMETER φ76mm DIAMETER φ92mm) OR 3.6” CORE ACCURACY: ≤ 0.30mm TENSION SETTING RANGE: 2 ~ 30KG WINDING MOTOR POWER: 11KW X 2 TRACTION MOTOR: 11KW MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED) QUANTITY: 1 SET Learn More -

MELT BLOWN CLOTH PRODUCTION LINE 600mmREFERENCE NUMBER: A-2488 MELT BLOWN CLOTH PRODUCTION LINE 600mm SPECIFICATIONS: PLASTIC AUTOMATIC CHARGER • FEEDING CAPACITY: 200 KG / H • AIR PUMP POWER: 0.75 KW HOPPER PLASTIC DRYER • HOPPER CUBIC CAPACITY: 100 L • FEEDING CAPACITY: 50 KG • HEATING POWER: 3.7 KW • BLOWER POWER: 0.12 KW SJ55/30 SINGLE SCREW EXTRUDER • SCREW, BARREL: SCREW AND BARREL MATERIAL 38CRMOALA, NITRIDE • SCREW DIAMETER: 55 mm • SCREW L/D: 30:1 • MAIN MOTOR POWER: 15 KW SIEMENS STANDARD • MOTOR MAIN MOTOR SPEED ADJUSTMENT: 15 KW ABB INVERTER • BARREL HEATING: CASTING - HEATER WITH AIR COOLING • HEATING POWER: 2.8 KW X 4 ZONES • GEAR BOX: ZLYJ SERIES RIGID GEAR BOX • EXTRUSION CAPACITY: 15 TO 40 KG/H HYDRAULIC SCREEN CHANGER • MOTOR POWER: 1.1 KW • STRUCTURE: DOUBLE POSITION, PLATE TYPE • HEATERS: STAINLESS STEEL HEATING BAR METERING PUMP • MOTOR POWER: 2.2KW • CAPACITY: 30CC • SPEED CONTROL: • HEATERS: STAINLESS STEEL HEATING BAR T-DIE • STRUCTURE: T-DIE • MATERIAL OF MOULD: HIGH QUALITY ALLOYED STEEL, SURFACE CHROME PLATED • FLOW CHANNEL CHROME PLATED, POLISHED • SPECIFICATION OF PRODUCT: WIDTH 600 mm • AIR INCOME HOLES: 12 PCS, HIGH PRECISION TEMPERATURE CONTROL FORMING MACHINE • MOTOR POWER: 1.5 KW • SPEED CONTROL: INVERTER • SUCTION FAN: 5.5 KW ELECTROSTATIC ELECTRET DEVICE • INCLUDES ELECTROSTATIC GENERATOR, VOLTAGE REGULATOR, ELECTRET FRAME • APPLICATION: GENERATE ELECTROSTATIC CHARGE, INCREASES THE FILTERING EFFICIENCY • MOTOR POWER: 2.2 KW • BLADES: 4 PCS • HAULING SPEED CONTROL: ADOPTABB INVERTER COLIER • COILING SHAFT: 2 PCS • COMPACTION: BY PNEUMATIC CONTROL • COILING METHOD: BY SELF FRICTION SCREW AIR COMPRESSOR • MOTOR POWER: 37 KW • STRUCTURE: SCREW TYPE, LOW NOISY • PLC CONTROL AIR FILTER • CAPACITY: 7 M3/min • PRESSURE: 1.0 MPA • FILTRATION EFFICIENCY: 3 MICRON / 5 PPM AIR DRYER • CAPACITY: 6 NM3/min • PRESSURE: 1 MPA • POWER: 2 HP AIR TANK • VOLUME: 1000 L • PRESSURE: 1.05 MPA HOT AIR SYSTEM • HEATING POWER: 60 KW • HEATING TYPE: ELECTRIC HEATING • WITH HEAT INSULATION LAYER Learn More

MELT BLOWN CLOTH PRODUCTION LINE 600mmREFERENCE NUMBER: A-2488 MELT BLOWN CLOTH PRODUCTION LINE 600mm SPECIFICATIONS: PLASTIC AUTOMATIC CHARGER • FEEDING CAPACITY: 200 KG / H • AIR PUMP POWER: 0.75 KW HOPPER PLASTIC DRYER • HOPPER CUBIC CAPACITY: 100 L • FEEDING CAPACITY: 50 KG • HEATING POWER: 3.7 KW • BLOWER POWER: 0.12 KW SJ55/30 SINGLE SCREW EXTRUDER • SCREW, BARREL: SCREW AND BARREL MATERIAL 38CRMOALA, NITRIDE • SCREW DIAMETER: 55 mm • SCREW L/D: 30:1 • MAIN MOTOR POWER: 15 KW SIEMENS STANDARD • MOTOR MAIN MOTOR SPEED ADJUSTMENT: 15 KW ABB INVERTER • BARREL HEATING: CASTING - HEATER WITH AIR COOLING • HEATING POWER: 2.8 KW X 4 ZONES • GEAR BOX: ZLYJ SERIES RIGID GEAR BOX • EXTRUSION CAPACITY: 15 TO 40 KG/H HYDRAULIC SCREEN CHANGER • MOTOR POWER: 1.1 KW • STRUCTURE: DOUBLE POSITION, PLATE TYPE • HEATERS: STAINLESS STEEL HEATING BAR METERING PUMP • MOTOR POWER: 2.2KW • CAPACITY: 30CC • SPEED CONTROL: • HEATERS: STAINLESS STEEL HEATING BAR T-DIE • STRUCTURE: T-DIE • MATERIAL OF MOULD: HIGH QUALITY ALLOYED STEEL, SURFACE CHROME PLATED • FLOW CHANNEL CHROME PLATED, POLISHED • SPECIFICATION OF PRODUCT: WIDTH 600 mm • AIR INCOME HOLES: 12 PCS, HIGH PRECISION TEMPERATURE CONTROL FORMING MACHINE • MOTOR POWER: 1.5 KW • SPEED CONTROL: INVERTER • SUCTION FAN: 5.5 KW ELECTROSTATIC ELECTRET DEVICE • INCLUDES ELECTROSTATIC GENERATOR, VOLTAGE REGULATOR, ELECTRET FRAME • APPLICATION: GENERATE ELECTROSTATIC CHARGE, INCREASES THE FILTERING EFFICIENCY • MOTOR POWER: 2.2 KW • BLADES: 4 PCS • HAULING SPEED CONTROL: ADOPTABB INVERTER COLIER • COILING SHAFT: 2 PCS • COMPACTION: BY PNEUMATIC CONTROL • COILING METHOD: BY SELF FRICTION SCREW AIR COMPRESSOR • MOTOR POWER: 37 KW • STRUCTURE: SCREW TYPE, LOW NOISY • PLC CONTROL AIR FILTER • CAPACITY: 7 M3/min • PRESSURE: 1.0 MPA • FILTRATION EFFICIENCY: 3 MICRON / 5 PPM AIR DRYER • CAPACITY: 6 NM3/min • PRESSURE: 1 MPA • POWER: 2 HP AIR TANK • VOLUME: 1000 L • PRESSURE: 1.05 MPA HOT AIR SYSTEM • HEATING POWER: 60 KW • HEATING TYPE: ELECTRIC HEATING • WITH HEAT INSULATION LAYER Learn More -

T-7966 SANFORIZER, NOMINAL WIDTH 2200mmT-7966 SANFORIZER, NOMINAL WIDTH 2200mm MACHINE HAND: LEFT OR RIGHT HAND WIDTH: 2200mm SPEED (M/MIN): 5~80M/MIN PRESHRINKAGE: 16%, VARIED FROM VARIETY SHRINKING RATE: ≤1% STEAM PRESSURE OF PRESS ROLLER: 0.5MPA DIAMETER OF DRYING CYLINDER OF FELT FINISH: Φ2000mm FELT: ABOUT 2200G/M2 WATER CONSUMPTION (TON /HR): 1 STEAM CONSUMPTION (KG/HR): 500 TRANSMISSION AND CONTROL: PLC CONTROL, PARAMETERS ON LINE DISPLAY IN COLOR TOUCH SCREEN, MULTI-UNIT AC FREQUENCY CONVERSION DRIVE INSTALLED POWER (KW): 38.45 OVERALL DIMENSION (L X W X H): 12010(L) X 4168(W) X 3925(H)mm QUANTITY: 1 SET Learn More

T-7966 SANFORIZER, NOMINAL WIDTH 2200mmT-7966 SANFORIZER, NOMINAL WIDTH 2200mm MACHINE HAND: LEFT OR RIGHT HAND WIDTH: 2200mm SPEED (M/MIN): 5~80M/MIN PRESHRINKAGE: 16%, VARIED FROM VARIETY SHRINKING RATE: ≤1% STEAM PRESSURE OF PRESS ROLLER: 0.5MPA DIAMETER OF DRYING CYLINDER OF FELT FINISH: Φ2000mm FELT: ABOUT 2200G/M2 WATER CONSUMPTION (TON /HR): 1 STEAM CONSUMPTION (KG/HR): 500 TRANSMISSION AND CONTROL: PLC CONTROL, PARAMETERS ON LINE DISPLAY IN COLOR TOUCH SCREEN, MULTI-UNIT AC FREQUENCY CONVERSION DRIVE INSTALLED POWER (KW): 38.45 OVERALL DIMENSION (L X W X H): 12010(L) X 4168(W) X 3925(H)mm QUANTITY: 1 SET Learn More