Search results for: 'automatic+cutting+ma'

- Related search terms

- automatic+cutting+machine

- automatic+cutting+ma'

-

YY-3097 SKIVER MODEL HR160HP – HEAVY DUTY SKIVER, WORKING WIDTH 1600mm – NEW, 1 YEAR WARRANTY – BAUMER TYPE FOR HALF THE PRICE; $225,000YY-3097 SKIVER MODEL HR160HP – HEAVY DUTY SKIVER, WORKING WIDTH 1600mm – NEW, 1 YEAR WARRANTY – BAUMER TYPE FOR HALF THE PRICE; $225,000 WORKING WIDTH: 1600mm IT CAN CUT 1mm 250 KG/M3 DENSITY WE CAN CUT PRECISE ON THIS MACHINE QUANTITY: 1 Learn More

YY-3097 SKIVER MODEL HR160HP – HEAVY DUTY SKIVER, WORKING WIDTH 1600mm – NEW, 1 YEAR WARRANTY – BAUMER TYPE FOR HALF THE PRICE; $225,000YY-3097 SKIVER MODEL HR160HP – HEAVY DUTY SKIVER, WORKING WIDTH 1600mm – NEW, 1 YEAR WARRANTY – BAUMER TYPE FOR HALF THE PRICE; $225,000 WORKING WIDTH: 1600mm IT CAN CUT 1mm 250 KG/M3 DENSITY WE CAN CUT PRECISE ON THIS MACHINE QUANTITY: 1 Learn More -

M-5299 AUTOMATIC WOVEN BAG CONVERSION LINE CUTTING-SEWING TYPEREFERENCE NUMBER: M-5299 (131324QND12UF) L AUTOMATIC WOVEN BAG CONVERSION LINE CUTTING-SEWING TYPE AUTOMATIC WOVEN BAG CONVERSION LINE CUTTING-SEWING TYPE MODEL: CS-2HS EQUIPPED WITH TWO SERVO MOTORS & 90° TRANSFER CLIPPER DIMENSIONS (LxWxH): 4850mm x 3880mm x 1180mm WEIGHT: 2800KG QUANTITY AVAILABLE: 1 Learn More

M-5299 AUTOMATIC WOVEN BAG CONVERSION LINE CUTTING-SEWING TYPEREFERENCE NUMBER: M-5299 (131324QND12UF) L AUTOMATIC WOVEN BAG CONVERSION LINE CUTTING-SEWING TYPE AUTOMATIC WOVEN BAG CONVERSION LINE CUTTING-SEWING TYPE MODEL: CS-2HS EQUIPPED WITH TWO SERVO MOTORS & 90° TRANSFER CLIPPER DIMENSIONS (LxWxH): 4850mm x 3880mm x 1180mm WEIGHT: 2800KG QUANTITY AVAILABLE: 1 Learn More -

M-1480 SLITTER REWINDER 1800mm WIDTH AND 1000mm DIAMETER-NEW MACHINE

M-1480 SLITTER REWINDER 1800mm WIDTH AND 1000mm DIAMETER-NEW MACHINEREFERENCE NUMBER: M-1480

SLITTER REWINDER 1800mm WIDTH AND 1000mm DIAMETER-NEW MACHINE

TECHNICAL CHARACTERISTICS:

UNWINDER

MAXIMUM WIDTH: 1800mm

MAXIMUM DIAMETER: 1100mm

MINIMUM WIDTH: 420mm

MAXIMUM WEIGHT: 300kgs

CORE ID: 3”

REWINDER:

MAXIMUM WIDTH: 1800mm

MAXIMUM DIAMETER: 1000mm

MINIMUM WIDTH: 100mm

MAXIMUM WEIGHT PER SHAFT: 300kgs

CORE ID: 3”

MATERIAL:

TYPE: 100% PP NONWOVEN

MINIMUM: 10gsm

MAXIMUM: 150gsm

TENSION:

MAXIMUM: 2 PLI

SPEED:

METERS PER MINUTE: 250

DESCRIPTION:

REWINDER MACHINE FOR NONWOVEN ROLLS: UP TO 1000 mm DIAMETER AT UNWINDER AND 1200 mm AT REWINDER.

THE WORKSTATION OFFERS EASY ACCESS TO THE TENSION CONTROL AREA AS WELL AS THE TRIMMING AREA; THIS WAY, ANY MODIFICATION ON THE MATERIAL MEASUREMENTS CAN BE DONE SAFELY.

THE WORKSTATION WILL DELIVER MODULES OF ROLLED MATERIAL WITH SPECIFIC DENSITY, AND SEPARATED FROM EACH OTHER IN ORDER TO KEEP OPERATION CONDITIONS WITHIN REQUIRED QUALITY CONTROLS.

UNWINDER WITH SHAFT:

THERE IS A CENTRAL UNWINDING SYSTEM SUPPORTED BY A 3” STEEL EXPANSION SHAFT.

THERE IS A TENSION CONTROL SYSTEM THAT WORKS THROUGH A PNEUMATIC DISK BRAKE WITH A REPLACEABLE PADS SYSTEM.

THE UNWINDER HAS A PIVOTABLE ROLLER SYSTEM WHEREBY TENSION MAY BE MODIFIED ON ONE END TO REDUCE TENSION DIFFERENCE ON MATERIAL IF NECESSARY.

THE SAFETY CHUCK HAS A MECHANICAL MOVEMENT SYSTEM FOR SHAFT INSERTION.

THE UNWINDER HAS AN ULTRASONIC OR LASER SENSOR FOR A REAL MEASURING OF ROLL DIAMETER. THIS INFORMATION WILL HELP TO KEEP A SPECIFIC TENSION ON MATERIAL DURING ALL THE PROCESS.

CUTTING:

THE LONGITUDINAL SHEAR CUT SYSTEM GUARANTEES CLEAN AND SAFE TRIMMING AT EVERY MODULE. THE CUTTING SYSTEM ADAPTED TO THE MAIN TRANSMISSION GUARANTEES AN OVER SPEED THAT MAY BE REGULATED ACCORDING TO THE MATERIAL DURING EVERY STAGE OF PROCESS. THE PNEUMATIC ACTIVATION KNIVES WILL ALLOW A FAST MODIFICATION OF THE CUTTING MEASUREMENTS.

THIS ROLLER IS LOCATED AT AN EASY ACCESS AREA FOR THE OPERATOR TO BE ABLE TO MAKE CHANGES ON THE CUTTING WIDTH SAFELY. THE COUNTER KNIVES ARE ASSEMBLED TO THE ROLLER BY 3 SETSCREWS THAT FIX THEIR POSITION ON THE ROLLER. THE COUNTERKNIVES HAVE TWO FACES, SO WHEN THE FIRST FACE HAS AN IMPORTANT WEAR, IT WILL BE REMOVED FROM THE ROLLER AND THE NEW FACE WILL BE PLACED INSTEAD. THIS WILL EXTEND THE LIFESPAN OF THIS IMPORTANT COMPONENT.

SHEAR CUT KNIVES: THERE IS AN ADJUSTMENT MECHANISM TO PLACE THEM ON THE COUNTER KNIFE AND TO ADJUST THE CUTTING LOAD ACCURATELY. THE COUNTER KNIVES ARE SUPPORTED TOWARDS THE ROLLER IN ORDER TO OBTAIN A CUTOFF. THE SPEED ON THIS SYSTEM IS AN OVER SPEED IN RELATION TO THAT OF THE MATERIAL, IN ORDER TO GENERATE A CLEAN CUT.

LONGITUDINAL SHEAR CUT: PNEUMATIC ACTIVATION.

COUNTER KNIVES ROLLER WITH 3 SUPPORT PLANES FOR THE COUNTER KNIVES; 120° DISPLACEMENT FROM EACH OTHER.

19 SLITTERS ARE INCLUDED.

REWINDER:

PERIPHERAL REWINDER FOR NONWOVEN. THIS SYSTEM HAS A COUPLE OF MAIN ROLLERS WHERE THE MATERIAL ROLL IS FORMED.

THIS SYSTEM HAS LINEAR GUIDES FOR COMPACTION THROUGH WICH A NIP IS OBTAINED ON THE MATERIAL. THE REWINDER WILL HAVE A TRANSMISSION BASED ON A VECTORIAL-TYPE MOTOR ADAPTED TO A CYCLOIDAL REDUCER. THE TRANSMISSION HAS A MECHANICAL TORQUE CONTROL SYSTEM TO CONTROL THE TORQUE DIFFERENTIAL BETWEEN MAIN ROLLS.

THIS SYSTEM WILL HAVE A 3” EXPANSION SHAFT WHERE THE CARDBOARD CORES WILL BE INSERTED AND THE MATERIAL ROLLS WILL BE FORMED.

FABRIC OPENING SYSTEM:

THIS SYSTEM IS BASED ON A VARIABLE CURVATURE SYSTEM BY A CENTER KNOB AND IT IS A BAR- TYPE SYSTEM. THIS KNOB IS THERE TO CONTROL THE CURVATURE OF THE BAR WHERE MATERIAL SLIDES THROUGH. THE SLIDING BAR IS MADE OUT OF AN ULTRA LOW FRICTION MATERIAL IN ORDER TO GENERATE A SMOOTH SLIDING OF MATERIAL WITHOUT ANY TENSION ADDED. THIS WILL REDUCE WRINKLES IN A SIGNIFICANT WAY.

AUTOMATIC TENSION SYSTEM:

THERE IS AN OPEN LOOP AUTOMATIC TENSION CONTROL SYSTEM WITH A SENSOR FOR DIAMETER MEASURING. BY THIS SYSTEM, A REAL VALUE OF DIAMETER IS OBTAINED AT THE REWINDER. PRESSURE OF PNEUMATIC BRAKE VARIES DURING PROCESS.

MANUAL POSITIONING (OPTIONAL):

THE MANUAL POSITIONING SYSTEM IS BASED ON THE POSITION CONTROL OF THE COUNTER KNIVES. THE MODULE IS POSITIONED AT A DESIRED CUTTING PARAMETER AND THE COUNTER KNIFE WILL PHYSICALLY COME ACROSS IT. THE REAL POSITION OF MODULE WILL BE SHOWN ON A SCREEN THAT OPERATOR WILL BE CONSTANTLY SUPERVISING. THIS SCREEN WILL SHOW THE REAL MEASUREMENTS OF THE CARRIAGE IN RELATION TO THE LAST ONE OR AS AN ABSOLUTE REFERENCE. OPERATOR WILL BE ABLE TO RESET THE MEASUREMENT ONCE THE COUNTER KNIFE IS REPLACED AND WILL REPEAT THIS PROCESS EVERY TIME A COUNTER KNIFE IS POSITIONED.

A DISPLAY WILL SHOW THE DESIRED POSITION IN MILLIMETERS OR INCHES.

THIS SYSTEM CAN SHOW MEASUREMENT IN AN EITHER ABSOLUTE OR INCREASING WAY.

POSITION TOLERANCE: +/- 0.30 mm.

THE POSITIONER IS INSTALLED ON A SUPPORT THAT WILL BE LOCATED ON THE REWINDER BENCHES. THEREFORE, THERE WILL BE AN EASY ACCESS TO SYSTEM AND AN EASY REPETITION OF POSITIONING PROCESS.

UNLOADING ROLL TABLE:

A HYDRAULIC PIVOTEABLE TABLE WILL HAVE AS MAIN FUNCTION THE UNLOADING OF FINISHED ROLLS THAT THEN WILL BE LOCATED ON FLOOR LEVEL. THIS SYSTEM WILL EJECT THE ROLL AND THEN IT WILL BE RECEIVED AT THE PIVOTING TABLE FOR AN EFFICIENT UNLOADING.

THE UNLOADING TABLE WILL ALSO WORK AS A PROTECTION FOR THE OPERATOR.

THIS EQUIPMENT WILL HAVE SECURITY CURTAINS AT FRONT TO KEEP OPERATOR FROM ENTERING THE REWINDING AREA. THERE WILL BE AN EMERGENCY STOP BUTTON OR WIRE WHERE OPERATOR WORKS AND WILL ALSO HAVE PHYSICAL PROTECTION WITH SECURITY SWITCHES AT CUTTING AREA.

CONTROL:

HMI CENTRAL CONTROL SYSTEM WITH TOUCH SCREEN TO PROGRAM THE OPERATION CYCLE AND ALL THE MATERIAL CHARACTERISTICS. OPERATOR WILL HAVE ACCESS TO ALL OPERATION PARAMETERS IN ORDER TO BE ABLE TO MAKE CHANGES ON THE EQUIPMENT OPERATION CONDITIONS, AND THEREFORE OBTAIN MATERIAL ROLLS WITH SPECIFIC DENSITIES.

TRANSMISSION: VECTORIAL MOTO REDUCER WITH 1000:1 TORQUE.

DIGITAL METER COUNTER WITH DISPLAY AND AUTOMATIC STOP AT DEFINED DISTANCE.

DOCUMENTS INCLUDED:

THE MACHINE WILL BE DELIVERED WITH THE FOLLOWING DOCUMENT:

OPERATION MANUAL

MAINTENANCE MANUAL

SAFETY MANUAL

ELECTRIC DIAGRAMS

CONTROL SYSTEM MANUAL

PLC BACKUP

REQUIREMENTS:

ELECTRIC 15 KW, 440 VAC, TRI PHASE.

PNEUMATIC 6 BAR - 60 LTS. / MIN.

DUCTS AND WIRING:

DUCTS AND WIRES RUNNING FROM UTILITIES SOURCES TO THE CONTROL PANEL AND FROM THE CONTROL PANEL TO THE MACHINE WILL BE AT CUSTOMER COSTS AND MUST BE DONE ACCORDING TO THE INSTRUCTIONS SHOWN IN OUR DIAGRAMS

SIEMENS PLC

Learn More -

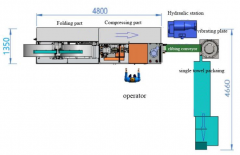

YY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINSYY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINS ASK FOR MORE DETAILS! PRODUCTION PROCESS: AUTOMATIC FEEDING→CUTTING→FOLDING→COMPRESSING→FORMING→DELIVERY→PACKING→OUTPUT Learn More

YY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINSYY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINS ASK FOR MORE DETAILS! PRODUCTION PROCESS: AUTOMATIC FEEDING→CUTTING→FOLDING→COMPRESSING→FORMING→DELIVERY→PACKING→OUTPUT Learn More -

YY-3347 FULLY AUTOMATIC SINGLE SHAFT BALONEY SLITTER, WORKING WIDTH 2000mm (78.7 INCHES) - NEWYY-3347 FULLY AUTOMATIC SINGLE SHAFT BALONEY SLITTER, WORKING WIDTH 2000mm (78.7 INCHES) - NEW This single-shaft cutting machine offers precision and versatility for processing various tapes such as PVC, masking, double-sided, OPP packaging, and foam tapes. With a working width of up to 2000mm and cutting widths ranging from 2mm to 2000mm, it accommodates diverse production needs. Servo motor-driven width setting and knife angle adjustment ensure precise control over dimensions and angles. The PLC-controlled system with a touch panel allows storage of up to 20 width settings for efficient operation. Features like inverter-controlled motors, automatic cooling, and error detection enhance performance and reliability, making it an ideal solution for high-quality tape cutting operations. QUANTITY: 1 Learn More

YY-3347 FULLY AUTOMATIC SINGLE SHAFT BALONEY SLITTER, WORKING WIDTH 2000mm (78.7 INCHES) - NEWYY-3347 FULLY AUTOMATIC SINGLE SHAFT BALONEY SLITTER, WORKING WIDTH 2000mm (78.7 INCHES) - NEW This single-shaft cutting machine offers precision and versatility for processing various tapes such as PVC, masking, double-sided, OPP packaging, and foam tapes. With a working width of up to 2000mm and cutting widths ranging from 2mm to 2000mm, it accommodates diverse production needs. Servo motor-driven width setting and knife angle adjustment ensure precise control over dimensions and angles. The PLC-controlled system with a touch panel allows storage of up to 20 width settings for efficient operation. Features like inverter-controlled motors, automatic cooling, and error detection enhance performance and reliability, making it an ideal solution for high-quality tape cutting operations. QUANTITY: 1 Learn More -

TT-3138 TTARP AUTOMATIC DIE CUTTING PRESS, 60” X 32”, CAPACITY 100 TON, YEAR 2016TT-3138 TTARP AUTOMATIC DIE CUTTING PRESS, 60” X 32”, CAPACITY 100 TON, YEAR 2016 TTARP AUTOMATIC DIE CUTTING PRESS YEAR BUILT IN 2016 BELT FEED QUANTITY: 1 Learn More

TT-3138 TTARP AUTOMATIC DIE CUTTING PRESS, 60” X 32”, CAPACITY 100 TON, YEAR 2016TT-3138 TTARP AUTOMATIC DIE CUTTING PRESS, 60” X 32”, CAPACITY 100 TON, YEAR 2016 TTARP AUTOMATIC DIE CUTTING PRESS YEAR BUILT IN 2016 BELT FEED QUANTITY: 1 Learn More -

TT-2175 ANTISLIP LAMINATING & PVC BACK-COATING LINE, WORKING WIDTH MINIMUM 1200mm, YEAR 2022TT-2175 ANTISLIP LAMINATING & PVC BACK-COATING LINE, WORKING WIDTH MINIMUM 1200mm, YEAR 2022 -FOR CARPET INDUSTRY WORKING WIDTH: MINIMUM 1200mm, MAXIMUM 4000mm WORKING SPEED: 7 METERS PER MINUTE PRIMARY GOODS: RUG AND BLANKET AND FABRIC COATING TYPE: PVC PLANT CAN BE USE FOR CARPET, FELT AND FABRIC FIRST FELT IS LAMINATED ON THE BACK FROM THE CARPET SECOND DOTTING FLEXIBLE PVC BACKING CARPET FELT PLANT IS BRAND NEW 2022 EXCLUSIVE TRANSPORT, FLIGHT TICKETS, HOTEL ACCOMODATION, FOOD & DRINKS QUANTITY: 1 Learn More

TT-2175 ANTISLIP LAMINATING & PVC BACK-COATING LINE, WORKING WIDTH MINIMUM 1200mm, YEAR 2022TT-2175 ANTISLIP LAMINATING & PVC BACK-COATING LINE, WORKING WIDTH MINIMUM 1200mm, YEAR 2022 -FOR CARPET INDUSTRY WORKING WIDTH: MINIMUM 1200mm, MAXIMUM 4000mm WORKING SPEED: 7 METERS PER MINUTE PRIMARY GOODS: RUG AND BLANKET AND FABRIC COATING TYPE: PVC PLANT CAN BE USE FOR CARPET, FELT AND FABRIC FIRST FELT IS LAMINATED ON THE BACK FROM THE CARPET SECOND DOTTING FLEXIBLE PVC BACKING CARPET FELT PLANT IS BRAND NEW 2022 EXCLUSIVE TRANSPORT, FLIGHT TICKETS, HOTEL ACCOMODATION, FOOD & DRINKS QUANTITY: 1 Learn More -

YY-2899 BALONEY FABRIC ROLL SLITTER, 3000mm X 400mm DIAMETER (118 INCHES BY 15.7 INCHES) – NEW MACHINEYY-2899 BALONEY FABRIC ROLL SLITTER, 3000mm X 400mm DIAMETER (118 INCHES BY 15.7 INCHES) – NEW MACHINE FOR THE FOLLOWING TYPES OF FABRICS: WOVEN FABRICS, TENT FABRIC, SHOE FABRIC, UMBRELLA FABRIC, FOAM, LEATHER, REFLECTIVE MATERIAL, PLASTIC, PAPER, DOUBLE SIDED TAPE, ACETATE FABRIC, REINFORCED BELTING MATERIAL, CONDUCTIVE CLOTH, AND OTHER MATERIALS OF VARIOUS WIDTHS. CAN DO BIAS FABRIC. QUANTITY: 1 Learn More

YY-2899 BALONEY FABRIC ROLL SLITTER, 3000mm X 400mm DIAMETER (118 INCHES BY 15.7 INCHES) – NEW MACHINEYY-2899 BALONEY FABRIC ROLL SLITTER, 3000mm X 400mm DIAMETER (118 INCHES BY 15.7 INCHES) – NEW MACHINE FOR THE FOLLOWING TYPES OF FABRICS: WOVEN FABRICS, TENT FABRIC, SHOE FABRIC, UMBRELLA FABRIC, FOAM, LEATHER, REFLECTIVE MATERIAL, PLASTIC, PAPER, DOUBLE SIDED TAPE, ACETATE FABRIC, REINFORCED BELTING MATERIAL, CONDUCTIVE CLOTH, AND OTHER MATERIALS OF VARIOUS WIDTHS. CAN DO BIAS FABRIC. QUANTITY: 1 Learn More -

HYDRAULIC CUTTING MACHINE WITH AUTO-FEEDING TABLE; 2000mm WIDTH x 1300mm DEPTH ( 78.7” X 51”)REFERENCE NUMBER: Y-2079 HYDRAULIC CUTTING MACHINE WITH AUTO-FEEDING TABLE; 2000mm WIDTH x 1300mm DEPTH ( 78.7” X 51”) AUTO-BALANCING STRUCTURE: DOUBLE-CYLINDER, FOUR-COLUMN, AND SELF-BALANCING CONNECTING ROD MAKE SURE EQUAL PRESSURE IS APPLIED THROUGHOUT WORKING AREA. MACHINE SLOWS DOWN WHEN THE CUTTING DIE TOUCHES MATERIAL TO BE CUT, TO CONFIRM THE PRECISION BETWEEN UPPER AND BOTTOM PLATEN FOR THICK MATERIALS. WITH STROKE ADJUSTMENT DEVICE, MAKES STROKE SIMPLE AND CORRECT TO ADJUST WITH CUTTING DIE, CUTTING BOARD, AND MATERIALS. CENTRAL AUTOMATIC LUBRICATION SYSTEM, INCREASES MACHINE LIFESPAN AUTOMATIC COUNTING ADJUSTABLE LIFT HEIGHT ADJUSTABLE CUTTING DEPTH CUTTING FORCE: 200 TONS DIMENSIONS: 2900 x 2950 x 2000mm DAYLIGHT: 230mm (9 inches) OIL PUMP: 53 ml PER ROTATION CUTTING AREA: WIDTH 2000mm X DEPTH 1300mm (78.7 inches x 51 inches) STROKE: 50 TO 230mm (from 2 inches to 9 inches) MOTOR: 11 KW WEIGHT: 6800 KG QUANTITY: 1 Learn More

HYDRAULIC CUTTING MACHINE WITH AUTO-FEEDING TABLE; 2000mm WIDTH x 1300mm DEPTH ( 78.7” X 51”)REFERENCE NUMBER: Y-2079 HYDRAULIC CUTTING MACHINE WITH AUTO-FEEDING TABLE; 2000mm WIDTH x 1300mm DEPTH ( 78.7” X 51”) AUTO-BALANCING STRUCTURE: DOUBLE-CYLINDER, FOUR-COLUMN, AND SELF-BALANCING CONNECTING ROD MAKE SURE EQUAL PRESSURE IS APPLIED THROUGHOUT WORKING AREA. MACHINE SLOWS DOWN WHEN THE CUTTING DIE TOUCHES MATERIAL TO BE CUT, TO CONFIRM THE PRECISION BETWEEN UPPER AND BOTTOM PLATEN FOR THICK MATERIALS. WITH STROKE ADJUSTMENT DEVICE, MAKES STROKE SIMPLE AND CORRECT TO ADJUST WITH CUTTING DIE, CUTTING BOARD, AND MATERIALS. CENTRAL AUTOMATIC LUBRICATION SYSTEM, INCREASES MACHINE LIFESPAN AUTOMATIC COUNTING ADJUSTABLE LIFT HEIGHT ADJUSTABLE CUTTING DEPTH CUTTING FORCE: 200 TONS DIMENSIONS: 2900 x 2950 x 2000mm DAYLIGHT: 230mm (9 inches) OIL PUMP: 53 ml PER ROTATION CUTTING AREA: WIDTH 2000mm X DEPTH 1300mm (78.7 inches x 51 inches) STROKE: 50 TO 230mm (from 2 inches to 9 inches) MOTOR: 11 KW WEIGHT: 6800 KG QUANTITY: 1 Learn More -

E-9384 HORIZONTAL AUTOMATIC CONTINUOUS FOAMING LINEINVENTORY NUMBER: E-9384 HORIZONTAL AUTOMATIC CONTINUOUS FOAMING LINE OVEN LENGTH: 16.9 M. FOAMING HEIGHT: 1.0 TO 1.3 M. FOAMING WIDTH: 1.15 TO 2.3 M. FOAMING DENSITY: 10 TO 50KG/M3. CONVEYOR BELT LENGTH: 16.9 M. SIDE BOARD WIDTH ADJUSTMENT: 0.98 TO 2.4M. CONVEYOR BELT SPEED: 2.0 TO 7.0M/MIN. MIXING-HEAD POWER: 37KW. WITH BLOCK CUTTING MACHINE. TOTAL POWER: 130KW. TOTAL OUTPUT: 200 TO 350KG/MIN. MACHINE EXTERNAL SIZE: L34000 X W4550 X H4200mm. CE CERTIFICATE GUARANTEE FOR ONE YEAR. QUANTITY AVAILABLE: 1 Learn More

E-9384 HORIZONTAL AUTOMATIC CONTINUOUS FOAMING LINEINVENTORY NUMBER: E-9384 HORIZONTAL AUTOMATIC CONTINUOUS FOAMING LINE OVEN LENGTH: 16.9 M. FOAMING HEIGHT: 1.0 TO 1.3 M. FOAMING WIDTH: 1.15 TO 2.3 M. FOAMING DENSITY: 10 TO 50KG/M3. CONVEYOR BELT LENGTH: 16.9 M. SIDE BOARD WIDTH ADJUSTMENT: 0.98 TO 2.4M. CONVEYOR BELT SPEED: 2.0 TO 7.0M/MIN. MIXING-HEAD POWER: 37KW. WITH BLOCK CUTTING MACHINE. TOTAL POWER: 130KW. TOTAL OUTPUT: 200 TO 350KG/MIN. MACHINE EXTERNAL SIZE: L34000 X W4550 X H4200mm. CE CERTIFICATE GUARANTEE FOR ONE YEAR. QUANTITY AVAILABLE: 1 Learn More