Search results for: 'machine de fa'

- Related search terms

- Machine c'

- Machine+fe

- machine+de

- machine de'

- machine de''

-

G-6734-F F-4-D FEATHER FILLING MACHINEMACHINE MODE: F -4-D ESPECIALLY SUITED FOR FILLING QUILTS DIMENSIONS: 700 x 600 x 1400mm POWER: 1.6KW FILLING RANGE: 1 TO 100 GRAMS, DEPENDING ON THE MATERIAL ACCURACY: O TO 3 GRAMS DEPENDING ON THE OPERATION WEIGHING AND FILLING WITH ONLY ONE MACHINE, IN ONLY ONE OPERATION, RELIABLE AND PRECISE. EASY AND FAULTLESS OPERATION BY PROGRAMMING, YOU CAN SET FILLING WEIGHT AND SAVE UP TO 20 RECIPES LOW NOISE, USES A SPECIAL FAN FOR GENTLE FEATHER PROCESSING TRANSPORTATION AT EXTREMELY HIGH PERFORMANCE. VARIABLE FILLING SPEED, QUICK-START AND QUICK-BRAKE OF THE FAN BY USE OF A FREQUENCY INVERTER. FOOT-SWITCH OPERATED, AUTOMATIC FINISH OF THE FILLING CYCLE Learn More

G-6734-F F-4-D FEATHER FILLING MACHINEMACHINE MODE: F -4-D ESPECIALLY SUITED FOR FILLING QUILTS DIMENSIONS: 700 x 600 x 1400mm POWER: 1.6KW FILLING RANGE: 1 TO 100 GRAMS, DEPENDING ON THE MATERIAL ACCURACY: O TO 3 GRAMS DEPENDING ON THE OPERATION WEIGHING AND FILLING WITH ONLY ONE MACHINE, IN ONLY ONE OPERATION, RELIABLE AND PRECISE. EASY AND FAULTLESS OPERATION BY PROGRAMMING, YOU CAN SET FILLING WEIGHT AND SAVE UP TO 20 RECIPES LOW NOISE, USES A SPECIAL FAN FOR GENTLE FEATHER PROCESSING TRANSPORTATION AT EXTREMELY HIGH PERFORMANCE. VARIABLE FILLING SPEED, QUICK-START AND QUICK-BRAKE OF THE FAN BY USE OF A FREQUENCY INVERTER. FOOT-SWITCH OPERATED, AUTOMATIC FINISH OF THE FILLING CYCLE Learn More -

G-6734-C F-4-A FEATHER FILLING MACHINEMACHINE MODE: F -4-A MAINLY USED TO FILL JACKETS, SLEEPING BAGS, CUSHIONS, PILLOWS, PADS, QUILTS, COMFORTERS, ETC. DIMENSIONS: 700 x 600 x 1400mm POWER: 1.6 KW FILLING RANGE: 1 TO 100 GRAMS DEPENDING ON THE MATERIAL ACCURACY: 0 TO 8 GRAMS DEPENDING ON THE OPERATION WEIGHING AND FILLING WITH ONLY ONE MACHINE, IN ONLY ONE OPERATION, RELIABLE AND PRECISE. LOW NOISE BY SPECIAL FAN FOR GENTLE FEATHER TRANSPORTATION AT EXTREMELY HIGH PERFORMANCE. VARIABLE FILLING SPEED, QUICK-START AND QUICK-BRAKE OF THE FAN BY USE OF A FREQUENCY INVERTER. EASY AND FAULTLESS OPERATION BIG DISPLAY CONTROL PANEL BASED ON UP-TO-DATE TECHNOLOGY FOOT-SWITCH OPERATED ON AND OFF STOP Learn More

G-6734-C F-4-A FEATHER FILLING MACHINEMACHINE MODE: F -4-A MAINLY USED TO FILL JACKETS, SLEEPING BAGS, CUSHIONS, PILLOWS, PADS, QUILTS, COMFORTERS, ETC. DIMENSIONS: 700 x 600 x 1400mm POWER: 1.6 KW FILLING RANGE: 1 TO 100 GRAMS DEPENDING ON THE MATERIAL ACCURACY: 0 TO 8 GRAMS DEPENDING ON THE OPERATION WEIGHING AND FILLING WITH ONLY ONE MACHINE, IN ONLY ONE OPERATION, RELIABLE AND PRECISE. LOW NOISE BY SPECIAL FAN FOR GENTLE FEATHER TRANSPORTATION AT EXTREMELY HIGH PERFORMANCE. VARIABLE FILLING SPEED, QUICK-START AND QUICK-BRAKE OF THE FAN BY USE OF A FREQUENCY INVERTER. EASY AND FAULTLESS OPERATION BIG DISPLAY CONTROL PANEL BASED ON UP-TO-DATE TECHNOLOGY FOOT-SWITCH OPERATED ON AND OFF STOP Learn More -

V-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTINGV-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTING For Max. Block Size: Length 2440 mm (96 in), Width 1220 mm (48 in), Height 600 mm (23.6 in) Machine for cutting pipe insulation A programmed-control cutting machine which runs on AutoCAD, controlled by computer. Main Features of Contour Cutter: 1. Integrated design & cutting program. Simply design and cut; 2. Big cost savings by automatically arranging the product; 3. Support numeric instrument; 4. Higher material utilization resulting from computer aided nesting of shapes; 5. Cut speed can be set to achieve the best-cut speed for different foam material; 6. Can pre-cut on the computer to check cutting course; 7. With Nesting System Learn More

V-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTINGV-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTING For Max. Block Size: Length 2440 mm (96 in), Width 1220 mm (48 in), Height 600 mm (23.6 in) Machine for cutting pipe insulation A programmed-control cutting machine which runs on AutoCAD, controlled by computer. Main Features of Contour Cutter: 1. Integrated design & cutting program. Simply design and cut; 2. Big cost savings by automatically arranging the product; 3. Support numeric instrument; 4. Higher material utilization resulting from computer aided nesting of shapes; 5. Cut speed can be set to achieve the best-cut speed for different foam material; 6. Can pre-cut on the computer to check cutting course; 7. With Nesting System Learn More -

TORRES MODEL MICROPUNT-153 YEAR 2000 WIDTH 2000mmTORRES MODEL MICROPUNT-153 SUEDING/EMERIZING MACHINE YEAR 2000 WIDTH 2000mm COMPLETE WITH DUST SUCTION FILTERS IT IS THE ONLY MACHINE ON THE MARKET WHICH CAN REALLY SUEDE BOTH HEAVY COTTON TWILL AND A LIGHT AND ELASTIC KNITTED FABRIC SUCH AS LYCRA. AS THE FABRIC CONTENT IS WITHIN THE WORKING AREA (ONLY 65 CM.), THE TENSION OF THE SAME CAN BE CONTROLLED PERFECTLY, AND THIS IS A MUST, IF YOU WANT TO OBTAIN A UNIFORM FINISH. EXTREMELY HIGH ABRASIVE/FABRIC EXCHANGE DUE TO THE FACT THAT ITS SUEDING ROLLERS ARE MANUFACTURED WITH HIGHLY ACCURATE CALIBRATED STEEL TUBE, DYNAMICALLY BALANCED AND TURN AROUND BEARINGS AT EXTREMELY HIGH SPEED (18 M/S). INNER COOLING OF THE SUEDING ROLLERS BY FORCED AIR FLOW. FABRIC SPEED BY MEANS OF ASYNCHRONOUS MOTORS DRIVEN BY A VECTORIAL INVERTER. FABRIC TENSIONING BY MEANS OF A PNEUMATIC SYSTEM OF OUR OWN DESIGN. CONTACT ARC VARIABLE BY MEANS OF A MOTORIZED SYSTEM. POSSIBILITY OF USING A CONVENTIONAL AND/OR A DIAMOND (LONG LIFE) ABRASIVE. AUTOMATIC SEAM PASSAGE. STATIC ELIMINATOR. FABRIC CLEANING BY MEANS OF A BEATING/BRUSHING PROCESS WITH A SUCTION NOZZLE. DUST SUCTION AND COLLECTION SYSTEM. ALL THE WORKING PARAMETERS ARE SHOWN ON THE PANEL AND THEY MAY BE REPRODUCED FAITHFULLY Learn More

TORRES MODEL MICROPUNT-153 YEAR 2000 WIDTH 2000mmTORRES MODEL MICROPUNT-153 SUEDING/EMERIZING MACHINE YEAR 2000 WIDTH 2000mm COMPLETE WITH DUST SUCTION FILTERS IT IS THE ONLY MACHINE ON THE MARKET WHICH CAN REALLY SUEDE BOTH HEAVY COTTON TWILL AND A LIGHT AND ELASTIC KNITTED FABRIC SUCH AS LYCRA. AS THE FABRIC CONTENT IS WITHIN THE WORKING AREA (ONLY 65 CM.), THE TENSION OF THE SAME CAN BE CONTROLLED PERFECTLY, AND THIS IS A MUST, IF YOU WANT TO OBTAIN A UNIFORM FINISH. EXTREMELY HIGH ABRASIVE/FABRIC EXCHANGE DUE TO THE FACT THAT ITS SUEDING ROLLERS ARE MANUFACTURED WITH HIGHLY ACCURATE CALIBRATED STEEL TUBE, DYNAMICALLY BALANCED AND TURN AROUND BEARINGS AT EXTREMELY HIGH SPEED (18 M/S). INNER COOLING OF THE SUEDING ROLLERS BY FORCED AIR FLOW. FABRIC SPEED BY MEANS OF ASYNCHRONOUS MOTORS DRIVEN BY A VECTORIAL INVERTER. FABRIC TENSIONING BY MEANS OF A PNEUMATIC SYSTEM OF OUR OWN DESIGN. CONTACT ARC VARIABLE BY MEANS OF A MOTORIZED SYSTEM. POSSIBILITY OF USING A CONVENTIONAL AND/OR A DIAMOND (LONG LIFE) ABRASIVE. AUTOMATIC SEAM PASSAGE. STATIC ELIMINATOR. FABRIC CLEANING BY MEANS OF A BEATING/BRUSHING PROCESS WITH A SUCTION NOZZLE. DUST SUCTION AND COLLECTION SYSTEM. ALL THE WORKING PARAMETERS ARE SHOWN ON THE PANEL AND THEY MAY BE REPRODUCED FAITHFULLY Learn More -

E-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBERE-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBER FOR POLYESTER STAPLE FIBER OPENING AND FILLING INTO UPHOLSTERY CUSHIONS OR PILLOWS. CAPACITY 250 KGS PER HOUR X 400 HOURS PER MONTH = 100,000 KGS PER MONTH AT 100% EFFICIENCY HOPPER FEED (REF G-3768) WITH 4.5 KW MOTOR FIBER OPENER TRANSFER FAN MIXING MACHINE (SILO WITH FOUR EXITS) FILLING STATION (FAN) , FOUR FILLING FANS WITH NOZZLE CLAMPS AND WITH TABLES SPARE PARTS SUGGESTED Learn More

E-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBERE-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBER FOR POLYESTER STAPLE FIBER OPENING AND FILLING INTO UPHOLSTERY CUSHIONS OR PILLOWS. CAPACITY 250 KGS PER HOUR X 400 HOURS PER MONTH = 100,000 KGS PER MONTH AT 100% EFFICIENCY HOPPER FEED (REF G-3768) WITH 4.5 KW MOTOR FIBER OPENER TRANSFER FAN MIXING MACHINE (SILO WITH FOUR EXITS) FILLING STATION (FAN) , FOUR FILLING FANS WITH NOZZLE CLAMPS AND WITH TABLES SPARE PARTS SUGGESTED Learn More -

A-1184 REGGIANI ROTARY PRINTING MACHINE MODEL RQ2, WORKING WIDTH 3200MM, 9 COLORSREFERENCE NUMBER: A-1184 (1212GHBXX11) A REGGIANI ROTARY PRINTING MACHINE MODEL RQ2, WORKING WIDTH 3200MM, 9 COLORS ROTARY PRINTING MACHINE MANUFACTURER REGGIANI MODEL RQ2 N° 9 MAGNETIC HEADS, (EXPANDABLE UP TO 12 HEADS) N° 9 COLOR PUMPS MAX WORKING WIDTH 3200 MM OVEN WITH 4 CHAMBER OIL HEATED QUANTITY AVAILABLE: 1 Learn More

A-1184 REGGIANI ROTARY PRINTING MACHINE MODEL RQ2, WORKING WIDTH 3200MM, 9 COLORSREFERENCE NUMBER: A-1184 (1212GHBXX11) A REGGIANI ROTARY PRINTING MACHINE MODEL RQ2, WORKING WIDTH 3200MM, 9 COLORS ROTARY PRINTING MACHINE MANUFACTURER REGGIANI MODEL RQ2 N° 9 MAGNETIC HEADS, (EXPANDABLE UP TO 12 HEADS) N° 9 COLOR PUMPS MAX WORKING WIDTH 3200 MM OVEN WITH 4 CHAMBER OIL HEATED QUANTITY AVAILABLE: 1 Learn More -

A-1876 END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mm

A-1876 END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mmREFERENCE NUMBER: A-1876

END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mmPRODUCT TO BE PROCESSED: NEEDLEPUNCHED NONWOVENS

PRODUCT WIDTH: 4.000 MMWORKING SPEED: 1 – 20 M/MIN

QUANTITY: 1

Learn More -

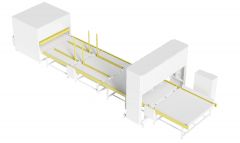

TT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXITTT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXIT AUTOMATIC GLUE SPRAY MACHINE APPLICATION: THE AUTOMATIC GLUE SPRAY MACHINE IS HIGHLY AUTOMATED. THROUGH INFRARED MEASUREMENT, IT CAN AUTOMATICALLY IDENTIFY THE HEIGHT AND WIDTH OF THE MATERIAL, AND AUTOMATICALLY ADJUST THE POSITION OF THE GLUE NOZZLE FOR SPRAYING ACCORDING TO THE DETECTION HEIGHT. AUTOMATIC GLUE SPRAY MACHINE CAN COMPLETE SUCH PROCESSES AS AUTOMATICALLY GLUE SPRAYING, PNEUMATIC TURNING OVER OF THE UNIT AND AUTOMATICALLY PRESSING. WITH PLC CONTROL, HIGH PRODUCTION EFFICIENCY, SINGLE SPRAYING IS ABOUT 30 SECONDS PER SHEET. IT IS SUITABLE FOR SHEETS WITH WIDTH OF 850 TO 2200mm AND HEIGHT OF 5 TO 400mm THE GLUE SPRAYING MACHINE IS SUITABLE FOR FOAM, LATEX, MATTRESS AND HOME TEXTILE INDUSTRIES. Learn More

TT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXITTT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXIT AUTOMATIC GLUE SPRAY MACHINE APPLICATION: THE AUTOMATIC GLUE SPRAY MACHINE IS HIGHLY AUTOMATED. THROUGH INFRARED MEASUREMENT, IT CAN AUTOMATICALLY IDENTIFY THE HEIGHT AND WIDTH OF THE MATERIAL, AND AUTOMATICALLY ADJUST THE POSITION OF THE GLUE NOZZLE FOR SPRAYING ACCORDING TO THE DETECTION HEIGHT. AUTOMATIC GLUE SPRAY MACHINE CAN COMPLETE SUCH PROCESSES AS AUTOMATICALLY GLUE SPRAYING, PNEUMATIC TURNING OVER OF THE UNIT AND AUTOMATICALLY PRESSING. WITH PLC CONTROL, HIGH PRODUCTION EFFICIENCY, SINGLE SPRAYING IS ABOUT 30 SECONDS PER SHEET. IT IS SUITABLE FOR SHEETS WITH WIDTH OF 850 TO 2200mm AND HEIGHT OF 5 TO 400mm THE GLUE SPRAYING MACHINE IS SUITABLE FOR FOAM, LATEX, MATTRESS AND HOME TEXTILE INDUSTRIES. Learn More -

TT-7362 ITEMA AIR JET LOOMS, WIDTH 1900mm TO 2600mm, YEAR 2022, CAM AND DOBBYTT-7362 ITEMA AIR JET LOOMS, WIDTH 1900mm TO 2600mm, YEAR 2022, CAM AND DOBBY YEAR MACHINES ORDERED IN 2022 AND DELIVERED IN 2023 Learn More

TT-7362 ITEMA AIR JET LOOMS, WIDTH 1900mm TO 2600mm, YEAR 2022, CAM AND DOBBYTT-7362 ITEMA AIR JET LOOMS, WIDTH 1900mm TO 2600mm, YEAR 2022, CAM AND DOBBY YEAR MACHINES ORDERED IN 2022 AND DELIVERED IN 2023 Learn More -

V-1805 FULLY AUTOMATIC DUST DISPOSABLE FACE MASK MACHINE

V-1805 FULLY AUTOMATIC DUST DISPOSABLE FACE MASK MACHINEMAKES MASKS WITH 3 PLIES FROM WHITE MELT-BLOWN FABRIC, AND BLUE NONWOVEN FABRIC & WHITE NONWOVEN FABRIC (SEE OFFER PICTURES)

THE 3 MASK LAYERS ARE COMPOSED OF:

NONWOVEN WHITE: T/ ONE MILLION MASKS 195 TO 200mm 25g 2800m

NONWOVEN BLUE: T/ ONE MILLION MASKS 175mm 25g 2800mm

MELT-BLOWN WHITE: T/ TWO MILLION MASKS 175 25g N95

MAIN MACHINE PARTS CONSTRUCTED WITH STAINLESS STEEL

MITSUBISHI BRAND PLCs

ULTRASONIC HEAD BRAND: HUIZHUAN

ULTRASONIC GENERATOR WATTAGE CAPACITY: 1500 TO 2000 WATTS

ULTRASONIC GENERATOR FREQUENCY: 20K

MIDDLE FABRIC LAYER IS SPUNBOND, MELTBLOWN AND SPUNBOND

ACTIVATED CARBON FABRIC NOT POSSIBLE, YET

OVERALL EQUIPMENT LAYOUT:

3. INTERMEDIATE WELDING AND SLICING

2. HEMMING, NASAL, WELDING

4. MASK CONVEYOR LINE

5. EARBAND MACHINE (1 CONVEYOR LINE)

6. EARBAND MACHINE (2 CONVEYOR LINE)

7. EAR STRAP MACHINE (1 ASSEMBLY WELDING)

8. EAR STRAP MACHINE (2 ASSEMBLY WELDING)

9. MASK LINE

10. MASK LINEPRODUCT DETAILS:

VOLTAGE: 220V, 50/60HZ

AUTOMATIC MASK MACHINE

POWER: 85KW

PRODUCTION OUTPUT: 100 MASKS PER MINUTE, THE MAXIMUM ACTUAL OUTPUT IS 5000 PER HOUR.

DIMENSIONS: 6500mm X 4500mm X 2000mm120 TO 150 MASKS PER MINUTE, ACTUAL DETECTION DATA

Learn More

DELIVERY TIME: 20 DAYS