Search results for: 'air+press'

- Related search terms

- air+pressure

-

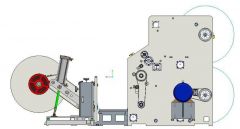

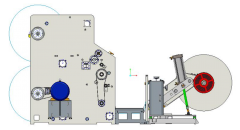

V-1806 HALF AUTOMATIC FACE MASK WITH INNER EAR LOOP PACKING MACHINE

V-1806 HALF AUTOMATIC FACE MASK WITH INNER EAR LOOP PACKING MACHINEI. FUNCTION

Learn More

THIS MACHINE IS USED TO PACK DISPOSABLE SURGICAL FACE MASK WITH THE SIZE OF 190 X 65mm. IT CAN ALSO BE USED TO PACK OTHER PRODUCTS SUCH AS WET TISSUE.

II. FEATURES:

1. ONE SET OF INK TO INJECT PRINTER IS INCLUDED; IT CAN BE USED TO PRINT THE DATA AND OTHER INFORMATION.

2. THE AIR COMPRESSOR EQUIPMENT IS OPTIONAL.

3. PACKING MATERIAL: SINGLE TO SIDE HEAT TO SEALING PACKAGING FILM MATERIALS, SUCH AS OPP, CPP, OPP COMPOSITE PE, PET COMPOSITE PE, SINGLE TO LAYER OR COMPOSITE PACKAGING FILM MATERIALS.

4. BAG FORM: BACK TO SEALED PACKING, CAN BE CUSTOMIZED.

5. VERTICAL/HORIZONTAL SEAL: RETICULATED PACKAGING/VERTICAL AND RETICULATED PACKAGING.

III. SPECIFICATION:

NAME: PILLOW PACKING MACHINE

TYPE KD TO 350

APPLICATION: FOR ALL KINDS OF OPP HEAT TO SEALING FILM, COMPOSITE FILM, SPRAY FILM PAPER, ALUMINUM FOIL FILM, ALUMINUM PLASTIC COMPOSITE FILM

MACHINE SIZE: 4600 X 850 X 1500

PACKING SPEED: 60 TO 220 BAG/MIN

MAX. PACKING SIZE: 330mm, 150mm, 80mm. LENGTH: 330mm, WIDTH: 150mm, HEIGHT: 80mm

MIN. PACKING SIZE: 50mm, 10mm, 5mm. LENGTH: 50mm, WIDTH: 10mm, HEIGHT: 5mm

ELECTRICAL: AC220V, 2.7KW

AIR PRESSURE 0.5 TO 0.7 MPA

AIR CONSUMPTION: >0.36 (M3/H)

(DB) NOISE: 60 TO 70DB

MACHINE WEIGHT: 550KG

MOTOR FREQUENCY ADJUST: 0 TO 50HZ

AUTOMATIC CONTROL

AUTOMATIC PRINTING

STANDARD: GMP STANDARD, PACKAGING MACHINE ENTERPRISE STANDARD

APPROVAL: ISO9001:2000, CE ISO:2000 -

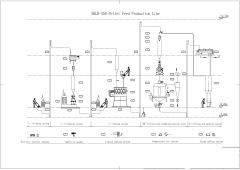

M-0652 CHICKEN FEED MILL-500 TO 1000 KG PER HOURREFERENCE NUMBER: M-0652 CHICKEN FEED MILL-500 TO 1000 KG PER HOUR MODEL: 250 500 TO 1000 KG PER HOUR QUANTITY AVAILABLE: 1 Learn More

M-0652 CHICKEN FEED MILL-500 TO 1000 KG PER HOURREFERENCE NUMBER: M-0652 CHICKEN FEED MILL-500 TO 1000 KG PER HOUR MODEL: 250 500 TO 1000 KG PER HOUR QUANTITY AVAILABLE: 1 Learn More -

M-5244 TOYOTA JAT610 AIR JET LOOMS YEAR 1998 WIDTH 1900mm-2800mmREFERENCE NUMBER: M-5244 (1313JTBVXX12) L TOYOTA JAT610 AIR JET LOOMS YEAR 1998 WIDTH 1900mm-2800mm TOYOTA JAT610 AIR JET LOOMS, YEAR 1998 (60 LOOMS) X WIDTH 1900mm (12 LOOMS) X WIDTH 2800mm RUNNING CONDITION YEAR 1999 1 INVERTER FOR 36 LOOMS (2 INVERTERS FOR ALL 72 LOOMS) QUANTITY AVAILABLE: 27 LOOMS Learn More

M-5244 TOYOTA JAT610 AIR JET LOOMS YEAR 1998 WIDTH 1900mm-2800mmREFERENCE NUMBER: M-5244 (1313JTBVXX12) L TOYOTA JAT610 AIR JET LOOMS YEAR 1998 WIDTH 1900mm-2800mm TOYOTA JAT610 AIR JET LOOMS, YEAR 1998 (60 LOOMS) X WIDTH 1900mm (12 LOOMS) X WIDTH 2800mm RUNNING CONDITION YEAR 1999 1 INVERTER FOR 36 LOOMS (2 INVERTERS FOR ALL 72 LOOMS) QUANTITY AVAILABLE: 27 LOOMS Learn More -

TT-8545 CATERPILLAR 772G ROCK TRUCK, YEAR 2017, 9930 HOURSTT-8545 CATERPILLAR 772G ROCK TRUCK, YEAR 2017, 9930 HOURS 1. MACHINE HOURS: 9930 - LOAD FACTOR: 22% - NEUTRAL HOURS: 2694 2. CATERPILLAR 772 ROCK TRUCK 3. CATERPILLAR C18 ACERT ENGINE QUANTITY: 1 Learn More

TT-8545 CATERPILLAR 772G ROCK TRUCK, YEAR 2017, 9930 HOURSTT-8545 CATERPILLAR 772G ROCK TRUCK, YEAR 2017, 9930 HOURS 1. MACHINE HOURS: 9930 - LOAD FACTOR: 22% - NEUTRAL HOURS: 2694 2. CATERPILLAR 772 ROCK TRUCK 3. CATERPILLAR C18 ACERT ENGINE QUANTITY: 1 Learn More -

T-8543 4 SIDE SEALING WET WIPES MACHINE, STABLE SPEED 60 TO 120 BAGS PER MINUTET-8543 4 SIDE SEALING WET WIPES MACHINE, STABLE SPEED 60 TO 120 BAGS PER MINUTE 4 SIDE SEALING WET WIPES MACHINE DRIVE MODE: AUTOMATIC STABLE SPEED: 60 TO 120 BAGS PER MINUTE MACHINE SIZE (L X W X H): 3000mm × 2500mm × 1800mm QUANTITY: 1 Learn More

T-8543 4 SIDE SEALING WET WIPES MACHINE, STABLE SPEED 60 TO 120 BAGS PER MINUTET-8543 4 SIDE SEALING WET WIPES MACHINE, STABLE SPEED 60 TO 120 BAGS PER MINUTE 4 SIDE SEALING WET WIPES MACHINE DRIVE MODE: AUTOMATIC STABLE SPEED: 60 TO 120 BAGS PER MINUTE MACHINE SIZE (L X W X H): 3000mm × 2500mm × 1800mm QUANTITY: 1 Learn More -

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More -

TT-5908 JENBACHER JMS620-GS-S.L GAS GENSET, 3.35MW, YEAR 2019, 50HzTT-5908 JENBACHER JMS620-GS-S.L GAS GENSET, 3.35MW, YEAR 2019, 50Hz JENBACHER JMS620-GS-S.L GAS GENSET FUEL: NATURAL GAS, COAL BED GAS 8 X 3.35MW, TOTAL 26.8MW YEAR: 2019 QUANTITY: 8 Learn More

TT-5908 JENBACHER JMS620-GS-S.L GAS GENSET, 3.35MW, YEAR 2019, 50HzTT-5908 JENBACHER JMS620-GS-S.L GAS GENSET, 3.35MW, YEAR 2019, 50Hz JENBACHER JMS620-GS-S.L GAS GENSET FUEL: NATURAL GAS, COAL BED GAS 8 X 3.35MW, TOTAL 26.8MW YEAR: 2019 QUANTITY: 8 Learn More -

G-8230 HIGH-TEMPERATURE AND HIGH-PRESSURE YARN DYEING MACHINE 40KG

G-8230 HIGH-TEMPERATURE AND HIGH-PRESSURE YARN DYEING MACHINE 40KGREFERENCE NUMBER: G-8230

HIGH-TEMPERETURE AND HIGH-PRESSURE YARN DYEING MACHINE 40KG

DESIGNED FOR DYEING, BOILING OFF, BLEACHING, AND WATER WASHING, ETC. SUITABLE FOR HANK YARN, BOBBIN OR RAW STOCK FIBER

MACHINE TYPE: VERTICAL CYLINDER

VAT DIAMETER: Ф600mm

CONE QUANTITY: 7 X 7 = 49 CONES

WORKING TEMPERATURE: 130C

MAX WORKING PRESSURE: 0.4MPA

BOTH RATIO: 1:7 TO 9

WITH COMPUTERIZED CONTROL SYSTEM

HEAT EXCHANGING: COIL TYPE HEAT EXCHANGER, WHICH CAN BE USED FOR EITHER HEATING OR COOLING.

HEAT EXCHANGING SPEED: WHEN THE HEATED STEAM PRESSURE IS 0.4MPA, 40MINUTES WILL BE REQUIRED FOR THE LIQUID INSIDE THE DYEING BARREL RAISING FROM 20OC TO 130OC. WHEN THE COOLING WATER PRESSURE IS 0. 3MPA AND THE WATER TEMPERATURE IS 20 OC, 40 MINUTES WILL BE REQUIRED FOR THE LIQUID INSIDE THE DYEING BECK TO LOWER FROM 130OC TO 80OC.

RECYCLING OF DYEING LIQUID: THE POSITIVE AND NEGATIVE RECYCLING OF DYEING LIQUID WILL BE ADJUSTED BY THE CYLINDER THROUGH THE SWITCHING DEVICE INSIDE THE CENTRIFUGAL PUMP.

SEALING OF BOILER: RUBBER ADHESIVE

THE WORKING PRESSURE INSIDE THE TANK WILL MAKE THE RUBBER SEAL CLOSELY TO ATTACH THE FLANGE. THE CONICAL SURFACE OF THE TANK MOUTH IS TO ENHANCE THE SEALING.

OPENING OF TANK COVER: FIRST OPEN THE AIR VALVE TO RELEASE THE PRESSURE INSIDE THE BOILER. WAIT UNTIL NO EXHAUSTED AIR GOING THRU THE EXHAUST VALVE AND THE READING OF PRESSURE GAUGE IS ZERO, WITHDRAW THE WRENCH HANDLE, OPEN THE CLAMPING HOOP TO REMOVE THE FLANGE; AND THEN OPEN THE COVER WITH DRAG WEIGHT. THE COVER WILL BE CLOSED.

CONFIGURATION:

1. ELECTRICAL CABINET: STAINLESS STEEL CABINET, PLASTIC COATING

2. ELECTRICAL COMPONENTS: SIEMENS, OMRON

3. COMPUTER: HG COMPUTER (MADE IN CHINA)

4. ELECTROMAGNETIC VALVE: TAIWAN YADEKE

5. PUMP: CENTRIFUGAL PUMP

6. MOTOR: WANNAN MOTOR

7. TEMPERATURE CONTROL: COMPUTER CONTROL, WITH HEATING, COOLING, KEEPING WARM, ETC. FUNCTION.

8. HEAT EXCHANGER: INTERNAL COIL HEATING

9. VALVE: STAINLESS ANGLE VALVES, PNEUMATIC BUTTERFLY VALVES

10. ONE CARRIER BASKET

11. MACHINE BODY MATERIAL: STAINLESS STEEL, 316 LITERS

12. ACCESSORIES: SEAL RING FOR DYE VAT, SEAL FOR MAIN PUMP, SEAL FOR REVERSING SHAFT

QUANTITY: 1

Learn More -

YY-2313 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1800mmYY-2313 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1800mm SUITABLE MATERIALS REEL-SHAPED PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0 TO 400 METERS PER MINUTE SLITTING WIDTH: 30 TO 1800mm; UNWINDING DIAMETER: MAXIMUM Ø1400mm; WINDING DIAMETER: Ø1000mm; MACHINE WEIGHT: 5000 KG; TOTAL MOTOR POWER: 31KW; DIMENSIONS: W 3500 × L 3500 × H 1900 (mm); RETRACTABLE PAPER CORE: 3 " (DIAMETER Φ76mm DIAMETER Φ92mm); CORRECTION ACCURACY: ≤ 0.30mm; TENSION SETTING RANGE: 2 ~ 30KG; WINDING MOTOR POWER: 11KW X 2; TRACTION MOTOR: 11KW; MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED). QUANTITY: 1 Learn More

YY-2313 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1800mmYY-2313 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1800mm SUITABLE MATERIALS REEL-SHAPED PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0 TO 400 METERS PER MINUTE SLITTING WIDTH: 30 TO 1800mm; UNWINDING DIAMETER: MAXIMUM Ø1400mm; WINDING DIAMETER: Ø1000mm; MACHINE WEIGHT: 5000 KG; TOTAL MOTOR POWER: 31KW; DIMENSIONS: W 3500 × L 3500 × H 1900 (mm); RETRACTABLE PAPER CORE: 3 " (DIAMETER Φ76mm DIAMETER Φ92mm); CORRECTION ACCURACY: ≤ 0.30mm; TENSION SETTING RANGE: 2 ~ 30KG; WINDING MOTOR POWER: 11KW X 2; TRACTION MOTOR: 11KW; MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED). QUANTITY: 1 Learn More -

YY-2260 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1700 mm, WINDING DIAMETER UP TO 1400mmYY-2260 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1700 mm, WINDING DIAMETER UP TO 1400mm SUITABLE MATERIALS REEL-SHAPED PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0 TO 400M/MIN; SLITTING WIDTH: 30 TO 1700mm; UNWINDING DIAMETER: MAXIMUM Ø1400mm; WINDING DIAMETER: Ø610mm; MACHINE WEIGHT: 1800KG; TOTAL MOTOR POWER: 29KW; DIMENSIONS: W 3200 × L 3500 × H 1900 (mm); RETRACTABLE PAPER CORE: 3" (DIAMETER Φ76mm DIAMETER Φ92mm); CORRECTION ACCURACY: ≤ 0.30mm; TENSION SETTING RANGE: 2 ~ 30KG; WINDING MOTOR POWER: 7.5KW X 2; TRACTION MOTOR: 7.5KW; MACHINE COLOR STANDARD WHITE (OR AS REQUIRED). QUANTITY: 1 Learn More

YY-2260 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1700 mm, WINDING DIAMETER UP TO 1400mmYY-2260 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1700 mm, WINDING DIAMETER UP TO 1400mm SUITABLE MATERIALS REEL-SHAPED PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0 TO 400M/MIN; SLITTING WIDTH: 30 TO 1700mm; UNWINDING DIAMETER: MAXIMUM Ø1400mm; WINDING DIAMETER: Ø610mm; MACHINE WEIGHT: 1800KG; TOTAL MOTOR POWER: 29KW; DIMENSIONS: W 3200 × L 3500 × H 1900 (mm); RETRACTABLE PAPER CORE: 3" (DIAMETER Φ76mm DIAMETER Φ92mm); CORRECTION ACCURACY: ≤ 0.30mm; TENSION SETTING RANGE: 2 ~ 30KG; WINDING MOTOR POWER: 7.5KW X 2; TRACTION MOTOR: 7.5KW; MACHINE COLOR STANDARD WHITE (OR AS REQUIRED). QUANTITY: 1 Learn More