Search results for: 'automatic'

- Related search terms

- automatic te

- AUTOMATIC P

- Automatic+4+s

- AUTOMATIC''

- AUTOMATIC+P'

-

YY-1835 AUTOMATIC PROFILE CUTTING MACHINE, WORKING WIDTH 2300mmYY-1835 AUTOMATIC PROFILE CUTTING MACHINE, WORKING WIDTH 2300mm THE MACHINE IS WITH TOUCH SCREEN & PLC AUTO CONTROL, WITH AUTOMATIC LOADING CONVEYOR WORKTABLE AND PRESS ROLLER, THE HEIGHT OF THE WORKTABLE AND PRESS ROLLER ARE AUTOMATIC DIGITAL CONTROL. PROFILE ROLLER HEIGHT IS AUTOMATIC DIGITAL CONTROL. QUANTITY: 1 Learn More

YY-1835 AUTOMATIC PROFILE CUTTING MACHINE, WORKING WIDTH 2300mmYY-1835 AUTOMATIC PROFILE CUTTING MACHINE, WORKING WIDTH 2300mm THE MACHINE IS WITH TOUCH SCREEN & PLC AUTO CONTROL, WITH AUTOMATIC LOADING CONVEYOR WORKTABLE AND PRESS ROLLER, THE HEIGHT OF THE WORKTABLE AND PRESS ROLLER ARE AUTOMATIC DIGITAL CONTROL. PROFILE ROLLER HEIGHT IS AUTOMATIC DIGITAL CONTROL. QUANTITY: 1 Learn More -

YY-1481 FULL-AUTOMATIC FOLDING MACHINE OF 4-PLY LAP FOAM, 15 PIECES PER MINUTEYY-1481 FULL-AUTOMATIC FOLDING MACHINE OF 4-PLY LAP FOAM, 15 PIECES PER MINUTE FEATURE: - USED FOR FULL-AUTOMATIC FOLDING OF SURGICAL TOWEL, LAP FOAM AND ABDOMINAL TOWEL. - GAUZE ROLL RUNNING ON THE EQUIPMENT WHICH IS AUTOMATICALLY FEEDING, CUTTING, HEMMING, PRESSING, FOLDING AND YARD OPERATING NEATLY. - EQUIPPED WITH 5-6 CNC MOTORS, THE PARAMETER CAN BE MODIFIED IN THE MAN-MACHINE INTERFACE, WHICH WILL BE VERY CONVENIENT TO CHANGE THE PRODUCT VARIETY. - FURTHERMORE, IT CONFIGURES AUTOMATIC DISCHARGING MACHINE, WHICH WITH HIGHER DEGREE OF AUTOMATION, DISCHARGING RESET AUTOMATICALLY AFTER THE OPERATION. - ADVANTAGES OF FULL-AUTOMATIC FOLDING MACHINE: FIRSTLY, THE PRODUCT SIZE IS ACCURATE AND APPEARANCE TIDY. SECONDLY, MACHINE FOLDING TO REDUCE THE SECONDARY POLLUTION, IMPROVE THE PRODUCT QUALITY. AT LAST, IT CAN SHARPLY REDUCE THE LABOR COST, THE INVESTMENT COSTS WILL BE RECOVERED IN HALF YEAR. Learn More

YY-1481 FULL-AUTOMATIC FOLDING MACHINE OF 4-PLY LAP FOAM, 15 PIECES PER MINUTEYY-1481 FULL-AUTOMATIC FOLDING MACHINE OF 4-PLY LAP FOAM, 15 PIECES PER MINUTE FEATURE: - USED FOR FULL-AUTOMATIC FOLDING OF SURGICAL TOWEL, LAP FOAM AND ABDOMINAL TOWEL. - GAUZE ROLL RUNNING ON THE EQUIPMENT WHICH IS AUTOMATICALLY FEEDING, CUTTING, HEMMING, PRESSING, FOLDING AND YARD OPERATING NEATLY. - EQUIPPED WITH 5-6 CNC MOTORS, THE PARAMETER CAN BE MODIFIED IN THE MAN-MACHINE INTERFACE, WHICH WILL BE VERY CONVENIENT TO CHANGE THE PRODUCT VARIETY. - FURTHERMORE, IT CONFIGURES AUTOMATIC DISCHARGING MACHINE, WHICH WITH HIGHER DEGREE OF AUTOMATION, DISCHARGING RESET AUTOMATICALLY AFTER THE OPERATION. - ADVANTAGES OF FULL-AUTOMATIC FOLDING MACHINE: FIRSTLY, THE PRODUCT SIZE IS ACCURATE AND APPEARANCE TIDY. SECONDLY, MACHINE FOLDING TO REDUCE THE SECONDARY POLLUTION, IMPROVE THE PRODUCT QUALITY. AT LAST, IT CAN SHARPLY REDUCE THE LABOR COST, THE INVESTMENT COSTS WILL BE RECOVERED IN HALF YEAR. Learn More -

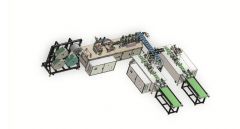

J-2730 AUTOMATIC DISPOSABLE SURGICAL MASK (N95) PRODUCTION LINE WITH PACKAGING -PRODUCES SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% -CAPACITY: 50 MASKS (N95) PER MINUTE

J-2730 AUTOMATIC DISPOSABLE SURGICAL MASK (N95) PRODUCTION LINE WITH PACKAGING -PRODUCES SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% -CAPACITY: 50 MASKS (N95) PER MINUTEITEM 001 - MASK PRODUCTION MACHINE WITH (2) ULTRASONIC EAR STRAP WELDING DEVICES

FOR THE PRODUCTION OF SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% (N95)

CAPACITY: 50 FOLDED N95 MASKS PER MINUTE

MASK DIMENSIONS: 175mm x 95mm

MATERIAL TYPE: 3 LAYERS OF POLYPROPYLENE NONWOVEN COMPOSITE FIBER

OPERATION CONTROLLED BY LCD TOUCH SCREEN

AUTOMATICALLY ALIGNS 3 ROLLS OF MATERIAL TO FEED IN (OUTER, FILTER AND INNER LAYERS)

PRESSES BOTH SIDES TOGETHER SYMMETRICALLY WHILE WELDING WITH ULTRASONIC HEAD

SPLITS TO 2 SERPATE WELDING DEVICES FOR EARLOOPS AND SENDS TO DIGITAL COUNTER

EARLOOPS ARE FINISHED WITH ULTRASONIC CUTTING AND WELDING

NOSE BRIDGE CAN BE PRODUCED WITH AUTOMATIC FEEDING, CUTTING AND ULTRASONIC WELDING

ULTRASONIC HEADS

VOLTAGE: 220 VOLTS

WATTS CAPACITY: 1500 WATT

FREQUENCY (KHZ): 20 KHZ

WARRANTY PERIOD FOR HEADS: 1 YEAR

COMPONENT MANUFACTURERS

SERVO MOTOR: PANASONIC / SCHNEIDER

CONTROL SYSTEM: PROPRIETARY

ULTRASONIC GENERATOR: PROPRIETARY, 220 VOLTS, 1.5 KW, 20 KHZ

SENSOR: OMRON / SICK

PNEUMATIC COMPONENT: SMC / FESTO

BELT: SAMSUNG / BANDO

MAIN BODY: PRE-MADE MATERIAL, WELDED ASSEMBLY

BEARINGS: NSK

BALL SCREWS: HIWIN

SECURITY DEVICE: SICK (SAFETY DEVICES TO PROTECT WORKERS)

TOTAL POWER: 4 KW

MACHINE MUST BE STOPPED TO FEED NEW ROLL OF MATERIAL

END OF ROLL DETECTOR INCLUDED: WHEN FABRIC IS FINISHED THE MACHINE WILL ALARM AND STOP

AIR PRESSURE: 0.6 MPa

VOLTAGE: 220 VOLTS, 60 Hz

DIMENSIONS: 6400mm x 4700mm x 1700mm

INCLUDES ELECTRONIC MANUAL BOOK (STORED ON USB MEMORY) AND WARRANTY CARD

OPTIONS (INQUIRE FOR PRICING): EAR STRAP FOLDER

ITEM 001 QUANTITY: 1 MASK PRODUCTION MACHINE AND 2 ULTRASONIC WELDING DEVICES FOR EAR STRAPS

ITEM 002 AUTOMATIC BAGGING MACHINE

SUITABLE FOR AUTOMATIC BAGGING OPERATIONS FOR VARIOUS MASK TYPES

MOTOR CONTROL SYSTEM: SERVO (3), AUTOMATICALLY SETS BAG LENGTH (UP TO 400mm) FOR SPECIFIED BAGGING LENGTH, WITH ANTI-AIR BAG , AUTOMATICALLY DETECTS PRODUCT BASE POINT AND MATERIAL POSITION, AUTOMATIC STOP WHEN OUT OF MATERIAL & STARTS WHEN MATERIAL IS PRESENT

FAST & CONVENIENT SETTING OF PARAMETERS, STORES SETS OF PARAMETERS FOR MULTIPLE PRODUCTS, OPERATOR CAN CHOOSE PARAMETERS ACCORDING TO PRODUCT SIZES

DIAGNOSTICS SYSTEM CLEARS ERROR & RESETS IN SINGLE STEP

HIGHLY SENSITIVE PHOTOELECTRIC EYE COLOR MARK TRACKER, DIGITAL INPUT SEAL/CUT POSITION MAKES SEAL & CUT POSITIONS MORE ACCURATE

TEMPERATURE CONTROLLED WITH INDEPENDENT PID, ALLOWS FOR VARIOUS MATERIALS IN PACKAGING

SIMPLE TRANSMISSION SYSTEM ALLOWS FOR EASY MAINTENANCE AND RELIABILITY

ALL CONTROLS SET BY SOFTWARE ALLOWING FOR ADJUSTING OF FUNCTIONS AND UPGRADES

MATERIALS

PVC FILM (HEAT SEALING), BOPP, OPP, CPP, ALUMINIZED PET FILM, ALUMINUM-PLASTIC FILM, PAPER FILM, PAPER GLUE, OTHER SINGLE- OR MULTIPLE-LAYERED HEAT-SEALED DIALYZABLE MATERIALS, ETC.

LENGTH OF PACKAGE BAGS: ≤400mm

WIDTH OF PACKAGE BAGS: 100 TO 165mm

HEIGHT OF PRODUCT: 55mm MAXIMUM

LENGTH OF FILM: 360mm MAXIMUM

DIAMETER OF FILM ROLL: 320mm MAXIMUM

CAPACITY/SPEED OF PACKAGING: 40 TO 230 BAGS PER MINUTE (1 TO 20 PIECES PER BAG)

POWER: 220 VOLTS, 50 OR 60 Hz, 2.4 KW

DIMENSIONS: 4050mm x 750mm x 1450mm

WEIGHT: APPROXIMATELY 300 KGS

COMPONENT MANUFACTURERS

TOUCH SCREEN: WEINVIEW

SERVO MOTOR: DORNA / WEIDE

SERVO CONTROLLER: DORNA / WEIDE

PROXIMITY SWITCH: OMRON

PHOTOELECTRIC SWITCH: OETAI

TEMPERATURE CONTROLLER: YATAI

SOLID STATE RELAY: SCHNEIDER

INTERMEDIATE RELAY: WEIDMUELLER

OPTIONS, INQUIRE FOR PRICING: STRAIGHT GRAIN SEALING, STAINLESS STEEL FRAME, CODE STAMPER (PRODUCTION DATE), EXHAUST (PINHOLE EXHAUST FEATURE)

ITEM 002 QUANTITY: 1 BAGGING MACHINE

ENTIRE LINE COMPOSED OF ITEM 001 AND ITEM 002

Learn More -

R-6856 FUTURA K AUTOMATIC ROASTING MACHINES

R-6856 FUTURA K AUTOMATIC ROASTING MACHINESR-6856 FUTURA K AUTOMATIC ROASTING MACHINES

AUTOMATIC ROASTING MACHINES RESULT OF LONG STUDIES AND LIVED EXPERIENCE.

THE ROASTING MACHINES SERIES FUTURA K ARE THE RESULT OF LONG STUDIES AND LIVED EXPERIENCE ALONGSIDE OUR CLIENTS COFFEE ROASTERS, FOR THE REALIZATION OF THE MOST ADVANCED MACHINERIES IN THE FIELD OF INDUSTRIAL COFFEE ROASTING.

THE COMPACT DIMENSIONS, RELIABILITY OF THE MATERIALS AND COMPONENTS, THERMAL MANAGEMENT WITH IMMEDIATE RESPONSE, CALIBRATED AND PARTICULARLY FUEL EFFICIENT, HIGH THERMAL AND ACOUSTIC INSULATION AND OTHER POSITIVE FEATURES, MAKE THESE MACHINES REFERENCEGUIDE IN PROFESSIONAL ROASTING FIELD.MAIN COMPONENTS:

FEEDING HOPPER INSULATED WITH PNEUMATIC FILLER DEVICE, MOVABLE INLET, ELECTROPNEUMATIC UNLOADING CONTROL.

ROASTING DRUM MADE BY A FIXED HOUSING WITH DOUBLE INSULATING WALLS FOR THERMAL PROTECTION AND SUPPORTING THE ROTARY CYCLINDER THAT MOVES THE PRODUCT. THE WHOLE CYCLINDER IS MADE OF COMPOUND STEEL TO WITHSTAND THERMAL SHOCKS, ABSOLUTELY ODOURLESS, WITH PERFORATED SHEET FOR PRODUCT CONTAINEMENT, RIGHT AND LEFT BLENDERS SETTLED AT DIFFERENT LEVELS TO OBTAIN PERFECT MIXTURE.

WHEN THE ROASTING PROCESS IS FINISHED, THE COFFEE IS UNLOADED THROUGH A LARGE DOOR WITH ELECTROPNEUMATIC CONTROL OF OPENING AND CLOSING.

THE HEATING GENERATOR IS SPECIFICALLY DESIGNED FOR ROASTING LINE APPLICATIONS. THE PRINCIPLE OF HEATING IS BASED ON HOT AIR FLOWS BY CONVECTION. GAS OR GASOIL BURNER TYPE MODULATING OR MULTI LEVEL- FLAMES ACCORDING THE APPLICATION.

COOLING TANK WITH LARGE STAINLESS STEEL SURFACE, SELF CLEANING, WHERE THE PRODUCT IS MOVED BY MEANS OF 4 CROSSED ARMS. TWO DISCHARGES: ONE IS ELECTROPNEUMATICALLY DRIVEN AND THE OTHER IS MANUAL FOR EMERGENCY. DOOR OF INSPECTION AND EASY CLEANING OF THE LOWER SIDE.

PELLICLES SEPARATOR WITH EXTRACTION, BY WORM CONVEYOR OR INCINERATOR FOR CONSTANT EFFICIENCY OF THE AIR CHAFFS SEPARATION SYSTEM.

SUPPORTING FRAME IN TUBULAR PROFILES, STEEL MADE, TO CONTAIN AND SUPPORT THE OPERATING DEVICES, SO TO OBTAIN A COMPACT MACHINE-LIMITED ENCUMBRANCE, COMPLETE WITH PANELS FOR HEATING AND NOISE CONTAINMENT.

INDEPENDENT ELECTRIC CONTROL BOARD WITH PLC + TOUCH SCREEN AND ALL DEVICES FOR MACHINE CONTROL AND

MANAGEMENT, CAREFULLY WIRED AND EQUIPPED WITH ALL SIGNALS USEFULL FOR ROASTING PROCESS.STANDARD EQUIPMENT:

AUTOMATIC ROASTING SYSTEM MANAGED BY PLC + TOUCH SCREEN WITH RECORDING FOR ROASTING CURVES – PROFILES.

VISUALIZATION BY MONITOR OF TEMPERATURES AND ROASTING FUNTIONS.

FIRE PREVENTION EQUIPMENT ON THE ROASTING DRUM AND COOLING TANK; ON THE CYCLONE-CHAFFS SEPARATOR IF EQUIPPED WITH WORM CONVEYOR FOR CHAFFS EXTRACTION.

ALARM SYSTEM BY BUZZER AND SIGNAL LAMP, UPON INTERVENTION OF THE OVERLOAD PROTECTION DEVICES ON THE ELECTRIC-MOTORS AND ON THE BURNER.

PROTECTING SAFETY SYSTEMS.

CYCLONE FOR COOLING TANK: STANDARD ON MOD. 240-300- 360-480.

OPTIONALS EQUIPMENTCOMPUTERIZED AUTOMATIC ROASTING PROCESS CARP MANAGED BY PC AND MONITOR.

Learn More

HEATING RECOVERY SYSTE

SMOKE BURNER TYPE THERMICAL AND/OR CATALYST

CLEAN AIR ROASTING SYSTEM

CHAFFS COMPACTOR. -

X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MOREREFERENCE NUMBER: X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MORE THIS MACHINE IS A STAND-ALONE AND VERY VERSATILE PILLOW STUFFING AND BAGGING MACHINE. ITS SIMPLE OPERATION ALLOWS TO USE THE SAME EQUIPMENT TO ACCOMPLISH THE TWO PROCESSES: STUFFING A BATT OR A FOAM CORE IN A COVER (OR AN INSERT IN THE FINAL DEC COVER / A PILLOW IN THE FINAL ZIPPERED COVER) AND/OR PUT A FINISHED PILLOW IN A BAG (INDIVIDUAL PE BAG, TWIN-PACK BAG, ZIPPERED VINYL BAG, ETC). THE MACHINE CAN BE LOADED MANUALLY OR WITH A CONVEYOR ON THE REAR PART, WHILE AN OPERATOR IS NEEDED IN THE FRONT: HE PUTS THE COVER/BAG ONTO THE STUFFING BELTS, ACTIVATES THE TENSIONING FORKS WITH THE PEDAL AND HOLDING THE COVER/BAG FACILITATES THE PILLOW STUFFING. POWER SUPPLY IS 400 VOLTS, WILL NEED A TRANSFORMER TO OPERATE ON 480 VOLTS, INQUIRE IF NEEDED Learn More

X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MOREREFERENCE NUMBER: X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MORE THIS MACHINE IS A STAND-ALONE AND VERY VERSATILE PILLOW STUFFING AND BAGGING MACHINE. ITS SIMPLE OPERATION ALLOWS TO USE THE SAME EQUIPMENT TO ACCOMPLISH THE TWO PROCESSES: STUFFING A BATT OR A FOAM CORE IN A COVER (OR AN INSERT IN THE FINAL DEC COVER / A PILLOW IN THE FINAL ZIPPERED COVER) AND/OR PUT A FINISHED PILLOW IN A BAG (INDIVIDUAL PE BAG, TWIN-PACK BAG, ZIPPERED VINYL BAG, ETC). THE MACHINE CAN BE LOADED MANUALLY OR WITH A CONVEYOR ON THE REAR PART, WHILE AN OPERATOR IS NEEDED IN THE FRONT: HE PUTS THE COVER/BAG ONTO THE STUFFING BELTS, ACTIVATES THE TENSIONING FORKS WITH THE PEDAL AND HOLDING THE COVER/BAG FACILITATES THE PILLOW STUFFING. POWER SUPPLY IS 400 VOLTS, WILL NEED A TRANSFORMER TO OPERATE ON 480 VOLTS, INQUIRE IF NEEDED Learn More -

SCHLAFHORST 238D AUTOMATIC WINDERS YEAR 1994(3 SET) SCHALFHORST AUTOMATIC WINDER YEAR: 1994 TYPE: 238D VERSION 147 60 SPINDLES STEEL DRUMS 2.5 TURNS YOKE CRADLE CONE ANGLE 4' 20 USTER POLYMATIC YARN CLEARER TYPE: MK-C15-AC WAXING DEVICE AUTO DOFFING INFORMATOR OHTC MAKE SOHLER (3 SET) SCHALFHORST AUTOMATIC WINDER YEAR: 1994 TYPE: 238D VERSION 147 60 SPINDLES STEEL DRUMS 2.5 TURNS YOKE CRADLE CONE ANGLE 4' 20 USTER QUANTUM-2 CLEARERS WAXING DEVICE AUTO DOFFING INFORMATOR OHTC MAKE SOHLER (1 SET) SCHALFHORST AUTOMATIC WINDER YEAR: 1994 TYPE: 238D VERSION 147 60 SPINDLES STEEL DRUMS 2.5 TURNS YOKE CRADLE CONE ANGLE 4' 20 USTER PEYER YARN CLEARER TYPE: MK-C15-AC WAXING DEVICE AUTO DOFFING INFORMATOR OHTC MAKE SOHLER (1 SET) SCHALFHORST AUTOMATIC WINDER YEAR: 1994 TYPE: 238D VERSION 147 60 SPINDLES STEEL DRUMS 2.5 TURNS YOKE CRADLE CONE ANGLE 4' 20 USTER QUANTUM-1 CLEARERS WAXING DEVICE AUTO DOFFING INFORMATOR OHTC MAKE SOHLER 380V, 50HZ SUPERB CONDITION. HIGHLY MAINTAINED MACHINES. Learn More

SCHLAFHORST 238D AUTOMATIC WINDERS YEAR 1994(3 SET) SCHALFHORST AUTOMATIC WINDER YEAR: 1994 TYPE: 238D VERSION 147 60 SPINDLES STEEL DRUMS 2.5 TURNS YOKE CRADLE CONE ANGLE 4' 20 USTER POLYMATIC YARN CLEARER TYPE: MK-C15-AC WAXING DEVICE AUTO DOFFING INFORMATOR OHTC MAKE SOHLER (3 SET) SCHALFHORST AUTOMATIC WINDER YEAR: 1994 TYPE: 238D VERSION 147 60 SPINDLES STEEL DRUMS 2.5 TURNS YOKE CRADLE CONE ANGLE 4' 20 USTER QUANTUM-2 CLEARERS WAXING DEVICE AUTO DOFFING INFORMATOR OHTC MAKE SOHLER (1 SET) SCHALFHORST AUTOMATIC WINDER YEAR: 1994 TYPE: 238D VERSION 147 60 SPINDLES STEEL DRUMS 2.5 TURNS YOKE CRADLE CONE ANGLE 4' 20 USTER PEYER YARN CLEARER TYPE: MK-C15-AC WAXING DEVICE AUTO DOFFING INFORMATOR OHTC MAKE SOHLER (1 SET) SCHALFHORST AUTOMATIC WINDER YEAR: 1994 TYPE: 238D VERSION 147 60 SPINDLES STEEL DRUMS 2.5 TURNS YOKE CRADLE CONE ANGLE 4' 20 USTER QUANTUM-1 CLEARERS WAXING DEVICE AUTO DOFFING INFORMATOR OHTC MAKE SOHLER 380V, 50HZ SUPERB CONDITION. HIGHLY MAINTAINED MACHINES. Learn More -

TT-6905 FORMIA NUOVA AUTOMATIC DIRECT BEAMS STORAGE, WIDTH 2000mm, 62 POSITIONSTT-6905 FORMIA NUOVA AUTOMATIC DIRECT BEAMS STORAGE, WIDTH 2000mm, 62 POSITIONS QUANTITY: 1 Learn More

TT-6905 FORMIA NUOVA AUTOMATIC DIRECT BEAMS STORAGE, WIDTH 2000mm, 62 POSITIONSTT-6905 FORMIA NUOVA AUTOMATIC DIRECT BEAMS STORAGE, WIDTH 2000mm, 62 POSITIONS QUANTITY: 1 Learn More -

TT-6460 TEXPA AUTOMATIC SHEETING / HEMMING MACHINE, WIDTH 72”TT-6460 TEXPA AUTOMATIC SHEETING / HEMMING MACHINE, WIDTH 72” QUANTITY: 1 Learn More

TT-6460 TEXPA AUTOMATIC SHEETING / HEMMING MACHINE, WIDTH 72”TT-6460 TEXPA AUTOMATIC SHEETING / HEMMING MACHINE, WIDTH 72” QUANTITY: 1 Learn More -

YY-3344 ELECTROTEK FULL AUTOMATIC MATTRESS PACKING AND ROLL PACK MACHINE WITH FOLDING UNIT, WORKING WIDTH 115 INCH, YEAR 2022YY-3344 ELECTROTEK FULL AUTOMATIC MATTRESS PACKING AND ROLL PACK MACHINE WITH FOLDING UNIT, WORKING WIDTH 115 INCH, YEAR 2022 COMPONENTS OF THE SYSTEM: a. PACKAGING WRAPPING LINE : 115 INCH X 150 INCH b. PACKAGING HYDRAULIC PRESS : 115 INCH X 150 INCH c. FOLDING CONVEYOR : 107 INCH X 125 INCH d. ROLL PACK PART: 121 INCH X 150 INCH QUANTITY: 1 Learn More

YY-3344 ELECTROTEK FULL AUTOMATIC MATTRESS PACKING AND ROLL PACK MACHINE WITH FOLDING UNIT, WORKING WIDTH 115 INCH, YEAR 2022YY-3344 ELECTROTEK FULL AUTOMATIC MATTRESS PACKING AND ROLL PACK MACHINE WITH FOLDING UNIT, WORKING WIDTH 115 INCH, YEAR 2022 COMPONENTS OF THE SYSTEM: a. PACKAGING WRAPPING LINE : 115 INCH X 150 INCH b. PACKAGING HYDRAULIC PRESS : 115 INCH X 150 INCH c. FOLDING CONVEYOR : 107 INCH X 125 INCH d. ROLL PACK PART: 121 INCH X 150 INCH QUANTITY: 1 Learn More -

YY-3098 AUTOMATIC VERTICAL FOAM CUTTING MACHINE, MAXIMUM BUN HEIGHT 1270mm, YEAR 2021YY-3098 AUTOMATIC VERTICAL FOAM CUTTING MACHINE, MAXIMUM BUN HEIGHT 1270mm, YEAR 2021 ALL SERVO MOTORS ON ALL MACHINES. ALL SIEMENS. QUANTITY: 1 Learn More

YY-3098 AUTOMATIC VERTICAL FOAM CUTTING MACHINE, MAXIMUM BUN HEIGHT 1270mm, YEAR 2021YY-3098 AUTOMATIC VERTICAL FOAM CUTTING MACHINE, MAXIMUM BUN HEIGHT 1270mm, YEAR 2021 ALL SERVO MOTORS ON ALL MACHINES. ALL SIEMENS. QUANTITY: 1 Learn More