Search results for: 'automatic+f'

-

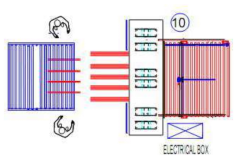

YY-2745 ELECTRONIC AUTOMATIC FILLING MACHINE FOR COVER & AUTOMATIC INSERTION OF FOAM LAYERS INTO COVERS, MACHINE N. 10, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES)YY-2745 ELECTRONIC AUTOMATIC FILLING MACHINE FOR COVER & AUTOMATIC INSERTION OF FOAM LAYERS INTO COVERS, MACHINE N. 10, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES) SPECIFICATION OF THE MACHINE: MAXIMUM WORKING AREA: FROM 700mm TO 2200mm; MAXIMUM HEIGHT: FROM 05CM TO 40CM; KING OF MATERIALS: ANY KIND OF FOAM LAYERS; PRODUCTION: 2 CYCLES/MINUTE; DIMENSIONS: 3500 X 3500 X H2200 mm (WITH ALL OPTIONAL); WEIGHT: 3.250 KG; POWER: 8 KW; POWER SUPPLY: 480V – AC – 60 Hz – 3PHASES; AIR PRESSURE: 6/8 BAR. QUANTITY: 1 Learn More

YY-2745 ELECTRONIC AUTOMATIC FILLING MACHINE FOR COVER & AUTOMATIC INSERTION OF FOAM LAYERS INTO COVERS, MACHINE N. 10, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES)YY-2745 ELECTRONIC AUTOMATIC FILLING MACHINE FOR COVER & AUTOMATIC INSERTION OF FOAM LAYERS INTO COVERS, MACHINE N. 10, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES) SPECIFICATION OF THE MACHINE: MAXIMUM WORKING AREA: FROM 700mm TO 2200mm; MAXIMUM HEIGHT: FROM 05CM TO 40CM; KING OF MATERIALS: ANY KIND OF FOAM LAYERS; PRODUCTION: 2 CYCLES/MINUTE; DIMENSIONS: 3500 X 3500 X H2200 mm (WITH ALL OPTIONAL); WEIGHT: 3.250 KG; POWER: 8 KW; POWER SUPPLY: 480V – AC – 60 Hz – 3PHASES; AIR PRESSURE: 6/8 BAR. QUANTITY: 1 Learn More -

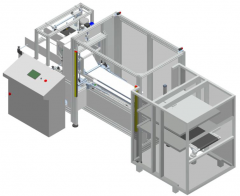

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More -

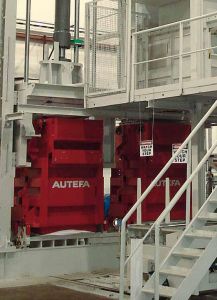

V-2151 AUTEFA, FULLY AUTOMATIC BALING PRESS MODEL LIFT BOX 1500 ADW (DOUBLE ROTATING LIFT BOXES) WITH FULLY AUTOMATIC STRAPPING AND FILM WRAPPING, YEAR 2011 – 45 BALES PER HOUR, BALE WEIGHT: 250KGS – VIDEOS AVAILABLE – NOW FULLY OPERATIONALV-2151 AUTEFA, FULLY AUTOMATIC BALING PRESS MODEL LIFT BOX 1500 ADW (DOUBLE ROTATING LIFT BOXES) WITH FULLY AUTOMATIC STRAPPING AND FILM WRAPPING, YEAR 2011 – 45 BALES PER HOUR, BALE WEIGHT: 250KGS – VIDEOS AVAILABLE – NOW FULLY OPERATIONAL – PERFECT CONDITION SHIPPING: • 3 TO 4 (40FT) CONTAINERS • OVERALL SHIPPING WEIGHT: 25 TONS (APPROXIMATELY) Learn More

V-2151 AUTEFA, FULLY AUTOMATIC BALING PRESS MODEL LIFT BOX 1500 ADW (DOUBLE ROTATING LIFT BOXES) WITH FULLY AUTOMATIC STRAPPING AND FILM WRAPPING, YEAR 2011 – 45 BALES PER HOUR, BALE WEIGHT: 250KGS – VIDEOS AVAILABLE – NOW FULLY OPERATIONALV-2151 AUTEFA, FULLY AUTOMATIC BALING PRESS MODEL LIFT BOX 1500 ADW (DOUBLE ROTATING LIFT BOXES) WITH FULLY AUTOMATIC STRAPPING AND FILM WRAPPING, YEAR 2011 – 45 BALES PER HOUR, BALE WEIGHT: 250KGS – VIDEOS AVAILABLE – NOW FULLY OPERATIONAL – PERFECT CONDITION SHIPPING: • 3 TO 4 (40FT) CONTAINERS • OVERALL SHIPPING WEIGHT: 25 TONS (APPROXIMATELY) Learn More -

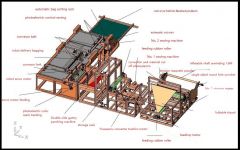

G-6402 AUTOMATIC PILLOWING FILLING MACHINE WITH AUTOMATIC SEALINGREFERENCE NUMBER: G-6402 AUTOMATIC PILLOWING FILLING MACHINE WITH AUTOMATIC SEALING THE PILLOW MACHINE LINE IS ASSEMBLED WITH A FIBER OPENER AND MINI BLOWER STUFFING MACHINES THAT MAINLY USED FOR TEXTILE STUFFING PRODUCTIONS SUCH AS BIG PLUSH TOYS, CUSHIONS AND PILLOWS ETC. IT CAN BE ALSO USED FOR FIBER QUILTING FILLING AFTER THE STUFFING SLOTS OF DUVET TYPE QUANTITY AVAILABLE: 1 Learn More

G-6402 AUTOMATIC PILLOWING FILLING MACHINE WITH AUTOMATIC SEALINGREFERENCE NUMBER: G-6402 AUTOMATIC PILLOWING FILLING MACHINE WITH AUTOMATIC SEALING THE PILLOW MACHINE LINE IS ASSEMBLED WITH A FIBER OPENER AND MINI BLOWER STUFFING MACHINES THAT MAINLY USED FOR TEXTILE STUFFING PRODUCTIONS SUCH AS BIG PLUSH TOYS, CUSHIONS AND PILLOWS ETC. IT CAN BE ALSO USED FOR FIBER QUILTING FILLING AFTER THE STUFFING SLOTS OF DUVET TYPE QUANTITY AVAILABLE: 1 Learn More -

YY-2869 SEMI-AUTOMATIC REWINDING MACHINE, WORKING WIDTH 2200mm – FLIPPING (ALTERNATING WINDING ROLLS)YY-2869 SEMI-AUTOMATIC REWINDING MACHINE, WORKING WIDTH 2200mm – FLIPPING (ALTERNATING WINDING ROLLS) 1. MACHINE STRUCTURE: THE MAIN BODY OF THE MACHINE IS MADE OF A STEEL PLATE STRUCTURE, AND THE REWINDING HAS A UP & DOWN AXIS REWINDING. THE CYLINDER LET OFF AUTOMATICALLY SETS FOR CUTTING, AND HAS FUNCTIONS SUCH AS METER COUNTING, RE-SETTING THE METER TO ZERO, AND AUTOMATIC SPEED INCREASE. 2. PRODUCT USAGE: THIS MACHINE IS MAINLY USED FOR RE-WINDING AND TRIMMING OF VARIOUS PAPERS, PAPER-PLASTIC COMPOSITES, FILM, DECORATIVE MATERIALS AS WELL AS PACKAGING MATERIALS, CLOTH, VINYLS AND SIMILAR MATERIALS. 3. CUTTING TYPE: ROTATING BLADE FOR AUTOMATIC CUTTING. 4. REWINDING ACCURACY ERROR: 0.1%. 5. MAXIMUM UNWINDING DIAMETER: Φ 915mm, WEIGHT 1000KGS. 6. MAXIMUM UNWINDING WIDTH: 2200mm. 7. MAXIMUM REWINDING DIAMETER: Φ420mm, WEIGHT 100KGS. 8. MAXIMUM MECHANICAL SPEED: 200 METERS/MINUTE. 9. COMPLETE MACHINE POWER: 20KW. 10. EQUIPMENT OVERALL SIZE: 2600×2900×1600mm. QUANTITY: 1 Learn More

YY-2869 SEMI-AUTOMATIC REWINDING MACHINE, WORKING WIDTH 2200mm – FLIPPING (ALTERNATING WINDING ROLLS)YY-2869 SEMI-AUTOMATIC REWINDING MACHINE, WORKING WIDTH 2200mm – FLIPPING (ALTERNATING WINDING ROLLS) 1. MACHINE STRUCTURE: THE MAIN BODY OF THE MACHINE IS MADE OF A STEEL PLATE STRUCTURE, AND THE REWINDING HAS A UP & DOWN AXIS REWINDING. THE CYLINDER LET OFF AUTOMATICALLY SETS FOR CUTTING, AND HAS FUNCTIONS SUCH AS METER COUNTING, RE-SETTING THE METER TO ZERO, AND AUTOMATIC SPEED INCREASE. 2. PRODUCT USAGE: THIS MACHINE IS MAINLY USED FOR RE-WINDING AND TRIMMING OF VARIOUS PAPERS, PAPER-PLASTIC COMPOSITES, FILM, DECORATIVE MATERIALS AS WELL AS PACKAGING MATERIALS, CLOTH, VINYLS AND SIMILAR MATERIALS. 3. CUTTING TYPE: ROTATING BLADE FOR AUTOMATIC CUTTING. 4. REWINDING ACCURACY ERROR: 0.1%. 5. MAXIMUM UNWINDING DIAMETER: Φ 915mm, WEIGHT 1000KGS. 6. MAXIMUM UNWINDING WIDTH: 2200mm. 7. MAXIMUM REWINDING DIAMETER: Φ420mm, WEIGHT 100KGS. 8. MAXIMUM MECHANICAL SPEED: 200 METERS/MINUTE. 9. COMPLETE MACHINE POWER: 20KW. 10. EQUIPMENT OVERALL SIZE: 2600×2900×1600mm. QUANTITY: 1 Learn More -

TT-3984 BALONEY SLITTER FABRIC AUTOMATIC CUTTING MACHINE – NEW, WIDTH 2500mm, 400mm DIAMETER (94.4 INCHES WIDE X 15.7 INCHES DIAMETER)TT-3984 BALONEY SLITTER FABRIC AUTOMATIC CUTTING MACHINE – NEW, WIDTH 2500mm, 400mm DIAMETER (94.4 INCHES WIDE X 15.7 INCHES DIAMETER) NEW 2500mm FABRIC AUTOMATIC CUTTING MACHINE FOR WOVEN FABRICS, TENTS, UMBRELLAS, LEATHER, REFLECTIVE MATERIAL, PLASTIC, PAPER, DOUBLE SIDED TAPE, ACETATE CLOTH, REINFORCED BELT, CONDUCTIVE CLOTH, AND STRAIGHT, OR 45° OBLIQUE CUT FOR CLOTH FOR APPAREL, BAGS, SHOES, CLOTHING ACCESSORIES, REFLECTIVE MATERIAL FACTORY, TENT FACTORY, UMBRELLA FACTORY, ELECTRONICS FACTORY AND OTHER INDUSTRIES. Learn More

TT-3984 BALONEY SLITTER FABRIC AUTOMATIC CUTTING MACHINE – NEW, WIDTH 2500mm, 400mm DIAMETER (94.4 INCHES WIDE X 15.7 INCHES DIAMETER)TT-3984 BALONEY SLITTER FABRIC AUTOMATIC CUTTING MACHINE – NEW, WIDTH 2500mm, 400mm DIAMETER (94.4 INCHES WIDE X 15.7 INCHES DIAMETER) NEW 2500mm FABRIC AUTOMATIC CUTTING MACHINE FOR WOVEN FABRICS, TENTS, UMBRELLAS, LEATHER, REFLECTIVE MATERIAL, PLASTIC, PAPER, DOUBLE SIDED TAPE, ACETATE CLOTH, REINFORCED BELT, CONDUCTIVE CLOTH, AND STRAIGHT, OR 45° OBLIQUE CUT FOR CLOTH FOR APPAREL, BAGS, SHOES, CLOTHING ACCESSORIES, REFLECTIVE MATERIAL FACTORY, TENT FACTORY, UMBRELLA FACTORY, ELECTRONICS FACTORY AND OTHER INDUSTRIES. Learn More -

J-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY -FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLEJ-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY-FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLE CAPACITY: 15 TO 36 PIECES PER MINUTE FABRIC WEIGHT: 60 TO 160gsm FOR NONWOVEN FABRIC BAG AUTOMATIC BOTTOM SEWING, SIDE SEWING, AUTOMATIC CUTTING PLC CONTROLLED SERVO MOTOR DRIVEN QUANTITY: 1 Learn More

J-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY -FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLEJ-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY-FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLE CAPACITY: 15 TO 36 PIECES PER MINUTE FABRIC WEIGHT: 60 TO 160gsm FOR NONWOVEN FABRIC BAG AUTOMATIC BOTTOM SEWING, SIDE SEWING, AUTOMATIC CUTTING PLC CONTROLLED SERVO MOTOR DRIVEN QUANTITY: 1 Learn More -

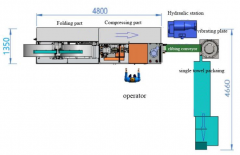

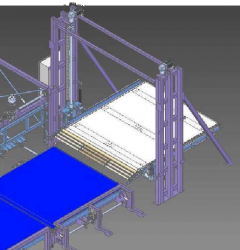

YY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINSYY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINS ASK FOR MORE DETAILS! PRODUCTION PROCESS: AUTOMATIC FEEDING→CUTTING→FOLDING→COMPRESSING→FORMING→DELIVERY→PACKING→OUTPUT Learn More

YY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINSYY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINS ASK FOR MORE DETAILS! PRODUCTION PROCESS: AUTOMATIC FEEDING→CUTTING→FOLDING→COMPRESSING→FORMING→DELIVERY→PACKING→OUTPUT Learn More -

YY-2748 AUTOMATIC UNSTACKER FOR FOAM LAYERS MOTORIZED 2 WAY, INTEGRATED BELT FOR FAST ALIGNMENT, MACHINE N. 1, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES)YY-2748 AUTOMATIC UNSTACKER FOR FOAM LAYERS MOTORIZED 2 WAY, INTEGRATED BELT FOR FAST ALIGNMENT, MACHINE N. 1, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES) AUTOMATIC UNLOADER FOR FOAM LAYERS MODEL: G220PRO QUANTITY: 1 Learn More

YY-2748 AUTOMATIC UNSTACKER FOR FOAM LAYERS MOTORIZED 2 WAY, INTEGRATED BELT FOR FAST ALIGNMENT, MACHINE N. 1, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES)YY-2748 AUTOMATIC UNSTACKER FOR FOAM LAYERS MOTORIZED 2 WAY, INTEGRATED BELT FOR FAST ALIGNMENT, MACHINE N. 1, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES) AUTOMATIC UNLOADER FOR FOAM LAYERS MODEL: G220PRO QUANTITY: 1 Learn More -

P-4339 CYLINDRICAL ARTICLES FULLY AUTOMATIC PACKAGING MACHINE

P-4339 CYLINDRICAL ARTICLES FULLY AUTOMATIC PACKAGING MACHINEREFERENCE NUMBER: P-4339

CYLINDRICAL ARTICLES FULLY AUTOMATIC PACKAGING MACHINE

Model: 626

SPECIFICATIONS

Packing speed:1-100bags/min

Packing length:70-400mm

Packing size: Max width:180mm Max high:60mm

Voltage: AC 220V 50/60Hz

Power:3.5KW

Weight:1000KG

Machine size:4500mmx1650mmx950mm

Use extersion: Column type group packing goods like ham banger, ice, cream, noodle, etc.

MACHINE CHARACTERISTIC

Touchable based, PLC double servo controlled, more safety and easiness

Free setting for bag length, automatic adjustment, convenient and accurate

All automatic electrical eye adjustment and press the button softly to change the category

Coule choose the automatic feed

Could choose the configuration manufactured date

Could choose the automatic feeder

Could choose the automatic hole making instrument

(Special manufacture based on the requirement from customer)

SPECIAL SET EQUIPMENT

A:All Automatic Feeder

Soft swaying lining and bring no damage to the product

Accurate computation, no fluctuation

Stainless material and confirm to the food manufacture requirement

Strong accommodation and suit the product of many diameter

B:Automatic Hole Maker

Round shape and beautiful outlook

Could set single hole, double hole, various meet

Collect the trash from making

Make hole by gas and has stable performanceQUANTITY: 1

Learn More