AA-1159 FOUR NOZZLES PILLOW FILLING PRODUCTION LINE

AA-1159

FOUR NOZZLES PILLOW FILLING PRODUCTION LINE

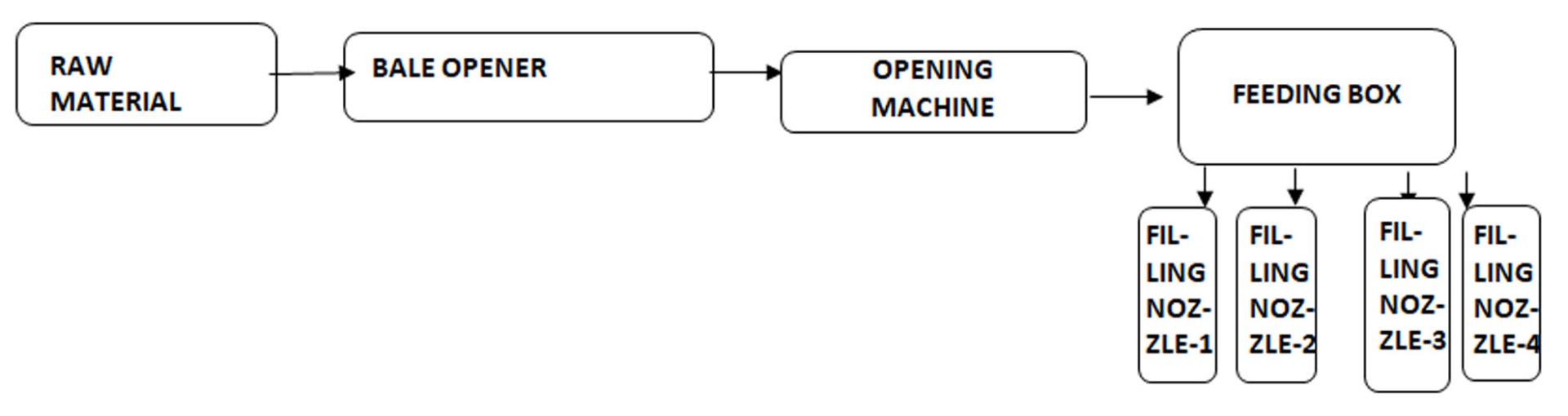

FOUR NOZZLES PILLOW FILLING MACHINE: IT IS SUITABLE FOR OPENING AND PROCESSING FIBER RAW MATERIAL, FILLING PILLOW CORE AND CUSHION. CHARACTERISTICS: LESS INVESTMENT, HIGH EFFICIENCY, SIMPLE OPERATION, WITH FREQUENCY CONVERSION DEVICE. RAW MATERIAL REQUIREMENTS: FIBERS ABOVE 0.78D, CAN BE OPENED AT ONE TIME.

In stock

SKU

AA-1159

REFERENCE NUMBER: AA-1159

FOUR NOZZLES PILLOW FILLING PRODUCTION LINE

FOUR NOZZLES PILLOW FILLING MACHINE: IT IS SUITABLE FOR OPENING AND PROCESSING FIBER RAW MATERIAL, FILLING PILLOW CORE AND CUSHION. CHARACTERISTICS: LESS INVESTMENT, HIGH EFFICIENCY, SIMPLE OPERATION, WITH FREQUENCY CONVERSION DEVICE. RAW MATERIAL REQUIREMENTS: FIBERS ABOVE 0.78D, CAN BE OPENED AT ONE TIME.

GENERAL DESCRIPTION:

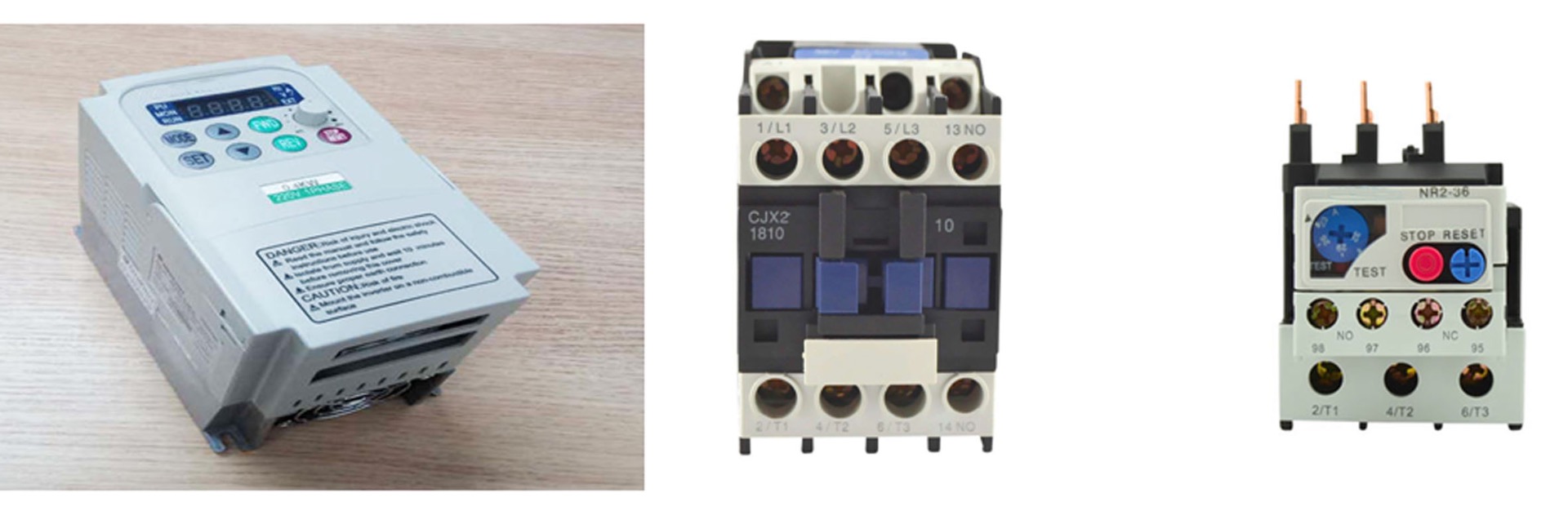

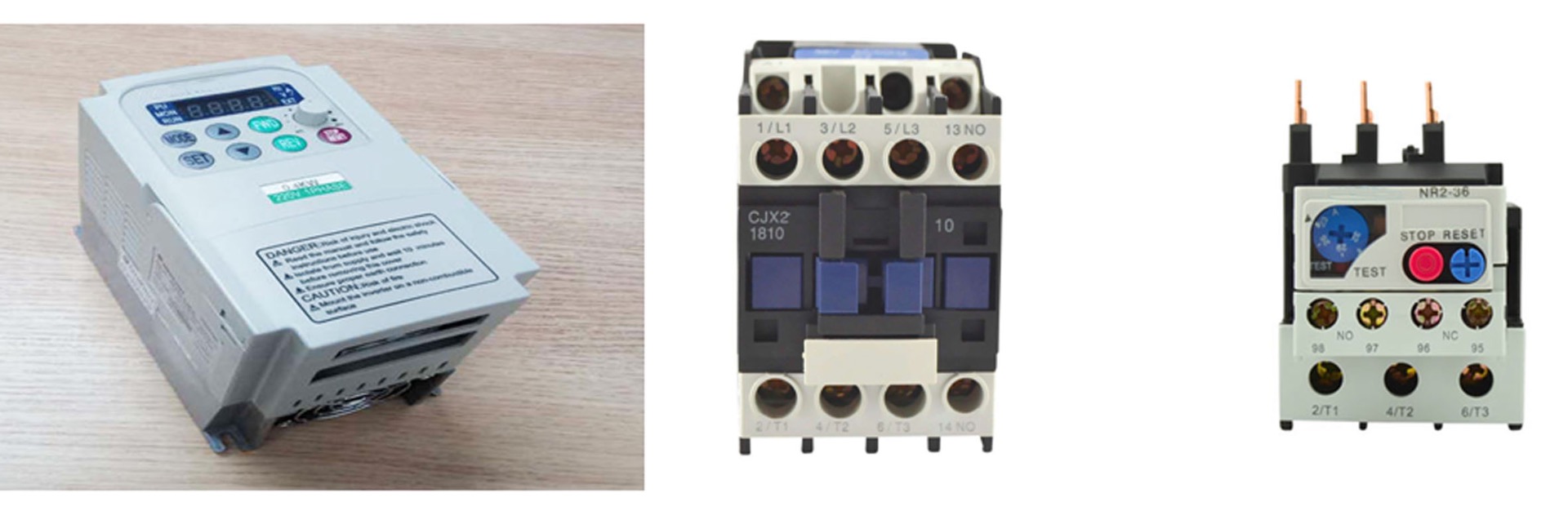

ELECTRICAL CONTROL PART:

ELECTRICAL CONTROL PART:

EQUIPMENT PARAMETERS:

1. OVERALL DIMENSIONS:

2. AUTOMATIC COTTON FEEDING PART: 5000 x 1100 x 2350mm

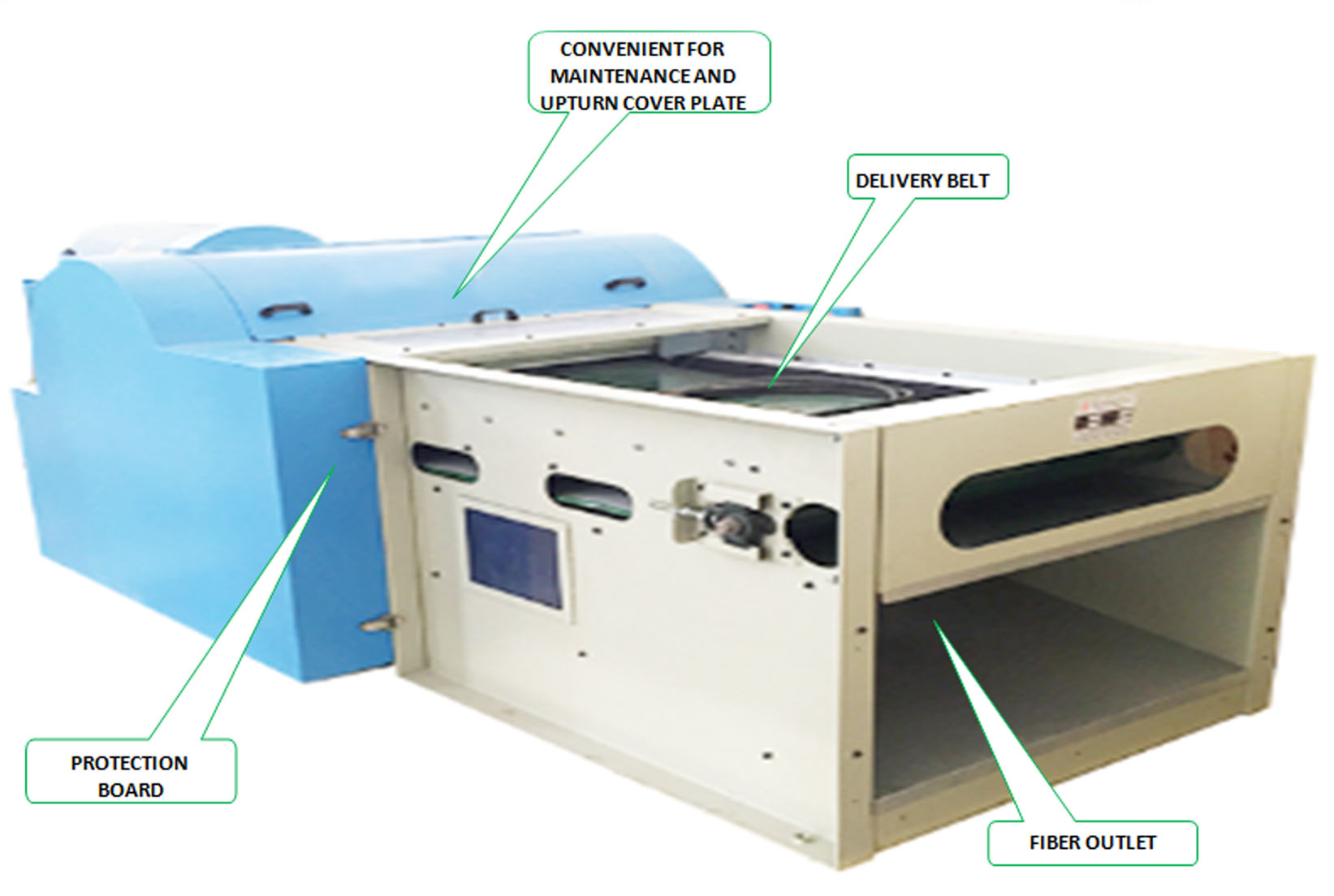

3. OPENING PART: 2400 x 1500 x 1350mm

4. FEEDING PART: 1100 x 600 x 1000mm

5. MATERIAL BOX PART: 1800 x 1250 x 180mm

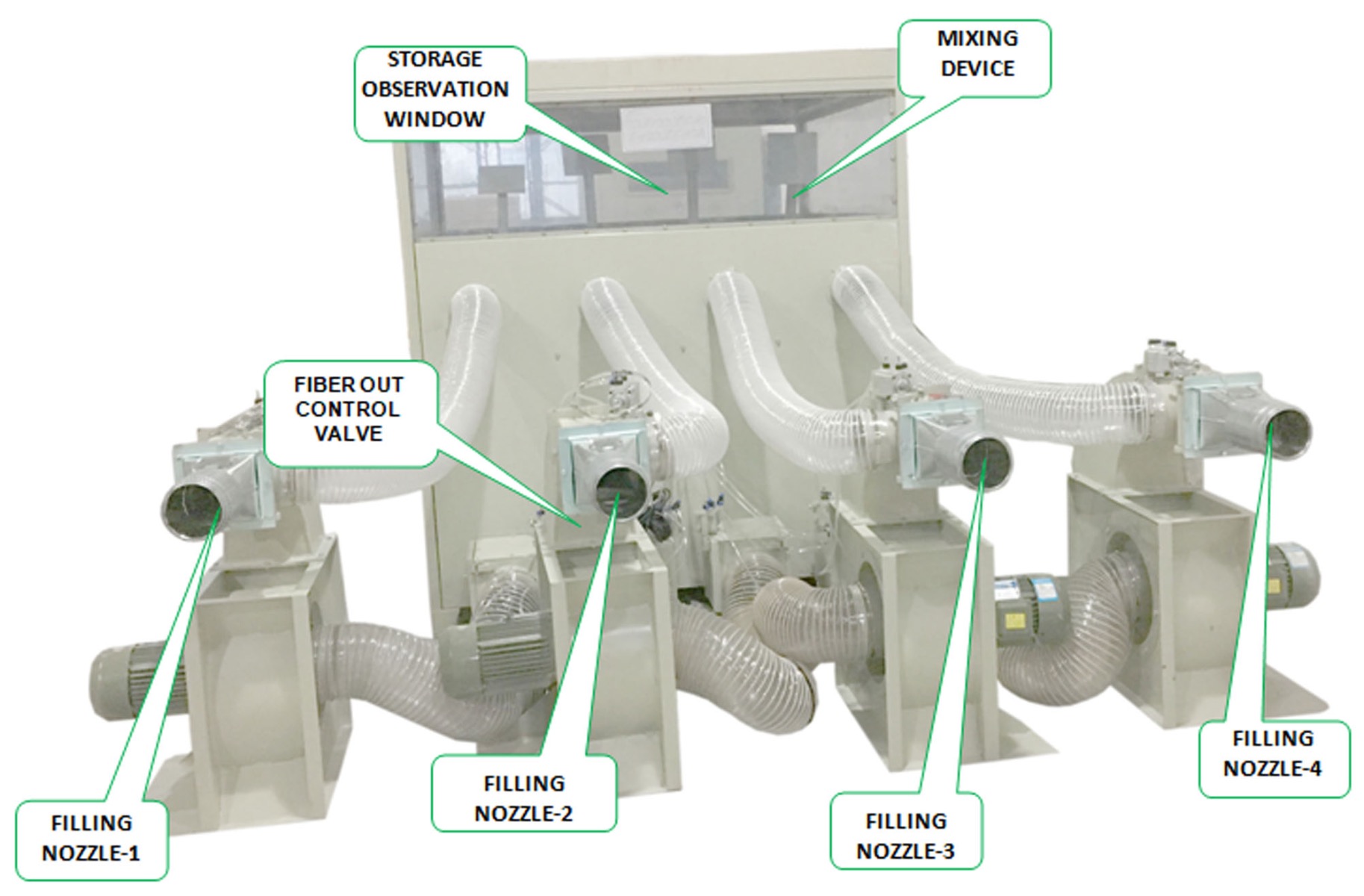

6. FILLING NOZZLE: 1000 x 600 x 1000mm

7. CONTROL BOX: 800 x 600 x 1260mm

8. POWER: 28.8KW

9. VOLTAGE: 220V/60Hz

10. OUTPUT: 350 TO 550KG/H

11. NET WEIGHT: 3200KG

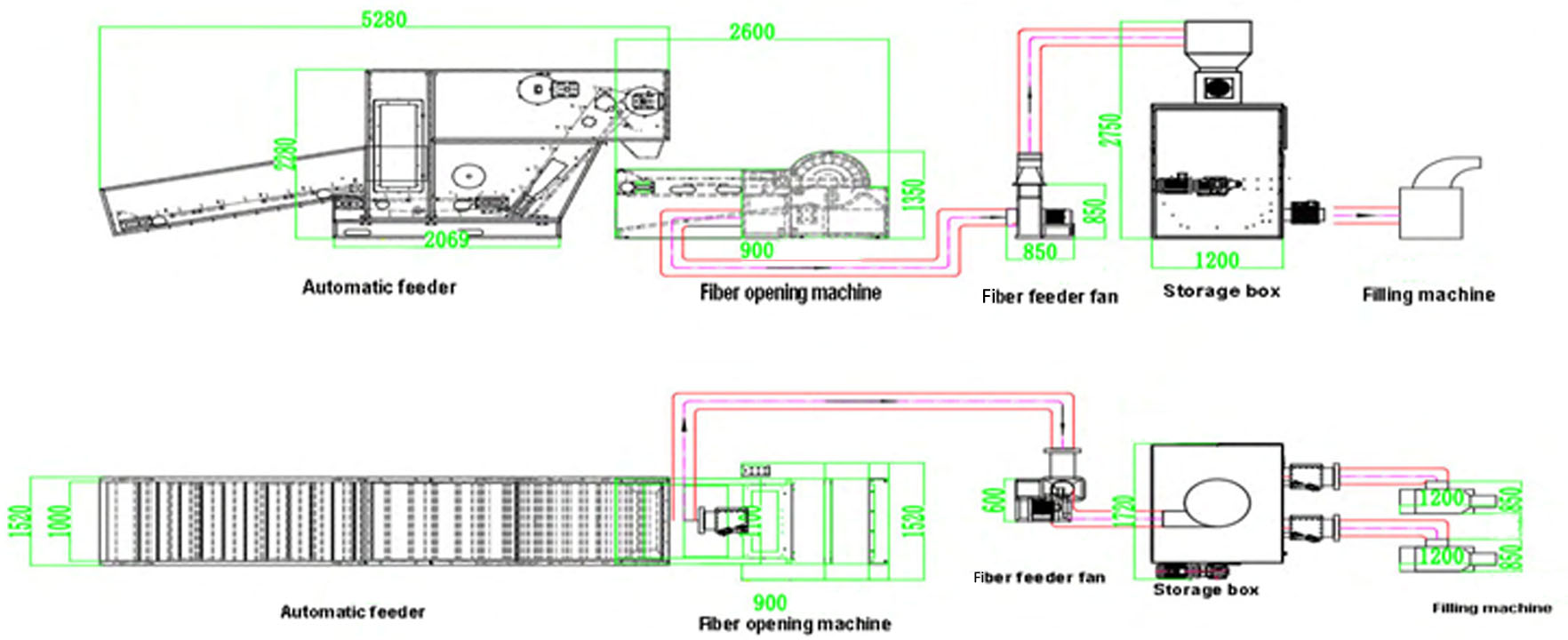

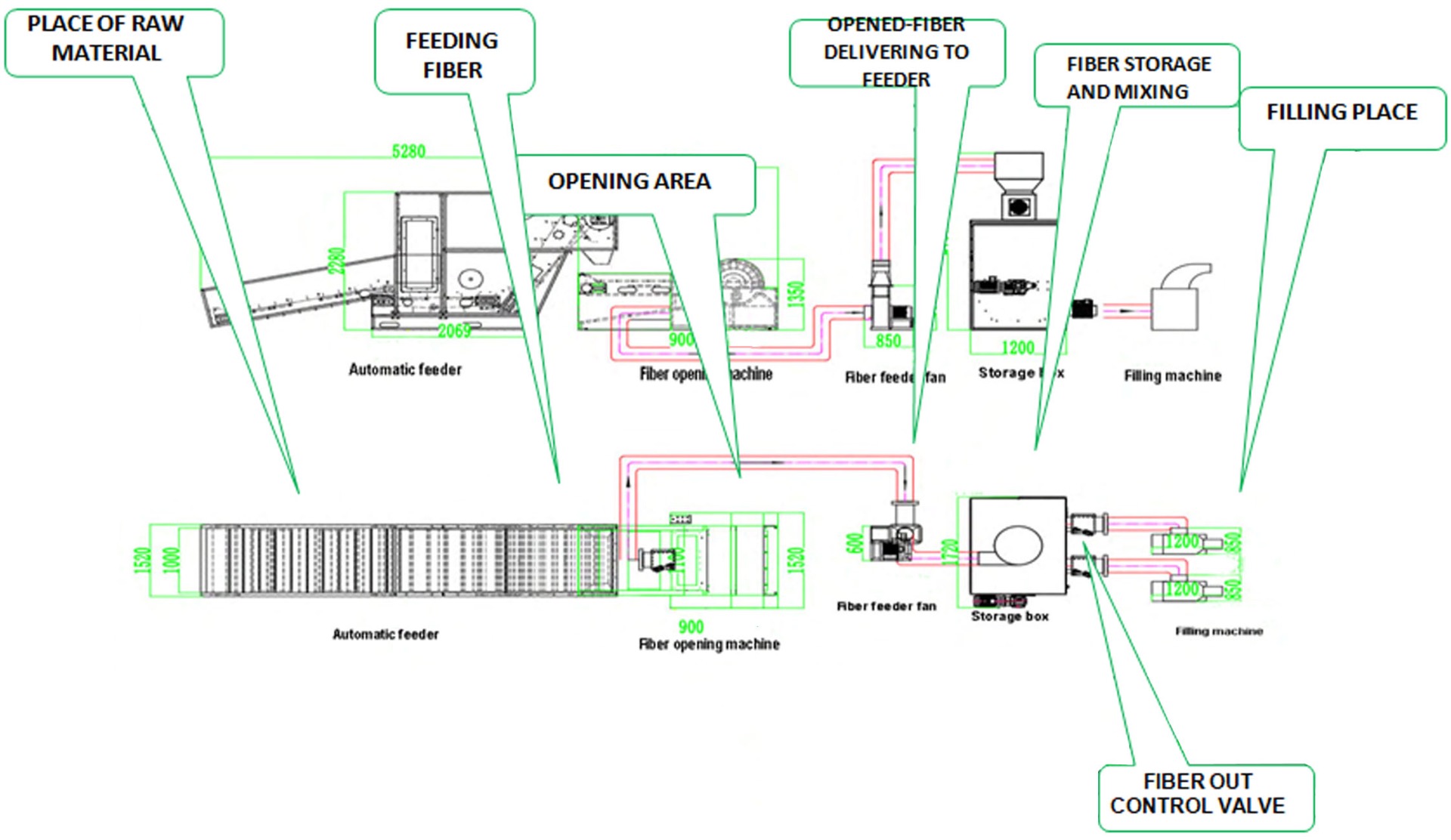

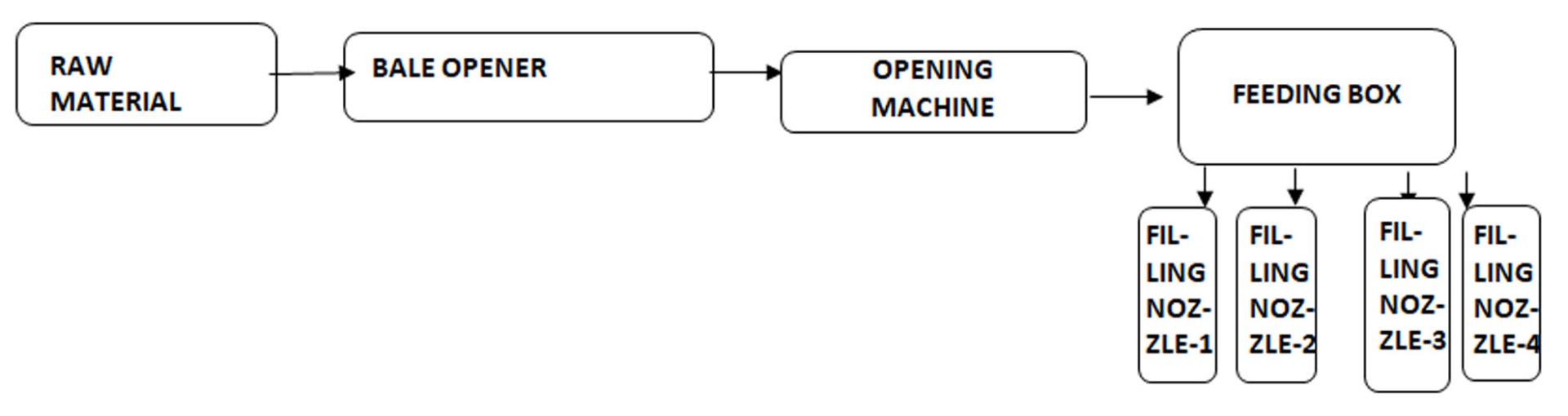

12. TECHNOLOGICAL PROCESS: PUT THE WHOLE PACKAGE OF FIBER RAW MATERIAL INTO THE AUTOMATIC COTTON FEEDER, FEED THAT INTO THE OPENER AT A CONSTANT SPEED, AND SEND THE OPENED CHEMICAL FIBER COTTON INTO THE FIBER BOX FOR MANUAL FILLING

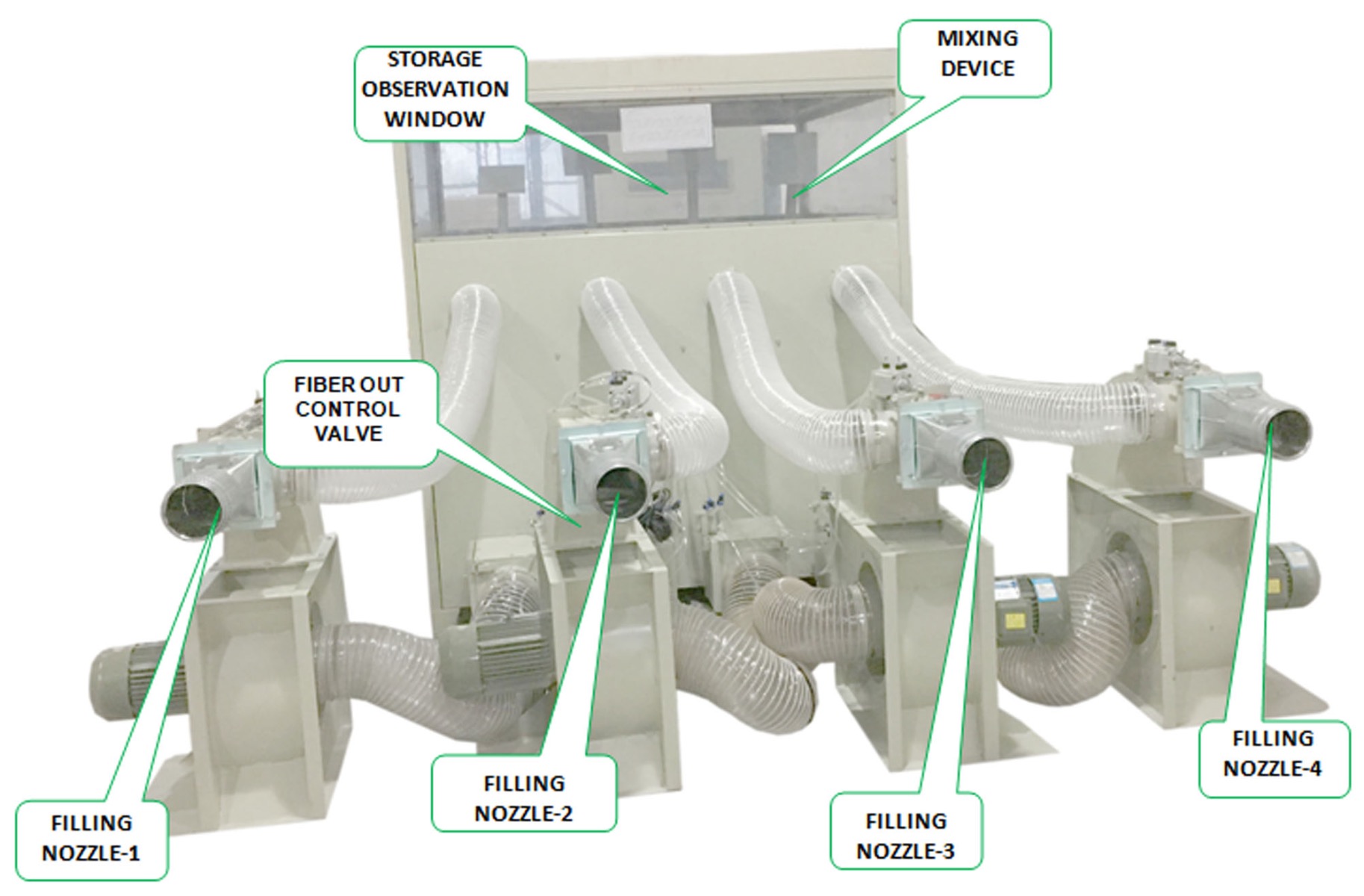

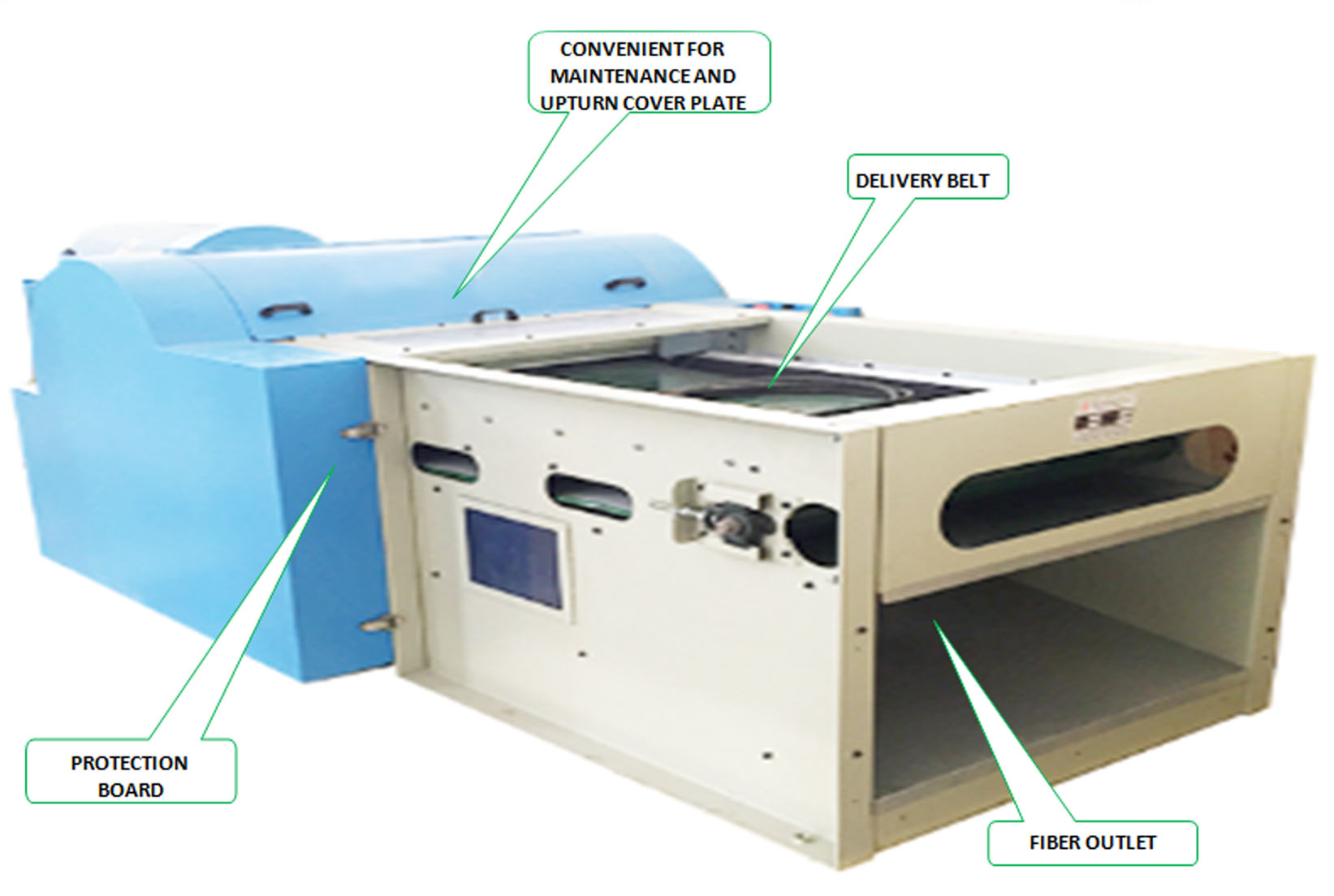

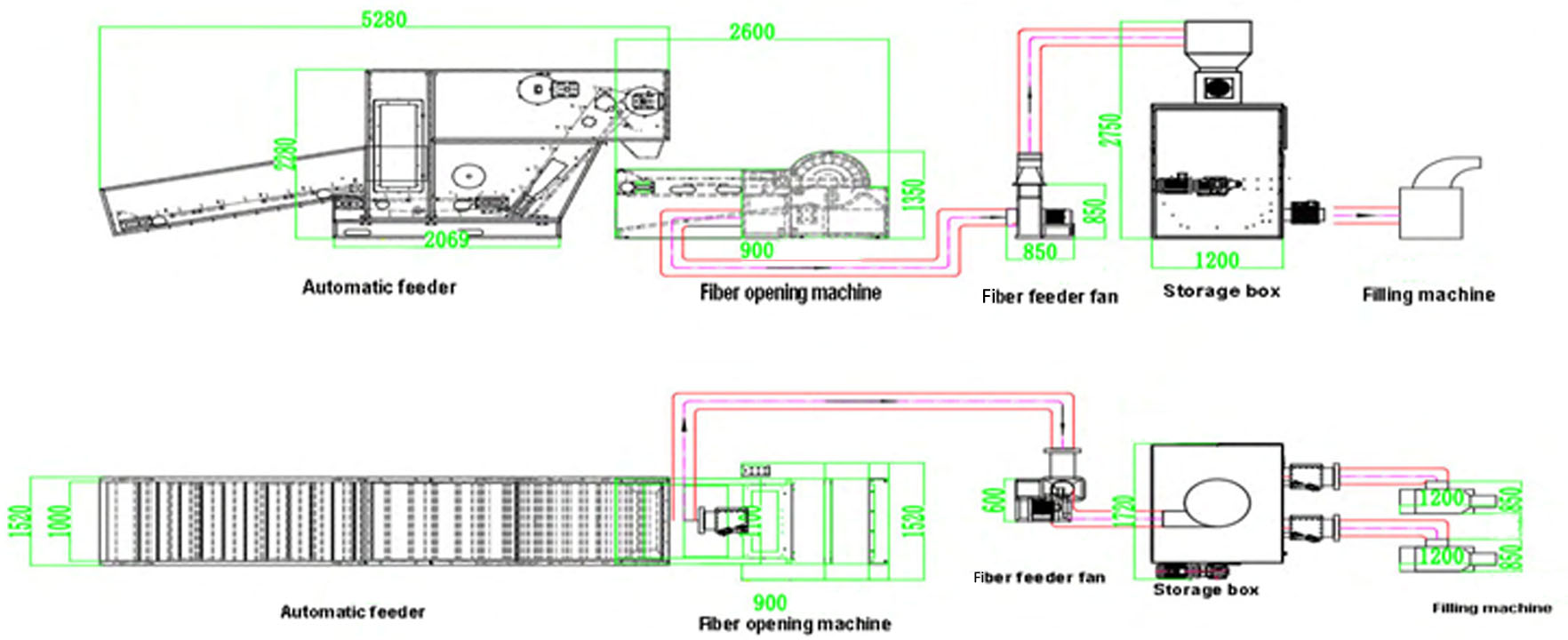

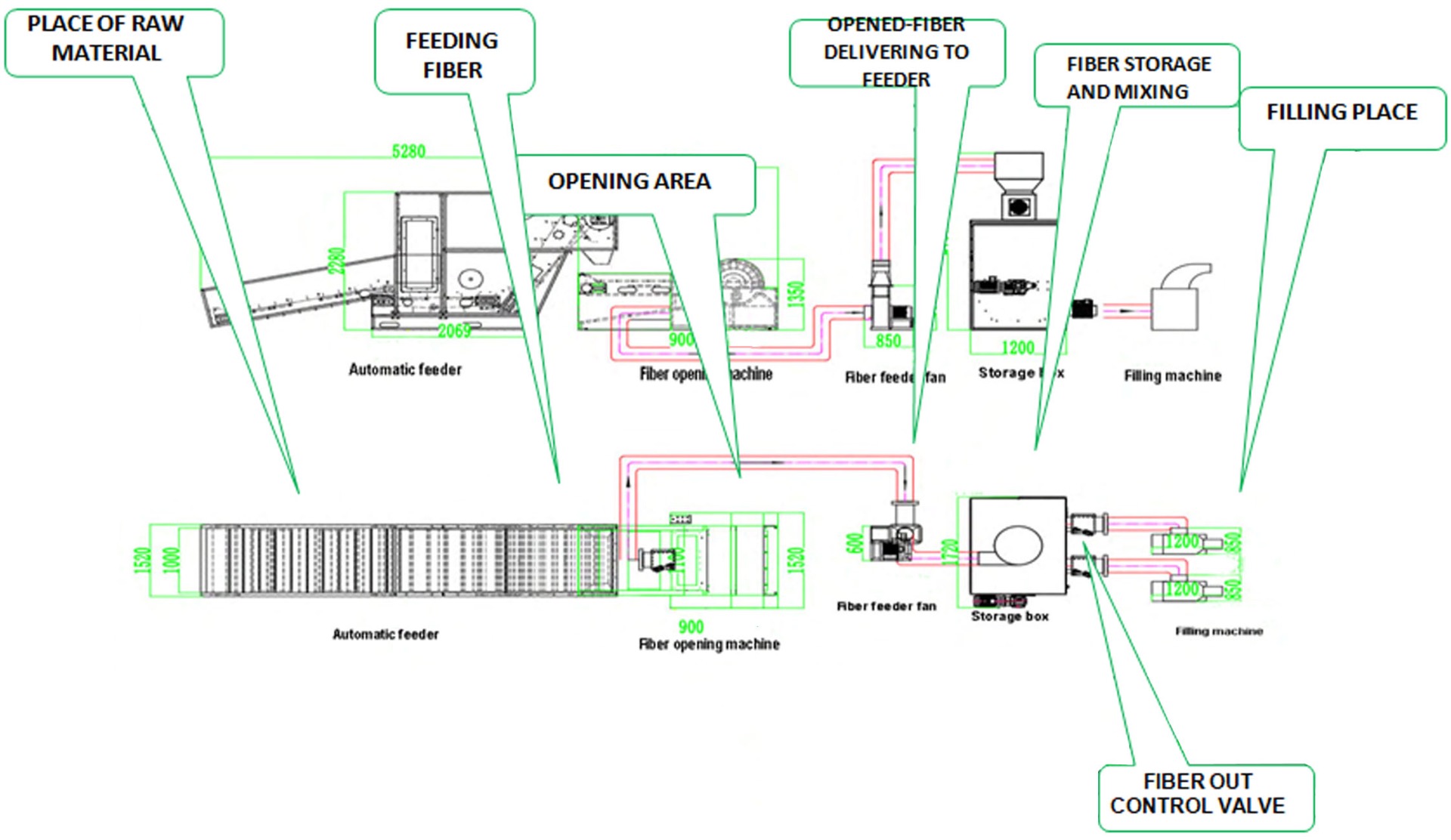

PREVIEW OF OVERALL APPEARANCE OF EQUIPMENT:

EQUIPMENT PARAMETERS:

1. OVERALL DIMENSIONS:

2. AUTOMATIC COTTON FEEDING PART: 5000 x 1100 x 2350mm

3. OPENING PART: 2400 x 1500 x 1350mm

4. FEEDING PART: 1100 x 600 x 1000mm

5. MATERIAL BOX PART: 1800 x 1250 x 180mm

6. FILLING NOZZLE: 1000 x 600 x 1000mm

7. CONTROL BOX: 800 x 600 x 1260mm

8. POWER: 28.8KW

9. VOLTAGE: 220V/60Hz

10. OUTPUT: 350 TO 550KG/H

11. NET WEIGHT: 3200KG

12. TECHNOLOGICAL PROCESS: PUT THE WHOLE PACKAGE OF FIBER RAW MATERIAL INTO THE AUTOMATIC COTTON FEEDER, FEED THAT INTO THE OPENER AT A CONSTANT SPEED, AND SEND THE OPENED CHEMICAL FIBER COTTON INTO THE FIBER BOX FOR MANUAL FILLING

PREVIEW OF OVERALL APPEARANCE OF EQUIPMENT:

ELECTRICAL CONTROL PART:

ELECTRICAL CONTROL PART:

EQUIPMENT PARAMETERS:

1. OVERALL DIMENSIONS:

2. AUTOMATIC COTTON FEEDING PART: 5000 x 1100 x 2350mm

3. OPENING PART: 2400 x 1500 x 1350mm

4. FEEDING PART: 1100 x 600 x 1000mm

5. MATERIAL BOX PART: 1800 x 1250 x 180mm

6. FILLING NOZZLE: 1000 x 600 x 1000mm

7. CONTROL BOX: 800 x 600 x 1260mm

8. POWER: 28.8KW

9. VOLTAGE: 220V/60Hz

10. OUTPUT: 350 TO 550KG/H

11. NET WEIGHT: 3200KG

12. TECHNOLOGICAL PROCESS: PUT THE WHOLE PACKAGE OF FIBER RAW MATERIAL INTO THE AUTOMATIC COTTON FEEDER, FEED THAT INTO THE OPENER AT A CONSTANT SPEED, AND SEND THE OPENED CHEMICAL FIBER COTTON INTO THE FIBER BOX FOR MANUAL FILLING

PREVIEW OF OVERALL APPEARANCE OF EQUIPMENT:

EQUIPMENT PARAMETERS:

1. OVERALL DIMENSIONS:

2. AUTOMATIC COTTON FEEDING PART: 5000 x 1100 x 2350mm

3. OPENING PART: 2400 x 1500 x 1350mm

4. FEEDING PART: 1100 x 600 x 1000mm

5. MATERIAL BOX PART: 1800 x 1250 x 180mm

6. FILLING NOZZLE: 1000 x 600 x 1000mm

7. CONTROL BOX: 800 x 600 x 1260mm

8. POWER: 28.8KW

9. VOLTAGE: 220V/60Hz

10. OUTPUT: 350 TO 550KG/H

11. NET WEIGHT: 3200KG

12. TECHNOLOGICAL PROCESS: PUT THE WHOLE PACKAGE OF FIBER RAW MATERIAL INTO THE AUTOMATIC COTTON FEEDER, FEED THAT INTO THE OPENER AT A CONSTANT SPEED, AND SEND THE OPENED CHEMICAL FIBER COTTON INTO THE FIBER BOX FOR MANUAL FILLING

PREVIEW OF OVERALL APPEARANCE OF EQUIPMENT:

Write Your Own Review