Search results for: 'generation Electric'

- Related search terms

- electric c

- electric co

- electrica

- electric'

- electrical 0

-

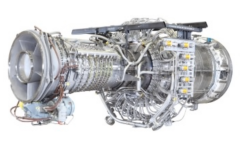

The TM 2500 Mobile Gas Turbine GeneratorThe TM 2500 Mobile Gas Turbine Generator Standard Description Quantity: 2 Units Available Immediately. Learn More

The TM 2500 Mobile Gas Turbine GeneratorThe TM 2500 Mobile Gas Turbine Generator Standard Description Quantity: 2 Units Available Immediately. Learn More -

TT-7849 JENBACHER JGS 620F GENERATOR SYSTEM, 6.712 MW TOTAL, 11KV, 20K/23K HOURS, NATURAL GAS, 2012TT-7849 JENBACHER JGS 620F GENERATOR SYSTEM, 6.712 MW TOTAL, 11KV, 20K/23K HOURS, NATURAL GAS, 2012 1. USED JENBACHER GENERATOR SYSTEM 2. CONSISTING OF (2) MODEL JGS 620F JENBACHER NATURAL GAS GENSETS 3. EACH RATED 3.356 MW; 2.9 MW NET OUTPUT; 1500 RPM; 3/50/11KV 4. YEAR BUILT 2012 5. REPORTED 20,000 HOURS AND 23,000 HOURS. CONTROLLED BY (1) PANEL. 6. BRAND: JENBACHER 7. MODEL: JGS 620F 8. USED EQUIPMENT FACTS ABOUT THIS MACHINE 9. FUEL TYPE: NATURAL GAS QUANTITY: 1 Learn More

TT-7849 JENBACHER JGS 620F GENERATOR SYSTEM, 6.712 MW TOTAL, 11KV, 20K/23K HOURS, NATURAL GAS, 2012TT-7849 JENBACHER JGS 620F GENERATOR SYSTEM, 6.712 MW TOTAL, 11KV, 20K/23K HOURS, NATURAL GAS, 2012 1. USED JENBACHER GENERATOR SYSTEM 2. CONSISTING OF (2) MODEL JGS 620F JENBACHER NATURAL GAS GENSETS 3. EACH RATED 3.356 MW; 2.9 MW NET OUTPUT; 1500 RPM; 3/50/11KV 4. YEAR BUILT 2012 5. REPORTED 20,000 HOURS AND 23,000 HOURS. CONTROLLED BY (1) PANEL. 6. BRAND: JENBACHER 7. MODEL: JGS 620F 8. USED EQUIPMENT FACTS ABOUT THIS MACHINE 9. FUEL TYPE: NATURAL GAS QUANTITY: 1 Learn More -

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mmM-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

OFFER 001

SPUNBOND PRODUCTION LINE

WORKING WIDTH: 4040mm

WEIGHT: 130 TO 250 G/M2OFFER 002

POLYMER CLEANING GROUPOFFER 003

CRYSTALLIZING GROUPOFFER 004

DRYING GROUPOFFER 005

PNEUMATIC CONVEYING SYSTEMOFFER 006

EXTRUDER HOPPEROFFER 007

EXTRUDEROFFER 008

FILTERING UNITOFFER 009

MELT TRANSFER LINEOFFER 010

SPINNING BEAMOFFER 011

SPINNING PACKSOFFER 012

FILAMENTS QUENCHING SYSTEMOFFER 013

FILAMENTS DRAWING AND DISTRIBUTION SYSTEMOFFER 014

WEB FORMING CONVEYOR BELTOFFER 015

CREEL FOR APPLICATION OF REINFORCING FILAMENTSOFFER 016

PRE-NEEDLING MACHINEOFFER 017

NEEDLING MACHINEOFFER 018

THERMOSETTING UNITOFFER 019

OUTLET CALENDEROFFER 020

FOULARDOFFER 021

BINDER PREPARATION SYSTEMOFFER 022

DRYEROFFER 023

OUTLET CALENDEROFFER 024

AUTOMATIC WINDEROFFER 025

AIR COMPRESSORS (FOR FILAMENTS STRETCHING EJECTORS)OFFER 026

DIATHERMIC OIL HEATING SYSTEMOFFER 027

CHILLED WATER CIRCULATION AND GENERATION SYSTEMOFFER 028

EQUIPMENT FOR CLEANING CYCLE, SPECIAL TOOLSOFFER 029

FIBRE DUST RECOVERY SYSTEMOFFER 030

EDGES RECOVERY SYSTEMOFFER 031

SPINNING SECTION STEEL STRUCTUREOFFER 032

DISTRIBUTION ELECTRIC CABINETSOFFER 033

PROCESS ELECTRIC SYSTEM OF EXISTING MACHINES ACCORDING TO THE ACTUAL LAYOUTOFFER 034

CABLES AND CABLING MATERIALSQUANTITY: 1 LINE

Learn More -

TT-7850 JENBACHER JGS 620F NATURAL GAS GENERATOR SYSTEM, 6.712 MW TOTAL, 11KV, 1500 RPM, YEAR 2012TT-7850 JENBACHER JGS 620F NATURAL GAS GENERATOR SYSTEM, 6.712 MW TOTAL, 11KV, 1500 RPM, YEAR 2012 1. JENBACHER GENERATOR SYSTEM 2. CONSISTING OF (2) MODEL JGS 620F JENBACHER NATURAL GAS GENSETS. 3. EACH RATED 3.356 MW; 2.9 MW NET OUTPUT; 1500 RPM; 3/50/11KV. YEAR BUILT 2012. 4. REPORTED 20,000 HOURS ON EACH UNIT. CONTROLLED BY (1) PANEL. 5. BRAND: JENBACHER 6. MODEL: JGS 620F 7. USED EQUIPMENT FACTS ABOUT THIS MACHINE 8. BRAND: JENBACHER (BY INNIO) 9. MODEL: JGS 620F 10. FUEL TYPE: NATURAL GAS 11. YEAR BUILT: 2012 QUANTITY: 1 Learn More

TT-7850 JENBACHER JGS 620F NATURAL GAS GENERATOR SYSTEM, 6.712 MW TOTAL, 11KV, 1500 RPM, YEAR 2012TT-7850 JENBACHER JGS 620F NATURAL GAS GENERATOR SYSTEM, 6.712 MW TOTAL, 11KV, 1500 RPM, YEAR 2012 1. JENBACHER GENERATOR SYSTEM 2. CONSISTING OF (2) MODEL JGS 620F JENBACHER NATURAL GAS GENSETS. 3. EACH RATED 3.356 MW; 2.9 MW NET OUTPUT; 1500 RPM; 3/50/11KV. YEAR BUILT 2012. 4. REPORTED 20,000 HOURS ON EACH UNIT. CONTROLLED BY (1) PANEL. 5. BRAND: JENBACHER 6. MODEL: JGS 620F 7. USED EQUIPMENT FACTS ABOUT THIS MACHINE 8. BRAND: JENBACHER (BY INNIO) 9. MODEL: JGS 620F 10. FUEL TYPE: NATURAL GAS 11. YEAR BUILT: 2012 QUANTITY: 1 Learn More -

TT-7878 JENBACHER JGS-416 GS-N L NATURAL GAS GENERATOR, 1203 KW, 50Hz, YEAR 2018TT-7878 JENBACHER JGS-416 GS-N L NATURAL GAS GENERATOR, 1203 KW, 50Hz, YEAR 2018 1. RATED COP 1203KW; 2. POWER FACTOR OF 1; 3. JENBACHER J416 ENGINE; 1500 RPM, 50Hz/400V. 4. WITH CONTROLS. 5. BRAND: JENBACHER (INNIO GROUP) 6. MODEL: JGS-416 GS-N L 7. ENGINE: JENBACHER J416 8. YEAR BUILT: 2018 9. RUN TIME: APPROX. 23,000 HOURS 10. CONTROLS: INCLUDED (OEM JENBACHER CONTROL PANEL) QUANTITY: 1 Learn More

TT-7878 JENBACHER JGS-416 GS-N L NATURAL GAS GENERATOR, 1203 KW, 50Hz, YEAR 2018TT-7878 JENBACHER JGS-416 GS-N L NATURAL GAS GENERATOR, 1203 KW, 50Hz, YEAR 2018 1. RATED COP 1203KW; 2. POWER FACTOR OF 1; 3. JENBACHER J416 ENGINE; 1500 RPM, 50Hz/400V. 4. WITH CONTROLS. 5. BRAND: JENBACHER (INNIO GROUP) 6. MODEL: JGS-416 GS-N L 7. ENGINE: JENBACHER J416 8. YEAR BUILT: 2018 9. RUN TIME: APPROX. 23,000 HOURS 10. CONTROLS: INCLUDED (OEM JENBACHER CONTROL PANEL) QUANTITY: 1 Learn More -

YY-2425 LM2500 PE SAC, 22.4 MW, WITH GE 6 STAGE POWER TURBINE, GAS TURBINES, QUANTITY 2YY-2425 LM2500 PE SAC, 22.4 MW, WITH GE 6 STAGE POWER TURBINE, GAS TURBINES, QUANTITY 2 ITEM 001 2500 HOURS AFTER ENGINE OVERHAUL ITEM 002 6500 HOURS AFTER ENGINE OVERHAUL Learn More

YY-2425 LM2500 PE SAC, 22.4 MW, WITH GE 6 STAGE POWER TURBINE, GAS TURBINES, QUANTITY 2YY-2425 LM2500 PE SAC, 22.4 MW, WITH GE 6 STAGE POWER TURBINE, GAS TURBINES, QUANTITY 2 ITEM 001 2500 HOURS AFTER ENGINE OVERHAUL ITEM 002 6500 HOURS AFTER ENGINE OVERHAUL Learn More -

TT-4060-B GENERAL ELECTRIC LM2500 SAC COMPLETE POWER PLANT, 22MW, YEAR 2022, 5000 HOURS, 50HzTT-4060-B GENERAL ELECTRIC LM2500 SAC COMPLETE POWER PLANT, 22MW, YEAR 2022, 5000 HOURS, 50Hz WE OFFER TWO TURBINES AND GENERATOR ALONE OR THE TURBINE ALONE, GENERATION 2 QUANTITY: 2 Learn More

TT-4060-B GENERAL ELECTRIC LM2500 SAC COMPLETE POWER PLANT, 22MW, YEAR 2022, 5000 HOURS, 50HzTT-4060-B GENERAL ELECTRIC LM2500 SAC COMPLETE POWER PLANT, 22MW, YEAR 2022, 5000 HOURS, 50Hz WE OFFER TWO TURBINES AND GENERATOR ALONE OR THE TURBINE ALONE, GENERATION 2 QUANTITY: 2 Learn More -

YY-3472 44MW WARTSILA POWER PLANT PACKAGEYY-3472 44MW WARTSILA POWER PLANT PACKAGE THE POWER STATION HAS BEEN SUPPLYING ELECTRICITY ON A RENTAL BASIS TO THE 33KV LOCAL GRID SINCE 2011. QUANTITY: 5 Learn More

YY-3472 44MW WARTSILA POWER PLANT PACKAGEYY-3472 44MW WARTSILA POWER PLANT PACKAGE THE POWER STATION HAS BEEN SUPPLYING ELECTRICITY ON A RENTAL BASIS TO THE 33KV LOCAL GRID SINCE 2011. QUANTITY: 5 Learn More -

TT-2014 WARTSILA 9L20 HFO PLANT, 1539 KW EACH 11KV 50Hz 1000 RPM HFO/LFO, YEAR 2009TT-2014 WARTSILA 9L20 HFO PLANT, 1539 KW EACH 11KV 50Hz 1000 RPM HFO/LFO, YEAR 2009 UNUSED NEW UNITS WARTSILA HFO OIL CUBES 1539 KW EACH VOLTAGE: 11000 VOLTS FREQUENCY: 50Hz 1000 RPM FUEL: HFO/LFO INCLUDING MV/LV SYSTEM LAID INTO TWO 40 FOOT CONTAINERS NOT MADE BY WARTSILA QUANTITY: 4 Learn More

TT-2014 WARTSILA 9L20 HFO PLANT, 1539 KW EACH 11KV 50Hz 1000 RPM HFO/LFO, YEAR 2009TT-2014 WARTSILA 9L20 HFO PLANT, 1539 KW EACH 11KV 50Hz 1000 RPM HFO/LFO, YEAR 2009 UNUSED NEW UNITS WARTSILA HFO OIL CUBES 1539 KW EACH VOLTAGE: 11000 VOLTS FREQUENCY: 50Hz 1000 RPM FUEL: HFO/LFO INCLUDING MV/LV SYSTEM LAID INTO TWO 40 FOOT CONTAINERS NOT MADE BY WARTSILA QUANTITY: 4 Learn More -

SUGAR AND ALCOHOL PLANTREFERENCE NUMBER: A-2511 SUGAR AND ALCOHOL PLANT CANE UNLOAD SECTOR THE CANE UNLOADING SECTOR IS EQUIPPED WITH THE EQUIPMENT LISTED BELOW IN THE CONDITION TO CARRY OUT A GRINDING OF 8400 TCD WHICH CORRESPONDS TO A HARVEST OF 1800000 TONNES OF CANE / YEAR • 01 HILO UNLOADER OF STORAGE • 01 HILO UNLOADER OF MILLING • 01 FEEDER SUGARCANE TABLE WITH INCLINATION OF 25 INCHES • 01 FEEDER SUGARCANE TABLE WITH INCLINATION OF 45 INCHES • 02 CRANES WITH CAPACITY OF 20 TONNES • 01 TRANSPORTER TYPE CUSCH - CUSH OF 40 INCHES • 02 MOTOR PUMP WITH CAPACITY OF 1000 M³/H TO 50 MCW FOR CANE WASHING • 01 CONTAMINATED FLUID TREATMENT SYSTEM • 01 METAL STRUCTURE BUILDING MEASURING 20000 X 100000 mm CANE PREPARATION SECTOR THE SUGARCANE PREPARATION SECTOR IS EQUIPPED WITH THE FOLLOWING AUTOMATED EQUIPMENT WITH THE CONTROL BY THE SUPERVISORY INSTALLED IN THE CONTROL ROOM AS SHOWN BELOW TO PERFORM A CRUSHING OF 7200 TCD WHICH CORRESPONDS TO A CROP OF 1600000 TONS OF SUGARCANE / YEAR • 01 METALLIC CONVEYOR OF 60 INCHES • 01 LEVELING OF CANE OF 60 INCHES • 01 CANE KNIVES SET TYPE COP-8 OF 60 INCHES • 01 CAN SHREDDER SET TYPE COP-5 OF 60 INCHES • 01 FEEDER ROLL 60 IINCHES • 01 RUBBER TRANSPORTER FOR CANE SHREDDED OF 60 INCHES • 01 TGM TURBINE FOR KNIVES SET • 01 TGM TURBINE FOR SHREDDER SET • 01 HIGH AND LOWER SPEED REDUCER OF KNIVES SET • 01 HIGH AND LOWER SPEED REDUCER OF SHREDDER SET • 01 REDUCER FOR METALLIC CONVEYOR • 01 REDUCER FOR FEEDER ROLL • 01 REDUCER OF SHREDDED CANE TRANSPORTER TYPE BELT MILLING CANE SECTOR THE CANE MILLING SECTOR OF THE PLANT IS EQUIPPED WITH THE FOLLOWING AUTOMATED EQUIPMENT WITH THE CONTROL BY THE SUPERVISORY INSTALLED IN THE CONTROL ROOM TO CARRY OUT A GRINDING OF 7200 TCD CORRESPONDING TO A 222 - DAY HARVEST TO GRIND 1600000 TONS. CANE / YEAR • 04 MILLS OF 32 X 60 INCHES • 03 INTERMIDIATE TRANSPORTER OF 60 INCHES • 01 ROTARY SIEVE FOR MILLING 300 TCD • 01 TGM TURBINE OF DRIVING THE 1º / 2º MILLS • 01 TGM TURBINE OF DRIVING OF 3º / 4º MILLS • 01 REDUCER OF HIGH AND LOW SPEED OF DRIVING THE 1º / 2º MILLS • 01 REDUCER OF HIGH AND LOW SPEED OF DRIVING THE 3º / 4º MILLS • 03 REDUCER INTERMEDIATE TRANSPORTER OF 60 INCHES • 02 PUMPS OF 1ST JUICE • 02 PUMPS OF JUICE IMBIBITION OF 3RD FOR 2ND MILL • 02 PUMPS OF JUICE IMBIBITION OF 4TH FOR 3RD MILLS • 02 PUMPS OF MIXED JUICE OF MILL FOR JUICE TREATMENT STEAM GENERATION SECTOR THE STEAM GENERATION SECTOR OF THE PLANT IS PREPARED TODAY TO PERFORM A 7200 TCD GRINDING CORRESPONDING TO A 220 - DAY HARVEST TO GRIND 1600000 TON. CANE / YEAR WITH THE FOLLOWING AUTOMATED EQUIPMENT WITH CONTROL BY THE SUPERVISORY INSTALLED IN THE CONTROL ROOM AS SHOWN BELOW • 01 BOILER N ° 01, MODEL: TS-3-150 MODIFIED FOR CBS-120-21 KG / CM² TODAY GENERATES AN AVERAGE OF 11000 KG / HR OF STEAM AT A PRESSURE OF 21 KG / CM² • 01 BOILER N ° 02, MODEL: TS-3-150-21 KG / CM² TODAY GENERATES AN AVERAGE OF 55000 KG / HR OF STEAM AT A PRESSURE OF 21 KG / CM² • 01 DEAERATOR WITH A CAPACITY OF 70 M³ • 01 78 INCHES BAGASSE METALLIC TRANSPORTER OF 32000 mm LENGTH • 01 48 INCHES BAGASSE TRANSPORTER FROM MILL TO BOILER • 01 48 INCHES BAGASSE RETURN TRANSPORTER FOR BOILER • 01 REDUCER OF BAGASSE TRANSPORTER FROM MILL TOBOILER • 01 REDUCER OF BAGASSE RETURN TRANSPORTER TOBOILER • 02 MOTO - PUMPS OF WATER FEEDING OF DEAERATOR • 02 MOTO - PUMPS OF WATER TREATMENT OF BOILER • 01 MOTO - PUMP WITH CAPACITY OF 300 M³/H TO 350 MCW FOR WATER FEEDING OF BOILER • 01 TURBO-PUMP WITH CAPACITY OF 300 M³/H TO 350 MCW FOR WATER FEEDING OF BOILER • 02 MOTO-PUMPS WITH CAPACITY OF 220 M³/H TO 50 MCW FOR WET SCRUBBER OF BOILER NO. 2 • 03 MOTO - PUMPS OF 40 M³/H TO 300 MCW • 01 METALLIC RESERVOIR WITH 200 M³ OF CONDENSED WATER CAPACITY POWER GENERATION SECTOR THE POWER GENERATION SECTOR IS EQUIPPED WITH THE FOLLOWING MODERN AND AUTOMATED EQUIPMENT LISTED BELOW TO MEET A GRINDING OF 8400 TCD • 01 THREE - PHASE GENERATOR OF 6250 KVA – 13800 VOLTS – 60Hz • 01 TGM STEAM TURBINE MODEL TM - 5000 • 01 REDUCER RENK - ZANINI WITH CAPACITY OF 5000 KW • SEVERAL ELECTRICALS PANELS OF THE GENERATOR • 01 TURBO GENERATOR HOUSE BUILDING • 02 WATER COOLING TOWERS FOR THE TURBO-GENERATOR • 02 MOTO - PUMPS OF 100 M³/H TO 30 MCW SUGAR FACTORY THE SUGAR FACTORY WAS SET UP BETWEEN 2007 / 2008 AND COMPLETELY AUTOMATED WITH THE CONTROL BY THE SUPERVISORY INSTALLED IN THE CONTROL ROOM, PRODUCING AN AVERAGE OF 500000 KG OF VHP SUGAR PER DAY, A VALUE CORRESPONDING TO A MILLING OF 5000 TCD. THE TRANSPORT OF THIS SUGAR MANUFACTURED AT THE DECASA PLANT IS BEING TRANSPORTED BY MEANS OF A BUCKET VEHICLE WITH A DESTINATION INFORMED BY THE CUSTOMER. FOR THIS PLANT TO PRODUCE CRYSTAL SUGAR IC - 150, WE WILL NEED TO ACQUIRE AND ASSEMBLE THE FOLLOWING EQUIPMENT • SULFITATION EQUIPAMENT • BAGGING EQUIPMENT OF 50 KG BAGS • BUILD OR RENT AN INFLATABLE WAREHOUSE TO STORE SUGAR WITH THE INSTALLATION OF THIS EQUIPMENT, THE SUGAR FACTORY IS PREPARED TO RECEIVE A MILLING OF 5000 TCD CORRESPONDING TO A DAILY PRODUCTION OF 500000 KG OF CRYSTAL SUGAR IC - 150 PER DAY ALCOHOL DISTILLERY THE DISTILLERY WAS INSTALLED IN 1982 WITH A CAPACITY OF 300000 LITERS OF HYDRATED ALCOHOL PER DAY. WHEN THE FORMER OWNER'S UNIT WAS SOLD TO THE OLIVAL TENÓRIO GROUP IN 2003, THE NEW ENTREPRENEUR INVESTED IN THE MANUFACTURE OF ALCOHOL IN 2006 BY INSTALLING ANOTHER COLUMN OF DISTILLATION WITH A CAPACITY OF 300,000 LITERS AND AUTOMATED 100% INCREASING ITS PRODUCTION CAPACITY TO 600,000 LITERS OF HYDRATED ALCOHOL PER DAY • 02 TYPE “A” DISTILLATION COLUMNS WITH CAPACITY TO PRODUCE 300 M³ OF ALCOHOL / DAY • 02 TYPE “B” RECTIFICATION COLUMNS WITH CAPACITY FOR PRODUCTION OF 300 M³ OF ALCOHOL / DAY • 01 TYPE “A” DISTILLATION COLUMN WITH CAPACITY FOR PRODUCTION OF 300 M³ OF ALCOHOL / DAY • 01 TYPE “B” RECTIFICATION COLUMN WITH CAPACITY FOR PRODUCTION OF 300 M³ OF ALCOHOL / DAY • 09 TUBULAR HEAT EXCHANGERS TYPE “K” • 02 TUBULAR HEAT EXCHANGERS TYPE “J” • 02 TUBULAR HEAT EXCHANGERS TYPE “E” • 02 TUBULAR HEAT EXCHANGERS TYPE “E1” • 02 TUBULAR HEAT EXCHANGERS TYPE “E2” • 02 TUBULAR HEAT EXCHANGERS TYPE “R” • 02 TUBULAR HEAT EXCHANGERS TYPE “R1” • 11 NEW FERMENTATION VATS WITH A CAPACITY OF 300 M³ • 03 PLATE HEAT EXCHANGERS FOR THE WORT • 05 PLATE TYPE HEAT EXCHANGERS FOR VATS • 01 VAT FOR WINE • 01 CO₂ RECOVERY COLUMN • 02 PUMPS WITH A CAPACITY OF 600 M³ / H - 50 MCA FOR THE COOLING SYSTEM OF THE PLATE HEAT EXCHANGERS • 01 PUMP WITH A CAPACITY OF 800 M³ / H FOR THE COOLING SYSTEM OF THE PLATE HEAT EXCHANGERS • 02 CENTRÍFUGES HAD - 90 • 04 CENTRÍFUGES HAD - 60 WITH THE INSTALLATION OF THIS EQUIPMENT, THE ALCOHOL DISTILLERY IS PREPARED TO PRODUCE 600000 LITERS OF ALCOHOL PER DAY, RECEIVING A MILLING OF 6500 TCD CORRESPONDING TO 2500000 TONS OF CANE / YEAR Learn More

SUGAR AND ALCOHOL PLANTREFERENCE NUMBER: A-2511 SUGAR AND ALCOHOL PLANT CANE UNLOAD SECTOR THE CANE UNLOADING SECTOR IS EQUIPPED WITH THE EQUIPMENT LISTED BELOW IN THE CONDITION TO CARRY OUT A GRINDING OF 8400 TCD WHICH CORRESPONDS TO A HARVEST OF 1800000 TONNES OF CANE / YEAR • 01 HILO UNLOADER OF STORAGE • 01 HILO UNLOADER OF MILLING • 01 FEEDER SUGARCANE TABLE WITH INCLINATION OF 25 INCHES • 01 FEEDER SUGARCANE TABLE WITH INCLINATION OF 45 INCHES • 02 CRANES WITH CAPACITY OF 20 TONNES • 01 TRANSPORTER TYPE CUSCH - CUSH OF 40 INCHES • 02 MOTOR PUMP WITH CAPACITY OF 1000 M³/H TO 50 MCW FOR CANE WASHING • 01 CONTAMINATED FLUID TREATMENT SYSTEM • 01 METAL STRUCTURE BUILDING MEASURING 20000 X 100000 mm CANE PREPARATION SECTOR THE SUGARCANE PREPARATION SECTOR IS EQUIPPED WITH THE FOLLOWING AUTOMATED EQUIPMENT WITH THE CONTROL BY THE SUPERVISORY INSTALLED IN THE CONTROL ROOM AS SHOWN BELOW TO PERFORM A CRUSHING OF 7200 TCD WHICH CORRESPONDS TO A CROP OF 1600000 TONS OF SUGARCANE / YEAR • 01 METALLIC CONVEYOR OF 60 INCHES • 01 LEVELING OF CANE OF 60 INCHES • 01 CANE KNIVES SET TYPE COP-8 OF 60 INCHES • 01 CAN SHREDDER SET TYPE COP-5 OF 60 INCHES • 01 FEEDER ROLL 60 IINCHES • 01 RUBBER TRANSPORTER FOR CANE SHREDDED OF 60 INCHES • 01 TGM TURBINE FOR KNIVES SET • 01 TGM TURBINE FOR SHREDDER SET • 01 HIGH AND LOWER SPEED REDUCER OF KNIVES SET • 01 HIGH AND LOWER SPEED REDUCER OF SHREDDER SET • 01 REDUCER FOR METALLIC CONVEYOR • 01 REDUCER FOR FEEDER ROLL • 01 REDUCER OF SHREDDED CANE TRANSPORTER TYPE BELT MILLING CANE SECTOR THE CANE MILLING SECTOR OF THE PLANT IS EQUIPPED WITH THE FOLLOWING AUTOMATED EQUIPMENT WITH THE CONTROL BY THE SUPERVISORY INSTALLED IN THE CONTROL ROOM TO CARRY OUT A GRINDING OF 7200 TCD CORRESPONDING TO A 222 - DAY HARVEST TO GRIND 1600000 TONS. CANE / YEAR • 04 MILLS OF 32 X 60 INCHES • 03 INTERMIDIATE TRANSPORTER OF 60 INCHES • 01 ROTARY SIEVE FOR MILLING 300 TCD • 01 TGM TURBINE OF DRIVING THE 1º / 2º MILLS • 01 TGM TURBINE OF DRIVING OF 3º / 4º MILLS • 01 REDUCER OF HIGH AND LOW SPEED OF DRIVING THE 1º / 2º MILLS • 01 REDUCER OF HIGH AND LOW SPEED OF DRIVING THE 3º / 4º MILLS • 03 REDUCER INTERMEDIATE TRANSPORTER OF 60 INCHES • 02 PUMPS OF 1ST JUICE • 02 PUMPS OF JUICE IMBIBITION OF 3RD FOR 2ND MILL • 02 PUMPS OF JUICE IMBIBITION OF 4TH FOR 3RD MILLS • 02 PUMPS OF MIXED JUICE OF MILL FOR JUICE TREATMENT STEAM GENERATION SECTOR THE STEAM GENERATION SECTOR OF THE PLANT IS PREPARED TODAY TO PERFORM A 7200 TCD GRINDING CORRESPONDING TO A 220 - DAY HARVEST TO GRIND 1600000 TON. CANE / YEAR WITH THE FOLLOWING AUTOMATED EQUIPMENT WITH CONTROL BY THE SUPERVISORY INSTALLED IN THE CONTROL ROOM AS SHOWN BELOW • 01 BOILER N ° 01, MODEL: TS-3-150 MODIFIED FOR CBS-120-21 KG / CM² TODAY GENERATES AN AVERAGE OF 11000 KG / HR OF STEAM AT A PRESSURE OF 21 KG / CM² • 01 BOILER N ° 02, MODEL: TS-3-150-21 KG / CM² TODAY GENERATES AN AVERAGE OF 55000 KG / HR OF STEAM AT A PRESSURE OF 21 KG / CM² • 01 DEAERATOR WITH A CAPACITY OF 70 M³ • 01 78 INCHES BAGASSE METALLIC TRANSPORTER OF 32000 mm LENGTH • 01 48 INCHES BAGASSE TRANSPORTER FROM MILL TO BOILER • 01 48 INCHES BAGASSE RETURN TRANSPORTER FOR BOILER • 01 REDUCER OF BAGASSE TRANSPORTER FROM MILL TOBOILER • 01 REDUCER OF BAGASSE RETURN TRANSPORTER TOBOILER • 02 MOTO - PUMPS OF WATER FEEDING OF DEAERATOR • 02 MOTO - PUMPS OF WATER TREATMENT OF BOILER • 01 MOTO - PUMP WITH CAPACITY OF 300 M³/H TO 350 MCW FOR WATER FEEDING OF BOILER • 01 TURBO-PUMP WITH CAPACITY OF 300 M³/H TO 350 MCW FOR WATER FEEDING OF BOILER • 02 MOTO-PUMPS WITH CAPACITY OF 220 M³/H TO 50 MCW FOR WET SCRUBBER OF BOILER NO. 2 • 03 MOTO - PUMPS OF 40 M³/H TO 300 MCW • 01 METALLIC RESERVOIR WITH 200 M³ OF CONDENSED WATER CAPACITY POWER GENERATION SECTOR THE POWER GENERATION SECTOR IS EQUIPPED WITH THE FOLLOWING MODERN AND AUTOMATED EQUIPMENT LISTED BELOW TO MEET A GRINDING OF 8400 TCD • 01 THREE - PHASE GENERATOR OF 6250 KVA – 13800 VOLTS – 60Hz • 01 TGM STEAM TURBINE MODEL TM - 5000 • 01 REDUCER RENK - ZANINI WITH CAPACITY OF 5000 KW • SEVERAL ELECTRICALS PANELS OF THE GENERATOR • 01 TURBO GENERATOR HOUSE BUILDING • 02 WATER COOLING TOWERS FOR THE TURBO-GENERATOR • 02 MOTO - PUMPS OF 100 M³/H TO 30 MCW SUGAR FACTORY THE SUGAR FACTORY WAS SET UP BETWEEN 2007 / 2008 AND COMPLETELY AUTOMATED WITH THE CONTROL BY THE SUPERVISORY INSTALLED IN THE CONTROL ROOM, PRODUCING AN AVERAGE OF 500000 KG OF VHP SUGAR PER DAY, A VALUE CORRESPONDING TO A MILLING OF 5000 TCD. THE TRANSPORT OF THIS SUGAR MANUFACTURED AT THE DECASA PLANT IS BEING TRANSPORTED BY MEANS OF A BUCKET VEHICLE WITH A DESTINATION INFORMED BY THE CUSTOMER. FOR THIS PLANT TO PRODUCE CRYSTAL SUGAR IC - 150, WE WILL NEED TO ACQUIRE AND ASSEMBLE THE FOLLOWING EQUIPMENT • SULFITATION EQUIPAMENT • BAGGING EQUIPMENT OF 50 KG BAGS • BUILD OR RENT AN INFLATABLE WAREHOUSE TO STORE SUGAR WITH THE INSTALLATION OF THIS EQUIPMENT, THE SUGAR FACTORY IS PREPARED TO RECEIVE A MILLING OF 5000 TCD CORRESPONDING TO A DAILY PRODUCTION OF 500000 KG OF CRYSTAL SUGAR IC - 150 PER DAY ALCOHOL DISTILLERY THE DISTILLERY WAS INSTALLED IN 1982 WITH A CAPACITY OF 300000 LITERS OF HYDRATED ALCOHOL PER DAY. WHEN THE FORMER OWNER'S UNIT WAS SOLD TO THE OLIVAL TENÓRIO GROUP IN 2003, THE NEW ENTREPRENEUR INVESTED IN THE MANUFACTURE OF ALCOHOL IN 2006 BY INSTALLING ANOTHER COLUMN OF DISTILLATION WITH A CAPACITY OF 300,000 LITERS AND AUTOMATED 100% INCREASING ITS PRODUCTION CAPACITY TO 600,000 LITERS OF HYDRATED ALCOHOL PER DAY • 02 TYPE “A” DISTILLATION COLUMNS WITH CAPACITY TO PRODUCE 300 M³ OF ALCOHOL / DAY • 02 TYPE “B” RECTIFICATION COLUMNS WITH CAPACITY FOR PRODUCTION OF 300 M³ OF ALCOHOL / DAY • 01 TYPE “A” DISTILLATION COLUMN WITH CAPACITY FOR PRODUCTION OF 300 M³ OF ALCOHOL / DAY • 01 TYPE “B” RECTIFICATION COLUMN WITH CAPACITY FOR PRODUCTION OF 300 M³ OF ALCOHOL / DAY • 09 TUBULAR HEAT EXCHANGERS TYPE “K” • 02 TUBULAR HEAT EXCHANGERS TYPE “J” • 02 TUBULAR HEAT EXCHANGERS TYPE “E” • 02 TUBULAR HEAT EXCHANGERS TYPE “E1” • 02 TUBULAR HEAT EXCHANGERS TYPE “E2” • 02 TUBULAR HEAT EXCHANGERS TYPE “R” • 02 TUBULAR HEAT EXCHANGERS TYPE “R1” • 11 NEW FERMENTATION VATS WITH A CAPACITY OF 300 M³ • 03 PLATE HEAT EXCHANGERS FOR THE WORT • 05 PLATE TYPE HEAT EXCHANGERS FOR VATS • 01 VAT FOR WINE • 01 CO₂ RECOVERY COLUMN • 02 PUMPS WITH A CAPACITY OF 600 M³ / H - 50 MCA FOR THE COOLING SYSTEM OF THE PLATE HEAT EXCHANGERS • 01 PUMP WITH A CAPACITY OF 800 M³ / H FOR THE COOLING SYSTEM OF THE PLATE HEAT EXCHANGERS • 02 CENTRÍFUGES HAD - 90 • 04 CENTRÍFUGES HAD - 60 WITH THE INSTALLATION OF THIS EQUIPMENT, THE ALCOHOL DISTILLERY IS PREPARED TO PRODUCE 600000 LITERS OF ALCOHOL PER DAY, RECEIVING A MILLING OF 6500 TCD CORRESPONDING TO 2500000 TONS OF CANE / YEAR Learn More