Search results for: 'pillows'

-

M-1456 COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATEDREFERENCE NUMBER: M-1456 (660211BTC5R) COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATED QUANTITY AVAILABLE: 1 Learn More

M-1456 COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATEDREFERENCE NUMBER: M-1456 (660211BTC5R) COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATED QUANTITY AVAILABLE: 1 Learn More -

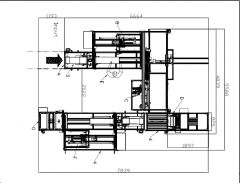

E-9988 AUTOMATIC PILLOW MACHINEREFERENC ENUMBER: E-9988 AUTOMATIC PILLOW MACHINE MODEL: CF INSTALLATION AREA: 9000 X 5000 X 2100mm (29.5 FEET X 16.4 FEET X 82 INCHES) MIXING CHAMBER SIZE: AROUND 300KG (600 LBS) VOLTAGE: AS PER CUSTOMER REQUIREMENT POWER: 11.8KW CAPACITY: 6 PILLOWS PER MINUTE WEIGHING: ACCORDING TO THE TIME OF FILLING DISCHARGE. WEIGHT: 1.8MT (4000 LBS) LABOR: 1 OPERATOR CONTROL SYSTEM: COMPUTERIZED CONTROL SYSTEM QUANTITY AVAILABLE: 1 Learn More

E-9988 AUTOMATIC PILLOW MACHINEREFERENC ENUMBER: E-9988 AUTOMATIC PILLOW MACHINE MODEL: CF INSTALLATION AREA: 9000 X 5000 X 2100mm (29.5 FEET X 16.4 FEET X 82 INCHES) MIXING CHAMBER SIZE: AROUND 300KG (600 LBS) VOLTAGE: AS PER CUSTOMER REQUIREMENT POWER: 11.8KW CAPACITY: 6 PILLOWS PER MINUTE WEIGHING: ACCORDING TO THE TIME OF FILLING DISCHARGE. WEIGHT: 1.8MT (4000 LBS) LABOR: 1 OPERATOR CONTROL SYSTEM: COMPUTERIZED CONTROL SYSTEM QUANTITY AVAILABLE: 1 Learn More -

E-4401-B NEW PILLOW OR CUSHION FILLING MACHINES (1 NOZZLE) FOR FIBER OR SHREDDED FOAMINVENTORY NUMBER: E-4401-B NEW PILLOW OR CUSHION FILLING MACHINES (1 NOZZLE) FOR FIBER OR SHREDDED FOAM MODEL: 1013 FOR POLYESTER STAPLE FIBER OPENING AND FILLING INTO UPHOLSTERY CUSHIONS OR PILLOWS. QUANTITY AVAILABLE: 1 Learn More

E-4401-B NEW PILLOW OR CUSHION FILLING MACHINES (1 NOZZLE) FOR FIBER OR SHREDDED FOAMINVENTORY NUMBER: E-4401-B NEW PILLOW OR CUSHION FILLING MACHINES (1 NOZZLE) FOR FIBER OR SHREDDED FOAM MODEL: 1013 FOR POLYESTER STAPLE FIBER OPENING AND FILLING INTO UPHOLSTERY CUSHIONS OR PILLOWS. QUANTITY AVAILABLE: 1 Learn More -

E-4401-A NEW PILLOW FILLING MACHINES (2 NOZZLE)INVENTORY NUMBER: E-4401-A NEW PILLOW FILLING MACHINES (2 NOZZLE) MODEL: 1013 FOR POLYESTER STAPLE FIBER OPENING AND FILLING INTO UPHOLSTERY CUSHIONS OR PILLOWS. QUANTITY AVAILABLE: 1 Learn More

E-4401-A NEW PILLOW FILLING MACHINES (2 NOZZLE)INVENTORY NUMBER: E-4401-A NEW PILLOW FILLING MACHINES (2 NOZZLE) MODEL: 1013 FOR POLYESTER STAPLE FIBER OPENING AND FILLING INTO UPHOLSTERY CUSHIONS OR PILLOWS. QUANTITY AVAILABLE: 1 Learn More -

V-1288 MERELLO ME-305 PILLOW & QUILTS PACKAGING SYSTEM, 10 to 12 UNITS PER MINUTE YEAR 2009

V-1288 MERELLO ME-305 PILLOW & QUILTS PACKAGING SYSTEM, 10 to 12 UNITS PER MINUTE YEAR 2009REFERENCE NUMBER: V-1288

MERELLO ME-305PILLOW & QUILTS PACKAGING SYSTEM, 10 to 12 UNITS PER MINUTE YEAR 2009

WRAPS PILLOWS AND CUSHIONS BETWEEN 35X35 AND 150X70cm IN POLYETHYLENE TUBE, WITHOUT LATERAL SEALS

HIGH QUALITY BAGS, MORE ESTHETICAL AND VERY WELL ADJUSTED. INCLUDES OPTIONAL PRINTER FOR LABELS DIRECTLY ON THE BAG, PUNCHES HANDLES AND DETECTS CENTERED LOGOS. MINIMUM WASTE, ENERGY SAVINGS.

AUTOMATIC CYCLE: IN-FEED, WRAPPING, COMPRESSION AND SEALING. EASY AND FAST CHANGE OF THE ROLL, MÁX. ROLL: 500 mm.. CYCLE CONTROLLED BY PLC WITH TOUCH SCREEN. SURFACE OCCUPATION: 4.5X2M (EXTRA BIG DIMENSIONS AVAILABLE AS OPTION).

HIGH PRODUCTIVITY: 10/12 UNITS PER MINUTE

WELL-ENGINEERED MACHINE FOR FLATTENING AND WRAPPING CUSHIONS FOR “FLAT PACK” OPERATIONS

THIS IS IDEAL FOR STORING AND SHIPPING PILLOWS AND CUSHIONS IN A MINIMAL AMOUNT OF SPACE

AUTOMATICALLY WRAPS EVERY TYPE OF PILLOW BETWEEN 40CM x 40CM (16”x16”) TO 110CM x 80CM (42”x32”)

CYCLES UP TO 8 PER MINUTE

AUTOMATICALLY ADJUSTS TO VARYING SIZES

PLASTIC ROLLS ARE EASILY CHANGES

THE MACHINE FORMS A TUBE STYLE BAG FROM A POLYETHYLENE ROLL, WITH PERFECT SIZE ADJUSTMENT AND REQUIRES NO LATERAL SEALING. CHANGING THE POLYETHYLENE ROLL IS FAST AND EASY, AND DIFFERENT SIZES CAN BE USED WITHOUT ADJUSTMENT

CUTS ARE MADE BY A MAINTENANCE-FREE, SMOKELESS COLD BLADE

A TOUCH SCREEN PLC CONTROL DISPLAYS INPUT PARAMETERS AND CYCLE INFORMATION

ELECTRONIC INVERTER ENABLES SMOOTH MOTORIZED MOVEMENTS

OPTIONAL VIDEO JET THERMAL PRINTER CAN PRINT PRODUCT DATA AND BAR CODES DIRECTLY ON FINISHED PACKAGE

MACHINE DIMENSIONS ARE: 4.5M x 2M (14.75’ x 6.5’)

SAVES SPACE AND MATERIAL EXPENSE BY EXTRACTING AIR FROM THE BAG DURING PACKAGING PROCESS

QUANTITY: 1

Learn More -

G-2253 PILLOW & CUSHION AUTOMATIC WEIGHING & FILLING LINEREFERENCE NUMBER: G-2253 PILLOW & CUSHION AUTOMATIC WEIGHING & FILLING LINE FOR SALE: (5 PILLOWS PER MINUTE) FIBER OPENING, ACCURATE WEIGHING BY WEIGH PAN WITH LOAD CELL AND HIGH SPEED FILLING SYSTEM TOUCH SCREEN PANEL, FULLY AUTOMATED AND ACCURATE HANDLES WEIGHTS OF PILLOWS: FROM 150g TO 1500g PRODUCTION RATE: 5 PIECES PER MIN, 2400 PIECES PER 8 HOURS METAL DETECTOR AND OVERLOAD ALARM INCLUDES FIBER OPENING MACHINE ONE PERSON CAN RUN WHOLE LINE TWO HEAD FILLING MACHINE WITH PATTING DEVICES OPTIONAL: VACUUM FILLING TABLE QUANTITY AVAILABLE: 1 Learn More

G-2253 PILLOW & CUSHION AUTOMATIC WEIGHING & FILLING LINEREFERENCE NUMBER: G-2253 PILLOW & CUSHION AUTOMATIC WEIGHING & FILLING LINE FOR SALE: (5 PILLOWS PER MINUTE) FIBER OPENING, ACCURATE WEIGHING BY WEIGH PAN WITH LOAD CELL AND HIGH SPEED FILLING SYSTEM TOUCH SCREEN PANEL, FULLY AUTOMATED AND ACCURATE HANDLES WEIGHTS OF PILLOWS: FROM 150g TO 1500g PRODUCTION RATE: 5 PIECES PER MIN, 2400 PIECES PER 8 HOURS METAL DETECTOR AND OVERLOAD ALARM INCLUDES FIBER OPENING MACHINE ONE PERSON CAN RUN WHOLE LINE TWO HEAD FILLING MACHINE WITH PATTING DEVICES OPTIONAL: VACUUM FILLING TABLE QUANTITY AVAILABLE: 1 Learn More -

E-4401 NEW PILLOW FILLING MACHINES (2 NOZZLE) FOR SALEINVENTORY NUMBER: E-4401 NEW PILLOW FILLING MACHINES (2 NOZZLE) FOR SALE: MODEL: 1013 (PICTURES AVAILABLE) FOR POLYESTER STAPLE FIBER OPENING AND FILLING INTO UPHOLSTERY CUSHIONS OR PILLOWS. WITH A MIXING CHAMBER IN WHICH THE UPHOLSTERY MANUFACTURER CAN ADD OTHER MATERIALS, SUCH AS FOAM PIECES, FEATHERS, WOOL FIBERS INTO THE PILLOWS OR CUSHIONS DURING FILLING. MODEL 1013 TECHNICAL DESCRIPTION: WIDTH OF THE FINE OPENER: 560 MM (CYLINDER WIDTH) DRUM DIAMETER OF THE FINE OPENER: BIG CYLINDER: 320 MM (1 PCS) SMALL CYLINDER: 56MM (9 PCS) PRINCIPLE OF FILLING UNIT: BLOWING FLOOR SPACE REQUIRED: ABOUT 9.5 SQUARE METERS TOTAL INSTALLED POWER: 13.95 KW AIR CONSUMPTION: <0.5 MPA (FOR EACH FILLING) ELECTRONIC COMPONENTS- MAKE AND TYPE: ALL THE ELECTRONIC COMPONETS ARE SCHNEIDER (BRAND) CAPACITY: 120-150KG/HOUR FIBER OPENER 1001-560 BELT WIDTH: 560 MM DIMENSIONS (MM) (LXWXH): 2050 X 900 X 940 POWER: 4.75 KW NET WEIGHT: 600 KG CAPACITY: 120 - 150 KG/HR VOLTAGE: AS PER CUSTOMER TRANSFER FAN 503 DIMENSIONS (MM) (LXWXH): 610 X 520 X 800 POWER: 2.2 KW NET WEIGHT: 75 KG CAPACITY: 120 - 150 KG/HR VOLTAGE: AS PER CUSTOMER MIXING MACHINE 1003-B DIMENSIONS (MM) (LXWXH): 1840 X 1100 X 1680 POWER: 4 KW NET WEIGHT: 400 KG CAPACITY: 120 - 150 KG/HR VOLTAGE: AS PER CUSTOMER FILLING STATION (FAN) 502 DIMENSIONS (MM) (LXWXH): 850 X 540 X 960 POWER: 1.5 KW NET WEIGHT: 70 KG CAPACITY: 120 - 150 KG/HR VOLTAGE: AS PER CUSTOMER AIR PRESSURE: <0.5 MPA MODEL 1013: (4 COMPONENTS) A) FIBER OPENER: B) TRANSFER FAN: C) MIXING CHAMBER: D) FILLING STATION (FAN): E) SECOND FILLING STATION: Learn More

E-4401 NEW PILLOW FILLING MACHINES (2 NOZZLE) FOR SALEINVENTORY NUMBER: E-4401 NEW PILLOW FILLING MACHINES (2 NOZZLE) FOR SALE: MODEL: 1013 (PICTURES AVAILABLE) FOR POLYESTER STAPLE FIBER OPENING AND FILLING INTO UPHOLSTERY CUSHIONS OR PILLOWS. WITH A MIXING CHAMBER IN WHICH THE UPHOLSTERY MANUFACTURER CAN ADD OTHER MATERIALS, SUCH AS FOAM PIECES, FEATHERS, WOOL FIBERS INTO THE PILLOWS OR CUSHIONS DURING FILLING. MODEL 1013 TECHNICAL DESCRIPTION: WIDTH OF THE FINE OPENER: 560 MM (CYLINDER WIDTH) DRUM DIAMETER OF THE FINE OPENER: BIG CYLINDER: 320 MM (1 PCS) SMALL CYLINDER: 56MM (9 PCS) PRINCIPLE OF FILLING UNIT: BLOWING FLOOR SPACE REQUIRED: ABOUT 9.5 SQUARE METERS TOTAL INSTALLED POWER: 13.95 KW AIR CONSUMPTION: <0.5 MPA (FOR EACH FILLING) ELECTRONIC COMPONENTS- MAKE AND TYPE: ALL THE ELECTRONIC COMPONETS ARE SCHNEIDER (BRAND) CAPACITY: 120-150KG/HOUR FIBER OPENER 1001-560 BELT WIDTH: 560 MM DIMENSIONS (MM) (LXWXH): 2050 X 900 X 940 POWER: 4.75 KW NET WEIGHT: 600 KG CAPACITY: 120 - 150 KG/HR VOLTAGE: AS PER CUSTOMER TRANSFER FAN 503 DIMENSIONS (MM) (LXWXH): 610 X 520 X 800 POWER: 2.2 KW NET WEIGHT: 75 KG CAPACITY: 120 - 150 KG/HR VOLTAGE: AS PER CUSTOMER MIXING MACHINE 1003-B DIMENSIONS (MM) (LXWXH): 1840 X 1100 X 1680 POWER: 4 KW NET WEIGHT: 400 KG CAPACITY: 120 - 150 KG/HR VOLTAGE: AS PER CUSTOMER FILLING STATION (FAN) 502 DIMENSIONS (MM) (LXWXH): 850 X 540 X 960 POWER: 1.5 KW NET WEIGHT: 70 KG CAPACITY: 120 - 150 KG/HR VOLTAGE: AS PER CUSTOMER AIR PRESSURE: <0.5 MPA MODEL 1013: (4 COMPONENTS) A) FIBER OPENER: B) TRANSFER FAN: C) MIXING CHAMBER: D) FILLING STATION (FAN): E) SECOND FILLING STATION: Learn More -

YY-2169 PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE, PILLOW COVER PACKING MACHINE WITH CONVEYOR FEEED AND TAKE OFFYY-2169 PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE, PILLOW COVER PACKING MACHINE WITH CONVEYOR FEEED AND TAKE OFF DETAILS: ITEM 001 PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE THIS MACHINE IS USED FOR PILLOWS, CUSHIONS AUTOMATICALLY PACKAGE. QUANTITY: 1 ITEM 002 PILLOW COVER PACKING MACHINE QUANTITY: 1 NOTE: THE PILLOW COVER PACKING MACHINE IS USUALLY WORKED TOGETHER WITH THE PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE. Learn More

YY-2169 PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE, PILLOW COVER PACKING MACHINE WITH CONVEYOR FEEED AND TAKE OFFYY-2169 PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE, PILLOW COVER PACKING MACHINE WITH CONVEYOR FEEED AND TAKE OFF DETAILS: ITEM 001 PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE THIS MACHINE IS USED FOR PILLOWS, CUSHIONS AUTOMATICALLY PACKAGE. QUANTITY: 1 ITEM 002 PILLOW COVER PACKING MACHINE QUANTITY: 1 NOTE: THE PILLOW COVER PACKING MACHINE IS USUALLY WORKED TOGETHER WITH THE PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE. Learn More -

J-4091 2 NOZZLE LARGE PILLOW FILLING MACHINE FOR DOWN AND FIBER – NEWJ-40912 NOZZLE LARGE PILLOW FILLING MACHINE FOR DOWN AND FIBER – NEW MAXIMUM THEORETICAL PRODUCTION: 900 KGS PER NOZZLE PER HOUR ACTUAL/PRACTICAL PRODUCTION: 450 KGS PER NOZZLE PER HOUR (FOR A 2 NOZZLE MACHINE THE REALISTIC PRODUCTION IS 900 KGS PER HOUR TOTAL) QUANTITY: 1 Learn More

J-4091 2 NOZZLE LARGE PILLOW FILLING MACHINE FOR DOWN AND FIBER – NEWJ-40912 NOZZLE LARGE PILLOW FILLING MACHINE FOR DOWN AND FIBER – NEW MAXIMUM THEORETICAL PRODUCTION: 900 KGS PER NOZZLE PER HOUR ACTUAL/PRACTICAL PRODUCTION: 450 KGS PER NOZZLE PER HOUR (FOR A 2 NOZZLE MACHINE THE REALISTIC PRODUCTION IS 900 KGS PER HOUR TOTAL) QUANTITY: 1 Learn More -

ORMONT FIBER FILLING MACHINEREFERENCE NUMBER: T-6865 ORMONT FIBER FILLING MACHINE ORMONT FIBER FILLING MACHINE TYPE TP-02 SIZE 5 OPERATING ON 240/2 PHASE MOTOR SPEED 1800 RPM WITH 30” CONVEYOR FEED WIDTH USED FOR FILLING SMALL DECORATIVE PILLOWS QUANTITY: 1 Learn More

ORMONT FIBER FILLING MACHINEREFERENCE NUMBER: T-6865 ORMONT FIBER FILLING MACHINE ORMONT FIBER FILLING MACHINE TYPE TP-02 SIZE 5 OPERATING ON 240/2 PHASE MOTOR SPEED 1800 RPM WITH 30” CONVEYOR FEED WIDTH USED FOR FILLING SMALL DECORATIVE PILLOWS QUANTITY: 1 Learn More