Search results for: 'Machin'

- Related search terms

- Machine c

- machine''

- MACHINE S

- machine''''

- machine de''

-

MASIAS PILLOW FILLING MACHINEMODEL: PESFIBRE 1 YEAR: 1997 COUNTRY OF ORIGIN: SPAIN COMPOSED OF: -FIBER OPENER MODEL DF 500-T WITH FEED -ELECTRONIC CONTROL WITH WEIGH UNIT AND FILLING STATION COMPOSED OF: -FIBER HOLD -FIBER OPENING AND FEED -WEIGHING CONVEYOR -FILLING STATION -TRANSPORT FAN PRODUCTION ON POLYESTER FIBER IS 180lbs/hour APPROX. (PICTURES AVAILABLE) QUANTITY: 1 PRICE: US$55,000.00 REDUCED PRICE: US$38,000.00 NEW REDUCED PRICE: US$36,000.00 Learn More

MASIAS PILLOW FILLING MACHINEMODEL: PESFIBRE 1 YEAR: 1997 COUNTRY OF ORIGIN: SPAIN COMPOSED OF: -FIBER OPENER MODEL DF 500-T WITH FEED -ELECTRONIC CONTROL WITH WEIGH UNIT AND FILLING STATION COMPOSED OF: -FIBER HOLD -FIBER OPENING AND FEED -WEIGHING CONVEYOR -FILLING STATION -TRANSPORT FAN PRODUCTION ON POLYESTER FIBER IS 180lbs/hour APPROX. (PICTURES AVAILABLE) QUANTITY: 1 PRICE: US$55,000.00 REDUCED PRICE: US$38,000.00 NEW REDUCED PRICE: US$36,000.00 Learn More -

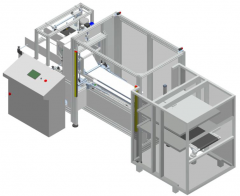

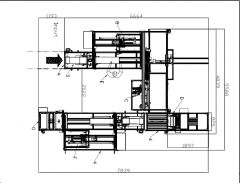

G-6926 SYSTEM FOR THE PRODUCTION OF PILLOWS AND FURNISHING CUSHIONSREFERENCE NUMBER: G-6926 SYSTEM FOR THE PRODUCTION OF PILLOWS AND FURNISHING CUSHIONS QUANTITY AVAILABLE: 1 Learn More

G-6926 SYSTEM FOR THE PRODUCTION OF PILLOWS AND FURNISHING CUSHIONSREFERENCE NUMBER: G-6926 SYSTEM FOR THE PRODUCTION OF PILLOWS AND FURNISHING CUSHIONS QUANTITY AVAILABLE: 1 Learn More -

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More -

G-2254 PILLOW & CUSHION FILLING LINE: CARDED FIBER SYSTEMREFERENCE NUMBER: G-2254 PILLOW & CUSHION FILLING LINE: (CARDED FIBER SYSTEM) COMPUTERIZED CONTROL SYSTEM WITH FIBER CARDING, FIBER ROLLING, AUTOMATIC FILLING AND ADJUSTABLE FIBER WEIGHT CONTROLS INCLUDES METAL DETECTOR AND OVERLOAD ALARM ROLLING FILLING MACHINE QUANTITY AVAILABLE: 1 Learn More

G-2254 PILLOW & CUSHION FILLING LINE: CARDED FIBER SYSTEMREFERENCE NUMBER: G-2254 PILLOW & CUSHION FILLING LINE: (CARDED FIBER SYSTEM) COMPUTERIZED CONTROL SYSTEM WITH FIBER CARDING, FIBER ROLLING, AUTOMATIC FILLING AND ADJUSTABLE FIBER WEIGHT CONTROLS INCLUDES METAL DETECTOR AND OVERLOAD ALARM ROLLING FILLING MACHINE QUANTITY AVAILABLE: 1 Learn More -

V-1288 MERELLO ME-305 PILLOW & QUILTS PACKAGING SYSTEM, 10 to 12 UNITS PER MINUTE YEAR 2009

V-1288 MERELLO ME-305 PILLOW & QUILTS PACKAGING SYSTEM, 10 to 12 UNITS PER MINUTE YEAR 2009REFERENCE NUMBER: V-1288

MERELLO ME-305PILLOW & QUILTS PACKAGING SYSTEM, 10 to 12 UNITS PER MINUTE YEAR 2009

WRAPS PILLOWS AND CUSHIONS BETWEEN 35X35 AND 150X70cm IN POLYETHYLENE TUBE, WITHOUT LATERAL SEALS

HIGH QUALITY BAGS, MORE ESTHETICAL AND VERY WELL ADJUSTED. INCLUDES OPTIONAL PRINTER FOR LABELS DIRECTLY ON THE BAG, PUNCHES HANDLES AND DETECTS CENTERED LOGOS. MINIMUM WASTE, ENERGY SAVINGS.

AUTOMATIC CYCLE: IN-FEED, WRAPPING, COMPRESSION AND SEALING. EASY AND FAST CHANGE OF THE ROLL, MÁX. ROLL: 500 mm.. CYCLE CONTROLLED BY PLC WITH TOUCH SCREEN. SURFACE OCCUPATION: 4.5X2M (EXTRA BIG DIMENSIONS AVAILABLE AS OPTION).

HIGH PRODUCTIVITY: 10/12 UNITS PER MINUTE

WELL-ENGINEERED MACHINE FOR FLATTENING AND WRAPPING CUSHIONS FOR “FLAT PACK” OPERATIONS

THIS IS IDEAL FOR STORING AND SHIPPING PILLOWS AND CUSHIONS IN A MINIMAL AMOUNT OF SPACE

AUTOMATICALLY WRAPS EVERY TYPE OF PILLOW BETWEEN 40CM x 40CM (16”x16”) TO 110CM x 80CM (42”x32”)

CYCLES UP TO 8 PER MINUTE

AUTOMATICALLY ADJUSTS TO VARYING SIZES

PLASTIC ROLLS ARE EASILY CHANGES

THE MACHINE FORMS A TUBE STYLE BAG FROM A POLYETHYLENE ROLL, WITH PERFECT SIZE ADJUSTMENT AND REQUIRES NO LATERAL SEALING. CHANGING THE POLYETHYLENE ROLL IS FAST AND EASY, AND DIFFERENT SIZES CAN BE USED WITHOUT ADJUSTMENT

CUTS ARE MADE BY A MAINTENANCE-FREE, SMOKELESS COLD BLADE

A TOUCH SCREEN PLC CONTROL DISPLAYS INPUT PARAMETERS AND CYCLE INFORMATION

ELECTRONIC INVERTER ENABLES SMOOTH MOTORIZED MOVEMENTS

OPTIONAL VIDEO JET THERMAL PRINTER CAN PRINT PRODUCT DATA AND BAR CODES DIRECTLY ON FINISHED PACKAGE

MACHINE DIMENSIONS ARE: 4.5M x 2M (14.75’ x 6.5’)

SAVES SPACE AND MATERIAL EXPENSE BY EXTRACTING AIR FROM THE BAG DURING PACKAGING PROCESS

QUANTITY: 1

Learn More -

P-1232 NOWO BLOW FIBRE FILLING LINES YEAR 2004/2006 CYCLONE WITH 2 DUST BAGSREFERENCE NUMBER: P-1232 NOWO BLOW FIBRE FILLING LINES YEAR 2004/2006 CYCLONE WITH 2 DUST BAGS NOWO BLOW FIBRE FILLING LINES YEAR: 2004 CYCLONE WITH 2 DUST BAGS SILO IMS500 SPRAY 50 BALL FIBRE MACHINE EXCLUDING CONTROL PLC AND SCREEN – AVAILABLE FOR EXTRA COST LINE 1 SILO 500-3 YEAR 2004 WEIGHING UNIT YEAR 2004 BLOW FILLING STATION WITH TABLE LINE 2 SUITABLE FOR FEATHER AND FIBRE SILO IMS 1000 YEAR 2006 WEIGHING UNIT YEAR 2004 BLOWING STATION WITH TABLE BLENDING MACHINE MIXING CHAMBER BS 8 FOR FEATHER and POLYESTER YEAR 2006 FIRE RETARDANT APPLICATOR * THE BALL FIBRE MACHINE (ROTOR AND CYCLONE) INCLUDES THE PANEL BUT EXCLUDES THE TOUCH SCREEN AND PLC AS THESE CONTROL ANOTHER ROTOR WHICH THE CUSTOMER IS RETAINING. WE CAN SUPPLY A NEW PLC AND SCREEN (EXTRA PRICE) OR YOU CAN DO IT IN-HOUSE IT DOES NOT INCLUDE A BALE OPENER OR PRE-OPENER QUANTITY AVAILABLE: 1 Learn More

P-1232 NOWO BLOW FIBRE FILLING LINES YEAR 2004/2006 CYCLONE WITH 2 DUST BAGSREFERENCE NUMBER: P-1232 NOWO BLOW FIBRE FILLING LINES YEAR 2004/2006 CYCLONE WITH 2 DUST BAGS NOWO BLOW FIBRE FILLING LINES YEAR: 2004 CYCLONE WITH 2 DUST BAGS SILO IMS500 SPRAY 50 BALL FIBRE MACHINE EXCLUDING CONTROL PLC AND SCREEN – AVAILABLE FOR EXTRA COST LINE 1 SILO 500-3 YEAR 2004 WEIGHING UNIT YEAR 2004 BLOW FILLING STATION WITH TABLE LINE 2 SUITABLE FOR FEATHER AND FIBRE SILO IMS 1000 YEAR 2006 WEIGHING UNIT YEAR 2004 BLOWING STATION WITH TABLE BLENDING MACHINE MIXING CHAMBER BS 8 FOR FEATHER and POLYESTER YEAR 2006 FIRE RETARDANT APPLICATOR * THE BALL FIBRE MACHINE (ROTOR AND CYCLONE) INCLUDES THE PANEL BUT EXCLUDES THE TOUCH SCREEN AND PLC AS THESE CONTROL ANOTHER ROTOR WHICH THE CUSTOMER IS RETAINING. WE CAN SUPPLY A NEW PLC AND SCREEN (EXTRA PRICE) OR YOU CAN DO IT IN-HOUSE IT DOES NOT INCLUDE A BALE OPENER OR PRE-OPENER QUANTITY AVAILABLE: 1 Learn More -

M-1456 COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATEDREFERENCE NUMBER: M-1456 (660211BTC5R) COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATED QUANTITY AVAILABLE: 1 Learn More

M-1456 COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATEDREFERENCE NUMBER: M-1456 (660211BTC5R) COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATED QUANTITY AVAILABLE: 1 Learn More -

G-2253 PILLOW & CUSHION AUTOMATIC WEIGHING & FILLING LINEREFERENCE NUMBER: G-2253 PILLOW & CUSHION AUTOMATIC WEIGHING & FILLING LINE FOR SALE: (5 PILLOWS PER MINUTE) FIBER OPENING, ACCURATE WEIGHING BY WEIGH PAN WITH LOAD CELL AND HIGH SPEED FILLING SYSTEM TOUCH SCREEN PANEL, FULLY AUTOMATED AND ACCURATE HANDLES WEIGHTS OF PILLOWS: FROM 150g TO 1500g PRODUCTION RATE: 5 PIECES PER MIN, 2400 PIECES PER 8 HOURS METAL DETECTOR AND OVERLOAD ALARM INCLUDES FIBER OPENING MACHINE ONE PERSON CAN RUN WHOLE LINE TWO HEAD FILLING MACHINE WITH PATTING DEVICES OPTIONAL: VACUUM FILLING TABLE QUANTITY AVAILABLE: 1 Learn More

G-2253 PILLOW & CUSHION AUTOMATIC WEIGHING & FILLING LINEREFERENCE NUMBER: G-2253 PILLOW & CUSHION AUTOMATIC WEIGHING & FILLING LINE FOR SALE: (5 PILLOWS PER MINUTE) FIBER OPENING, ACCURATE WEIGHING BY WEIGH PAN WITH LOAD CELL AND HIGH SPEED FILLING SYSTEM TOUCH SCREEN PANEL, FULLY AUTOMATED AND ACCURATE HANDLES WEIGHTS OF PILLOWS: FROM 150g TO 1500g PRODUCTION RATE: 5 PIECES PER MIN, 2400 PIECES PER 8 HOURS METAL DETECTOR AND OVERLOAD ALARM INCLUDES FIBER OPENING MACHINE ONE PERSON CAN RUN WHOLE LINE TWO HEAD FILLING MACHINE WITH PATTING DEVICES OPTIONAL: VACUUM FILLING TABLE QUANTITY AVAILABLE: 1 Learn More -

V-1187 FIBERFILL (WADDING) GARNETT LINE AND OVER PILLOW FILLER

V-1187 FIBERFILL (WADDING) GARNETT LINE AND OVER PILLOW FILLERV-1187 FIBERFILL (WADDING) GARNETT LINE AND OVER PILL

OFFER 001

FIBER HOPPER FEEDS WITH WEIGHT PANS (BLENDING LINE)OFFER 002

CONVEYOR WHICH INCLUDES ONE (1) MOTOR – ½ HPOFFER 003

PRE-OPENING MACHINEOFFER 004

BLENDING UNIT BEFORE THE GARNETT LINEOFFER 005

SHAKER CHUTE MOUNTED ON THE FEEDER TO FEED THE GARNETTOFFER 006

GARNETT WITH CYLINDERS IN PERFECT CONDITIONS-BRAND WISEOFFER 007

HIGH SPEED CROSS LAPPERQUANTITY: 1 LINE

Learn More -

M-3007 ATLANTA ATTACHMENT RUFFLER FLANGER FOR PILLOW TOP

M-3007 ATLANTA ATTACHMENT RUFFLER FLANGER FOR PILLOW TOPREFERENCE NUMBER: M-3007

ATLANTA ATTACHMENT RUFFLER FLANGER FOR PILLOW TOP

ATLANTA ATT. MODEL #1335

PILLOW TOP MACHINE RUFFLER

BRAND: ATLANTA ATTACHMENT

MODEL: 1335MF

NEEDLE: SN 62×5721

INCLUDES:

-S.S. TABLE WITH AIR FLOTATION ON IT

-SEWING TABLE, MOTOR AND ELECTRICAL BOXES

-METAL FRAME FOR MATERIAL FEEDING

NOTE: THE SEWING HEAD HAS (4) EYELETS FOR THREAD

AUTOMATIC FLANGER

Learn More