Search results for: 'heating w'

- Related search terms

- heating el

- heating wi

- heating wire f

- heating wire for a

- heating+wire+for

-

M-5119 LAMINATION SYSTEM AND STORK DRYER YEAR 2012 WIDTH 1200-1900mmREFERENCE NUMBER: M-5119 (1212HGFNXX11) L LAMINATION SYSTEM AND STORK DRYER YEAR 2012 WIDTH 1200-1900mm LAMINATION SYSTEM AND DRYER SYSTEM WAS COMPLETELY REFURBISHED IN 2012 LAMINATION AND DRYER CAN BE USED SEPARATELY QUANTITY AVAILABLE: 1 Learn More

M-5119 LAMINATION SYSTEM AND STORK DRYER YEAR 2012 WIDTH 1200-1900mmREFERENCE NUMBER: M-5119 (1212HGFNXX11) L LAMINATION SYSTEM AND STORK DRYER YEAR 2012 WIDTH 1200-1900mm LAMINATION SYSTEM AND DRYER SYSTEM WAS COMPLETELY REFURBISHED IN 2012 LAMINATION AND DRYER CAN BE USED SEPARATELY QUANTITY AVAILABLE: 1 Learn More -

TT-7453 COMPLETE SUCHY/KLIEVERIK LAMINATING LINE, WORKING WIDTH 3200mm, YEAR 2012TT-7453 COMPLETE SUCHY/KLIEVERIK LAMINATING LINE, WORKING WIDTH 3200mm, YEAR 2012 1. COMPLETE SUCHY/KLIEVERIK LAMINATING LINE 2. YEAR 2012 3. WORKING WIDTH 3200mm 4. ROLLER WIDTH 3400mm 5. FABRIC WEIGHTS 125 TO 1.800 G/M² 6. SPEED 2M TO 60M/MIN. 7. PRESSURE 6 BAR 8. E & L GUIDES WITH EDGE SCANNING 9. LENGTHMEASURING 10. TOTAL LENGTH 28.10 M QUANTITY: 1 Learn More

TT-7453 COMPLETE SUCHY/KLIEVERIK LAMINATING LINE, WORKING WIDTH 3200mm, YEAR 2012TT-7453 COMPLETE SUCHY/KLIEVERIK LAMINATING LINE, WORKING WIDTH 3200mm, YEAR 2012 1. COMPLETE SUCHY/KLIEVERIK LAMINATING LINE 2. YEAR 2012 3. WORKING WIDTH 3200mm 4. ROLLER WIDTH 3400mm 5. FABRIC WEIGHTS 125 TO 1.800 G/M² 6. SPEED 2M TO 60M/MIN. 7. PRESSURE 6 BAR 8. E & L GUIDES WITH EDGE SCANNING 9. LENGTHMEASURING 10. TOTAL LENGTH 28.10 M QUANTITY: 1 Learn More -

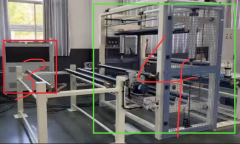

YY-3093 FLATBED DOUBLE-BELT LAMINATING MACHINE, 2000mm WORKING WIDTH - NEWYY-3093 FLATBED DOUBLE-BELT LAMINATING MACHINE, 2000mm WORKING WIDTH - NEW ASK FOR MORE DETAILS! Learn More

YY-3093 FLATBED DOUBLE-BELT LAMINATING MACHINE, 2000mm WORKING WIDTH - NEWYY-3093 FLATBED DOUBLE-BELT LAMINATING MACHINE, 2000mm WORKING WIDTH - NEW ASK FOR MORE DETAILS! Learn More -

YY-1293 FLAME LAMINATING MACHINE, WORKING WIDTH 2200mmYY-1293 FLAME LAMINATING MACHINE, WORKING WIDTH 2200mm ROLL WIDTH: 2400mm ELECTRIC POWER: 220/380V, 50/60Hz (OPTION) QUANTITY: 1 Learn More

YY-1293 FLAME LAMINATING MACHINE, WORKING WIDTH 2200mmYY-1293 FLAME LAMINATING MACHINE, WORKING WIDTH 2200mm ROLL WIDTH: 2400mm ELECTRIC POWER: 220/380V, 50/60Hz (OPTION) QUANTITY: 1 Learn More -

A-1327 KANNEGEISSER MULTI-STAR LAMINATING MACHINE WITH TEFLON BELT APPROXIMATELY 57 INCHES WIDEREFERENCE NUMBER: A-1327 (0202125DL01U) C KANNEGEISSER MULTI-STAR LAMINATING MACHINE WITH TEFLON BELT APPROXIMATELY 57 INCHES WIDE LAMINATING MACHINE KANNEGEISSER MULTI-STAR WITH TEFLON BELT APPROXIMATELY 57 INCHES WIDE MODEL VK1400 SERIAL 40834 ELECTRIC HEATING ELEMENTS DO THE FUSING THERE IS AN ENTRY AND AN EXIT CONVEYOR COMPLETE AND READY TO RUN , AT THE MOMENT IN STORAGE QUANTITY AVAILABLE: 1 Learn More

A-1327 KANNEGEISSER MULTI-STAR LAMINATING MACHINE WITH TEFLON BELT APPROXIMATELY 57 INCHES WIDEREFERENCE NUMBER: A-1327 (0202125DL01U) C KANNEGEISSER MULTI-STAR LAMINATING MACHINE WITH TEFLON BELT APPROXIMATELY 57 INCHES WIDE LAMINATING MACHINE KANNEGEISSER MULTI-STAR WITH TEFLON BELT APPROXIMATELY 57 INCHES WIDE MODEL VK1400 SERIAL 40834 ELECTRIC HEATING ELEMENTS DO THE FUSING THERE IS AN ENTRY AND AN EXIT CONVEYOR COMPLETE AND READY TO RUN , AT THE MOMENT IN STORAGE QUANTITY AVAILABLE: 1 Learn More -

TT-7115 LACOM COMPACT HOTMELT COATING - LAMINATING, WORKING WIDTH 2400mm, YEAR 2016TT-7115 LACOM COMPACT HOTMELT COATING - LAMINATING, WORKING WIDTH 2400mm, YEAR 2016 1. LACOM COMPACT HOTMELT COATING - LAMINATING 2. ENGRAVING & MULTI-ROLLER 3. WORKING WIDTH 2400mm 4. YEAR 2016 QUANTITY: 1 Learn More

TT-7115 LACOM COMPACT HOTMELT COATING - LAMINATING, WORKING WIDTH 2400mm, YEAR 2016TT-7115 LACOM COMPACT HOTMELT COATING - LAMINATING, WORKING WIDTH 2400mm, YEAR 2016 1. LACOM COMPACT HOTMELT COATING - LAMINATING 2. ENGRAVING & MULTI-ROLLER 3. WORKING WIDTH 2400mm 4. YEAR 2016 QUANTITY: 1 Learn More -

YY-3488 KBA/FLEXOTECNICA ROLL TO ROLL LAMINATOR, YEAR 2017YY-3488 KBA/FLEXOTECNICA ROLL TO ROLL LAMINATOR, YEAR 2017 SUITABLE FOR THE FOLLOWING MATERIALS: 1. BOPP – 12 – 80 μm 2. PET 10 – 30 μm 3. LDPE, LLDPE 20 – 100 μm 4. OPA 12 – 18 μm 5. ALU 7 – 40 μm 6. PA CAST 20 – 80 μm 7. CPP 20 - 100 G/M2 8. PAPER - 20-60GSM Learn More

YY-3488 KBA/FLEXOTECNICA ROLL TO ROLL LAMINATOR, YEAR 2017YY-3488 KBA/FLEXOTECNICA ROLL TO ROLL LAMINATOR, YEAR 2017 SUITABLE FOR THE FOLLOWING MATERIALS: 1. BOPP – 12 – 80 μm 2. PET 10 – 30 μm 3. LDPE, LLDPE 20 – 100 μm 4. OPA 12 – 18 μm 5. ALU 7 – 40 μm 6. PA CAST 20 – 80 μm 7. CPP 20 - 100 G/M2 8. PAPER - 20-60GSM Learn More -

TT-4003 LACOM MODEL MBL 2400-ECO HOTMELT COATING & LAMINATING MACHINE, WORKING WIDTH 2400mm, YEAR 2016TT-4003 LACOM MODEL MBL 2400-ECO HOTMELT COATING & LAMINATING MACHINE, WORKING WIDTH 2400mm, YEAR 2016 LACOM MODEL MBL 2400-ECO HOTMELT COATING & LAMINATING MACHINE MANUFACTURED BY KIENER CO, GERMANY YEAR 2016 WORKING WIDTH 2400mm QUANTITY: 1 Learn More

TT-4003 LACOM MODEL MBL 2400-ECO HOTMELT COATING & LAMINATING MACHINE, WORKING WIDTH 2400mm, YEAR 2016TT-4003 LACOM MODEL MBL 2400-ECO HOTMELT COATING & LAMINATING MACHINE, WORKING WIDTH 2400mm, YEAR 2016 LACOM MODEL MBL 2400-ECO HOTMELT COATING & LAMINATING MACHINE MANUFACTURED BY KIENER CO, GERMANY YEAR 2016 WORKING WIDTH 2400mm QUANTITY: 1 Learn More -

J-1937 LAMINATING MACHINE FOR FOAM TO FABRIC – CONTINUOUS WITH SLITTING, NEW

J-1937 LAMINATING MACHINE FOR FOAM TO FABRIC – CONTINUOUS WITH SLITTING, NEWSILICON COATED NOMEX FELT (ITB BRAND – ITALIAN)

BLANKET THICKNESS: 8mm

PNEUMATICALLY ADJUSTABLE FELT PRESSURE

MAXIMUM WORKING WIDTH: 2100mm (82.6”)

EVA HOT MELT FILM, FILM ROLL MIMIMUM 500 METERS, MAXIMUM 1000 METERS

36 KW HEATER RESISTANCE

MAIN DRUM DIAMETER: 500mm

TEFLON COATED MAIN CYLINDER

PNEUMATIC BLANKET EDGE CONTROL BY PHOTOCELL

WORKING SPEED: 5 TO 10 METERS PER MINUTE, DEPENDING ON FABRIC THICKNESS (THICK FABRIC IS SLOWER, NORMAL FABRIC IS FASTER)

PLC CONTROLLER WITH TOUCH SCREEN OPERATOR PANEL

PROGRAMMABLE HEATING UP AND COOLING DOWN

ROLL TO ROLL WORKING SYSTEM

SLITTING UNIT WITH 3 PIECE PNEUMATIC CUTTER AND DUAL CENTER REWINDING UNIT (OPTIONAL)

440 V 3-PHASE, 60 Hz, 55 AMPLEAD TIME: 6 TO 8 WEEKS AFTER RECEIPT OF DEPOSIT

Learn More -

V-0021 LAMINATOR FOR FABRIC 1600mmREFERENCE NUMBER: V-0021 LAMINATOR FOR FABRIC 1600mm THIS MACHINE IS DESIGNED SPECIFICALLY FOR THE HIGH PRODUCTION AND LOW TEMPERATURE FUSING NEEDS OF SPORTSWEAR. THE ADVANCED HEATING SYSTEM ASSURES A SOFT FLEXIBLE FUSED ASSEMBLY, MAINTAINING FABRIC STRUCTURE AND AVOIDING SHRINKAGE OR FADING, WHILE IT PROVIDES ABSOLUTE CONTROL OF THE ADHESIVE RESINS ON ANY TYPE OF INTERLINING SELECTED. BELT SIZE IS 63”. THE COMBINATION OF TWO ZONE, CONDUCTIVE HEAT APPLICATION WITH PRECISE SPEED AND PRESSURE CONTROL, ASSURES QUALITY RESULTS ON ALL FUSED ASSEMBLIES. OPTIONAL EQUIPMENT INCLUDES FOLDING LATERAL LOADING SHELVES, UNROLL & RE-ROLL SYSTEMS, AND 380 VOLT ELECTRICAL SYSTEM. THE SC SERIES IS DESIGNED WITH SAFETY AND OPERATOR COMFORT IN MIND. THIS MODEL MEETS OR EXCEEDS WORLDWIDE STANDARDS IN SAFETY AND EFFICIENCY, INCLUDING THE EUROPEAN CE RATING. QUANTITY AVAILABLE: 1 Learn More

V-0021 LAMINATOR FOR FABRIC 1600mmREFERENCE NUMBER: V-0021 LAMINATOR FOR FABRIC 1600mm THIS MACHINE IS DESIGNED SPECIFICALLY FOR THE HIGH PRODUCTION AND LOW TEMPERATURE FUSING NEEDS OF SPORTSWEAR. THE ADVANCED HEATING SYSTEM ASSURES A SOFT FLEXIBLE FUSED ASSEMBLY, MAINTAINING FABRIC STRUCTURE AND AVOIDING SHRINKAGE OR FADING, WHILE IT PROVIDES ABSOLUTE CONTROL OF THE ADHESIVE RESINS ON ANY TYPE OF INTERLINING SELECTED. BELT SIZE IS 63”. THE COMBINATION OF TWO ZONE, CONDUCTIVE HEAT APPLICATION WITH PRECISE SPEED AND PRESSURE CONTROL, ASSURES QUALITY RESULTS ON ALL FUSED ASSEMBLIES. OPTIONAL EQUIPMENT INCLUDES FOLDING LATERAL LOADING SHELVES, UNROLL & RE-ROLL SYSTEMS, AND 380 VOLT ELECTRICAL SYSTEM. THE SC SERIES IS DESIGNED WITH SAFETY AND OPERATOR COMFORT IN MIND. THIS MODEL MEETS OR EXCEEDS WORLDWIDE STANDARDS IN SAFETY AND EFFICIENCY, INCLUDING THE EUROPEAN CE RATING. QUANTITY AVAILABLE: 1 Learn More