Search results for: 'Reference N''

- Related search terms

- reference nu'

- Reference Number: J-'

- reference number -

- reference number -v-

- reference number -v-2

-

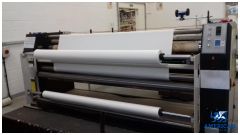

J-3785 GRIBETZ STRATA LAMINATOR, YEAR 2016, WORKING WIDTH 1400 TO 2200mmJ-3785 GRIBETZ STRATA LAMINATOR, YEAR 2016, WORKING WIDTH 1400 TO 2200mm 3 POSITION CREEL FOR: SCRIM GLUE FABRICS AREA 4000 x 3000mm QUANTITY: 1 Learn More

J-3785 GRIBETZ STRATA LAMINATOR, YEAR 2016, WORKING WIDTH 1400 TO 2200mmJ-3785 GRIBETZ STRATA LAMINATOR, YEAR 2016, WORKING WIDTH 1400 TO 2200mm 3 POSITION CREEL FOR: SCRIM GLUE FABRICS AREA 4000 x 3000mm QUANTITY: 1 Learn More -

YY-1293 FLAME LAMINATING MACHINE, WORKING WIDTH 2200mmYY-1293 FLAME LAMINATING MACHINE, WORKING WIDTH 2200mm ROLL WIDTH: 2400mm ELECTRIC POWER: 220/380V, 50/60Hz (OPTION) QUANTITY: 1 Learn More

YY-1293 FLAME LAMINATING MACHINE, WORKING WIDTH 2200mmYY-1293 FLAME LAMINATING MACHINE, WORKING WIDTH 2200mm ROLL WIDTH: 2400mm ELECTRIC POWER: 220/380V, 50/60Hz (OPTION) QUANTITY: 1 Learn More -

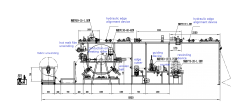

J-3175 HOT MELT FILM LAMINATING MACHINE FOR PLAIN WOVEN FABRICJ-3175 HOT MELT FILM LAMINATING MACHINE FOR PLAIN WOVEN FABRIC MACHINE SPEED: 20 TO 40 METERS PER MINUTE ESTIMATED MACHINE DIMENSIONS: 8850mm x 2450mm x 2200mm (L*W*H) ESTIMATED MACHINE WEIGHT: 6000 KG MOTOR BRAND: SIEMENS ELECTRIC BRAND: SCHNEIDER QUANTITY: 1 Learn More

J-3175 HOT MELT FILM LAMINATING MACHINE FOR PLAIN WOVEN FABRICJ-3175 HOT MELT FILM LAMINATING MACHINE FOR PLAIN WOVEN FABRIC MACHINE SPEED: 20 TO 40 METERS PER MINUTE ESTIMATED MACHINE DIMENSIONS: 8850mm x 2450mm x 2200mm (L*W*H) ESTIMATED MACHINE WEIGHT: 6000 KG MOTOR BRAND: SIEMENS ELECTRIC BRAND: SCHNEIDER QUANTITY: 1 Learn More -

J-3163 PUR HOT MELT GLUE LAMINATING MACHINE, WORKING WIDTH 2200mmJ-3163 PUR HOT MELT GLUE LAMINATING MACHINE, WORKING WIDTH 2200mm WORKING WIDTH: 2200mm ROLLER WIDTH: 2400mm LAMINATES FABRIC TO FABRIC AND FABRIC TO FILM GLUE TYPE: HOT MELT PUR GLUE WORKING SPEED: 0 TO 40M/MIN HEATING METHOD: ELECTRICITY, THERMAL OIL INSTALLED CAPACITY: ABOUT 80KVA COMPRESSED AIR: 4-8BAR HEATED PIPE LENGTH: 5M MAIN CONFIGURATION PART ONE BASE FABRIC UNWINDING DEVICE UNWINDING RACK - 4 SET φ74 PNEUMATIC SHAFT - 4 PC DAMPING DEVICE - 4 SET UNWINDING UNIT - 4 EA EPC POSITION ADJUST DEVICE - 1 SET φ75 ALUMINUM ALLOY ROLLER - 5 PC MACHINE RACK - 1 SET FOOTBOARD - 1 EA Learn More

J-3163 PUR HOT MELT GLUE LAMINATING MACHINE, WORKING WIDTH 2200mmJ-3163 PUR HOT MELT GLUE LAMINATING MACHINE, WORKING WIDTH 2200mm WORKING WIDTH: 2200mm ROLLER WIDTH: 2400mm LAMINATES FABRIC TO FABRIC AND FABRIC TO FILM GLUE TYPE: HOT MELT PUR GLUE WORKING SPEED: 0 TO 40M/MIN HEATING METHOD: ELECTRICITY, THERMAL OIL INSTALLED CAPACITY: ABOUT 80KVA COMPRESSED AIR: 4-8BAR HEATED PIPE LENGTH: 5M MAIN CONFIGURATION PART ONE BASE FABRIC UNWINDING DEVICE UNWINDING RACK - 4 SET φ74 PNEUMATIC SHAFT - 4 PC DAMPING DEVICE - 4 SET UNWINDING UNIT - 4 EA EPC POSITION ADJUST DEVICE - 1 SET φ75 ALUMINUM ALLOY ROLLER - 5 PC MACHINE RACK - 1 SET FOOTBOARD - 1 EA Learn More -

YY-1126 EASY MELT LAMINATING MACHINEYY-1126 EASY MELT LAMINATING MACHINE DETAILS: -TYPE EASY -YEAR 2013 -ROTOGRAVURE SYSTEM FOR COATING -3 ROLLERS ON THE MACHINE (ONE WORKING, TWO IN STAND-BY MODE) -INLET FROM ROLL -OUTLET WITH ROLL -CONTROL PANEL -NORDSON MELTING UNIT FOR PUR, YEAR 2015 Learn More

YY-1126 EASY MELT LAMINATING MACHINEYY-1126 EASY MELT LAMINATING MACHINE DETAILS: -TYPE EASY -YEAR 2013 -ROTOGRAVURE SYSTEM FOR COATING -3 ROLLERS ON THE MACHINE (ONE WORKING, TWO IN STAND-BY MODE) -INLET FROM ROLL -OUTLET WITH ROLL -CONTROL PANEL -NORDSON MELTING UNIT FOR PUR, YEAR 2015 Learn More -

A-2502 PUR LAMINATING MACHINEA-2502 PUR LAMINATING MACHINE MODE SPECIFICATION: 240 X 1350 mm BOARD LENGTH: ANY MORE THAN 600 mm BOARD THICKNESS: 3 TO 50 mm BOARD WIDTH: 1220 mm OUTER DIMENSION OF MACHINE: 14100 X 2300 X 2500 mm RATE OF MATERIAL DELIVER: 1 TO 25 M/min GENERAL POWER: 46 KW TEMPERATURE MEASUREMENT SYSTEM: GERMANY IMPAC PRINCIPAL AXIS ROLLER DIAMETER: 320 mm MACHINE WEIGHT: 6000 KG PAPER WIDTH: 1280 mm Learn More

A-2502 PUR LAMINATING MACHINEA-2502 PUR LAMINATING MACHINE MODE SPECIFICATION: 240 X 1350 mm BOARD LENGTH: ANY MORE THAN 600 mm BOARD THICKNESS: 3 TO 50 mm BOARD WIDTH: 1220 mm OUTER DIMENSION OF MACHINE: 14100 X 2300 X 2500 mm RATE OF MATERIAL DELIVER: 1 TO 25 M/min GENERAL POWER: 46 KW TEMPERATURE MEASUREMENT SYSTEM: GERMANY IMPAC PRINCIPAL AXIS ROLLER DIAMETER: 320 mm MACHINE WEIGHT: 6000 KG PAPER WIDTH: 1280 mm Learn More -

L-4879 T & A FLAME LAMINATING MACHINE, MODEL ACCD 2300, WIDTH 2300mm, YEAR 2001

L-4879 T & A FLAME LAMINATING MACHINE, MODEL ACCD 2300, WIDTH 2300mm, YEAR 2001YEAR: 2001

Learn More

MODEL ACCD 2300

ROLLER WIDTH: 2300mm

FABRIC WIDTH: 2200mm

DOUBLE BURNERS

RUNNING UNTIL NEXT NOVEMBER

QUANTITY: 1 -

C-4013 VILLARS AG SCATTER- COATING AND LAMINATING MACHINE, WORKING WIDTH 1000mm, YEAR 1994

C-4013 VILLARS AG SCATTER- COATING AND LAMINATING MACHINE, WORKING WIDTH 1000mm, YEAR 1994C-4013 VILLARS AG SCATTER- COATING AND LAMINATING MACHINE, WORKING WIDTH 1000mm, YEAR 1994

MAKE: VILLARS AG

YEAR: 1994

WORKING WIDTH: 1000mm

WORKING SPEED: 0 TO 10 M/MIN

ELECTRICAL POWER: 3 X 400 VOLT + PN + PE, 50 HZ

POWER: 140 KW

WEIGHT: 8637 KGSQUANTITY: 1

Learn More -

K-3774 LACOM HOT MELT COATING AND LAMINATING LINE FOR MATTRESS TICKING 2400mm YEAR 2002-LIKE NEWREFERENCE NUMBER: K-3774 LACOM HOT MELT COATING AND LAMINATING LINE FOR MATTRESS TICKING 2400mm YEAR 2002-LIKE NEW SUITABLE FOR MATTRESS TICKING LAMINATION MULTIROLLER SYSTEM WITH EXTRUDER AND DRUM MELTER (MELTING WITH BOTH SYSTEM IS POSSIBLE) POLIMERS TO BE USED ARE; EVA, PP, PE, REACTIVE PU QUANTITY AVAILABLE: 1 Learn More

K-3774 LACOM HOT MELT COATING AND LAMINATING LINE FOR MATTRESS TICKING 2400mm YEAR 2002-LIKE NEWREFERENCE NUMBER: K-3774 LACOM HOT MELT COATING AND LAMINATING LINE FOR MATTRESS TICKING 2400mm YEAR 2002-LIKE NEW SUITABLE FOR MATTRESS TICKING LAMINATION MULTIROLLER SYSTEM WITH EXTRUDER AND DRUM MELTER (MELTING WITH BOTH SYSTEM IS POSSIBLE) POLIMERS TO BE USED ARE; EVA, PP, PE, REACTIVE PU QUANTITY AVAILABLE: 1 Learn More -

M-4608 VILLARS-SANTEX HOTMELT POWDER SCATTERING AND LAMINATING MACHINE YEAR 1993 WIDTH 2100mmREFERENCE NUMBER: M-4608 (11116SWJK10R) L VILLARS-SANTEX HOTMELT POWDER SCATTERING AND LAMINATING MACHINE YEAR 1993 WIDTH 2100mm LAMINATING LINE MANUFACTURER: VILLARS (CH) ACTUALLY SANTEX YEAR OF CONSTRUCTION: 1993 WORKING WIDTH: 2200mm (NOMINAL WIDTH 2100mm) OPERATING VOLTAGE: 3X380(400)V TOTAL POWER: 158KW RECOMMENDED MAX. SPEED 10M BUT 15M IS POSSIBLE ORIGINAL CONFIGURATION: INPUT UNIT (WITH POSSIBILITY TO HANG IN ROLLERS BY MEANS OF E.G. FLAT BEARINGS), POWDER SPREADER, INFRARED PREHEATING ZONE AND DOUBLE BAND LAMINATING PRESS (HEATING THROUGH IR) LATER EXTENSION (1997): 2ND INFRARED ZONE WITH COLD WATER COOLED CALENDAR AT THE BACK EQUIPPED WITH SELVEDGE CUTTING SYSTEM WITH ADJUSTABLE INFRARED FOLLOW UP SYSTEM. STRENGTH OF INFRARED CAN BE ADJUSTED SO THAT E.G. THE UPPER SUBSTRATE CAN BE ‘NEGLECTED’. KNOWN PROBLEMS: 1)INFRARED PREHEATING ZONE : 2 IR STRIPS BROKEN 2)CERTAIN PARTS IR ZONES (MOSTLY EXTERIOR ZONES) OF THE DOUBLE BAND LAMINATING PRESS DO NOT LONGER FUNCTION, BUT SECOND PART OF THE MACHINE CAN STILL BE HEATED TILL 160 À 170°C AND EVEN MORE, BUT THEN AT VERY LOW SPEED. ACCUMULATOR WITH WINDER AND CONTROLLING SYSTEM MANUFACTURER: MATTHIJS (ELECTRICAL PART BY ELECTRO VANDEVELDE) YEAR OF CONSTRUCTION: 1999 OPERATING VOLTAGE: 3X380V CAPACITY ACCUMULATOR: +/- 50M UNIT FUNCTIONS INDEPENDENTLY FROM LAMINATING MACHINE AND SPEED VARIES FROM 0 TILL 50M (SPEED OF WINDING UP UNIT = SPEED LAMINATING MACHINE WHEN ACCUMULATOR IS EMPTY) SUPERSTRUCTURE FOR SUPPLY SECOND SUBSTRATE MANUFACTURER: MENZEL YEAR OF CONSTRUCTION: 2000 OPERATING VOLTAGE: 3X380V FUNCTIONS INDEPENDENTLY FROM THE LAMINATING MACHINE. SPEED REGULATION BASED ON A 0-10V (=0-15M) EXIT SIGNAL OF THE LAMINATING MACHINE MANUAL RIGHT-LEFT GUIDANCE OF THE SUBSTRATE. A SECOND AUTOMATIC PRE-GUIDANCE IS FORESEEN, BUT THE MOTOR DOES NO LONGER FUNCTION AND IT IS IN PRACTICE NOT REQUIRED BECAUSE THE ROLLS ARE ALWAYS WINDED STRAIGHT. A MEASURING ROLLER IS INCLUDED TO MEASURE THE TENSION OF THE SUBSTRATE. THIS MEASURING ROLLER DIRECTS THE MOTOR SPEED SO THAT THE ADJUSTING OF THE TENSION STAYS STEADY. IT IS EVEN POSSIBLE TO GO TO A +/- TENSIONLESS SITUATION. THE LINE IS MOUNTED ON A SELF-MADE PLATFORM EQUIPPED WITH A SIMPLE UNWINDING UNIT. KNOWN PROBLEM: PRESSURE ROLLER TO AVOID THAT THE SUBSTRATE “SLIDES” OVER THE BRAKE ROLLER IS WORN OUT, BUT IS IN PRAXIS NOT NEEDED. MOTOR OF THE PRE-GUIDANCE IS BROKEN (SEE ABOVE) MISCELLANEA SELF-BUILD ENTRY J-BOX WITH SIMPLE ROLL MEASUREMENT SEPARATE J-BOX FOR UNWINDING FROM DOCKS, SO THAT CAN BE LAMINATED IN THE POLE DIRECTION SEWING MACHINE MERROW TO MAKE FLAT SEAMS ON FINE/THIN FABRICS SELVEDGE CUTTERS ARE MOUNTED ON A SYSTEM SO THAT THE FABRIC CAN BE LEVELLED EASILY, EVENTUALLY CAN BE WINDED ON DOCKS. INCLUDING 2 DOCKS OF 2M30 OF WHICH 1 WITH FLAP BEARINGS CAN BE INSPECTED BUT NOT IN PRODUCTION MACHINE WILL BE DISMANTLED AT END OF NOV 2014 QUANTITY AVAILABLE: 1 Learn More

M-4608 VILLARS-SANTEX HOTMELT POWDER SCATTERING AND LAMINATING MACHINE YEAR 1993 WIDTH 2100mmREFERENCE NUMBER: M-4608 (11116SWJK10R) L VILLARS-SANTEX HOTMELT POWDER SCATTERING AND LAMINATING MACHINE YEAR 1993 WIDTH 2100mm LAMINATING LINE MANUFACTURER: VILLARS (CH) ACTUALLY SANTEX YEAR OF CONSTRUCTION: 1993 WORKING WIDTH: 2200mm (NOMINAL WIDTH 2100mm) OPERATING VOLTAGE: 3X380(400)V TOTAL POWER: 158KW RECOMMENDED MAX. SPEED 10M BUT 15M IS POSSIBLE ORIGINAL CONFIGURATION: INPUT UNIT (WITH POSSIBILITY TO HANG IN ROLLERS BY MEANS OF E.G. FLAT BEARINGS), POWDER SPREADER, INFRARED PREHEATING ZONE AND DOUBLE BAND LAMINATING PRESS (HEATING THROUGH IR) LATER EXTENSION (1997): 2ND INFRARED ZONE WITH COLD WATER COOLED CALENDAR AT THE BACK EQUIPPED WITH SELVEDGE CUTTING SYSTEM WITH ADJUSTABLE INFRARED FOLLOW UP SYSTEM. STRENGTH OF INFRARED CAN BE ADJUSTED SO THAT E.G. THE UPPER SUBSTRATE CAN BE ‘NEGLECTED’. KNOWN PROBLEMS: 1)INFRARED PREHEATING ZONE : 2 IR STRIPS BROKEN 2)CERTAIN PARTS IR ZONES (MOSTLY EXTERIOR ZONES) OF THE DOUBLE BAND LAMINATING PRESS DO NOT LONGER FUNCTION, BUT SECOND PART OF THE MACHINE CAN STILL BE HEATED TILL 160 À 170°C AND EVEN MORE, BUT THEN AT VERY LOW SPEED. ACCUMULATOR WITH WINDER AND CONTROLLING SYSTEM MANUFACTURER: MATTHIJS (ELECTRICAL PART BY ELECTRO VANDEVELDE) YEAR OF CONSTRUCTION: 1999 OPERATING VOLTAGE: 3X380V CAPACITY ACCUMULATOR: +/- 50M UNIT FUNCTIONS INDEPENDENTLY FROM LAMINATING MACHINE AND SPEED VARIES FROM 0 TILL 50M (SPEED OF WINDING UP UNIT = SPEED LAMINATING MACHINE WHEN ACCUMULATOR IS EMPTY) SUPERSTRUCTURE FOR SUPPLY SECOND SUBSTRATE MANUFACTURER: MENZEL YEAR OF CONSTRUCTION: 2000 OPERATING VOLTAGE: 3X380V FUNCTIONS INDEPENDENTLY FROM THE LAMINATING MACHINE. SPEED REGULATION BASED ON A 0-10V (=0-15M) EXIT SIGNAL OF THE LAMINATING MACHINE MANUAL RIGHT-LEFT GUIDANCE OF THE SUBSTRATE. A SECOND AUTOMATIC PRE-GUIDANCE IS FORESEEN, BUT THE MOTOR DOES NO LONGER FUNCTION AND IT IS IN PRACTICE NOT REQUIRED BECAUSE THE ROLLS ARE ALWAYS WINDED STRAIGHT. A MEASURING ROLLER IS INCLUDED TO MEASURE THE TENSION OF THE SUBSTRATE. THIS MEASURING ROLLER DIRECTS THE MOTOR SPEED SO THAT THE ADJUSTING OF THE TENSION STAYS STEADY. IT IS EVEN POSSIBLE TO GO TO A +/- TENSIONLESS SITUATION. THE LINE IS MOUNTED ON A SELF-MADE PLATFORM EQUIPPED WITH A SIMPLE UNWINDING UNIT. KNOWN PROBLEM: PRESSURE ROLLER TO AVOID THAT THE SUBSTRATE “SLIDES” OVER THE BRAKE ROLLER IS WORN OUT, BUT IS IN PRAXIS NOT NEEDED. MOTOR OF THE PRE-GUIDANCE IS BROKEN (SEE ABOVE) MISCELLANEA SELF-BUILD ENTRY J-BOX WITH SIMPLE ROLL MEASUREMENT SEPARATE J-BOX FOR UNWINDING FROM DOCKS, SO THAT CAN BE LAMINATED IN THE POLE DIRECTION SEWING MACHINE MERROW TO MAKE FLAT SEAMS ON FINE/THIN FABRICS SELVEDGE CUTTERS ARE MOUNTED ON A SYSTEM SO THAT THE FABRIC CAN BE LEVELLED EASILY, EVENTUALLY CAN BE WINDED ON DOCKS. INCLUDING 2 DOCKS OF 2M30 OF WHICH 1 WITH FLAP BEARINGS CAN BE INSPECTED BUT NOT IN PRODUCTION MACHINE WILL BE DISMANTLED AT END OF NOV 2014 QUANTITY AVAILABLE: 1 Learn More