Search results for: 'gas burner machine'

- Related search terms

- Machine ope

- Machine+we

- machine de

- Machine+fe

- machine''''

-

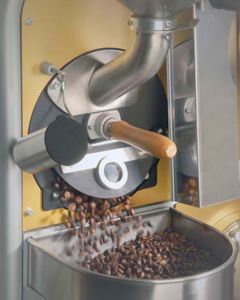

P-5044 STA IMPIANTI ROASTER 5 KILOS

P-5044 STA IMPIANTI ROASTER 5 KILOSP-5044 STA IMPIANTI ROASTER 5 KILOS

STA

MODEL: IMPIANTI

ROASTER

5 KILOS

STA IS A MANUFACTURING GROUP IN ITALY - THAT IS MADE UP OF SEASONED ENGINEERS FROM MOST OF THE BIG OLD ITALIAN ROASTING MACHINE MAKERS - SO THEIR SCOPE OF KNOWLEDGE AND HISTORY IS FANTASTIC. BASICALLY - THEIR CLAIM TO FAME IS HOT AIR INTRODUCED INTO THE TOP OF THE ROASTING CHAMBER . . . BEING PULLED THROUGH THE TURBULATING COFFEE AND EXITING THROUGH DRUM PERFORATIONS INTO THE BOTTOM. FIRST, THAT MAKES IT REALLY FRIENDLY TO BLENDING FORMULAS AND SECOND IT MAKES FOR SMALLER CHAFF - AS THE TURNING COFFEE BEATS IT UP A LITTLE AND THUS THE ROAST COMES OUT MORE CLEAN THAN THE OLD DAYS OF SOME SOLID DRUMS . . . SO IT IS DIFFERENT - WHICH DOES NOT MAKE IT BETTER - BUT IF YOU HAVE A BACKGROUND ON JABEZ BURNS . . THEN YOU WILL REALLY LOVE THIS PRODUCTION. BIG NATURALLY DEVELOPED BEANS - VERY EVEN ROAST. FOLLOWING IS THE MANUFACTURERS SPECS AND WE WILL BE GLAD TO DISCUSS MORE IN-DEPTH AS YOU HAVE QUESTIONS.ROASTING MACHINES LINE, PARTICULARLY SUITABLE FOR LITTLE PRODUCTION ACTIVITIES OF HIGH QUALITY ROASTED COFFEE, SUCH AS SHOPS, PASTRIES OR ARTISAN LABORATORIES. SMALL SIZE, TECHNOLOGICALLY ADVANCED, CONFIRM THEM ELVES AS IDEAL TOOL FOR THE PRODUCTION OF SELECTED COFFEES IN LITTLE QUANTITY. MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTING MACHINES, ARE AVAILABLE WITH HEATING GENERATOR TYPE GAS BURNER (AVAILABLE ALSO BY ELECTRIC RESISTANCES) AND AUTOMATIC CONTROL SYSTEM WITH SEMIAUTOMATIC MANAGEMENT.

TECHNICAL DATA:

ROASTER CAPACITY: 5 KG. - MAX. 7 KG. CYCLE

ROASTING CYCLE: 9 MINUTES ÷ 20

RAW COFFEE PROCESSING PER HOUR: 20 KG. ÷ 30

INSTALLED ELECTRIC POWER: 0.9 KW | SINGLEPHASE 220 VOLTS 50 HZ

THERMAL POWER (NATURAL GAS OR LPG): 8000 KCAL/H

MAIN COMPONENTS:

HOPPER OF CHARGE IN STAINLESS STEEL

ROASTING DRUM

HEATING GENERATOR OF NEW GENERATION, PATENTED AND COMPLETE OF BURNER

RAMP VALVES FOR GAS SAFETY AND ELECTRIC DEVICE TO CHECK FLAMES RATIFIED AND COMPLETE OF ALARM SIGNAL

COOLING TANK IN STAINLESS STEEL

SAFETY PREVENTION SYSTEM ON THE COOLING TANK

SUPPORTING FRAME FOR THE OVER INDICATED COMPONENTS

ELECTRIC CONTROL BOARD MADE ACCORDING CE RULES, INTEGRATED, COMPLETE OF PLC + TOUCH SCREEN DEVICE FOR ROASTING MACHINE CONTROL AND MANAGEMENT.

INDEPENDENT FANS FOR THE ROASTING DRUM AND THE COOLING TANK

INDEPENDENT MOTORS FOR THE ROASTING DRUM AND THE COOLING TANK

CYCLONE FOR CHAFFS COLLECTING

DETAILS OF COMPONENTS:

HOPPER OF CHARGE IN STAINLESS STEEL WITH MANUAL IN-LET OF COFFEE WITH DOORUNLOADING SYSTEM.

ROASTING DRUM: MADE BY A FIXED ELEMENT WITH DOUBLE WALLS INSULATED FOR THERMAL PROTECTION AND SUPPORT OF THE ROTATING CYLINDER MOVING THE PRODUCT. SUCH CYLINDER, COMPLETELY MADE IN COMPOUND STEEL TO OVERCOME THE THERMAL CHANGES, IS DEVELOPED WITH A PERFORATED PLATE FOR THE CONTAINMENT AND SPECIAL BLENDERS ON THE RIGHT AND LEFT SIDE PLACED ON DIFFERENT LEVELS TO GET A PERFECT BLENDING OF COFFEE. AT THE END OF THE ROASTING CYCLE, THE PRODUCT UNLOADING IS ALLOWED BY A WIDE DOOR WITH MANUAL OPENING/CLOSING SYSTEM.

HEATING GAS GENERATOR OF NEW CONCEPT, PATENTED, COMPLETE OF BURNER, RAMP VALVES FOR GAS SAFETY AND ELECTRONIC EQUIPMENTS FOR FLAME CONTROL RATIFIED AND COMPLETE OF SIGNALLING ALARM.

COOLING TANK IN STAINLESS STEEL: WIDE SURFACE PERFORATED WITH TWO ARMS AND CROSSED FLOWS. UNLOADING MOUTH WITH HAND DRIVE.

SUPPORTING FRAME: MONO-BLOCK, PLATE PRESS-BENDED, STEEL MADE, SUPPORTING THE COMPONENTS PREVIOUSLY DESCRIBED.

SAFETY PROTECTION FOR COOLING TANK

ELECTRIC CONTROL BOARD FOR MACHINE MANAGEMENT ACCORDING CE RULES INTEGRATED. COMPLETE OF PLC + TOUCH SCREEN FOR ROASTING MACHINE CONTROL AND MANAGEMENT.

POSSIBLE RECORDING OF ROASTING PARAMETERS

CYCLONE FOR CHAFFS COLLECTING.

INDEPENDENT MOTORIZATION FOR ROASTING DRUM AND COOLING TANK

INDEPENDENT ELECTRIC-FAN FOR ROASTING DRUM AND ELECTRIC –FAN FOR COOLING TANK.QUANTITY: 1

Learn More -

P-5047 STA IMPIANTI ROASTER 10 KILOS

P-5047 STA IMPIANTI ROASTER 10 KILOSP-5047 STA IMPIANTI ROASTER 10 KILOS

STA

MODEL: IMPIANTI

ROASTER

10 KILOS

ROASTING MACHINES LINE, PARTICULARLY SUITABLE FOR LITTLE PRODUCTION ACTIVITIES OF HIGH QUALITY ROASTED COFFEE, SUCH AS SHOPS, PASTRIES OR ARTISANAL LABORATORIES. SMALL SIZE, TECHNOLOGICALLY ADVANCED, CONFIRM THEM ELVES AS IDEAL TOOL FOR THE PRODUCTION OF SELECTED COFFEES IN LITTLE QUANTITY. MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTING MACHINES, ARE AVAILABLE WITH HEATING GENERATOR TYPE GAS BURNER ( AVAILABLE ALSO BY ELECTRIC RESISTANCES ) AND AUTOMATIC CONTROL SYSTEM WITH SEMIAUTOMATIC MANAGEMENT.TECHNICAL DATA:

ROASTER CAPACITY: 10 KG. / MAX. 13 KG. CYCLE

ROASTING CYCLE: 9 MINUTES ÷ 20

RAW COFFEE PROCESSING PER HOUR: 40 KG. ÷ 60

INSTALLED ELECTRIC POWER: 1,5 KW, SINGLEPHASE: 220 VOLT, 50 HZ | SPECIAL TRIPLEPHASE: 220 VOLT, 60 HZ

THERMAL POWER (NATURAL GAS OR LPG): 16000 KCAL/HMAIN COMPONENTS:

HOPPER OF CHARGE IN STAINLESS STEEL

ROASTING DRUM

HEATING GENERATOR OF NEW GENERATION, PATENTED AND COMPLETE OF BURNER

RAMP VALVES FOR GAS SAFETY AND ELECTRIC DEVICE TO CHECK FLAMES RATIFIED AND COMPLETE OF ALARM SIGNAL

COOLING TANK IN STAINLESS STEEL

SAFETY PREVENTION SYSTEM ON THE COOLING TANK

SUPPORTING FRAME FOR THE OVER INDICATED COMPONENTS

ELECTRIC CONTROL BOARD ACCORDING CE RULES, INTEGRATED, COMPLETE OF PLC + TOUCH SCREEN DEVICE FOR ROASTING MACHINE CONTROL AND MANAGEMENT

POSSIBLE RECORDING OF ROASTING PARAMETERS

INDEPENDENT FANS FOR THE ROASTING DRUM AND THE COOLING TANK

INDEPENDENT MOTORS FOR THE ROASTING DRUM AND THE COOLING TANK

CYCLONE FOR CHAFFS COLLECTINGDETAILS OF COMPONENTS:

HOPPER OF CHARGE IN STAINLESS STEEL WITH MANUAL IN-LET OF COFFEE WITH DOOR UNLOADING SYSTEM

ROASTING DRUM: MADE BY A FIXED ELEMENT WITH DOUBLE WALLS INSULATED FOR THERMAL PROTECTION AND SUPPORT OF THE ROTATING CYLINDER MOVING THE PRODUCT. SUCH CYLINDER, COMPLETELY MADE IN COMPOUND STEEL TO OVERCOME THE THERMAL CHANGES, IS DEVELOPED WITH A PERFORATED PLATE FOR THE CONTAINMENT AND SPECIAL BLENDERS ON THE RIGHT AND LEFT SIDE PLACED ON DIFFERENT LEVELS TO GET A PERFECT BLENDING OF COFFEE. AT THE END OF THE ROASTING CYCLE, A WIDE DOOR WITH MANUAL OPENING/CLOSING SYSTEM ALLOWS THE PRODUCT UNLOADING.

HEATING GAS GENERATOR OF NEW CONCEPT, PATENTED, COMPLETE OF BURNER, RAMP VALVES FOR GAS SAFETY AND ELECTRONIC EQUIPMENTS FOR FLAME CONTROL RATIFIED AND COMPLETE OF SIGNALLING ALARM (N°2 FLAME LEVELS).

COOLING TANK IN STAINLESS STEEL: WIDE SURFACE PERFORATED WITH TWO ARMS AND CROSSED FLOWS. UNLOADING MOUTH WITH HAND DRIVE.

SUPPORTING FRAME: MONO-BLOCK, PLATE PRESS-BENDED, STEEL MADE, SUPPORTING THE ELEMENTS PREVIOUSLY DESCRIBED.

SAFETY PROTECTION FOR COOLING TANK

ELECTRIC CONTROL BOARD ACCORDING CE RULES INTEGRATED, COMPLETE OF PLC + TOUCH SCREEN FOR ROASTING MACHINE CONTROL AND MANAGEMENT.

POSSIBLE RECORDING OF ROASTING PARAMETERS

CYCLONE FOR CHAFFS COLLECTING

INDEPENDENT MOTORIZATION FOR ROASTING DRUM AND COOLING TANK

INDEPENDENT ELECTRIC-FAN FOR ROASTING DRUM AND ELECTRIC-FAN FOR COOLING TANK.QUANTITY: 1

Learn More -

R-3261 OFFICINE VITTORIA ROASTER WORKING ANTIQUE - 20 KILOS

R-3261 OFFICINE VITTORIA ROASTER WORKING ANTIQUE - 20 KILOSR-3261 OFFICINE VITTORIA ROASTER WORKING ANTIQUE - 20 KILOS

NICE RESTORED WORKING ANTIQUE FOR THE CIRCA 1950'S. THERE IS A LITTLE GAS BURNER ON THE END OF THE HEAT INLET TUBE - AS THAT IS A COMMON FIX AS ORIGINALLY THE HEAT CAME FROM AN INCINERATOR LOOKING COAL BURNER - SO THE STICKING OF A SMALL PACKAGE BURNER ON THE SAME INLET TUBE WORKS GREAT AS THE SUCTION EXHAUSTING THE AIR THROUGH THE ROASTING DRUM (PERFORATED) SIMPLY PULLS IN THE HEAT NEEDED AND EVERYBODY IS HAPPY. YOU WILL NEED TO SUPPORT THAT INLET ARM IN SOME MANOR.

ADDITIONAL CONCERN IS THERE IS NO SHOWN CHAFF COLLECTOR - AS I WILL HAVE TO VERIFY IF THERE IS ONE - OTHERWISE A SEPARATE CHAFF COLLECTOR WILL NEED TO BE ADDED. THIS IS ALL SET FOR EUROPEAN VOLTAGE - 3 PHASE.

KEEP IN MIND, THE BASE IS ALL CAST IRON - SO THIS OPERATES REALLY QUIETLY, AND THAT IS A GOOD THING. THE SHOWMANSHIP IS STRONG ON THIS MACHINE AS IT LOOKS REALLY GREAT ON A SHOWROOM OR COFFEEHOUSE FLOOR. AS IT IS MADE TO BE SEEN. THIS IS A PARTIAL PROJECT AS THE INSTALLATION WILL TAKE SOME DETAIL AND REMEMBER THAT THERE ARE NO OFFICIAL PARTS SUPPLY - BUT EVERYTHING ON THESE MACHINES IS QUITE EASY TO ACCESS AND HAVING A LOCAL MACHINE SHOP AT HAND IS PROBABLY GOING TO BE NEEDED IN THE FUTURE - AFTER ALL, IT IS A 1950'S VINTAGE.

ALLOW FOR A FLOOR SPACE OF 4' X 7' TO ACCOMMODATE THE ROASTER AND CHAFF COLLECTOR. (1.22M X 2.12M)

THERE WILL BE SOME COST TO CRATE - TO BE ADVISED AS SOON AS YOU KNOW THIS IS THE RIGHT MACHINE FOR YOUR OPERATION.

IN PERFECT WORKING CONDITION

QUANTITY: 1

Learn More -

R-6858 LITTLE COFFEE ROASTERS

R-6858 LITTLE COFFEE ROASTERSR-6858 LITTLE COFFEE ROASTERS

ROASTING MACHINE MODEL EXPO 500

THE LITTLE ROASTING MACHINE MODEL EXPO IS USED FOR LABORATORY TESTS OR TO SEARCH FOR NEW BLENDS AND FLAVORS. TECHNOLOGICALLY ADVANCED, CONFIRMS ITSELF AS IDEAL TOOL FOR LABORATORYES TEST, LIKE QUALITY CONTROL ON RAW COFFEE.

ROASTER MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTING MACHINES, IS AVAILABLE WITH HEATING GENERATOR TYPE ELECTRIC RESISTANCE OR GAS, WITH MANUAL CONTROL SYSTEM.COMPONENTS:

HOPPER OF CHARGE

HEATING GENERATOR BY ELECTRIC RESISTANCE OR GAS BURNER

COOLING TANK

2 ELECTRONIC DISPLAYS TO CONTROL THE PRODUCT TEMPERATURE INSIDE

THE ROASTING DRUM AND HEATING GENERATOR.SAFETY DEVICE FOR ELECTRIC RESISTANCE SWITCHING OFF

DRUM ROTATION BY GEARED MOTOR

ELECTRIC FAN FOR ROASTING DRUM AND COOLING TANK

CYCLONE WITH REMOVABLE CONTAINER

COLOURS AVAILABLE: ACCORDING CLIENTS REQUEST

ROASTING MACHINE MOD.ROAST.1000

ROASTING MACHINE PARTICULARLY SUITABLE FOR SPECIALIZED ACTIVITIES IN SMALL BATCHES OF ROASTED COFFEE OF SUPERIOR QUALITY, SUCH AS THE MARKET “SLOW FOOD”, COFFEE SHOPS, CONFECTIONERY SHOP. TECHNOLOGICALLY ADVANCED, CONFIRMS ITSELF AS IDEAL TOOL SPECIALIZED IN PRODUCTION OF SELECTED ROASTED COFFEES OF HIGH QUALITY. MACHINE MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTERS, IS AVAILABLE WITH HEATING GENERATOR BY ELECTRIC RESISTANCE AND PLC CONTROL SYSTEM OR AUTOMATIC.

COMPONENTS:HOPPER OF CHARGE

Learn More

HEATING GENERATOR BY ELECTRIC RESISTANCE OR GAS BURNER

COOLING TANK

MONITOR TOUCH SCREEN TO SEE AND CONTROL ALL THE ROASTING PROCESS FUNCTIONS.

SAFETY DEVICE FOR ELECTRIC RESISTANCES SWITCHING OFF

DRUM ROTATION BY GEARED MOTOR

ELECTRIC FAN FOR ROASTING DRUM

ELECTRIC FAN FOR COOLING TANK

CYCLONE WITH REMOVABLE CONTAINER

DEVICE FOR AUTOMATIC UNLOADING AT THE END OF ROASTING CYCLE

ACOUSTIC ALARM ADVISING THE ENDING OF ROASTING CYCLE

AVAILABLE COLOURS: ALUMINIUM / BRASS -

R-3270 SAMIAC CAST-IRON ROASTER COMPLETE SYSTEM - 60 KILOS

R-3270 SAMIAC CAST-IRON ROASTER COMPLETE SYSTEM - 60 KILOSR-3270 SAMIAC CAST-IRON ROASTER COMPLETE SYSTEM - 60 KILOS

5.8 KW/H ELECTRICAL - 220 VAC, 60HZ. 3 PHASE - 30 AMP BREAKER.

NATURAL GAS

INCLUDES: LOADER, ROASTER COOLER, DE-STONER, DUAL CHAFF COLLECTORS INCLUDING INCINERATING STYLE COLLECTOR, AFTERBURNER. ALL AUTOMATED CONTROLS FROM YOUR CONTROL PANEL. THIS IS EXTREME INDUSTRIAL IN EVERY WAY.

NOTE: THE COLOR ON ALL EXTERIOR SURFACES LOOKS NEW - THE FRONT PANEL OF THE ROASTER HAS BE LEFT "NATURAL" SHOWING THE GRAIN OF THE CAST IRON - THIS WAS DONE ON PURPOSE - AS ENGINEERING AND THE ORIGINAL OWNER WANTED TO OIL THE SURFACE IN ORDER TO DEMONSTRATE THE TEXTURE OF THE CAST IRON. SORT OF A HIGH-TECH APPEAL.HERE IS A MOST UNUSUAL 60 KILO ROASTER THAT HAS COME UP. THIS IS A CLOSE TO NEW AS YOU WILL EVER SEE - AS IT HAS BEEN USED SPARINGLY SINCE NEW IN 2008 AND IT IS NOW GOING TO BE REMOVED TO MAKE WAY FOR A PLANT REMODEL. SAMIAC WAS A GREAT MAKER OF CAST IRON ROASTERS - DOUBLE DRUM TOO. EVERYTHING IN THE ROASTER IS "OFF THE SHELF" AND THE FACT THAT SAMIAC IS NO LONGER AROUND IS A NON ISSUE AS ALL OF THE COMPONENTS LIKE MOTORS, CONTROLS, SWITCHES, BURNER ARE ALL EITHER US OR CANADA SUPPLIED AND ARE ALL UL, CSA, AGA ETC, ETC. PERHAPS YOU GET THE IDEA THAT I LIKE THIS ROASTER.

STUDY THE PHOTOS (TAKEN END OF MAY 2016. AND YOU WILL SEE HOW CLEAN THIS MACHINE REALLY IS. IT IS TOTALLY CLEANED EVERY DAY OF USE (NOT USED EVERY DAY EITHER) AS PART OF THE SHUT DOWN - THERE IS NEVER EVEN A SPECK OF CRUD LEFT ON THIS MACHINE, EVER. I KNOW OF NO OTHER PLANT THAT IS KEPT THIS CLEAN. WE COULD EAT OFF THIS MACHINE - TOTALLY SUPER CLEAN!

QUANTITY: 1

Learn More -

R-3246 STA RE-5 CONVECTION ROASTER - 5 KILOS

R-3246 STA RE-5 CONVECTION ROASTER - 5 KILOSR-3246 STA RE-5 CONVECTION ROASTER - 5 KILOS

THIS IS A REALLY GREAT ROASTER - ESPECIALLY FRIENDLY TO BLENDS AS IT CREATES A VERY EVEN ROAST WITH NO TIPPING OR SCORCHING. THIS IS A BRAND THAT IS MORE KNOWN IN ITALY - BUT THE STA ROASTING GROUP HAS A HISTORY OF PRINCIPALS WITH LOTS OF ROASTING MACHINERY BACKGROUND. THUS THEIR CHANGES ARE MORE TECHNICALLY ADVANCED AND NOT SO MUCH FOR COSMETICS.

FEATURES:

SINGLE PHASE

FOUR MOTORS

AUTOMATIC GAS BURNER TWO FANS (COOLING AND CHAFF COLLECTION)

CHAFF COLLECTION CHAMBER

CAPACITY IS 20 KG PER HOUR.

LOCATED IN CROATIATECHNICAL DATA:

CHARGE HOPPER OF CHARGE IN STAINLESS STEEL

ROASTING DRUM IS PERFORATED FOR MAXIMUM AIR CONTROL

HEATING IS HOT CONVECTION AIR GENERATOR OF NEW GENERATION

RAMP VALVES FOR GAS SAFETY AND ELECTRIC DEVICE TO CHECK FLAMES RATIFIED AND COMPLETE OF ALARM SIGNAL - COOLING TRAY IN STAINLESS STEEL

SAFETY PREVENTION SYSTEM ON THE COOLING TRAY

ELECTRIC CONTROL BOARD TO CHECK AND CONTROL THE MACHINE ACCORDING CE RULES, INTEGRATED COMPLETE OF THERMO-REGULATOR DEVICE FOR BURNER MANAGEMENT AND DISPLAY FOR TEMPERATURES SIGHT

INDEPENDENT FANS FOR THE ROASTING DRUM AND THE COOLING TRAY

INDEPENDENT MOTORS FOR THE ROASTING DRUM AND THE COOLING TRAY

CYCLONE FOR CHAFF COLLECTING

SEMIAUTOMATIC MANAGEMENT OF THE ROASTING CYCLE.

FUEL: NATURAL GAS OR PROPANE

HEATING CONVECTION SYSTEM:

PATENTED SYSTEM BY STA IMPIANTI. THIS SYSTEM ALLOWS SHORTER AND HOMOGENEOUS ROASTING TIME:

BY CONVECTION OF HOT AIR FLOWING THROUGH THE COFFEE IN THE DRUM.

BY CONDUCTION (LIMITED AMOUNT ONLY) DUE TO THE HEATED AIR HITTING THE PERFORATED ROASTING DRUM.

BY RADIANCE FROM THE GRATE LOCATED BETWEEN THE FLAME AND THE ROASTING DRUM (INFRARED RAYS).SPECS:

ROASTER CAPACITY: 5 STANDARD 7 MAX TO KILOS PER CYCLE

INDICATIVE ROASTING CYCLE: 9 ÷ 20 MINUTES

INSTALLED POWER: 0,9 KW

THERMAL POWER: 10 KW

WEIGHT: 170 KG

DIMENSIONS: 850mm (34") L X 1150mm (45") W X 1530mm H (60")QUANTITY: 1

Learn More -

P-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOS

P-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOSP-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOS

THIS ROASTER OFFERS EXACTLY WHAT CUSTOMERS NEED TO PRODUCE TOP-QUALITY COFFEE. AN INNOVATIVE AND EASY-TO-USE PLC CONTROL SYSTEM ENSURES CONSTANT QUALITY DURING PRODUCTION BUT ALSO RETAINS THE ABILITY TO INFLUENCE THE PROCESSING WHEN NECESSARY. OPTIMIZED PARAMETERS CAN BE SAVED IN THE MACHINE’S MEMORY AND RE-USED. THE MACHINE IS MADE OF STAINLESS STEEL AND OTHER HIGH-QUALITY MATERIALS WHICH PROVIDE SUPERIOR HYGIENE AND MAKE CLEANING COMFORTABLE. THIS ROASTER PROVES THAT DURABILITY AND A MODERN DESIGN CAN BE COMBINED.

THE ROASTER BECOMES A PLUG-AND-PLAY MACHINE BY THE COMBINATION OF SEPARATE COOLING AND HEATING FANS WHICH ALLOW TO ROAST AND COOL AT THE SAME TIME WITH THE INCLUDED CYCLONE. HOT AIR IS THE BEST CHOICE TO ENSURE A UNIFORM ROAST, BECAUSE OF THE HOMOGENOUS HEAT TRANSFER.

THE VARIABLE DRUM SPEED OF THE ROASTING CHAMBER AND THE TWO STEP BURNER ALWAYS DELIVER THE BEST CONDITIONS FOR THE PRODUCT – NO MATTER IF THE BEANS ARE HEAVY AND SMALL AT THE BEGINNING OF THE PROCESS OR IF THEY HAVE ALREADY BECOME LIGHTER TOWARDS TO THE END OF THE ROAST. THE HELICOIDAL BLADES POWERED BY A VARIABLE DRUM SPEED DRIVE OFFER A PERFECT BLENDING AND AN OPTIMAL HEAT EXCHANGE AT ANY TIME OF THE PROCESS. MOREOVER, THE ERGONOMICALLY DESIGNED ROASTER PROVIDES MAXIMUM SAFETY.

THIS ROASTER WAS DESIGNED TO PROVIDE SMALL AND MEDIUM-SIZED COMPANIES WITH A FLEXIBLE HIGH-QUALITY SOLUTION. THE SOPHISTICATED DESIGN OF THE ROASTING MACHINE PLUS MODERN PROCESS TECHNOLOGY ENSURES A HIGH-QUALITY COFFEE PRODUCT THAT IS UNIFORMLY ROASTED – FROM THE SURFACE TO THE CORE OF EVERY SINGLE COFFEE BEAN.

THE COFFEE AND THE HOT AIR TEMPERATURE AS WELL AS THE ROASTING TIME PER BATCH IS PERMANENTLY MONITORED VIA THE TOUCH SCREEN. THE MACHINE’S DESIGN FEATURES AND INSULATING MATERIALS REDUCE INERTIA AND HEAT LOSS TO A MINIMUM, WHICH IMPACTS POSITIVELY ON WORKING ENVIRONMENTS AND FUEL CONSUMPTION.

FEATURES:

AUTOMATIC AND EASY-TO-USE PLC CONTROL SYSTEM WITH INTEGRATED TOUCH PANEL, PARAMETER MEMORY, TEMPERATURE TREND AND SAFETY FEATURES.

GOOD VALUE FOR MONEY.

INDIRECT, CONVECTIVE HOT-AIR SYSTEM FOR UNIFORM ROASTING.

FULL RANGE HEAT CONTROL - BURNER MODULATES BETWEEN 130,000 BTU ALL THE WAY DOWN TO A MERE 20,000 BTU

VARIABLE DRUM SPEEDS OFFER OPTIMAL HEAT TRANSFER AND PRODUCT QUALITY.

FUNCTIONAL AND ATTRACTIVE MACHINE DESIGN MADE OF HIGH-QUALITY MATERIAL.

STATE-OF-THE-ART TECHNOLOGY AND A PLC CONTROL SYSTEM OFFER USER-FRIENDLY AND EFFICIENT COFFEE ROASTING.

A WIDE VARIETY OF GREEN COFFEE CHARACTERISTICS AND BLENDS CAN BE PROCESSED TO HIGH-CLASS COFFEE PRODUCTS.

A USER-FRIENDLY AUTOMATION-PANEL ALLOWS THE PERFECT CONTROL OVER VARIOUS PROCESS PARAMETERS.

UL LISTED AND MADE RIGHT HERE IN MINNEAPOLIS.

GAS CONSUMPTION: RATED AT MAXIMUM - UP TO 150,000BTU (44KW/HR) OPERATES BEST BETWEEN 75 - 80,000 BTUOPTIONAL FEATURES:

PNEUMATIC FEEDER

PNEUMATIC DESTONER/DISCHARGE UNIT

AFTERBURNERQUANTITY: 1

Learn More -

P-5042 JOPER CAST IRON SMALL BATCH ROASTER 5 KILOS

P-5042 JOPER CAST IRON SMALL BATCH ROASTER 5 KILOSP-5042 JOPER CAST IRON SMALL BATCH ROASTER 5 KILOS

JOPER

CAST IRON SMALL BATCH ROASTER

5 KILOS

JOPER 5 KILOS AUTOMATIC PROFILING CONTROLS. SHIPS WITH YOUR ELECTRICAL AND GAS SPECIFICATIONS. FEATURES THE SAME CAST IRON ATTRIBUTES OF THE OLD PROBAT SCHOOL. THE DRUM ROASTING MACHINE RUNS QUIETLY DUE TO THE HIGH FIBER INSULATION AND NO PULLEYS OR CHAINS IN ITS DESIGN. CHAFF REMOVAL IS QUICK AND EFFICIENT DUE TO THE FREE STANDING DESING. THE POWERFUL SELF CLEANING ROASTING AND COOLING FANS ALLOWS THE SEPARATE AIRFLOW. TWO MODELS: MANUAL AND PROFILE (AUTOMATIC)DATA:

LOAD CAPACITY 11/POUUNDS BATCH 44 POUNDS PER HOUR

ROASTING TIME 15 MINUTES COOLING 3 MINUTES

NATURAL GAS OR PROPANE

ELECTRICAL REQUIREMENTS CAN NE BEUILT TO YOUR SPECIFICATIONS.

220v 3 PHASE IS THE MOST QUIET, BUT THE ELECTRICAL CAN BE BUILT TO YOUR NEEDED VOLTAGE AND PHASE.

LOW NOX PRECISE BURNER ADJUSTMENT

WEIGHT WITH COOLOR AND CHAFF 992 POUNDS

DIRECT DRIVE SEPARATE MOTORS (4 OF THEM)

REQUIRED FLOOR SPACE: 56 INCHES WIDE 84 INCHES FRONT TO BACK, 79 INCHES HIGH

(DIMS INCLUDE EXTERNAL CHAFF COLLECTOR)

BURNER POWER: 95,000 BTU

BUILT TO UL295 STANDARDSQUANTITY: 1

Learn More -

R-3266 SIROCCO SR 35 ROASTER - 35 KILOS

R-3266 SIROCCO SR 35 ROASTER - 35 KILOSR-3266 SIROCCO SR 35 ROASTER - 35 KILOS

SEVEN “MACHINES” IN ONE BODY. THAT SAVES YOU PRECIOUS SPACE, EXPENSIVE ENERGY, REDUCES WASTE AND TOTALLY QUIET. WHEN COMPARING, REMEMBER THAT YOU WILL NEVER NEED TO BUY OXIDIZER, AND A AFTERBURNER, SINCE IT IS ALL INCLUDED.

AFTERBURNER

INCINERATOR

CHAFF COLLECTOR

MANUALLY & PROGRAMMED PROFILE CONTROLLER

VARIABLE AIR SPEED CONTROLLER

SEPARATE HEAT CONTROLLER

GAS MODULATING CONTROLLERCOMPLETE ROASTING PROCESS WITH ALL FEATURES BUILT INSIDE ONE MACHINE

GENTLE CAST IRON ROASTING ENVIRONMENT

MECHANICALLY FLUIDIZED BEAN MOVEMENT

INTEGRATED AFTERBURNER AND INCINERATOR

TO ELIMINATE SMOKE, ODOR AND CHAFF

GRAPHICAL TOUCH SCREEN WITH PROFILE MEMORY

OVERSIZED INSPECTION PORTS

STIRFLEX COOLING TRAY

QUICK-RELEASE COOLER WITH REMOVABLE SCREEN

MAINTENANCE FREE SEALED ROASTING DRUM

BUILT-IN STONER BOOT

LOW PROFILE INFEED HOPPER

WEB-ENABLED FOR FACTORY ASSISTANCE AND DIAGNOSTICS

AUTOMATIC OR SEMI-AUTOMATIC OPERATION FOR CONSISTENT BATCHES

CLEAR PROCESS INFORMATION INCLUDES BEAN TEMP., ELAPSED TIME,

TEMPERATURE CHANGE AND STATUSSPECIFICATIONS:

MODEL #: SR 35

BATCH CAPACITY: 35 KGS

DIMENSIONS: 35" W X 112" L X 84" H

COOLER DIAMETER: 40

HEAT SPECIFICATIONS: GAS & 380K-760K

WEIGHT: 3600 LBSQUANTITY: 1

Learn More -

P-5079 COMMERCIAL JOPER CAST IRON CRM-30 ROASTER 30 KILOS

P-5079 COMMERCIAL JOPER CAST IRON CRM-30 ROASTER 30 KILOSP-5079 COMMERCIAL JOPER CAST IRON CRM-30 ROASTER 30 KILOS

WHAT WE HAVE HERE IS A VERY RUGGED CAST IRON ROASTING FRAME AND ROASTING CONTACT CLEARANCES WITH THE MACHINE - JUST PLAIN SOLID AND DOES NOT MOVE UNDER LONG OR EXTENDED USE. DOUBLE WALL DRUM MEANS THAT THE HEAT IS ALL DESIGNED TO GO THROUGH THE CENTER OF THE ROASTING CHAMBER, NOT "ONTO" THE DRUM EXTERIOR. TOTAL TRUE CONVECTION. NOT ONLY IS THIS THE SAME STYLE FROM THE OLD GOTHOT & BARTH ROASTER DAYS. . . BUT EVEN BETTER AS THE SHAFT DESIGN SO THAT BEARINGS ARE EXTERNALLY MOUNTED AND ADDITIONALLY ARE AIR COOLED FOR LONG LIFE AND TROUBLE-FREE CONTROL. EVEN THE SIDE PANELS OR PRODUCT FLIGHTS HAVE A LONGER CURVE POSITIONING MORE PRODUCT FLOW INTO THE HOT AIR STREAM, RESULTING IN A SLIGHTLY MORE RAPID ROAST WITH MORE EVEN BEAN INTERIOR AND EXPANSION THAT FRANKLY LEADS THE INDUSTRY.

ALL THIS COMMENTARY ABOVE MEANS THIS ROASTER SIMPLY IS MORE QUIET THAN ANYTHING ON THE MARKET. PERIOD. THERMAL INSULATION WITH HIGHEST QUALITY OF FIBER FOR LOW GAS CONSUMPTION; DIGITAL TEMPERATURE CONTROL. CYCLONE IS SEPARATE. THE COOLER, BEING TOTALLY SEPARATE ALSO HAS THE LARGEST AIR COLLECTION AREA OF ANY ROASTER MADE ALLOWING FOR TOTAL AMBIENT COOL COFFEE IN LESS THAN THREE MINUTES. ADD TO THIS PACKAGE A LOADER OR YOUR CHOICE OF DESTONERS AND EVEN YOUR CHOICE OF CONTROL METHODS.

DATA INFORMATION:

BATCH CAPACITY: 30 KG / 66 LBS

CONTROL DESIGN: MANUAL

CAPACITY PER HOUR: 120 KG / 265 LBS

ROASTING TIME: 12-18 MIN (4 BATCHES AN HOUR)

EXHAUST AIR TREATMENT: OPTIONAL

COOLING CYCLONE: OPTIONAL

PRE-COOLING WITH WATER IN DRUM: OPTIONAL

COOLING TIME: 3-4 MIN

TYPE OF COOLING: AIR AMBIENT

SAFETY DEVICE: YES

BURNER POWER: 110 KW / 375000 BTU

BURNERS MANUFACTURER: RIELLO

OPERATION TYPE BURNER: BS2D-2 STAGE

FUEL TYPE: PROPANE/NAUTRAL GAS/DIESEL

SIDE OF OPERATION: LEFT

POWER REQUIREMENTS: 20 AMP

VOLTAGE/FREQUENCY/PHASES: 400+N-230 V / 50-60 HZ / 3 PH

9 AMP. . . 3 PHASE 50/60 HZ PREFERRED, YOUR CHOICE OF 220/440 - SINGLE PHASE AVAILABLE AT SPECIAL REQUEST

(NOTE ON 3 PHASE. . . NOT ONLY IS IT LESS EXPENSIVE TO OPERATE, BUT IT RUNS MORE QUIETLY THAN SINGLE PHASE WHENEVER OR WHEREVER IT IS USED. KEEP THIS IN MIND FOR ANY MACHINERY.)

Ø EXHAUST CHIMNEY (ROASTER CYCLONE): 250MM / 9,8 INCH

Ø EXHAUST CHIMNEY (COOLER): 250MM / 9,8 INCH

Ø HOPPER ROAST CHIMNEY: 150MM / 5,9 INCH

ROASTER WEIGHT WITH CYCLONE: 1050 KG / 2310 LBS

COOLER WEIGHT: 300 KG / 660 LBS

ROASTER FAN MOTOR: 1, 5 HP

COOLER FAN: 4 HP

DRUM GEARBOX: 1 HP

COOLER GEARBOX: 0, 75 HP

BUILT TO UL295 STANDARDS.QUANTITY: 1

Learn More