Search results for: 'qua'

- Related search terms

- quart

- quả cà na

- quant prep

- qua'

- quadra

-

R-7087 901N-TQ ESPRESSO GRINDER (TIMER QUANTITATIVE)

R-7087 901N-TQ ESPRESSO GRINDER (TIMER QUANTITATIVE)R-7087 ESPRESSO GRINDER (TIMER QUANTITATIVE)

SIZE: 330X200X570 (mm)

WEIGHT: 10.8KG

PACKING SIZE: 600X260X405 (mm)

PACKING WEIGHT: 12.5KG

POWER: 360W 1/2HP

BLADES SPEED: 1400 R.P.M

FUNNEL CAPACITY: 1.2KG

BLADES SIZE: FLAT Ø 64mm (MADE IN ITALY)

GRINDING CAPACITY: 10-15KG/HR.

COLOR: RED/BLACK/SILVER

STRONG HORSEPOWER. TWO SETS OF TIMER SETTING AND MANUAL SWITCH. RAPID GRINDING BECAUSE OF THE LARGE BLADES, IT IS NOT EASY TO LET THE BLADES HOT. STEPLESS MICRO GRINDING ADJUSTMENT. TUNNEL OF POWDER OUTLET IS VERY SHORT, RARELY POWDER LEAVE AND EASILY CLEAN. BUILT-IN WITH COOLING FAN SUITABLE FOR COFFEE SHOP.QUANTITY: 1

Learn More -

R-4395 SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

R-4395 SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOURREFERENCE NUMBER: R-4395

SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

MAIN TECHNICAL PARAMETERS:

PROFILES:

THIS LINE IS USED TO PRODUCE CANDIES IN VARIOUS COLORS AND DESIGNS, ESPECIALLY BUBBLE GUM IN X SHAPE, CUBIC, CORRUGATED, CHANNEL STYLE, AND OTHER KINDS.

IT IS DESIGNED TO FACILITATE THE OPERATION WITH RELIABLE PERFORMANCE AND CHANGEABLE CANDY STYLE.

A CORRUGATION-STYLE WRAPPING MACHINE OR A CUTTING/WRAPPING MACHINE CAN BE SUPPLIED IF REQUIRED.

ADVANTAGES:

1) RELIABILITY, EASY CLEANING AND MAINTENANCE

2) ACCURATE CUTTING AND SIMPLE CHANGEOVER

3) EASY OPERATION

4) AUTOMATIC BELT TENSIONING

REFERENCE NUMBER: R-4395

SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

MAIN TECHNICAL PARAMETERS:

PROFILES:

THIS LINE IS USED TO PRODUCE CANDIES IN VARIOUS COLORS AND DESIGNS, ESPECIALLY BUBBLE GUM IN X SHAPE, CUBIC, CORRUGATED, CHANNEL STYLE, AND OTHER KINDS.

IT IS DESIGNED TO FACILITATE THE OPERATION WITH RELIABLE PERFORMANCE AND CHANGEABLE CANDY STYLE.

A CORRUGATION-STYLE WRAPPING MACHINE OR A CUTTING/WRAPPING MACHINE CAN BE SUPPLIED IF REQUIRED.

ADVANTAGES:

1) RELIABILITY, EASY CLEANING AND MAINTENANCE

2) ACCURATE CUTTING AND SIMPLE CHANGEOVER

3) EASY OPERATION

4) AUTOMATIC BELT TENSIONING

Learn More -

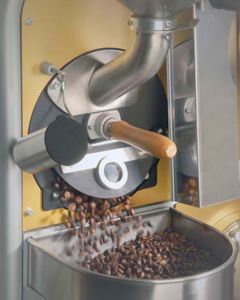

P-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOS

P-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOSP-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOS

THIS ROASTER OFFERS EXACTLY WHAT CUSTOMERS NEED TO PRODUCE TOP-QUALITY COFFEE. AN INNOVATIVE AND EASY-TO-USE PLC CONTROL SYSTEM ENSURES CONSTANT QUALITY DURING PRODUCTION BUT ALSO RETAINS THE ABILITY TO INFLUENCE THE PROCESSING WHEN NECESSARY. OPTIMIZED PARAMETERS CAN BE SAVED IN THE MACHINE’S MEMORY AND RE-USED. THE MACHINE IS MADE OF STAINLESS STEEL AND OTHER HIGH-QUALITY MATERIALS WHICH PROVIDE SUPERIOR HYGIENE AND MAKE CLEANING COMFORTABLE. THIS ROASTER PROVES THAT DURABILITY AND A MODERN DESIGN CAN BE COMBINED.

THE ROASTER BECOMES A PLUG-AND-PLAY MACHINE BY THE COMBINATION OF SEPARATE COOLING AND HEATING FANS WHICH ALLOW TO ROAST AND COOL AT THE SAME TIME WITH THE INCLUDED CYCLONE. HOT AIR IS THE BEST CHOICE TO ENSURE A UNIFORM ROAST, BECAUSE OF THE HOMOGENOUS HEAT TRANSFER.

THE VARIABLE DRUM SPEED OF THE ROASTING CHAMBER AND THE TWO STEP BURNER ALWAYS DELIVER THE BEST CONDITIONS FOR THE PRODUCT – NO MATTER IF THE BEANS ARE HEAVY AND SMALL AT THE BEGINNING OF THE PROCESS OR IF THEY HAVE ALREADY BECOME LIGHTER TOWARDS TO THE END OF THE ROAST. THE HELICOIDAL BLADES POWERED BY A VARIABLE DRUM SPEED DRIVE OFFER A PERFECT BLENDING AND AN OPTIMAL HEAT EXCHANGE AT ANY TIME OF THE PROCESS. MOREOVER, THE ERGONOMICALLY DESIGNED ROASTER PROVIDES MAXIMUM SAFETY.

THIS ROASTER WAS DESIGNED TO PROVIDE SMALL AND MEDIUM-SIZED COMPANIES WITH A FLEXIBLE HIGH-QUALITY SOLUTION. THE SOPHISTICATED DESIGN OF THE ROASTING MACHINE PLUS MODERN PROCESS TECHNOLOGY ENSURES A HIGH-QUALITY COFFEE PRODUCT THAT IS UNIFORMLY ROASTED – FROM THE SURFACE TO THE CORE OF EVERY SINGLE COFFEE BEAN.

THE COFFEE AND THE HOT AIR TEMPERATURE AS WELL AS THE ROASTING TIME PER BATCH IS PERMANENTLY MONITORED VIA THE TOUCH SCREEN. THE MACHINE’S DESIGN FEATURES AND INSULATING MATERIALS REDUCE INERTIA AND HEAT LOSS TO A MINIMUM, WHICH IMPACTS POSITIVELY ON WORKING ENVIRONMENTS AND FUEL CONSUMPTION.

FEATURES:

AUTOMATIC AND EASY-TO-USE PLC CONTROL SYSTEM WITH INTEGRATED TOUCH PANEL, PARAMETER MEMORY, TEMPERATURE TREND AND SAFETY FEATURES.

GOOD VALUE FOR MONEY.

INDIRECT, CONVECTIVE HOT-AIR SYSTEM FOR UNIFORM ROASTING.

FULL RANGE HEAT CONTROL - BURNER MODULATES BETWEEN 130,000 BTU ALL THE WAY DOWN TO A MERE 20,000 BTU

VARIABLE DRUM SPEEDS OFFER OPTIMAL HEAT TRANSFER AND PRODUCT QUALITY.

FUNCTIONAL AND ATTRACTIVE MACHINE DESIGN MADE OF HIGH-QUALITY MATERIAL.

STATE-OF-THE-ART TECHNOLOGY AND A PLC CONTROL SYSTEM OFFER USER-FRIENDLY AND EFFICIENT COFFEE ROASTING.

A WIDE VARIETY OF GREEN COFFEE CHARACTERISTICS AND BLENDS CAN BE PROCESSED TO HIGH-CLASS COFFEE PRODUCTS.

A USER-FRIENDLY AUTOMATION-PANEL ALLOWS THE PERFECT CONTROL OVER VARIOUS PROCESS PARAMETERS.

UL LISTED AND MADE RIGHT HERE IN MINNEAPOLIS.

GAS CONSUMPTION: RATED AT MAXIMUM - UP TO 150,000BTU (44KW/HR) OPERATES BEST BETWEEN 75 - 80,000 BTUOPTIONAL FEATURES:

PNEUMATIC FEEDER

PNEUMATIC DESTONER/DISCHARGE UNIT

AFTERBURNERQUANTITY: 1

Learn More -

M-4690 FULL AUTOMATIC SINGLE HEAD CHOCOLATE PRODUCTION LINEREFERENCE NUMBER: M-4690 (11111B176Y10UF) L FULL AUTOMATIC SINGLE HEAD CHOCOLATE PRODUCTION LINE TOTAL ELECTRIC POWER: 21KW AIR COMPRESSOR: CONSUMPTION: 0.22M3/MIN, PRESSURE: 0.7MPA WORKING CNDITION: TEMPERATURE: 20 TO 25°C CHOCOLATE WEIGHT: PURE CHOCOLATE: 2.5 TO 512 G, CENTRE FILLED CHOCOLATE: 15 TO 40G TOTAL MACHINE WEIGHT: 5,250KGS TOTAL MACHINE SIZE: 16.7 x 1.21 x 2.5 M MOULD SIZE: 280 x 200 x 30mm AND 300 x 225 x 30mm THE FOOD CONTACT SPARE PARTS ARE ALL PLATED WITH NICKEL. DOUGH HOPPER INSIDE SURFACE IS MADE OF STAINLESS STEEL 304, BEAUTIFUL AND CLEAN. TO MEET THE STANDARD OF FOOD STANDARD. COCOA BUTTER MELTING TANK (1SET) SUGAR GRINDING MACHINE (1SET) 500L CHOCOLATE CONCH (REFINER) (2SET) 500L CHOCOLATE HOLDING TANK (2SET) QH320 CHOCOLATE SYRUP PUMP (2SET) QH25CHOCOLATE SYRUP PUMP (2SET) QH-I SINGLE HEAD CHOCOLATE DEPOSITING AND COOLING TUNNEL (1SET) CHOCOLATE MOULDS (280PCS) CONTROL PANEL BOX (1PCS) OTHER OPTIONAL EQUIPMENTS: (CHOOSE WHEN USE NATURAL COCOA BUTTER) 250KG CHOCOLATE TEMPERING MACHINE 1SET QUANTITY AVAILABLE: 1 Learn More

M-4690 FULL AUTOMATIC SINGLE HEAD CHOCOLATE PRODUCTION LINEREFERENCE NUMBER: M-4690 (11111B176Y10UF) L FULL AUTOMATIC SINGLE HEAD CHOCOLATE PRODUCTION LINE TOTAL ELECTRIC POWER: 21KW AIR COMPRESSOR: CONSUMPTION: 0.22M3/MIN, PRESSURE: 0.7MPA WORKING CNDITION: TEMPERATURE: 20 TO 25°C CHOCOLATE WEIGHT: PURE CHOCOLATE: 2.5 TO 512 G, CENTRE FILLED CHOCOLATE: 15 TO 40G TOTAL MACHINE WEIGHT: 5,250KGS TOTAL MACHINE SIZE: 16.7 x 1.21 x 2.5 M MOULD SIZE: 280 x 200 x 30mm AND 300 x 225 x 30mm THE FOOD CONTACT SPARE PARTS ARE ALL PLATED WITH NICKEL. DOUGH HOPPER INSIDE SURFACE IS MADE OF STAINLESS STEEL 304, BEAUTIFUL AND CLEAN. TO MEET THE STANDARD OF FOOD STANDARD. COCOA BUTTER MELTING TANK (1SET) SUGAR GRINDING MACHINE (1SET) 500L CHOCOLATE CONCH (REFINER) (2SET) 500L CHOCOLATE HOLDING TANK (2SET) QH320 CHOCOLATE SYRUP PUMP (2SET) QH25CHOCOLATE SYRUP PUMP (2SET) QH-I SINGLE HEAD CHOCOLATE DEPOSITING AND COOLING TUNNEL (1SET) CHOCOLATE MOULDS (280PCS) CONTROL PANEL BOX (1PCS) OTHER OPTIONAL EQUIPMENTS: (CHOOSE WHEN USE NATURAL COCOA BUTTER) 250KG CHOCOLATE TEMPERING MACHINE 1SET QUANTITY AVAILABLE: 1 Learn More -

R-6858 LITTLE COFFEE ROASTERS

R-6858 LITTLE COFFEE ROASTERSR-6858 LITTLE COFFEE ROASTERS

ROASTING MACHINE MODEL EXPO 500

THE LITTLE ROASTING MACHINE MODEL EXPO IS USED FOR LABORATORY TESTS OR TO SEARCH FOR NEW BLENDS AND FLAVORS. TECHNOLOGICALLY ADVANCED, CONFIRMS ITSELF AS IDEAL TOOL FOR LABORATORYES TEST, LIKE QUALITY CONTROL ON RAW COFFEE.

ROASTER MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTING MACHINES, IS AVAILABLE WITH HEATING GENERATOR TYPE ELECTRIC RESISTANCE OR GAS, WITH MANUAL CONTROL SYSTEM.COMPONENTS:

HOPPER OF CHARGE

HEATING GENERATOR BY ELECTRIC RESISTANCE OR GAS BURNER

COOLING TANK

2 ELECTRONIC DISPLAYS TO CONTROL THE PRODUCT TEMPERATURE INSIDE

THE ROASTING DRUM AND HEATING GENERATOR.SAFETY DEVICE FOR ELECTRIC RESISTANCE SWITCHING OFF

DRUM ROTATION BY GEARED MOTOR

ELECTRIC FAN FOR ROASTING DRUM AND COOLING TANK

CYCLONE WITH REMOVABLE CONTAINER

COLOURS AVAILABLE: ACCORDING CLIENTS REQUEST

ROASTING MACHINE MOD.ROAST.1000

ROASTING MACHINE PARTICULARLY SUITABLE FOR SPECIALIZED ACTIVITIES IN SMALL BATCHES OF ROASTED COFFEE OF SUPERIOR QUALITY, SUCH AS THE MARKET “SLOW FOOD”, COFFEE SHOPS, CONFECTIONERY SHOP. TECHNOLOGICALLY ADVANCED, CONFIRMS ITSELF AS IDEAL TOOL SPECIALIZED IN PRODUCTION OF SELECTED ROASTED COFFEES OF HIGH QUALITY. MACHINE MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTERS, IS AVAILABLE WITH HEATING GENERATOR BY ELECTRIC RESISTANCE AND PLC CONTROL SYSTEM OR AUTOMATIC.

COMPONENTS:HOPPER OF CHARGE

Learn More

HEATING GENERATOR BY ELECTRIC RESISTANCE OR GAS BURNER

COOLING TANK

MONITOR TOUCH SCREEN TO SEE AND CONTROL ALL THE ROASTING PROCESS FUNCTIONS.

SAFETY DEVICE FOR ELECTRIC RESISTANCES SWITCHING OFF

DRUM ROTATION BY GEARED MOTOR

ELECTRIC FAN FOR ROASTING DRUM

ELECTRIC FAN FOR COOLING TANK

CYCLONE WITH REMOVABLE CONTAINER

DEVICE FOR AUTOMATIC UNLOADING AT THE END OF ROASTING CYCLE

ACOUSTIC ALARM ADVISING THE ENDING OF ROASTING CYCLE

AVAILABLE COLOURS: ALUMINIUM / BRASS -

R-6854 BUHLER ROASTMASTER™20

R-6854 BUHLER ROASTMASTER™20R-6854 BUHLER ROASTMASTER™20

THE ROASTMASTER™20 BY BUHLER OFFERS EXACTLY WHAT START-UP BUSINESSES AND SMALL-SCALE INDUSTRIAL OPERATIONS REQUIRE TO PRODUCE TOP-QUALITY COFFEE. THE CAPACITY RANGES UP TO 70 KG OF GREEN BEANS PER HOUR. HOT AIR IS THE BEST CHOICE TO ENSURE A UNIFORM ROAST. ALL HOT AIR PASSES THROUGH THE ROTATING DRUM AND TRANSFERS ITS HEAT DIRECTLY TO THE BEANS IN A HOMOGENEOUS WAY. THIS HOT AIR PATHWAY ENSURES A HIGH PROPORTION OF CONVECTIVE HEAT TRANSFER RATHER THAN TO HEAT THE DRUM FROM BELOW. NO MATTER AT WHICH STAGE OF THE PROCESS, THE VARIABLE DRUM SPEED AND THE SOPHISTICATED INTERIOR DESIGN OF THE ROASTING CHAMBER DELIVER AN OPTIMAL BEAN DISTRIBUTION AND AN EFFICIENT INTERACTION OF THE BEANS WITH THE AIR. SILVERSKINS ARE SEPARATED IN THE CYCLONE. THE COMPACT DRUM ROASTER IS EQUIPPED WITH SEPARATE HEATING AND COOLING FANS WHICH ALLOW TO ROAST AND COOL AT THE SAME TIME. AN INNOVATIVE AND EASY-TO-USE PLC CONTROL SYSTEM ENSURES QUALITY CONSISTENCY DURING PRODUCTION BUT ALSO LEAVES ROOM FOR MANUAL INTERVENTION TO STEER THE PROCESSING WHEN NECESSARY.

ROASTMASTER™20. PROCESS FLEXIBILITY FOR YOUR FLAVOR SIGNATURE.

EACH COFFEE VARIETY IS UNIQUE BY NATURE AND REQUIRES INDIVIDUAL ROASTING CONDITIONS TO TRANSFORM THE FULL INTRINSIC FLAVOR POTENTIAL INTO GREAT FLAVOR. THE ROASTMASTER™20 IS EQUIPPED WITH A FULLY VARIABLE BURNER FOR FLEXIBLE ENERGY INPUT. THE FREQUENCY CONVERTER ON THE MAIN FAN ALLOWS FOR VARIABLE SPEED AND OPTIMIZED AIR-TO-BEAN-RATIO DURING THE DIFFERENT STAGES OF THE PROCESS. REGARDLESS WETHER YOU PREFER TRADITIONAL OR NON-CONVENTIONAL PROFILES, THE SOPHISTICATED MULTISTEP PROCESS CONTROL SOFTWARE INSPIRES PROFILE ROASTING FOR BEST FLAVOR GENERATION.DATA MANAGEMENT AND NEXT GENERATION CONNECTIVITY.

Learn More

THE FUTURE-SAFE CONCEPT INCLUDES AN EASY-TO-USE PLC CONTROL SYSTEM WITH INTEGRATED TOUCH PANEL, RECIPE MANAGEMENT, ONLINE TREND MONITORING, BATCH REPORT CREATION AND SAFETY FEATURES. MOREOVER THE EASY DATA EXPORT VIA USB PORT, ONLINE DATA TRANSFER TO EXTERNAL THIRD PARTY PROCESS MONITORING SOFTWARE AND REMOTE HMI VISUALIZATION AND PROCESS CONTROL ENSURE QUALITY CONSISTENCY DURING PRODUCTION. -

Z-1677 CHOCOLATE CHIPSZ-1677 CHOCOLATE CHIPS CAPACITY (APPROX): 30KG PER HOUR COOLING TUNNEL: 10000mm MACHINE WEIGHT: 2400KG MACHINE SIZE: 12000X850X1600mm QUANTITY: 1 Learn More

Z-1677 CHOCOLATE CHIPSZ-1677 CHOCOLATE CHIPS CAPACITY (APPROX): 30KG PER HOUR COOLING TUNNEL: 10000mm MACHINE WEIGHT: 2400KG MACHINE SIZE: 12000X850X1600mm QUANTITY: 1 Learn More -

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINEREFERENCE NUMBER: M-7873

CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

AUTOMATIC LINE

FOR CHOCOLATE CEREAL AND GRANOLA BARS

AUTOMATIC COMBINATION BETWEEN THE FREEZING, FORMING, AND PRESSING ROLLERS, AND THE SLITTING TECHNOLOGY.

THIS PRODUCING LINE IS A MULTI-FUNCTION LINE WHICH CONSISTS OF KITCHEN EQUIPMENTS, FORMING AND SHEETING SYSTEM, NUTS SPRINKLING SYSTEM, FORMING AND PRESSING ROLLER, REFRIGERATION SYSTEM, COOLING TUNNEL, CANDY BAR SLITTING, CUTTING AND CONVEYING SYSTEM, AND CHOCOLATE ENROBING MACHINE, ETC.

THIS LINE TAKES THE PLACE OF THE TRADITIONAL, MANUAL WORKSHOP PRODUCTION WITH FULL AUTOMATIC MACHINERY PRODUCTION. THIS LINE WILL BE IDEAL FOR THE CANDY BAR LEISURE FOOD INDUSTRY, WITH MODERN AND LARGE QUANTITY PRODUCTION.

Learn More -

G-3569 CHICKEN SLAUGHTER LINE (1500/HR)REFERENCE NUMBER: G-3569 CHICKEN SLAUGHTER LINE (1500/HR) QUANTITY AVAILABLE: 1 Learn More

G-3569 CHICKEN SLAUGHTER LINE (1500/HR)REFERENCE NUMBER: G-3569 CHICKEN SLAUGHTER LINE (1500/HR) QUANTITY AVAILABLE: 1 Learn More -

R-6860 RE-ROAST 15-30-60

R-6860 RE-ROAST 15-30-60R-6860 RE-ROAST 15-30-60

ROASTING MACHINES LINE PARTICULARLY SUITABLE FOR ARTISANAL SPECIALIZED ACTIVITIES IN MEDIUM BATCHES OF ROASTED COFFEE OF HIGH QUALITY, SUCH AS ARTISAN MARKET OR COFFEE SHOPS.

TECHNOLOGICALLY ADVANCED, CONFIRMS THEMELVES AS IDEAL TOOL FOR ROASTING COMPANIES SPECIALIZED IN SELECTED COFFEES OF HIGHER QUALITY. MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTING MACHINES, ARE AVAILABLE WITH HEATING GENERATOR TYPE GAS OR DIESEL-FUEL BURNER AT MULTIPLE LEVELS OF FLAME AND MANUAL OR AUTOMATIC CONTROL SYSTEM.TECHNICAL DATA:

Learn More

PATENTED ROASTING SYSTEM FOR HIGHER THERMAL EFFICIENCY ALLOWING THE BEST POSSIBLE RESULT IN ROASTING COFFEE BY HOT AIR-CONVENTION.

HOPPER OF CHARGE STEEL MADE

HEATING GENERATOR BY BURNER AT MULTIPLE LEVELS OF FLAME

COOLING TANK SELFCLEANING

INDEPENDENT MOTORIZATIONS FOR ROASTING DRUM AND COOLING TANK

INDEPENDENT FANS FOR ROASTING DRUM AND COOLING TANK.

CICLONE-CHAFF COLLECTOR FOR CHAFFS WITH OPTION FOR AUTOMATIC EXTRACTION SYSTEM.

ELECTRIC CONTROL BOARD WITH PLC + TOUCH SCREEN

MACHINE COLOURS AVAILABLE ACCORDING CLIENT REQUEST.