Search results for: 'finishing'

- Related search terms

- Finishing padder

- Finishing padde

-

K-2221 DYEING AND FINISHING MACHINE FOR ELASTIC RIBBON AND LACES YEAR 2011 - NEWREFERENCE NUMBER: K-2221 DYEING AND FINISHING MACHINE FOR ELASTIC RIBBON AND LACES YEAR 2011-NEW MAKE: TONTUN-TAIWAN YEAR 2011 (1)TAPE INLET DEVICE (2) DYEING PADDER: ONE BIG AND ONE SMALL WITH MIXING TANK (1) 45 METERS STEAM CHAMBER (4) WASHING TANKS (1) FIXED STEAM CHAMBER (1)STARCHING AND FINISHING PADDER (2)STEAM DRYING CYLINDERS WITH TEFLON COATING (1)TAKE OFF DEVICE (1)ELECTRIC BOX MACHINE IS STILL NEW AND PACKED IN ITS ORIGINAL BOXES QUANTITY AVAILABLE: 1 Learn More

K-2221 DYEING AND FINISHING MACHINE FOR ELASTIC RIBBON AND LACES YEAR 2011 - NEWREFERENCE NUMBER: K-2221 DYEING AND FINISHING MACHINE FOR ELASTIC RIBBON AND LACES YEAR 2011-NEW MAKE: TONTUN-TAIWAN YEAR 2011 (1)TAPE INLET DEVICE (2) DYEING PADDER: ONE BIG AND ONE SMALL WITH MIXING TANK (1) 45 METERS STEAM CHAMBER (4) WASHING TANKS (1) FIXED STEAM CHAMBER (1)STARCHING AND FINISHING PADDER (2)STEAM DRYING CYLINDERS WITH TEFLON COATING (1)TAKE OFF DEVICE (1)ELECTRIC BOX MACHINE IS STILL NEW AND PACKED IN ITS ORIGINAL BOXES QUANTITY AVAILABLE: 1 Learn More -

M-4141 BIANCALANI FINISHING MACHINE YEAR 1994 TYPE AIRO 1000REFERENCE NUMBER: M-4141 (1010175AD9UX)-A BIANCALANI FINISHING MACHINE YEAR 1994 TYPE AIRO 1000 BIANCALANI FINISHING MACHINE YEAR 1994 TYPE AIRO 1000 TWO ROPES QUANTITY: 1 Learn More

M-4141 BIANCALANI FINISHING MACHINE YEAR 1994 TYPE AIRO 1000REFERENCE NUMBER: M-4141 (1010175AD9UX)-A BIANCALANI FINISHING MACHINE YEAR 1994 TYPE AIRO 1000 BIANCALANI FINISHING MACHINE YEAR 1994 TYPE AIRO 1000 TWO ROPES QUANTITY: 1 Learn More -

J-2640 DYEING AND FINISHING PLANT FOR SALE

J-2640 DYEING AND FINISHING PLANT FOR SALEREFERENCE NUMBER: J-2640

DYEING AND FINISHING PLANT FOR SALEITEM 001

THIES SAMPLE DYEING MACHINE

MODEL: MINISOFT SAMPLE

CAPACITY: 50 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 002

THIES DYEING MACHINE

MODEL ECOSOFT PLUS

3 PORT SPLIT/SPLIT

CAPACITY: 900 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 003

THIES DYEING MACHINE

MODEL: ECOSOFT PLUS

2 PORT SPLIT/SPLIT

CAPACITY: 600 KGS

YEAR: 1999

MICROPROCESSOR CONTROL

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 004

THIES DYEING MACHINE

MODEL ECOSOFT PLUS

1 PORT SPLIT/SPLIT

CAPACITY: 300 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: A460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 005

GASTON COUNTY DYEING MACHINE

MODEL: AQUAFLOW

2 PORT

CAPACITY; 250 KGS

YEAR: 1987

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING AND UNLOADING REEL

QUANTITY: 1ITEM 006

THIES DYEING MACHINE

MODEL: SOFT TRD

2 TUBE

CAPACITY: 700 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 007 (also our J-2647)

LAFER OPEN WIDTH COMPACTOR MACHINE

MODEL: KSA 500 2400/2200

YEAR: 1998

LAFER TEXEN CONTROLS

VOLTAGE: 480 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSION BAR ENTRY TO LATTICE ROLL GUIDER

• OPERATOR’S PLATFORM

• PUP TENTER WITH KNIT ENTRY, VERTICAL PIN CHAIN, WITH PLATE GUIDES, RAIL OPENING, PINNING BRUSHES, PINS ONLY, WITH SUPPORT SECTION FOR THE FABRIC IN THE CENTER, AT 10’ THERE IS A STEAMING SECTION, TOTAL LENGTH OF THE TENTER IS 30’, WITH AUTOMATIC LUBRICATION FOR THE CHAIN

• KSA 500 COMPACTOR BENCH WITH TEXEN CONTROLS

• TENSIONLESS FABRIC CONVEYOR

• PLAITOR AND FABRIC SCRAY WITH OPTICAL LOAD SENSOR

• INLINE INSPECTION BATCHER MACHINE, WITHH A BACK LIGHTED BOARD, MANUAL CUT

• SCALE TO WEIGHT THE FABRIC

QUANTITY: 1ITEM 008 (also our J-2648)

SANTEX TUBULAR 4-ROLL EXTRACTION PAD

MODEL: SANTASTRETCH PLUS 140

YEAR: 1998

COMPOSED OF TURNTABLE, DETWISTER, TUBULAR 4-ROLL PAD WITH WET SPREADERS, PLAITOR

WITH ADDITION TANKS FOR SOFTENER

REEL FABRIC PLAITOR EXIT

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

QUANTITY: 1ITEM 009

SANTEX CONVEYOR DRYER FOR OPEN WIDTH AND TUBULAR FABRIC

MODEL: SANTASHRINK 4/5240

YEAR: 1998

SANTEX CONTROLS

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSION BAR ENTRY TO LATTICE ROLL GUIDER TO

• (2) SANTEX 2-ROLL PADS, RUBBER OVER RUBBER, 102” WIDE x 12” DIAMETER, STAINLESS STEEL PAN, 10-TON PAD, SWING-AWAY PAN, TENSION BAR WITH 2 STAINLESS STEEL MIXING TANKS, 75 GALLONS EACH

• DRIVEN SCROLL ROLLS WITH EDGE GUIDE CONTROL, WIDTH 95”

• OPERATOR’S PLATFORM

• PUP TENTER WITH KNIT ENTRY 45°, YEAR 1998, VERTICAL PIN CHAIN, 30’ LONG WITH TANDEMATIC PLATE GUIDES, RAIL GUIDES, PINNING BRUSHES, GUIDE SUPPORT FOR THE FABRIC, FABRIC CONVEYOR TO ENTER BOTH TUBULAR OR OPEN WIDTH FABRIC TO

• CONVEYOR DRYER 100” WIDE, 5 ZONES, 3-PASS WITH MAXON BURNERS, 5 CIRCULATING FANS TO CONVEYOR BELT TO PLAITOR

• ALL MOTORS AND SANTEX CONTROLS AND MONITORS

QUANTITY: 1ITEM 010

SANTEX AG TUBULAR COMPACTOR MACHINE

MODEL: SANTASPREAD 140

YEAR: 1998

SANTEX CONTROLS

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSIONS BAR ENTRY

• OPERATOR’S PLATFORM

• TENSION DEVICE

• DRIVEN SPREADER BARS

• STEAMING DEVICE

• TUBULAR COMPACTING BENCH

• FELT BLANKET ONTO THE CONVEYOR BELT

• PRECISION PLAITOR

• TABELTOP ELECTRONIC SCALE

QUANTITY: 1ITEM 011

COMET NAPPER

MODEL: PEGSO-X4

YEAR: 1998

VOLTAGE: 480 VOLTS, 3-PHASE, 60 Hz

24 ROLLS WITH TURNING BARS FOR TUBULAR 90” WIDE

XYCOM CONTROLS

12-BAG COLLECTION SYSTEM AND PLAITOR

YEAR: 1996

QUANTITY: 1ITEM 012

STENTEX TENTER FRAME

MODEL: STENTOTHERM 3300

YEAR: 1999

STENTEX CONTROLS

VOLTAGE: 480 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSION ENTRY TO TEXT-STAR TYPE GUIDER TO 2 ROLL PAD

• ADDITION TANK TOP SCRAY PAD TO TEXT-STAR TYPE GUIDER

• TWO ROLL PAD R/R 10 TON

• OPERATOR’S PLATFORM

• WORKING WIDTH 1800mm

• HORIZONTAL PIN CHAIN, KNIT ENTRY

• TANDEMATIC SPLITLEVEL DECURLERS

• OVERFEED

• PINNING BRUSHES

• STEAM BOX

• RAIL GUIDERS, 20 FEET ENTRY, 8 ZONES

• 80 FEET HOUSING

• SCREEN MONITORS

• GAS FIRED, MAXON OVEPAK 408 BURNERS

• HONEYWELL CONTROLS

• 3 FEET COOLING ZONE

• 2 COOLING CANS, SELVEDGE TRIMMERS

• PLIATOR, SCRAY

• ZONE IN LINE INSPECTION BATCHER

QUANTITY: 1ITEM 013

ZIMMER ROTARY SCREEN PRINTING MACHINE

MODEL: R92-S153

YEAR: 1993

COMPOSED OF:

• TENSION BAR SKY ENTRY

• SCRAY

• CORINO BRUSH

• CORINO PRINT GUIDER

• ZIMMER PRINTER, 8 COLOR, 86” BLANEKT

• PRINT CONVEYOR DRYER, 30’ LONG, 3-ZONE, GAS FIRED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

QUANTITY: 1ITEM 014

Learn More

SAFETY SWITCH BULLET NOSE SLITTER

MODEL: CUTTING

WITH REEL FABRIC PLIATOR

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

QUANTITY: 1 -

P-4925 DILO OD II/25 FINISHING NEEDLE LOOM YEAR 1982 WIDTH 2500mm DOUBLE BOARD DOWNSTROKE 15,000 NEEDLES

P-4925 DILO OD II/25 FINISHING NEEDLE LOOM YEAR 1982 WIDTH 2500mm DOUBLE BOARD DOWNSTROKE 15,000 NEEDLESP-4925 DILO OD II/25 FINISHING NEEDLE LOOM YEAR 1982 WIDTH 2500mm DOUBLE BOARD DOWNSTROKE 15,000 NEEDLES

DILO

TYPE: OD II/25

FINISHING NEEDLE LOOM

YEAR: 1982

WORKING WIDTH: 2500mm

DOUBLE BOARD DOWNSTROKE

TOTAL 15,000 NEEDLESQUANTITY: 1

Learn More -

P-4924 DILO OM25 FINISHING NEEDLE LOOM YEAR 1979 WIDTH 2500mm DOUBLE BOARD DOWNSTROKE 15,000 NEEDLES

P-4924 DILO OM25 FINISHING NEEDLE LOOM YEAR 1979 WIDTH 2500mm DOUBLE BOARD DOWNSTROKE 15,000 NEEDLESP-4924 DILO OM25 FINISHING NEEDLE LOOM YEAR 1979 WIDTH 2500mm DOUBLE BOARD DOWNSTROKE 15,000 NEEDLES

DILO

TYPE: NL32968

FINISHING NEEDLE LOOM

YEAR: 1979

WORKING WIDTH: 2500mm

DOUBLE BOARD DOWNSTROKE

TOTAL 15,000 NEEDLESQUANTITY: 1

Learn More -

M-5300 UNDER PAD PRODUCTION LINEREFERENCE NUMBER: M-5300 (131342BVGT12UF) L UNDER PAD PRODUCTION LINE UNDER PAD PRODUCTION LINE MODEL: 100CD PRODUCTS TO BE PRODUCED: 3 SIZES OF DISPOSABLE UNDER PAD (SIZE: 600x900mm, 600x600mm, 600x400mm) MECHANICAL DRIVING SYSTEM WITH INVERTER CONTROL PRODUCT STRUCTURE: FLUFF +SAP; TOP TISSUE; BOTTOM TISSUE; TOP SHEET; BACK SHEET QUANTITY AVAILABLE: 1 Learn More

M-5300 UNDER PAD PRODUCTION LINEREFERENCE NUMBER: M-5300 (131342BVGT12UF) L UNDER PAD PRODUCTION LINE UNDER PAD PRODUCTION LINE MODEL: 100CD PRODUCTS TO BE PRODUCED: 3 SIZES OF DISPOSABLE UNDER PAD (SIZE: 600x900mm, 600x600mm, 600x400mm) MECHANICAL DRIVING SYSTEM WITH INVERTER CONTROL PRODUCT STRUCTURE: FLUFF +SAP; TOP TISSUE; BOTTOM TISSUE; TOP SHEET; BACK SHEET QUANTITY AVAILABLE: 1 Learn More -

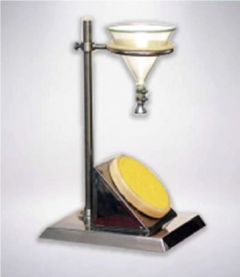

T-6548 FABRIC SURFACE WETTING TESTER

T-6548 FABRIC SURFACE WETTING TESTERREFERENCE NUMBER: T-6548

FABRIC SURFACE WETTING TESTER

INSTRUMENT TECHNICAL DESCRIPTION:

WATER TESTER IS TO INSTALL THE SAMPLE ON THE SAMPLE HOLDER AND MAKE AN ANGLE OF 45 ° WITH THE LEVEL. THE CENTER OF THE SAMPLE IS LOCATED AT A SPECIFIED DISTANCE BELOW THE NOZZLE. THE SAMPLE IS SPRAYED WITH A SPECIFIED VOLUME OF DISTILLED OR DEIONIZED WATER. BY COMPARING THE APPEARANCE OF THE SAMPLE WITH THE EVALUATION STANDARDS AND PICTURES TO DETERMINE ITS WATER-SOAKING GRADE, IT IS SUITABLE FOR MEASURING VARIOUS WATER-SOAKING TESTS ON THE SURFACE OF FABRICS WITH OR WITHOUT WATER RESISTANCE AND WATER REPELLENT FINISHING. THIS INSTRUMENT IS NOT SUITABLE FOR MEASURING THE WATER PERMEABILITY OF FABRICS, SO IT CANNOT BE USED TO PREDICT THE RAINPROOF PERMEABILITY OF FABRICS.

STANDARD:

GB19082-2009 TECHNICAL REQUIREMENTS FOR MEDICAL PRIMARY PROTECTIVE CLOTHINGGB / T4745 SURFACE MOISTURE RESISTANCE TEST

THE MAIN TECHNICAL INDICATORS OF THE INSTRUMENT:

GLASS FUNNEL: φ150mm

MEASURING CUP: 500ML

SAMPLE SUPPORT ANGLE: 45 °

INSTRUMENT CONFIGURATION:

1. ONE HOST

2. A GLASS FUNNEL

3. 500ML MEASURING CUP

QUANTITY: 1

Learn More -

J-2216 DOWN & FEATHER FILLING MACHINE, 4 WEIGH SCALES, 1 NOZZLE, 1400 GRAMS PER FILL -1400 GRAMS PER FILL

J-2216 DOWN & FEATHER FILLING MACHINE, 4 WEIGH SCALES, 1 NOZZLE, 1400 GRAMS PER FILL -1400 GRAMS PER FILLFOR FILLING DOWN FEATHER PILLOWS

FILLING RANGE: 1 TO 120 GRAMS (70% FEATHER & 30% DOWN)

WEIGHING SYSTEM: 4 SETS

POWER: 4.5 KW

VOLTAGE: 220 / 380 V, 3-PHASE

AIR PRESSURE: 0.5 TO 0.7 MPA

ACCURATE WEIGHING RESULTS WITH TOLERANCE OF ONLY 1 GRAM

WORKING TABLE DIMENSIONS: 1200 x 2400mm (FOR CUSTOMERS FILLING PILLOWS AND QUILTS)

WORKING TABLE DIMENSIONS FOR PILLOWS ONLY: 1200 x 1200mm (EASIER TO FIT IN A 20 FOOT CONTAINER)

OPERATION CAN BE HANDLED BY ONLY 1 EMPLOYEE

INCLUDES ONE AUTOMATIC FILLING TABLE WITH FOOT SWITCH AND CLAMP DEVICE

THE WORKER STEPS ON THE FOOT SWITCH AND THE CLAMP DEVICE WILL RUN TO CLAMP THE PILLOW BAG

THE FILLING PROCESS AUTOMATICALLY STARTS TO FILL THE PILLOW AND AFTER FINISHING THE CLAMP DEVICE WILL RESET

DURING THIS PERIOD, THE WORKER MAY SEAL THE PILLOW WITH SEWING MACHINE

FOUR HOPPER SYSTEM FOR CONSTANT SUPPLY

ONE KEY FOR CHARGE AND RECHARGE REDUCES WASTED TIME

HIGH-QUALITY, RELIABLE ELECTRICAL COMPONENTS

PREPROGRAMMABLE FOR UP TO 50 GROUPS OF RECIPES WITH EACH RECIPE CONTAINING UP TO 60 SETS OF DIFFERENT FILLING PARTS FOR THE SAME PRODUCTION

FULLY ENCLOSED DESIGN TO KEEP ENVIRONMENT CLEAN AND REDUCE MATERIAL WASTE

AUTOMATIC, ACCURATE WEIGHING WITH LOAD CELL TO ENSURE PRODUCTION QUALITY

CE CERTIFICATE INCLUDED

FLOORSPACE 4000mm LONG X 3000mm WIDE X 2500mm HIGH

TABLE FOR PILLOWS IS 1200 X 1200mm

Learn More

QUANTITY: 1 -

C-4181 TEMAFA/DILO/SPINNBAU/AUTEFA NEEDLING LINE, WORKING WIDTH 5300mm, YEAR 2000

C-4181 TEMAFA/DILO/SPINNBAU/AUTEFA NEEDLING LINE, WORKING WIDTH 5300mm, YEAR 2000REFERENCE NUMBER: C-4181

TEMAFA-DILO-SPINNBAU-AUTEFA NEEDLING LINE WORKING WIDTH 5300mm YEAR 2000NEEDLING LINE

YEAR: 2000

WORKING WIDTH: 5300mmCONSISTING OF:

ITEM 001

TEMAFA BALE OPENER

QUANTITY: 1ITEM 002

SPINNBAU SUPER SERVO CARD

WORKING WIDTH: 3000mm

QUANTITY: 1ITEM 003

AUTEFA TOPLINER CL 4004 CROSS-LAPPER

INPUT: 3000mm

OUTPUT: 6500mm

QUANTITY: 1ITEM 004

DI-LOOM OD-II 60 PRE-NEEDLE LOOM

WORKING WIDTH: 6000mm

QUANTITY: 1ITEM 005

DILO DI-LOOM OUG-II 60 FINISHING NEEDLE LOOM

WORKING WIDTH: 6000mm

QUANTITY: 1ITEM 006

DILO WSP 25/55 ACCUMULATOR

QUANTITY: 1ITEM 007

DILO CUTTING AND WINDING UNIT

QUANTITY: 1ITEM 008

TEMAFA EDGE TRIM OPENER

UP TO 960 KG/H

QUANTITY: 1QUANTITY: 1 LINE

Learn More