Search results for: 'FIL'

- Related search terms

- filling

- film

- FILLING MACHI

- filling ca

- fillin machine

-

J-2811 AIRBORNE PARTICLE COUNTER

J-2811 AIRBORNE PARTICLE COUNTERAIRBORNE PARTICLE COUNTER

PORTABLE PARTICLE COUNTER WITH 0.10 MICRON SENSITITIVITY AND 1.0 CFM (28.3 LPM) FLOW RATE USING LONG LIFE LASER DIODE TECHNOLOGY.

DESIGNED TO OPERATE IN ISO CLASS 1 TO CLASS 7 CLEANROOMS WITHOUT CONCERNS OF IT DEGRADING ITS ENVIRONMENT OR EXCEEDING CONCENTRATION LIMITS

USES AN OPTICS AND PHOTODIODE SYSTEM DESIGNED TO REDUCE OR ELIMINATE THE TEMPERATURE ISSUES ASSOCIATED WITH HIGH POWER LASER DIODE SENSORS

WITH THERMALLY CONTROLLED EXHAUST SYSTEM AND HEPA FILTER OPTION TO PREVENT ANY EXTERNAL CONTAMINATIONFEATURES

0.1- 1.0 µm SENSITIVITY

1.0 CFM (28.3 LPM)

UP TO 8 CHANNELS OF SIMULTANEOUS COUNT DATA

21 CFR PART 11 COMPLIANT SECURE USB FLASH TRANSFER

LASER DIODE SENSOR TECHNOLOGY

5.7 INCH COLOR TOUCH SCREEN DISPLAY

THERMAL PRINTER

STAINLESS STEEL CONSTRUCTION

ETHERNET/RS485/MODBUS, 4X 4-20MA ANALOG OUTPUTS

3,000 RECORD DATA STORAGE

50-RECORD CONFIGURABLE RECIPE DATABASE

Report wizard: ISO-14644-1, EU GMP Annex 1, FS-209ESTANDARD CHANNEL SIZES: 0.10, 0.15, 0.2, 0.25, 0.3, 0.5, 0.7, 1.0 µm

INCLUDES

OPERATING MANUAL ON CD; ISOKINETIC SAMPLE PROBE WITH TRIPOD AND TUBING; PURGE FILTER; POWER CABLE AND SPARE FUSE; LMS XCHANGE AND EXPRESS SOFTWARE; PRINTER; PRINTER PAPERQUANTITY: 1

Learn More -

L-7134 PP NONWOVEN FABRIC PRODUCTION LINE, SPUNBONDED, MELT BLOWN

L-7134 PP NONWOVEN FABRIC PRODUCTION LINE, SPUNBONDED, MELT BLOWNEFFECTIVE WIDTH: 1600mm

DAILY OUTPUT: 10,000 KGS PER DAY

WEIGHT RANGE: 10 TO 150 GSM

FILAMENT DIAMETER: 1.6 TO 2.0 DENIER

SPEED: 350 TO 400 METERS PER MINUTE

RAW MATERIAL: POLYPROPYLENE (PP)

DIMENSIONS: 35,000 X 15,000 X 11,000mm

VOLTAGE: 380 VOLTS, 3 PHASECONSISTING OF:

SPUNBOND EQUIPMENT

PP VACUUM SUCTION MACHINE (2)

7800 TO 900 KGS PER HOUR

AIR CAPACITY: 300 CUBIC METERS PER HOUR

POWER: 7.5 KWMASTER BATCH DOSING UNIT (2)

ACCURACY: 0.01%EXTRUDER (2)

DIAMETER: 130mm

SINGLE SCREW (2)

HEATING SYSTEM: ELECTRICITY

MOTOR: 75 KWMELT FILTRATION MACHINE (2)

PIPE SIZE: 50mm

FILTER AREA: 3.5 SQUARE METERS

MELT FLOW: 650 KGS PER HOUR

DOUBLE FILTRATION CHAMBERMELTING PUMP (2)

40 RPM

FLOW CAPACITY: 400 KGS PER HOUR

POWER: 7.5 KWSPINNING BEAM (2)

DIMENSIONS: 1900 X 256mm

HANGER TYPE MELT DISTRIBUTION

HEATING SYSTEM: OIL

WORKING TEMPERATURE: 200 TO 260 CELSIUSSPINNERET (4)

HARDNESS: 30

SIZE: 1900mm LONG X 256mm WIDE

HOLE DIAMETER 0.45mm

HOLE QUANTITY: 6500 HOLE PER METERQUENCHING UNIT (2)

WORKING TEMP: 20 CELSIUS

AIR FLOW CAPACITY: 12,000 CUBIC METERS/H

AIR PRESSURE: 6500

FILTER SIZE: 80#FILAMENT DRAFT UNITS (2)

AIR PRESSURE: 5020PA

AIR FLOW CAPACITY: 12,000 CUBIC METERS/H

INSIDE TEMP: 10 TO 25 CELSIUS

FILAMENT FINENESS: 1.6 TO 2.0 DENIERMELT BLOWN EQUIPMENT

VACUUM SUCTION MACHINE (2)

LOAD CAPACITY: 700 TO 900 KGS PER HOUR

AIR CAPACITY: 300 CUBIC METERS/H

POWER: 7.5 KWMASTER BATCH DOSING UNIT (2)

4 HOPPERS

200 KGS HOPPER LOADEXTRUDER

DIAMETER: 105mm

SINGLE SCREW

MOTOR: 18.5 KWMELT FILTER

DOUBLE CYLINDER

HYDRAULIC

MELT FLOW CAPACITY: 450 KGS/HR

FILTER SIZE: 150mm DIAMETER

ELECTRIC HEATINGMELTING PUMP

SPEED: 40 RPM

MELT FLOW CAPACITY: 450 KGS PER HOUR

POWER: 7.5 KWMELT BLOWN DIE SPINNARET

SPINNERET HOLE SIZE: 0.32 TO 0.35mm

HOLE DISTANCE: 40 TO 42 PER INCH

FABRIC WEIGHT: 2 TO 200 GSMHIGH PRESSURE AIR BLOWER

AIR FLOW CAPACITY: 70 TO 100 CUBIC METERS PER MINUTE

AIR PRESSURE: 100 KPA

POWER: 200 KWWEB FORMING MACHINE

SPEED: 100 METERS PER MINUTEELECTRIC TREATMENT

VOLTAGE: 220 VOLTS, 50 Hz

INPUT CURRENT: 3A

OUTPUT VOLTAGE: 60 KV

TREAT WEB WIDTH: 1.6 METERSHOT AIR HEATING MACHINE

WORKING TEMP: 350 CELSIUS

PRESSURE: 0.8 KPA

HEATING: ELECTRIC

POWER: 200 KWTHERMAL CALENDER

PROCESSING SPEED: 400 METERS PER MINUTE

ROLLER SIZE: 2000mm LONG, 520mm DIAMETER

EMBOSSING ROLLER: 1

LINEAR PRESSURE: 30 TO 125 N/mm

HEATING SYSTEM: OILHYDROPHILIC MACHINE

SPEED: 400 METERS PER MINUTE

FEEDING SYSTEM: DOUBLE KISSING ROLLER

KISS ROLLER DIAMETER: 215mm

LIQUID TANK: 200 KGS WITH HEAT/WARM AND MIXDRYING SYSTEM:

INFRARED + HOT AIR

DRIVE ROLL SIZE: 150mm

HEATING EQUIPMENT: QUARTZ HEATER, HOT AIR BLOWER, EXHAUST AIR BLOWERINSPECTION MACHINE

EFFECTIVE WIDTH: 1600mm

INSPECTION SPEED: 400 METERS PER MINUTE

INSPECT GSM: 10 TO 40 GSMAUTOMATIC WINDING MACHINE

SPEED: 400 METERS PER MINUTE

ROLLER DIAMETER: 2000mm

ROLLER EXCHANGE SYSTEM: AUTOMATIC

FABRIC INSPECTOR: ONLINE

POWER: 15 KWHIGH SPEED SLITTING MACHINE

PROCESS SPEED: 800 METERS PER MIN

ROLL DIAMETER: MAX 1500mm

SLITTING WIDTH: 80mm

PAPER TUBE SIZE: 76mm DIAMETER

AUTO TENSILE CONTROL: AVAILABLE ONLINE

METER COUNTING: AVAILABLE ONLINEOIL HEATER (4)

HEATING POWER: 60 KW

MOTOR POWER: 7.5 KW

OIL PUMP FLOW: 30 CUBIC METERS PER SECOND

PRESSURE: 0.4 KPAWATER CHILLER

DRIVE SYSTEM: SCREW

COOLING CAPACITY: 300,000 CALORIES

TEMP: 0 TO 20 CELSIUS

POWER: 110 KWAIR BLOWER

SPEED: 1450 RPM

AIR BLOW CAPACITY: 12,000 CUBIC METERS PER HOUR

PRESSURE: 5200 PA

POWER: 30 KW x 3, 45 KW x 1AIR COMPRESSOR

DRIVE SYSTEM: SCREW

PRESSURE: 0.8 KPA

POWER: 15 KWHEATING SYSTEM: ELECTRIC

TEMP: 350 CELSIUS

HEATING TIME: 6 TO 8 HOURS

POWER: 4 KWULTRASONIC CLEANING MACHINE

3mm THICK

SIZE: 2000 X 500mm

FREQUENCY VIBRATION: 100 KHZ

TEMP: 40 CELSIUSELECTRONIC PANEL BOARD

PLATFORM

Learn More -

J-1937 LAMINATING MACHINE FOR FOAM TO FABRIC – CONTINUOUS WITH SLITTING, NEW

J-1937 LAMINATING MACHINE FOR FOAM TO FABRIC – CONTINUOUS WITH SLITTING, NEWSILICON COATED NOMEX FELT (ITB BRAND – ITALIAN)

BLANKET THICKNESS: 8mm

PNEUMATICALLY ADJUSTABLE FELT PRESSURE

MAXIMUM WORKING WIDTH: 2100mm (82.6”)

EVA HOT MELT FILM, FILM ROLL MIMIMUM 500 METERS, MAXIMUM 1000 METERS

36 KW HEATER RESISTANCE

MAIN DRUM DIAMETER: 500mm

TEFLON COATED MAIN CYLINDER

PNEUMATIC BLANKET EDGE CONTROL BY PHOTOCELL

WORKING SPEED: 5 TO 10 METERS PER MINUTE, DEPENDING ON FABRIC THICKNESS (THICK FABRIC IS SLOWER, NORMAL FABRIC IS FASTER)

PLC CONTROLLER WITH TOUCH SCREEN OPERATOR PANEL

PROGRAMMABLE HEATING UP AND COOLING DOWN

ROLL TO ROLL WORKING SYSTEM

SLITTING UNIT WITH 3 PIECE PNEUMATIC CUTTER AND DUAL CENTER REWINDING UNIT (OPTIONAL)

440 V 3-PHASE, 60 Hz, 55 AMPLEAD TIME: 6 TO 8 WEEKS AFTER RECEIPT OF DEPOSIT

Learn More -

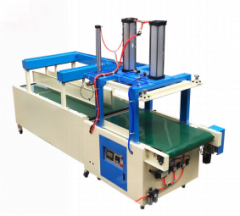

J-1948 PILLOW & CUSHION COMPRESSION PACKING MACHINE- NEW -AUTOMATIC , 12 PILLOWS PER MINUTE

J-1948 PILLOW & CUSHION COMPRESSION PACKING MACHINE- NEW -AUTOMATIC , 12 PILLOWS PER MINUTEREDUCES VOLUME FOR STORAGE AND TRANSPORTATION

USES COMPRESSED AIR AND PLASTIC COMPOSITE FILM BAGS FOR PACKAGING ITEMS AFTER COMPRESSION

EQUIPPED WITH AUTOMATIC TRANSMISSION TO COMPRESS AND FILM ITEMS UNINTERRUPTED

STANDARD MODEL EQUIPPED WITH ONE WORKSTATION WITH SINGLE SEAL (OPTIONAL ONE WORKSTATION WITH DOUBLE SEALS)

PLC TOUCH SCREEN OPERATION, USER FRIENDLY INTERFACE

CONSTANT TEMPERATURE CONTROL FUNCTION TO PREVENT BAG BURNSVOLTAGE AND POWER: 220 V SINGLE-PHASE, 0.5 KW, 50 Hz

AIR PRESSURE: 0.4 – 0.8 MPA

PACKING CAPACITY: : 8 TO 12 ITEMS PER MINUTE

PRESS BOARD SIZE: LENGTH 700mm x WIDTH 900mm

MAXIMUM COMPRESSION THICKNESS: 500mm (AIR CYLINDER TRAVEL)

SEAL LENGTH: 880mm x 10mm

OVERALL DIMENSIONS: LENGTH 3390mm x WIDTH 940mm x HEIGHT 2010mm

POWER: 1.5 KW

NET WEIGHT: 350 KG

GROSS WEIGHT: 400 KGQUANTITY: 1

Learn More -

R-7504 LLOVERAS CHOCOLATE MOULDING LINE MOULD SIZES OF 400 X 200 X 30mm HIGH

R-7504 LLOVERAS CHOCOLATE MOULDING LINE MOULD SIZES OF 400 X 200 X 30mm HIGHREFERENCE NUMBER: R-7504

Learn More

LLOVERAS CHOCOLATE MOULDING LINE

MANUFACTURED BY LLOVERAS

MODEL SIMA N400/1M

MOULD SIZES OF 400 X 200 X 30mm HIGH

QUANTITY: 1 -

M-6059 BEMATIC/MECCANICA THERMOBONDING PRODUCTION LINE, WIDTH 2700mm, YEAR 2012

M-6059 BEMATIC/MECCANICA THERMOBONDING PRODUCTION LINE, WIDTH 2700mm, YEAR 2012M-6059 BEMATIC/MECCANICA THERMOBONDING PRODUCTION LINE, WIDTH 2700mm, YEAR 2012

OFFER 001

THERMOBONDING PRODUCTION LINE

YEAR: 2012

WORKING WIDTH: 2700mmOFFER 002

BEMATIC BALE OPENEROFFER 003

BEMATIC BALE OPENER FOR BICO FIBEROFFER 004

BEMATIC WEIGHT CONTROL TOWEROFFER 005

BEMATIC FINE OPENEROFFER 006

BEMATIC FINE OPENEROFFER 007

CF DOUBLE FILTEROFFER 008

BEMABLOW OPENEROFFER 009

T-MAX FORMEROFFER 010

BEMAMULTISCALEOFFER 011

CF DOUBLE FILTEROFFER 012

SPRAY CABINOFFER 013

BOMBI MECCANICA OVENOFFER 014

CALANDEROFFER 015

COOLING SECTIONOFFER 016

CUTTING SYSTEMQUANTITY: 1 LINE

Learn More -

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mmM-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

OFFER 001

SPUNBOND PRODUCTION LINE

WORKING WIDTH: 4040mm

WEIGHT: 130 TO 250 G/M2OFFER 002

POLYMER CLEANING GROUPOFFER 003

CRYSTALLIZING GROUPOFFER 004

DRYING GROUPOFFER 005

PNEUMATIC CONVEYING SYSTEMOFFER 006

EXTRUDER HOPPEROFFER 007

EXTRUDEROFFER 008

FILTERING UNITOFFER 009

MELT TRANSFER LINEOFFER 010

SPINNING BEAMOFFER 011

SPINNING PACKSOFFER 012

FILAMENTS QUENCHING SYSTEMOFFER 013

FILAMENTS DRAWING AND DISTRIBUTION SYSTEMOFFER 014

WEB FORMING CONVEYOR BELTOFFER 015

CREEL FOR APPLICATION OF REINFORCING FILAMENTSOFFER 016

PRE-NEEDLING MACHINEOFFER 017

NEEDLING MACHINEOFFER 018

THERMOSETTING UNITOFFER 019

OUTLET CALENDEROFFER 020

FOULARDOFFER 021

BINDER PREPARATION SYSTEMOFFER 022

DRYEROFFER 023

OUTLET CALENDEROFFER 024

AUTOMATIC WINDEROFFER 025

AIR COMPRESSORS (FOR FILAMENTS STRETCHING EJECTORS)OFFER 026

DIATHERMIC OIL HEATING SYSTEMOFFER 027

CHILLED WATER CIRCULATION AND GENERATION SYSTEMOFFER 028

EQUIPMENT FOR CLEANING CYCLE, SPECIAL TOOLSOFFER 029

FIBRE DUST RECOVERY SYSTEMOFFER 030

EDGES RECOVERY SYSTEMOFFER 031

SPINNING SECTION STEEL STRUCTUREOFFER 032

DISTRIBUTION ELECTRIC CABINETSOFFER 033

PROCESS ELECTRIC SYSTEM OF EXISTING MACHINES ACCORDING TO THE ACTUAL LAYOUTOFFER 034

CABLES AND CABLING MATERIALSQUANTITY: 1 LINE

Learn More -

M-5300 UNDER PAD PRODUCTION LINEREFERENCE NUMBER: M-5300 (131342BVGT12UF) L UNDER PAD PRODUCTION LINE UNDER PAD PRODUCTION LINE MODEL: 100CD PRODUCTS TO BE PRODUCED: 3 SIZES OF DISPOSABLE UNDER PAD (SIZE: 600x900mm, 600x600mm, 600x400mm) MECHANICAL DRIVING SYSTEM WITH INVERTER CONTROL PRODUCT STRUCTURE: FLUFF +SAP; TOP TISSUE; BOTTOM TISSUE; TOP SHEET; BACK SHEET QUANTITY AVAILABLE: 1 Learn More

M-5300 UNDER PAD PRODUCTION LINEREFERENCE NUMBER: M-5300 (131342BVGT12UF) L UNDER PAD PRODUCTION LINE UNDER PAD PRODUCTION LINE MODEL: 100CD PRODUCTS TO BE PRODUCED: 3 SIZES OF DISPOSABLE UNDER PAD (SIZE: 600x900mm, 600x600mm, 600x400mm) MECHANICAL DRIVING SYSTEM WITH INVERTER CONTROL PRODUCT STRUCTURE: FLUFF +SAP; TOP TISSUE; BOTTOM TISSUE; TOP SHEET; BACK SHEET QUANTITY AVAILABLE: 1 Learn More -

M-5261 PICANOL OMNI AIRJET WEAVING MACHINES YEAR 1994-1997 WIDTH 1900mmREFERENCE NUMBER: M-5261 (131399WN12UC) L PICANOL OMNI AIRJET WEAVING MACHINES YEAR 1994-1997 WIDTH 1900mm QUANTITY AVAILABLE: 40 Learn More

M-5261 PICANOL OMNI AIRJET WEAVING MACHINES YEAR 1994-1997 WIDTH 1900mmREFERENCE NUMBER: M-5261 (131399WN12UC) L PICANOL OMNI AIRJET WEAVING MACHINES YEAR 1994-1997 WIDTH 1900mm QUANTITY AVAILABLE: 40 Learn More -

M-4089 COMPLETE RIETER RING SPINNING & YARN DYE FACTORY – 37,056 SPINDLES - Will Sell Individually

M-4089 COMPLETE RIETER RING SPINNING & YARN DYE FACTORY – 37,056 SPINDLES - Will Sell IndividuallyREFERENCE NUMBER: M-4089 (990DJSKXX8) L

COMPLETE RIETER RING SPINNING & YARN DYE FACTORY – 37,056 SPINDLES- will sell individually

FACTORY WAS PRODUCING VARIOUS SPECIALTY YARNS FOR USE IN APPAREL AND TECHNICAL TEXTILES

ALL RING FRAMES SHORT STAPLE FOR FIBERS UP TO 40mm, 220mm TUBES, APPROXIMATELY HALF OF THE RING FRAMES ARE WITH PINTER CORE DEVICE OR AMSLER SLUBBING DEVICE. AMSLER AND PINTER AVAILABLE TO SELL SEPARATELY.

COMPLETE YARN DYE HOUSE & DYE LAB

QUANTITY AVAILABLE: 1

Learn More