Search results for: 'can lin'

-

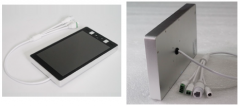

H-2414 8” FACIAL RECOGNITION WITH TEMPERATURE DETECTION PANEL PC

H-2414 8” FACIAL RECOGNITION WITH TEMPERATURE DETECTION PANEL PCPC MAIN SPECS:

CPU: HISILICON HI3516D V300 DUAL CORE, CORTEX-A7, 1.0 TOPS

RAM: 4GB

STORAGE: 16GB (CAN SAVE 50,000 FACE DATABASE)

LINUX OS

WORKING TEMPERATURE: -20°C TO 60°C

SUPPORT LIVE DETECTION

SUPPORT FACE RECOGNITION, RECOGNITION DISTANCE: ≤500mm, TIME: ≤ 0.2S

SUPPORT AUTOMATIC TEMPERATURE DETECTION, RECOGNITION DISTANCE: ≤ 500mm, TIME: ≤0.3S

SUPPORT THE SECONDARY DEVELOPMENT OF DEVICE-SIDE APPLICATION

SOFTWARELCD PANEL MAIN SPECS:

Learn More

RESOLUTION: 800 X 1280 (10:16)

BRIGHTNESS: 500CD/M2 (TYP)

CONTRAST: 800:1

INTERFACES: 1 X LAN/ 1 X WIGEN OUTPUT/1 X RELAY OUTPUT/ 1 X DC INPUT

SUPPORT DISPLAY OUTPUT TO LAPTOP PC OR DESKTOP PC VIA LAN PORT

SENSOR:

1 X FAR INFRARED TEMPERATURE SENSOR

1 X 2MP FRONT CAMERA -

V-1468 COTTON GAUZE MEDICAL COMPRESS FOLDING AND BAGGING MACHINE, WHICH AUTOMATICALLY FOLDS COTTON GAUZE COMPRESSES

V-1468 COTTON GAUZE MEDICAL COMPRESS FOLDING AND BAGGING MACHINE, WHICH AUTOMATICALLY FOLDS COTTON GAUZE COMPRESSESREFERENCE NUMBER: V-1468

SURGICAL GAUZE COMPRESSING, FOLDING, AND BAGGING MACHINE

COTTON GAUZE MEDICAL COMPRESS FOLDING AND BAGGING MACHINE, WHICH AUTOMATICALLY FOLDS COTTONG GAUZE, COMPRESSES, AND THEN PACKS THEM INDIVIDUALLY OR IN GROUPS INTO SACHETS.

FEATURES

USEFUL WIDTH: 45 CM

NUMBER OF TRACKS: MAXIMUM 2 (VARIES ACCORDING TO THE SIZE OF COMPRESSES)

SIZE:

MINIMUM DIMENSIONS OF COMPRESSES: 5 CM X 5 CM

MAXIMUM DIMENSIONS OF COMPRESSES: 10 CM X 20 CM (16 PLIES)

ALL THE USUAL OR INTERMEDIATE SIZES CAN BE PRODUCED ON THE MACHINE BY SIMPLE ADJUSTMENTS.

NUMBER OF PLIES 8 / 12 / 16 / 20 / 24 / 28 / 32 PLIES (VARIES ACCORDING TO THE SIZE OF COMPRESSES)

FOLDING: THE CONVENTIONAL FOLDING IS THE 5-FOLD "SURGICAL" OR "AMERICAN" TYPE, WITH EDGES AND CORNERS TUCKED-IN, HOWEVER BY OFFSETTING FOLDS OTHER COMBINATIONS ARE POSSIBLE.

STACKING: STACKING IS CARRIED OUT IN THE CHANNELS WHERE THE COMPRESSES ARE COUNTED AND READY TO BE MANUALLY INSERTED INTO PAPER BAGS.

PRODUCTION :

EXAMPLES OF THEORETICAL PRODUCTIONS:

5 CM X5 CM 8 PLIES (2 TRACKS) 13200 COMPRESSES PER HOUR

7.5 CM X 7.5 CM 12 PLIES (2 TRACKS) 13200 COMPRESSES PER HOUR

10 CM X 10 CM 12 PLIES (2 TRACKS) 12000 COMPRESSES PER HOUR

OPTIONS:

BARIUM FIXING TRACK BY TRACK

GAUZE ROLL LOADING BY PNEUMATIC CYLINDERS"

FEATURES LIST:

MATERIAL SUPPORT ADJUSTABLE IN WIDTH,

POSITIVE UNWINDING WITH TENSION CHECK ADJUSTABLE TRACK BY TRACK,

MULTIPLE LENGTH FOLDING DEVICE ADJUSTABLE TRACK BY TRACK,

SPRAY HUMIDIFYING SYSTEM,

SUCTION SYSTEM,

ANTI-STATIC BARS,

ADJUSTABLE FLY CUT MODULE MOTORISED WITH BRUSHLESS MOTOR,

THREE CROSS FOLDING MECHANISMS WITH INDEPENDENT ADJUSTMENT OF EACH FOLD,

TRANSFER BELTS FOR THE COMPRESSES,

MOTORISED LATERAL UNWINDING OF THE PAPER ROLL MODULE,

DEVICE FOR INDIVIDUAL, IN MULTIPLES OR IN SHINGLED FORM PACKAGING - WITH A CHANGEABLE

NUMBER OF COMPRESSES BY SACHET,

CHECK OF FOLLOWING OPERATIONS TRACK BY TRACK:

. END OF FABRIC,

. PRESENCE OF SEAM,

. PRESENCE OF CROSS-FOLDED COMPRESS,

. JAM PREVENTION BEFORE PACKAGING.

COLD SEALING BY PRESSURE AND CUTTING OF SACHETS IN PRINTED AND ZONED PAPER,

POWER SYSTEM OF PACKAGING BY BRUSHLESS MOTOR ALLOWING FOR FLY ADJUSTMENT OF:

. THE COMPRESS POSITION IN THE SACHET,

. THE CROSSWISE KNURLING POSITION,

. THE CROSSWISE CUTTING OF SACHETS.

ACCELERATION RAMP BY FREQUENCY VARIATION,

MACHINE OPERATION BY TOUCH-SENSITIVE SCREEN:

. STORABLE CONFIGURATIONS,

. CLEAR LANGUAGE FAULT DISPLAY,

. COUNTERS : TOTALIZER, PRE-SELECTION, ETC.,

. SOUND AND VISUAL ALARMS,

. "INCIDENT" STATISTICS.

STARTING, STOPPING, STEP BY STEP - BY REMOTE CONTROL.

* CONTINUOUS, TRACK BY TRACK INTEGRATION OF ULTRASONIC BARIUM FIXING.

* PAPER ROLL LOADING BY PNEUMATIC CYLINDERS.

* INK JET MARKING UP TILL 8 LINES.

* SACHETS QUALITY CONTROL DEVICE: EITHER A CHECK BY PHOTO CELLS, OR BY CAMERAS,

* FAULTY SACHET EJECTION DEVICE.

* TABLE WITH CONVERGING BELTS.

Learn More -

M-6093 COTTON SWAB AUTOMATIC PRODUCTION AND PACKING EQUIPMENT – Q-TIPS

M-6093 COTTON SWAB AUTOMATIC PRODUCTION AND PACKING EQUIPMENT – Q-TIPSREFERENCE NUMBER: M-6093

COTTON SWAB AUTOMATIC PRODUCTION AND PACKING EQUIPMENT – Q-TIPSIT AUTOMATICALLY MAKES DOUBLE TIP OR SINGLE TIP COTTON SWABS, AND SIMULTANEOUSLY DRIES THE COTTON SWABS ON THE SYNCHRONIZED DRYING AND LINE, AND FINALLY PACKS COTTON SWABS INTO PLASTIC BAGS, ROUND BOX, OR SQUARE BOX WITH DIFFERENT QUANTITY (NORMAL 100 TO 300 PIECES PER PLASTIC BAG, ROUND BOX, OR SQUARE BOX).

MATERIAL OF STICK: PLASTIC, PAPER, WOOD, OR BAMBOO

Learn More

MAKING AND PACKING SPEED: 1,000 TO 1,100 PCS PER MINUTE DEPENDING ON THE TYPE OF STICK -

M-6095 GAUZE MACHINE PRODUCTION LINE

M-6095 GAUZE MACHINE PRODUCTION LINEREFERENCE NUMBER: M-6095

GAUZE MACHINE PRODUCTION LINEGAUZE SLITTING MACHINE

GAUZE FOLDING MACHINE

GAUZE PACKING MACHINE

ETHYLENE OXIDE STERILIZER

Learn More -

M-5189 ROUND COTTON PADS MAKING MACHINE (1200 PIECES PER MINUTE)REFERENCE NUMBER: M-5189 (13132M16K12UX) L ROUND COTTON PADS MAKING MACHINE (1200 PIECES PER MINUTE) ROUND COTTON PADS MAKING MACHINE MODEL: XR MACHINE CAN MAKE PADS TYPE ROUND AND OVAL AVERAGE PRODUCTIVITY: 1200 PIECES PER MINUTE OUTPUT OF PADS: 4 LINES EMBOSSING POSSIBLE MULTILAYER COTTON PADS POSSIBLE TO MAKE WITH MACHINE (I.E. 3PLY: NON-WOVEN LAYER + COTTON LAYER + NON-WOVEN LAYER) PACKING METHOD: MANUAL QUANTITY AVAILABLE: 1 Learn More

M-5189 ROUND COTTON PADS MAKING MACHINE (1200 PIECES PER MINUTE)REFERENCE NUMBER: M-5189 (13132M16K12UX) L ROUND COTTON PADS MAKING MACHINE (1200 PIECES PER MINUTE) ROUND COTTON PADS MAKING MACHINE MODEL: XR MACHINE CAN MAKE PADS TYPE ROUND AND OVAL AVERAGE PRODUCTIVITY: 1200 PIECES PER MINUTE OUTPUT OF PADS: 4 LINES EMBOSSING POSSIBLE MULTILAYER COTTON PADS POSSIBLE TO MAKE WITH MACHINE (I.E. 3PLY: NON-WOVEN LAYER + COTTON LAYER + NON-WOVEN LAYER) PACKING METHOD: MANUAL QUANTITY AVAILABLE: 1 Learn More