Search results for: 'Mate'

- Related search terms

- material of c channel

- material panel veneer

- materi bei

-

P-8698 PROTECTIVE SUIT

P-8698 PROTECTIVE SUITREFERENCE NUMBER: P-8698

PROTECTIVE SUIT

BREATH-ABILITY OF PROTECTIVE CLOTHING

HIGH STRENGTH OF ANTIBACTERIAL FILM COMPOSITE FABRIC

MATERIAL: NON WOVEN

WEIGHT AND DIMENSIONS: 50X35X48mm

50 PCS IN A CARTON

NORMAL PACKING: 300 CTNS

STERILIZED BY ETHYLENE OXIDE GAS

1 PC IN A PE BAG

QUANTITY: 1

Learn More -

T-6580 ISOLATION GOWNS SEAM STRIP AND STERILIZED

T-6580 ISOLATION GOWNS SEAM STRIP AND STERILIZEDISOLATION GOWNS

Learn More

SEAM STRIP AND STERILIZED

BY ETHYLENE OXIDE GAS

CAN BE USED IN ICU

NON WOVEN MATERIAL

BREATHABLE COMPOSITE FILM

PACKED WITH PLASTIC BAG 1 PIECE

1 CARTON 30 PIECES

CARTON SIZE IS 520 X 420 X 320mm

CAN BE LOADED 11200 PIECES PER 20’FT -

T-6579 ISOLATION GOWNS WITHOUT SEAM STRIP AND NOT STERILIZATION

T-6579 ISOLATION GOWNS WITHOUT SEAM STRIP AND NOT STERILIZATIONISOLATION GOWNS

Learn More

WITHOUT SEAM STRIP AND NOT STERILIZATION

PP AND PE

NOT STERILE

WATERPROOF

NON WOVEN MATERIAL

BREATHABLE COMPOSITE FILM

PACKED WITH PLASTIC BAG 1 PIECE

1 CARTON 30 PIECES

CARTON SIZE IS 520 X 420 X 320mm

CAN BE LOADED 11200 PIECES PER 20’FT -

T-6560 NON-STERILIZATION AND STERILIZATION PROTECTIVE CLOTHING

T-6560 NON-STERILIZATION AND STERILIZATION PROTECTIVE CLOTHINGAVAILABILITY: NON-STERILE 740CTNS/ 29600PCS, STERILE 720CTNS/ 14400PCS

STERILE TYPE: 1PC PER BAG, 20 BAGS PER CARTON

NON-STERILE TYPE: 1PC PER BAG, 40 BAGS PER CARTON

WEIGHT AND DIMENSIONS OF CARTONS:

STERILE TYPE: 510 X 370 X 380mm, WEIGHT IS AROUND 6.5KG

NON-STERILE TYPE: CARTON SIZE: 560 X 350 X 350mm, WEIGHT IS AROUND 10.4KG

NO PALLET

CARTONS IN A 20 FOOT CONTAINER:

STERILE TYPE: 720 CARTONS/20'GP

NON-STERILE TYPE: 740 CARTONS/20'GP

STANDARD MATERIAL OF PROTECTIVE CLOTHINGNON-STERILIZATION PROTECTIVE CLOTHING

MODEL: RS-PTCL-M175 OR RS-PTCL-L180 OR RS-PTCL-XL185

ITEM 001

QUANTITY: 1000 PCS

ITEM 002

QUANTITY: 10000 PCSSTERILIZATION PROTECTIVE CLOTHING

Learn More

MODEL: RS-PTCL-M175-S OR RS-PTCL-L180-S OR RS-PTCL-XL185-S

ITEM 003

QUANTITY: 1000 PCS

ITEM 004

QUANTITY: 10000 PCS -

P-8697 PP MELT BLOWN NONWOVEN FABRIC FOR MASKS MELTBLOWN, MELT-BLOWN, MIDDLE LAYER, MASK FILTER

P-8697 PP MELT BLOWN NONWOVEN FABRIC FOR MASKS MELTBLOWN, MELT-BLOWN, MIDDLE LAYER, MASK FILTERENVIRONMENT: 380V/50Hz

Learn More

RAW MATERIAL: MFI=1000 TO 1600

PRODUCT SPECIFICATION: WIDTH: 1600mm (AS PER 50G/M2)

WEIGHT RANGE: 10 TO 80G/M2

PRODUCT CAPACITY: 80KG/H (AS PER WEIGHT RANGE ≥80G/M2, WIDTH: 1600mm)

MAX MECHANICAL SPEED: 0 TO 50M/MIN

FIBER FINENESS: 2 TO 5μM

TOTAL INSTALLED POWER: 400 KW

OUTPUT FOR 25G/M2: ABOUT 1 TON

DIMENSION: 16MX8MX6M

QUANTITY: 1 -

L-7129 NONWOVEN SMS PRODUCTION LINE, 1600mm, SPUNBONDED, MELT BLOWN

L-7129 NONWOVEN SMS PRODUCTION LINE, 1600mm, SPUNBONDED, MELT BLOWNPP CHIPS FOR MELTBLOWN: 1200 TO 2000

FABRIC WIDTH: 1600mm

2 SPINNING BEAMS FOR SPUNBOND & 1 FOR MELTBLOWN

BASIC WEIGHT: SMS 9 TO 80 GRAMS PER SQUARE METER

SS: 15 TO 100 GRAMS PER SQUARE METERPRODUCT:

SMS LAMINATED NONWOVEN FABRIC

SS SPUNBOND NONWOVEN FABRIC SS

M MELTBLOWN NONWOVEN FABRIC MTO MAKE HYGENIC FABRICS SUCH AS BABY DIAPERS, SANITARY NAPKINS, ADULT DIAPERS, MEDICAL OPERATION SUITS, OPERATION CAPS, OPERATIONS SHOES, MASKS, ETC.

CONSISTING OF:

3 X FEEDING SYSTEMS

AUTOMATIC VACUUM SUCTION FOR BOTH MAIN MATERIAL AND ADDITIVES

CAPACITY (SB + MB) 2 X 520 KGS/H, (SB) 2 X 200 KGS/HR

WITH THREE HOPPERS, THREE SUPPLIYING DEVICESSPUNBOND SYSTEM

2 X EXTRUDERS

DIAMETER: 150mm

CAPACITY: 450 KGS/HR

L/D 30:1

DRIVE POWER: 110 KW

HEATING POWER: 90 KW2 X RECYCLING SYSTEMS

DIAMETER: 105mm

CAPACITY: 100 KGS PER HOUR

L/D: 15:12 X MELT FILTERS

WORKING TEMPERATURE: UP TO 280 CELSIUS

FILTRATION CAPACITY: 520 KGS PER HOUR2 X METERING PUMPS

TYPE: GEAR PUMP

FLOW VOLUME: 250 ML/R

DESIGNING TEMPERATURE: 280 CELSIUS2 X MELT PIPELINES

WITH STATIC MIXER2 X MONOMER EXHAUSTER

INCLUDING BLOWER, CHILLER, PIPELINE, VALVE, INSULATION, ETC2 X SPINNING BEAMS

SINGLE COAT-HANGER MELT DISTRIBUTION

DESIGNING PRESSURE: 9MPA

WORKING TEMPERATURE: MAX 280 CELSIUS4 X SPINNERETS

HOLE DIAMETER: 0.45mm

L/D: 5:1

15,500 HOLESMELTBLOWN SYSTEM

1 X EXTRUDER

DIAMETER 120mm

CAPACITY: 280 KGS/HR

L/D: 30:1

DRIVE POWER: 75 KW

HEATING POWER: 80 KW1 X MELT FILTER

FILTRATION PRECISION: 20 TO 60 MICROMETERS

FILTRATION: 280 KGS PER HOUR1 X METERING PUMP

GEAR PUMP

MAX. FLOW VOLUME: 100ML/R

DESIGNED TEMPERATURE: 300 CELSIUS1 X MELT PIPELINE

WITH STATIC MIXER1 X SPINNING BEAM

INCLUDING STRETCHING CHANNEL, NOZZLE, ETC. WITH INSULATION MATERIAL

DESIGNED PRESSURE: 6 MPA2 X SPINNING DIE PACKS

COMPACT DIE PACKS

HOLE DIAMETER: 0.35mm

L/D: 12:1

# OF HOLES: 42HPI1 X SCREW BLOWER

INCLUDING MUFFLE, PRESSURE REDUCER VALVE, PIPELINE, ETC.

POWER: 200 KW1 X HOT AIR SYSTEM

FLOW VOLUME: 6000 CUBIC METERS PER HOUR

WORKING TEMP: MAX 350 CELSIUS

INCLUDING HEATER, STAINLESS STEEL PIPELINE, ETC.

POWER: 290 KW1 X OFF-LINE CONVEYOR

RANGE OF SPEED: 5 TO 100 METERS PER MINUTE1 X CONVEYOR

MECHANICAL SPEED: MAX 400 METERS PER MINUTE

BELT WIDTH AND PENETRATION

3800±10mm, 10000 CUBIC METERS PER H.M21 X CALENDAR

DOUBLE ROLLS HEATED BY OIL

PROCESS SPEED: 350 METERS PER MINUTE

EMBOSSING WIDTH: UP TO 2000mm

MAX LINEAR PRESSURE: 110 DAN/C

MAX. TEMP OF EMBOSSING ROLLER, 180 CELSIUS1 X WINDER

ONLINE CHANGING ROLL, ONLINE EDGE CUTTING, TENSION CONTROL

MAX. LINEAR SPEED: 350 METERS PER MINUTE

WIDTH: 1600mm

WIND DIAMETER: MAX 1500mm1 X SLITTER

MAX. LINE SPEED: 600 METERS PER MINUTE

MAX. WIND DIAMETER: 1200mm

MIN. SLITTING WIDE: 120mm

22 CIRCULAR BLADES1 X STEEL PLATFORM

1 X ELECTRICAL CONTROL SYSTEM

2 X OIL OVEN

1 X AIR CONDITIONING SYSTEM

1 X WATER COOLING SYSTEM

1 X CLEANING EQUIPMENTS FOR DIE PACK

1 X AUXILIARY PLATFORM

1 X AUXILIARY EQUIPMENTS

1 X LABORATORY TESTING DEVICE

Learn More -

V-1468 COTTON GAUZE MEDICAL COMPRESS FOLDING AND BAGGING MACHINE, WHICH AUTOMATICALLY FOLDS COTTON GAUZE COMPRESSES

V-1468 COTTON GAUZE MEDICAL COMPRESS FOLDING AND BAGGING MACHINE, WHICH AUTOMATICALLY FOLDS COTTON GAUZE COMPRESSESREFERENCE NUMBER: V-1468

SURGICAL GAUZE COMPRESSING, FOLDING, AND BAGGING MACHINE

COTTON GAUZE MEDICAL COMPRESS FOLDING AND BAGGING MACHINE, WHICH AUTOMATICALLY FOLDS COTTONG GAUZE, COMPRESSES, AND THEN PACKS THEM INDIVIDUALLY OR IN GROUPS INTO SACHETS.

FEATURES

USEFUL WIDTH: 45 CM

NUMBER OF TRACKS: MAXIMUM 2 (VARIES ACCORDING TO THE SIZE OF COMPRESSES)

SIZE:

MINIMUM DIMENSIONS OF COMPRESSES: 5 CM X 5 CM

MAXIMUM DIMENSIONS OF COMPRESSES: 10 CM X 20 CM (16 PLIES)

ALL THE USUAL OR INTERMEDIATE SIZES CAN BE PRODUCED ON THE MACHINE BY SIMPLE ADJUSTMENTS.

NUMBER OF PLIES 8 / 12 / 16 / 20 / 24 / 28 / 32 PLIES (VARIES ACCORDING TO THE SIZE OF COMPRESSES)

FOLDING: THE CONVENTIONAL FOLDING IS THE 5-FOLD "SURGICAL" OR "AMERICAN" TYPE, WITH EDGES AND CORNERS TUCKED-IN, HOWEVER BY OFFSETTING FOLDS OTHER COMBINATIONS ARE POSSIBLE.

STACKING: STACKING IS CARRIED OUT IN THE CHANNELS WHERE THE COMPRESSES ARE COUNTED AND READY TO BE MANUALLY INSERTED INTO PAPER BAGS.

PRODUCTION :

EXAMPLES OF THEORETICAL PRODUCTIONS:

5 CM X5 CM 8 PLIES (2 TRACKS) 13200 COMPRESSES PER HOUR

7.5 CM X 7.5 CM 12 PLIES (2 TRACKS) 13200 COMPRESSES PER HOUR

10 CM X 10 CM 12 PLIES (2 TRACKS) 12000 COMPRESSES PER HOUR

OPTIONS:

BARIUM FIXING TRACK BY TRACK

GAUZE ROLL LOADING BY PNEUMATIC CYLINDERS"

FEATURES LIST:

MATERIAL SUPPORT ADJUSTABLE IN WIDTH,

POSITIVE UNWINDING WITH TENSION CHECK ADJUSTABLE TRACK BY TRACK,

MULTIPLE LENGTH FOLDING DEVICE ADJUSTABLE TRACK BY TRACK,

SPRAY HUMIDIFYING SYSTEM,

SUCTION SYSTEM,

ANTI-STATIC BARS,

ADJUSTABLE FLY CUT MODULE MOTORISED WITH BRUSHLESS MOTOR,

THREE CROSS FOLDING MECHANISMS WITH INDEPENDENT ADJUSTMENT OF EACH FOLD,

TRANSFER BELTS FOR THE COMPRESSES,

MOTORISED LATERAL UNWINDING OF THE PAPER ROLL MODULE,

DEVICE FOR INDIVIDUAL, IN MULTIPLES OR IN SHINGLED FORM PACKAGING - WITH A CHANGEABLE

NUMBER OF COMPRESSES BY SACHET,

CHECK OF FOLLOWING OPERATIONS TRACK BY TRACK:

. END OF FABRIC,

. PRESENCE OF SEAM,

. PRESENCE OF CROSS-FOLDED COMPRESS,

. JAM PREVENTION BEFORE PACKAGING.

COLD SEALING BY PRESSURE AND CUTTING OF SACHETS IN PRINTED AND ZONED PAPER,

POWER SYSTEM OF PACKAGING BY BRUSHLESS MOTOR ALLOWING FOR FLY ADJUSTMENT OF:

. THE COMPRESS POSITION IN THE SACHET,

. THE CROSSWISE KNURLING POSITION,

. THE CROSSWISE CUTTING OF SACHETS.

ACCELERATION RAMP BY FREQUENCY VARIATION,

MACHINE OPERATION BY TOUCH-SENSITIVE SCREEN:

. STORABLE CONFIGURATIONS,

. CLEAR LANGUAGE FAULT DISPLAY,

. COUNTERS : TOTALIZER, PRE-SELECTION, ETC.,

. SOUND AND VISUAL ALARMS,

. "INCIDENT" STATISTICS.

STARTING, STOPPING, STEP BY STEP - BY REMOTE CONTROL.

* CONTINUOUS, TRACK BY TRACK INTEGRATION OF ULTRASONIC BARIUM FIXING.

* PAPER ROLL LOADING BY PNEUMATIC CYLINDERS.

* INK JET MARKING UP TILL 8 LINES.

* SACHETS QUALITY CONTROL DEVICE: EITHER A CHECK BY PHOTO CELLS, OR BY CAMERAS,

* FAULTY SACHET EJECTION DEVICE.

* TABLE WITH CONVERGING BELTS.

Learn More -

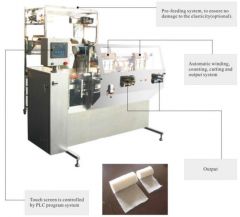

V-1471 AUTOMATIC CORELESS ROLL WINDER

V-1471 AUTOMATIC CORELESS ROLL WINDERREFERENCE NUMBER: V-1471

AUTOMATIC CORELESS ROLL WINDER

THE MACHINE IS SUITABLE TO PROCESS CORELESS ELASTIC BANDAGE ROLLS.

HAS PRE-FEEDING SYSTEM, TO ENSURE NO DAMAGE TO THE ELASTICITY (OPTIONAL).

WITH AUTOMATIC WINDING, COUNTING, CUTTING, AND OUTPUT SYSTEM.

TOUCH SCREEN IS CONTROLLED BY PLC PROGRAM SYSTEM.

WORKING SPEED: 7 TO 11 BEATS PER MINUTE

END SURFACE TOLERANCE OF FINAL ROLLS (DEPENDS ON MATERIAL): ±2 TO 3.5mm

ROLLING TENSION: ADJUSTABLE

MAX. DIAMETER OF FINISHED BANDAGE: 6cm

QUANTITY: 1

Learn More -

V-1472 MEDICAL BANDAGE WEAVING MACHINE

V-1472 MEDICAL BANDAGE WEAVING MACHINEREFERENCE NUMBER: V-1472

MEDICAL BANDAGE WEAVING MACHINE

THIS MACHINE IS SUITABLE TO WEAVE MEDICAL GAUZE BANDAGES, CREPE BANDAGES, PBT ELASTIC BANDAGES, CONFIRMING BANDAGES, ETC. BY CHANGING DIFFERENT KINDS OF RAW MATERIAL.

ADVANTAGES: EASY OPERATION, HIGH EFFICIENCY, STABLE AND RELIABLE PERFORMANCE

BANDAGE WIDTH: 2 TO 20cm

SPEED: 400 TO 800 WEFT/MINUTE

SPECIFICATION: 8/27, 4/75, 2/100, 2/150, 2/200

WEIGHT (APPROXIMATE): 450KG (EXCLUDING CREEL OF YARNS)

POWER: 1.1 KW

QUANTITY : 1

Learn More -

M-6098 PRODUCTION LINE FOR 100% COTTON CREPE BANDAGES

M-6098 PRODUCTION LINE FOR 100% COTTON CREPE BANDAGESREFERENCE NUMBER: M-6098

PRODUCTION LINE FOR 100% COTTON CREPE BANDAGESFOR AUTOMATIC AND CONTINUOUS PRODUCTION OF 100% COTTON CREPE BANDAGES FROM 100% COTTON GAUZE FABRICS. THE PRODUCTION LINE HAS 3 CONTINUOUS FUNCTIONS REALIZED BY 3 MACHINES

Learn More