Search results for: 'FINISH'

- Related search terms

- finishing

- finisher

- Finishi

- Finishing padder

- Finishing padde

-

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More -

M-5138 SQUARE COTTON PAD PRODUCTION MACHINEREFERENCE NUMBER: M-5138 (12121745V11UX) L SQUARE COTTON PAD PRODUCTION MACHINE MODEL: XF SPEED: 1800 TO 3000 PCS/MINUTE PRODUCT SIZE: WIDTH: 40 TO 100mm, LENGTH 40 TO 100mm RAW MATERIAL SIZE: 1000mm, DIAMETER LESS THAN 1000mm POWER: 380V FREQUENCY: 50 HZ TOTAL POWER: 4.5KW DIMENSION: LENGTH: 2500mm, WIDTH: 1900mm, HEIGHT: 1600mm WEIGHT: 2500KG QUANTITY AVAILABLE: 1 Learn More

M-5138 SQUARE COTTON PAD PRODUCTION MACHINEREFERENCE NUMBER: M-5138 (12121745V11UX) L SQUARE COTTON PAD PRODUCTION MACHINE MODEL: XF SPEED: 1800 TO 3000 PCS/MINUTE PRODUCT SIZE: WIDTH: 40 TO 100mm, LENGTH 40 TO 100mm RAW MATERIAL SIZE: 1000mm, DIAMETER LESS THAN 1000mm POWER: 380V FREQUENCY: 50 HZ TOTAL POWER: 4.5KW DIMENSION: LENGTH: 2500mm, WIDTH: 1900mm, HEIGHT: 1600mm WEIGHT: 2500KG QUANTITY AVAILABLE: 1 Learn More -

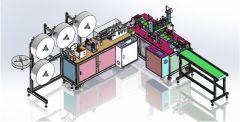

VJ-1116 FULLY AUTOMATIC FLAT FACE MASK PRODUCTION LINE, 300 MASKS PER MINUTEVJ-1116 FULLY AUTOMATIC FLAT FACE MASK PRODUCTION LINE, 300 MASKS PER MINUTE MASK BODY PRODUCTION WITH AUTOMATIC FEEDING TO EAR LOOP WELDING FOR COMPLETE, AUTOMATED PRODUCTION MASK TYPE: SURGICAL, FLAT MASK WITH EAR LOOPS MASK DIMENSIONS: 175 x 95mm CAPACITY: 250 TO 300 PIECES PER MINUTE (FINISHED PRODUCT) NONWOVEN MATERIAL: SPUNBONDED AND MELT-BLOWN FABRIC QUANTITY: 1 Learn More

VJ-1116 FULLY AUTOMATIC FLAT FACE MASK PRODUCTION LINE, 300 MASKS PER MINUTEVJ-1116 FULLY AUTOMATIC FLAT FACE MASK PRODUCTION LINE, 300 MASKS PER MINUTE MASK BODY PRODUCTION WITH AUTOMATIC FEEDING TO EAR LOOP WELDING FOR COMPLETE, AUTOMATED PRODUCTION MASK TYPE: SURGICAL, FLAT MASK WITH EAR LOOPS MASK DIMENSIONS: 175 x 95mm CAPACITY: 250 TO 300 PIECES PER MINUTE (FINISHED PRODUCT) NONWOVEN MATERIAL: SPUNBONDED AND MELT-BLOWN FABRIC QUANTITY: 1 Learn More -

INNER EARLOOP SURGICAL MASK PRODUCTION LINE 1+1 FULLY AUTOMATIC MASK MACHINEREFERENCE NUMBER: A-2490 INNER EARLOOP SURGICAL MASK PRODUCTION LINE 1+1 FULLY AUTOMATIC MASK MACHINE MACHINE WILL COMPLETE THE WHOLE PRODUCTION PROCESS FROM RAW MATERIAL ROLL TO FINISHED PRODUCT OF THE MASK. THE EQUIPMENT INCORPORATES ULTRASONIC WELDING MODE, SANITATION AND ENVIRONMENTAL PROTECTION. SPECIFICATIONS: MACHINE SIZE: 5000 X 2500 X 1900 mm NET WEIGHT: <= 2000 KGS GROUND BEARING ≤200 KG/M2 WORKING POWER: 220 VOLTS AND 50/60 Hz COMPRESSED AIR: 0.5 TO 0.7 MPA USAGE FLOW: 150 L/min USE ENVIRONMENT: TEMPERATURE 1O TO 35℃ HUMIDITY: 5 TO 55% HR, NO COMBUSTIBLE OR CORROSIVE GAS OR DUST NORMAL PRODUCTION: 60 TO 90 PCS/min FEATURES • INCORPORATING ULTRASONIC WELDING TECHNOLOGY, SANITARY AND ENVIRONMENTAL - FRIENDLY • WHOLE PRODUCTION LINE IS AUTOMATIC FROM FEEDING, NOSE STRAP INSERTING, EDGE SEALING AND CUTTING FINISHED PRODUCTS • THE FRAME STRUCTURE IS MADE OF ALUMINUM ALLOY AND THE KEY PARTS ARE MADE OF STAINLESS STEEL. • COMPUTER PLC PROGRAMMING CONTROL, STEP OR SERVO DRIVE, PARTIAL PNEUMATIC DRIVE, HIGH STABILITY, LOW FAILURE RATE, HIGH EFFICIENCY • FEEDING, WELDING AND BINDING OF EARBELT ARE DRIVEN BY STEP OR SERVO MOTOR • THE TENSION OF THE RAW MATERIALS HAS AUTOMATIC CONTROL TO ENSURE THE TENSION BALANCE OF RAW MATERIALS • PHOTOELECTRIC (OPTICAL FIBER) DETECTION OF RAW MATERIALS TO AVOID MISTAKES AND REDUCE MATERIAL WASTE Learn More

INNER EARLOOP SURGICAL MASK PRODUCTION LINE 1+1 FULLY AUTOMATIC MASK MACHINEREFERENCE NUMBER: A-2490 INNER EARLOOP SURGICAL MASK PRODUCTION LINE 1+1 FULLY AUTOMATIC MASK MACHINE MACHINE WILL COMPLETE THE WHOLE PRODUCTION PROCESS FROM RAW MATERIAL ROLL TO FINISHED PRODUCT OF THE MASK. THE EQUIPMENT INCORPORATES ULTRASONIC WELDING MODE, SANITATION AND ENVIRONMENTAL PROTECTION. SPECIFICATIONS: MACHINE SIZE: 5000 X 2500 X 1900 mm NET WEIGHT: <= 2000 KGS GROUND BEARING ≤200 KG/M2 WORKING POWER: 220 VOLTS AND 50/60 Hz COMPRESSED AIR: 0.5 TO 0.7 MPA USAGE FLOW: 150 L/min USE ENVIRONMENT: TEMPERATURE 1O TO 35℃ HUMIDITY: 5 TO 55% HR, NO COMBUSTIBLE OR CORROSIVE GAS OR DUST NORMAL PRODUCTION: 60 TO 90 PCS/min FEATURES • INCORPORATING ULTRASONIC WELDING TECHNOLOGY, SANITARY AND ENVIRONMENTAL - FRIENDLY • WHOLE PRODUCTION LINE IS AUTOMATIC FROM FEEDING, NOSE STRAP INSERTING, EDGE SEALING AND CUTTING FINISHED PRODUCTS • THE FRAME STRUCTURE IS MADE OF ALUMINUM ALLOY AND THE KEY PARTS ARE MADE OF STAINLESS STEEL. • COMPUTER PLC PROGRAMMING CONTROL, STEP OR SERVO DRIVE, PARTIAL PNEUMATIC DRIVE, HIGH STABILITY, LOW FAILURE RATE, HIGH EFFICIENCY • FEEDING, WELDING AND BINDING OF EARBELT ARE DRIVEN BY STEP OR SERVO MOTOR • THE TENSION OF THE RAW MATERIALS HAS AUTOMATIC CONTROL TO ENSURE THE TENSION BALANCE OF RAW MATERIALS • PHOTOELECTRIC (OPTICAL FIBER) DETECTION OF RAW MATERIALS TO AVOID MISTAKES AND REDUCE MATERIAL WASTE Learn More -

OUTER EARLOOP MASK PRODUCTION LINEREFERENCE NUMBER: A-2489 OUTER EARLOOP MASK PRODUCTION LINE MACHINE WILL COMPLETE THE WHOLE PRODUCTION PROCESS FROM RAW MATERIAL ROLL TO FINISHED PRODUCT OF MASK. THE EQUIPMENT INCORPORATES ULTRASONIC WELDING MODE, WITH BEAUTIFUL STYLE, SANITATION AND ENVIRONMENTAL PROTECTION. SPECIFICATIONS: MACHINE SIZE: 5000 X 2500 X 1900 mm ULTRASONIC: 3 PCS, 20 K 2000W NET WEIGHT: <= 2000 KGS GROUND BEARING ≤200 KG/M2 WORKING POWER: 220 VOLTS AND 50/60 Hz COMPRESSED AIR: 0.4 TO 0.7 MPA USAGE FLOW: 300 L/min USE ENVIRONMENT: TEMPERATURE 1O TO 35℃ HUMIDITY: 5 TO 55% HR, NO COMBUSTIBLE OR CORROSIVE GAS OR DUST NORMAL PRODUCTION: 60 TO 70 PCS/min ACCURACY: ≥99% EXCLUDING RAW MATERIAL DEFECTS AND MISOPERATION FEATURES • INCORPORATING ULTRASONIC WELDING TECHNOLOGY, SANITARY AND ENVIRONMENTAL - FRIENDLY • WHOLE PRODUCTION LINE IS AUTOMATIC FROM FEEDING, NOSE STRAP INSERTING, EDGE SEALING AND CUTTING FINISHED PRODUCTS • THE FRAME STRUCTURE IS MADE OF ALUMINUM ALLOY AND THE KEY PARTS ARE MADE OF STAINLESS STEEL. • COMPUTER PLC PROGRAMMING CONTROL, STEP OR SERVO DRIVE, PARTIAL PNEUMATIC DRIVE, HIGH STABILITY, LOW FAILURE RATE, HIGH EFFICIENCY • FEEDING, WELDING AND BINDING OF EAR BELT ARE DRIVEN BY STEP OR SERVO MOTOR • THE TENSION OF THE RAW MATERIALS HAS AUTOMATIC CONTROL TO ENSURE THE TENSION BALANCE OF RAW MATERIALS • PHOTOELECTRIC (OPTICAL FIBER) DETECTION OF RAW MATERIALS TO AVOID MISTAKES AND REDUCE MATERIAL WASTE Learn More

OUTER EARLOOP MASK PRODUCTION LINEREFERENCE NUMBER: A-2489 OUTER EARLOOP MASK PRODUCTION LINE MACHINE WILL COMPLETE THE WHOLE PRODUCTION PROCESS FROM RAW MATERIAL ROLL TO FINISHED PRODUCT OF MASK. THE EQUIPMENT INCORPORATES ULTRASONIC WELDING MODE, WITH BEAUTIFUL STYLE, SANITATION AND ENVIRONMENTAL PROTECTION. SPECIFICATIONS: MACHINE SIZE: 5000 X 2500 X 1900 mm ULTRASONIC: 3 PCS, 20 K 2000W NET WEIGHT: <= 2000 KGS GROUND BEARING ≤200 KG/M2 WORKING POWER: 220 VOLTS AND 50/60 Hz COMPRESSED AIR: 0.4 TO 0.7 MPA USAGE FLOW: 300 L/min USE ENVIRONMENT: TEMPERATURE 1O TO 35℃ HUMIDITY: 5 TO 55% HR, NO COMBUSTIBLE OR CORROSIVE GAS OR DUST NORMAL PRODUCTION: 60 TO 70 PCS/min ACCURACY: ≥99% EXCLUDING RAW MATERIAL DEFECTS AND MISOPERATION FEATURES • INCORPORATING ULTRASONIC WELDING TECHNOLOGY, SANITARY AND ENVIRONMENTAL - FRIENDLY • WHOLE PRODUCTION LINE IS AUTOMATIC FROM FEEDING, NOSE STRAP INSERTING, EDGE SEALING AND CUTTING FINISHED PRODUCTS • THE FRAME STRUCTURE IS MADE OF ALUMINUM ALLOY AND THE KEY PARTS ARE MADE OF STAINLESS STEEL. • COMPUTER PLC PROGRAMMING CONTROL, STEP OR SERVO DRIVE, PARTIAL PNEUMATIC DRIVE, HIGH STABILITY, LOW FAILURE RATE, HIGH EFFICIENCY • FEEDING, WELDING AND BINDING OF EAR BELT ARE DRIVEN BY STEP OR SERVO MOTOR • THE TENSION OF THE RAW MATERIALS HAS AUTOMATIC CONTROL TO ENSURE THE TENSION BALANCE OF RAW MATERIALS • PHOTOELECTRIC (OPTICAL FIBER) DETECTION OF RAW MATERIALS TO AVOID MISTAKES AND REDUCE MATERIAL WASTE Learn More -

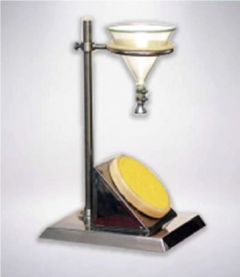

T-6548 FABRIC SURFACE WETTING TESTER

T-6548 FABRIC SURFACE WETTING TESTERREFERENCE NUMBER: T-6548

FABRIC SURFACE WETTING TESTER

INSTRUMENT TECHNICAL DESCRIPTION:

WATER TESTER IS TO INSTALL THE SAMPLE ON THE SAMPLE HOLDER AND MAKE AN ANGLE OF 45 ° WITH THE LEVEL. THE CENTER OF THE SAMPLE IS LOCATED AT A SPECIFIED DISTANCE BELOW THE NOZZLE. THE SAMPLE IS SPRAYED WITH A SPECIFIED VOLUME OF DISTILLED OR DEIONIZED WATER. BY COMPARING THE APPEARANCE OF THE SAMPLE WITH THE EVALUATION STANDARDS AND PICTURES TO DETERMINE ITS WATER-SOAKING GRADE, IT IS SUITABLE FOR MEASURING VARIOUS WATER-SOAKING TESTS ON THE SURFACE OF FABRICS WITH OR WITHOUT WATER RESISTANCE AND WATER REPELLENT FINISHING. THIS INSTRUMENT IS NOT SUITABLE FOR MEASURING THE WATER PERMEABILITY OF FABRICS, SO IT CANNOT BE USED TO PREDICT THE RAINPROOF PERMEABILITY OF FABRICS.

STANDARD:

GB19082-2009 TECHNICAL REQUIREMENTS FOR MEDICAL PRIMARY PROTECTIVE CLOTHINGGB / T4745 SURFACE MOISTURE RESISTANCE TEST

THE MAIN TECHNICAL INDICATORS OF THE INSTRUMENT:

GLASS FUNNEL: φ150mm

MEASURING CUP: 500ML

SAMPLE SUPPORT ANGLE: 45 °

INSTRUMENT CONFIGURATION:

1. ONE HOST

2. A GLASS FUNNEL

3. 500ML MEASURING CUP

QUANTITY: 1

Learn More -

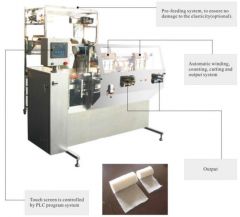

V-1471 AUTOMATIC CORELESS ROLL WINDER

V-1471 AUTOMATIC CORELESS ROLL WINDERREFERENCE NUMBER: V-1471

AUTOMATIC CORELESS ROLL WINDER

THE MACHINE IS SUITABLE TO PROCESS CORELESS ELASTIC BANDAGE ROLLS.

HAS PRE-FEEDING SYSTEM, TO ENSURE NO DAMAGE TO THE ELASTICITY (OPTIONAL).

WITH AUTOMATIC WINDING, COUNTING, CUTTING, AND OUTPUT SYSTEM.

TOUCH SCREEN IS CONTROLLED BY PLC PROGRAM SYSTEM.

WORKING SPEED: 7 TO 11 BEATS PER MINUTE

END SURFACE TOLERANCE OF FINAL ROLLS (DEPENDS ON MATERIAL): ±2 TO 3.5mm

ROLLING TENSION: ADJUSTABLE

MAX. DIAMETER OF FINISHED BANDAGE: 6cm

QUANTITY: 1

Learn More -

M-6091 FULLY AUTOMATIC PVC MEDICAL URINE BAG MACHINE

M-6091 FULLY AUTOMATIC PVC MEDICAL URINE BAG MACHINEREFERENCE NUMBER: M-6091

FULLY AUTOMATIC PVC MEDICAL URINE BAG MACHINEMACHINE FOR PRODUCING DISPOSABLE URINE/URINARY COLLECTING BAG, DRAINAGE BAG, ETC.

Learn More

PLC CONTROL, COMPUTER TOUCH SCREEN CONTROLLING SYSTEM, WITH PRECISE, EASY OPERATION. -

M-5300 UNDER PAD PRODUCTION LINEREFERENCE NUMBER: M-5300 (131342BVGT12UF) L UNDER PAD PRODUCTION LINE UNDER PAD PRODUCTION LINE MODEL: 100CD PRODUCTS TO BE PRODUCED: 3 SIZES OF DISPOSABLE UNDER PAD (SIZE: 600x900mm, 600x600mm, 600x400mm) MECHANICAL DRIVING SYSTEM WITH INVERTER CONTROL PRODUCT STRUCTURE: FLUFF +SAP; TOP TISSUE; BOTTOM TISSUE; TOP SHEET; BACK SHEET QUANTITY AVAILABLE: 1 Learn More

M-5300 UNDER PAD PRODUCTION LINEREFERENCE NUMBER: M-5300 (131342BVGT12UF) L UNDER PAD PRODUCTION LINE UNDER PAD PRODUCTION LINE MODEL: 100CD PRODUCTS TO BE PRODUCED: 3 SIZES OF DISPOSABLE UNDER PAD (SIZE: 600x900mm, 600x600mm, 600x400mm) MECHANICAL DRIVING SYSTEM WITH INVERTER CONTROL PRODUCT STRUCTURE: FLUFF +SAP; TOP TISSUE; BOTTOM TISSUE; TOP SHEET; BACK SHEET QUANTITY AVAILABLE: 1 Learn More -

M-5146 ROUND COTTON PADS MAKING MACHINEREFERENCE NUMBER: M-5146 (1212KKBCXX11) L ROUND COTTON PADS MAKING MACHINE AUTOMATIC ROUND MAKE UP COTTON PADS MACHINE RAW MATERIAL ROLL AUTOMATIC DELIVER EMBOSSING CUTTING OUTPUT IN ARRANGEMENT WASTE MATERIAL ROLLING AUTOMATIC COUNTING FROM LOADING THE RAW MATERIAL TO FINISHED PRODUCT, ALL AUTOMATIC MECHANICAL DRIVE CUTTING, RUNNING STABILITY, EFFICIENCY CAN MAKE FLAT COTTON PADS AND EMBOSSING COTTON PADS MODEL: HZM-1 PRODUCT DIAMETER: 58mm OR ACCORDING TO CUSTOMER RAW MATERIAL: ABSORBENT COTTON, NON-WOVEN FABRICS WEIGHT: 2300KG VOLTAGE: AC 380V 50/60HZ POWER: 5.5KW CAPACITY 400 PIECES PER MINUTE DIMENSION: 5000x1000x2000mm QUANTITY: 1 Learn More

M-5146 ROUND COTTON PADS MAKING MACHINEREFERENCE NUMBER: M-5146 (1212KKBCXX11) L ROUND COTTON PADS MAKING MACHINE AUTOMATIC ROUND MAKE UP COTTON PADS MACHINE RAW MATERIAL ROLL AUTOMATIC DELIVER EMBOSSING CUTTING OUTPUT IN ARRANGEMENT WASTE MATERIAL ROLLING AUTOMATIC COUNTING FROM LOADING THE RAW MATERIAL TO FINISHED PRODUCT, ALL AUTOMATIC MECHANICAL DRIVE CUTTING, RUNNING STABILITY, EFFICIENCY CAN MAKE FLAT COTTON PADS AND EMBOSSING COTTON PADS MODEL: HZM-1 PRODUCT DIAMETER: 58mm OR ACCORDING TO CUSTOMER RAW MATERIAL: ABSORBENT COTTON, NON-WOVEN FABRICS WEIGHT: 2300KG VOLTAGE: AC 380V 50/60HZ POWER: 5.5KW CAPACITY 400 PIECES PER MINUTE DIMENSION: 5000x1000x2000mm QUANTITY: 1 Learn More