Search results for: 'fillin machine'

- Related search terms

- Machine+c

- Machine f

- Machine fl

- machine''[0]

- machine de''

-

ORMONT FIBER FILLING MACHINEREFERENCE NUMBER: T-6865 ORMONT FIBER FILLING MACHINE ORMONT FIBER FILLING MACHINE TYPE TP-02 SIZE 5 OPERATING ON 240/2 PHASE MOTOR SPEED 1800 RPM WITH 30” CONVEYOR FEED WIDTH USED FOR FILLING SMALL DECORATIVE PILLOWS QUANTITY: 1 Learn More

ORMONT FIBER FILLING MACHINEREFERENCE NUMBER: T-6865 ORMONT FIBER FILLING MACHINE ORMONT FIBER FILLING MACHINE TYPE TP-02 SIZE 5 OPERATING ON 240/2 PHASE MOTOR SPEED 1800 RPM WITH 30” CONVEYOR FEED WIDTH USED FOR FILLING SMALL DECORATIVE PILLOWS QUANTITY: 1 Learn More -

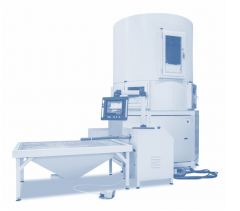

J-2968 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT, FOR FEATHERJ-2968 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT, FOR FEATHER SILO CAPACITY: 4.4m3 AUTOMATIC PRE-WEIGHING UNIT: 1, 300 LITER CAPACITY FILLING NOZZLES: 1 OUTPUT CAPACITY: UP TO 400 FILLINGS PER HOUR FILLING WEIGHT ACCURACY: UP TO 1 GRAM (UP TO 2% OF THE TOTAL WEIGHT) EXPECTED OUTPUT: 3 PILLOWS PER MINUTE WITH 2 LBS FEATHER PILLOWS VOLTAGE: 480 VOLTS (+/- 10%) PHASE: 3-PHASE + N + PE FREQUENCY: 60 Hz (+/- 2%) VOLTAGE AUXILIARY CIRCUITS: 24 VDC / 24 VAC INSTALLED POWER: 5.2 KW – 16 AMPS OPERATING PRESSURE: 6 BAR AIR CONSUMPTION: 50 LITERS PER MINUTE NOISE: < 70 Db QUANTITY: 1 Learn More

J-2968 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT, FOR FEATHERJ-2968 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT, FOR FEATHER SILO CAPACITY: 4.4m3 AUTOMATIC PRE-WEIGHING UNIT: 1, 300 LITER CAPACITY FILLING NOZZLES: 1 OUTPUT CAPACITY: UP TO 400 FILLINGS PER HOUR FILLING WEIGHT ACCURACY: UP TO 1 GRAM (UP TO 2% OF THE TOTAL WEIGHT) EXPECTED OUTPUT: 3 PILLOWS PER MINUTE WITH 2 LBS FEATHER PILLOWS VOLTAGE: 480 VOLTS (+/- 10%) PHASE: 3-PHASE + N + PE FREQUENCY: 60 Hz (+/- 2%) VOLTAGE AUXILIARY CIRCUITS: 24 VDC / 24 VAC INSTALLED POWER: 5.2 KW – 16 AMPS OPERATING PRESSURE: 6 BAR AIR CONSUMPTION: 50 LITERS PER MINUTE NOISE: < 70 Db QUANTITY: 1 Learn More -

J-2967 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT FOR FEATHERJ-2967 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT FOR FEATHER SILO VOLUME: 6.0m3 AUTOMATIC PRE-WEIGHING UNITS: 2 UNITS WITH 210 LITER CAPACITY FILLING NOZZLE: 1 OUTPUT CAPACITY: UP TO 700 FILLINGS PER HOUR FILLING WEIGHT ACCURACY: UP TO 1 GRAM (2% OF THE TOTAL WEIGHT) EXPECTED OUTPUT: 6 PILLOWS PER MINUTE WITH 2 LBS FEATHER PILLOWS VOLTAGE: 480 VOLTS (+/- 10%) PHASE: 3-PHASE + N + PE FREQUENCY: 60 Hz (+/- 2%) VOLTAGE AUXILIARY CIRCUITS: 24 VDC / 24 VAC INSTALLED POWER: 7.4 KW – 32 AMPS OPERATING PRESSURE: 6 BAR AIR CONSUMPTION: 50 LITERS PER MINUTE NOISE: < 70 Db Learn More

J-2967 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT FOR FEATHERJ-2967 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT FOR FEATHER SILO VOLUME: 6.0m3 AUTOMATIC PRE-WEIGHING UNITS: 2 UNITS WITH 210 LITER CAPACITY FILLING NOZZLE: 1 OUTPUT CAPACITY: UP TO 700 FILLINGS PER HOUR FILLING WEIGHT ACCURACY: UP TO 1 GRAM (2% OF THE TOTAL WEIGHT) EXPECTED OUTPUT: 6 PILLOWS PER MINUTE WITH 2 LBS FEATHER PILLOWS VOLTAGE: 480 VOLTS (+/- 10%) PHASE: 3-PHASE + N + PE FREQUENCY: 60 Hz (+/- 2%) VOLTAGE AUXILIARY CIRCUITS: 24 VDC / 24 VAC INSTALLED POWER: 7.4 KW – 32 AMPS OPERATING PRESSURE: 6 BAR AIR CONSUMPTION: 50 LITERS PER MINUTE NOISE: < 70 Db Learn More -

FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60HzREFERENCE NUMBER: T-6869 FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60Hz FEED HOPPER WITH LONG EXTENDED APRON 1500mm FEED HOPPER MODEL: OP-B POWER: 3.6KW FILLING CAPACITY: 800KG/H LAYOUT: 5940 X 1600 X 2200mm WEIGHT: 3200KG WORKING WIDTH: 1500mm VOLTAGE: 440V 60Hz 3 PHASES (AS PER ORDER) AIR PRESSURE: 0.6 TO 0.8MPA MAIN STRUCTURE: MADE BY COMPUTERIZED LASER CUTTING MACHINE ELECTRICITY: KEY PARTS ARE WORLD FAMOUS BRAND, OMRON, SCHNEIDER. BEARING: SKF SPRAY: RUST-PROOF PRETREATMENT AND ELECTROSTATIC COATING. ROLLERS: WITH DYNAMIC BALANCE PROCESSING. DESCRIPTION: • MACHINE IS MAINLY USED TO LOAD A BALE OF FIBER AND SEND IT TO NEXT PROGRAM AUTOMATICALLY. • THE SUITABLE MATERIAL CAN BE CONJUGATE SILICON POLYESTER FIBER THAT SHORTER THAN 100mm. POLYESTER FIBER: RECYCLE AND VIRGIN POLYESTER STAPLE FIBER. 0.6 TO 15D, 32mm TO 64mm, MICROFIBER ALSO POSSIBLE. • ANTI-DEVIATION DEVICE, CONVEYOR BELT TRACK PROTECTION, TO ENSURE THAT BELT ALWAYS RUNNING STRAIGHT. • ONE OPERATOR • WORKING PROCESS: 1. USE FORKLIFT TO PUT BALE OF FIBER ON THE CONVEYOR. 2. THE FIRST CONVEYOR WILL SEND FIBER TO THE SECOND CONVEYOR 3. THEN THE SPIKED INCLINE BELT LIFTS THE FIBER, THE EVENING ROLLER TAKES THE EXCESSIVE FIBER OFF AND THE STRIPPING ROLLER STRIP THE FIBER OFF AND FIBER FALLS DOWN TO NEXT PROCESS. 4. THERE ARE PHOTO CELLS TO CONTROL THE MATERIAL FIBER LEVEL, FEEDING AND SUPPLY SPEED. • ELECTRICAL KEY PARTS ARE WORLD FAMOUS BRANDS, SUCH AS SCHNEIDER ETC. AVAILABLE WORLDWIDE. • ELECTRICAL WITH OVERLOAD PROTECTION. Learn More

FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60HzREFERENCE NUMBER: T-6869 FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60Hz FEED HOPPER WITH LONG EXTENDED APRON 1500mm FEED HOPPER MODEL: OP-B POWER: 3.6KW FILLING CAPACITY: 800KG/H LAYOUT: 5940 X 1600 X 2200mm WEIGHT: 3200KG WORKING WIDTH: 1500mm VOLTAGE: 440V 60Hz 3 PHASES (AS PER ORDER) AIR PRESSURE: 0.6 TO 0.8MPA MAIN STRUCTURE: MADE BY COMPUTERIZED LASER CUTTING MACHINE ELECTRICITY: KEY PARTS ARE WORLD FAMOUS BRAND, OMRON, SCHNEIDER. BEARING: SKF SPRAY: RUST-PROOF PRETREATMENT AND ELECTROSTATIC COATING. ROLLERS: WITH DYNAMIC BALANCE PROCESSING. DESCRIPTION: • MACHINE IS MAINLY USED TO LOAD A BALE OF FIBER AND SEND IT TO NEXT PROGRAM AUTOMATICALLY. • THE SUITABLE MATERIAL CAN BE CONJUGATE SILICON POLYESTER FIBER THAT SHORTER THAN 100mm. POLYESTER FIBER: RECYCLE AND VIRGIN POLYESTER STAPLE FIBER. 0.6 TO 15D, 32mm TO 64mm, MICROFIBER ALSO POSSIBLE. • ANTI-DEVIATION DEVICE, CONVEYOR BELT TRACK PROTECTION, TO ENSURE THAT BELT ALWAYS RUNNING STRAIGHT. • ONE OPERATOR • WORKING PROCESS: 1. USE FORKLIFT TO PUT BALE OF FIBER ON THE CONVEYOR. 2. THE FIRST CONVEYOR WILL SEND FIBER TO THE SECOND CONVEYOR 3. THEN THE SPIKED INCLINE BELT LIFTS THE FIBER, THE EVENING ROLLER TAKES THE EXCESSIVE FIBER OFF AND THE STRIPPING ROLLER STRIP THE FIBER OFF AND FIBER FALLS DOWN TO NEXT PROCESS. 4. THERE ARE PHOTO CELLS TO CONTROL THE MATERIAL FIBER LEVEL, FEEDING AND SUPPLY SPEED. • ELECTRICAL KEY PARTS ARE WORLD FAMOUS BRANDS, SUCH AS SCHNEIDER ETC. AVAILABLE WORLDWIDE. • ELECTRICAL WITH OVERLOAD PROTECTION. Learn More -

M-7752 DOWN PILLOW FILLING MACHINE WITH WEIGHING SYSTEM

M-7752 DOWN PILLOW FILLING MACHINE WITH WEIGHING SYSTEMREFERENCE NUMBER: M-7752

DOWN PILLOW FILLING MACHINE WITH WEIGHING SYSTEM

DOWN FILLING MACHINE

WITH WEIGHING SYSTEM

BEST FOR GETTING AN EXACT WEIGHT FOR EVERY PILLOW

QUANTITY: 1

Learn More -

G-6401 PILLOW FILLING MACHINEREFERENCE NUMBER: G-6401 PILLOW FILLING MACHINE THE PILLOW MACHINE LINE IS ASSEMBLED WITH A FIBER OPENER AND MINI BLOWER STUFFING MACHINES THAT MAINLY USED FOR TEXTILE STUFFING PRODUCTIONS SUCH AS BIG PLUSH TOYS, CUSHIONS AND PILLOWS ETC. IT CAN BE ALSO USED FOR FIBER QUILTING FILLING AFTER THE STUFFING SLOTS OF DUVET TYPE - ADJUSTABLE FOOT SWITCH CONTROLLING FOR THE MATERIAL INSIDE OF THE STUFFER HOPPER THAT AVOIDS THE MATERIAL TO BALL UP SO THAT THE FINISHED PRODUCT IS RETAINS GOOD ELASTICITY - LOWER AIR PRESSURE REQUIRED. - HIGH PRODUCTIVITY QUANTITY AVAILABLE: 1 Learn More

G-6401 PILLOW FILLING MACHINEREFERENCE NUMBER: G-6401 PILLOW FILLING MACHINE THE PILLOW MACHINE LINE IS ASSEMBLED WITH A FIBER OPENER AND MINI BLOWER STUFFING MACHINES THAT MAINLY USED FOR TEXTILE STUFFING PRODUCTIONS SUCH AS BIG PLUSH TOYS, CUSHIONS AND PILLOWS ETC. IT CAN BE ALSO USED FOR FIBER QUILTING FILLING AFTER THE STUFFING SLOTS OF DUVET TYPE - ADJUSTABLE FOOT SWITCH CONTROLLING FOR THE MATERIAL INSIDE OF THE STUFFER HOPPER THAT AVOIDS THE MATERIAL TO BALL UP SO THAT THE FINISHED PRODUCT IS RETAINS GOOD ELASTICITY - LOWER AIR PRESSURE REQUIRED. - HIGH PRODUCTIVITY QUANTITY AVAILABLE: 1 Learn More -

G-6400 HEAVY DUTY PILLOW FILLING MACHINEREFERENCE NUMBER: G-6400 HEAVY DUTY PILLOW FILLING MACHINE THE PILLOW MACHINE LINE IS ASSEMBLED WITH A FIBER OPENER AND MINI BLOWER STUFFING MACHINES THAT MAINLY USED FOR TEXTILE STUFFING PRODUCTIONS SUCH AS BIG PLUSH TOYS, CUSHIONS AND PILLOWS ETC. IT CAN BE ALSO USED FOR FIBER QUILTING FILLING AFTER THE STUFFING SLOTS OF DUVET TYPE QUILTS - ADJUSTABLE FOOT SWITCH CONTROLLING FOR THE MATERIAL INSIDE OF THE STUFFER HOPPER THAT AVOIDS THE MATERIAL TO BALL UP SO THAT THE FINISHED PRODUCT IS RETAINS GOOD ELASTICITY - LOW AIR PRESSURE REQUIRED. - HIGH PRODUCTIVITY QUANTITY AVAILABLE: 1 Learn More

G-6400 HEAVY DUTY PILLOW FILLING MACHINEREFERENCE NUMBER: G-6400 HEAVY DUTY PILLOW FILLING MACHINE THE PILLOW MACHINE LINE IS ASSEMBLED WITH A FIBER OPENER AND MINI BLOWER STUFFING MACHINES THAT MAINLY USED FOR TEXTILE STUFFING PRODUCTIONS SUCH AS BIG PLUSH TOYS, CUSHIONS AND PILLOWS ETC. IT CAN BE ALSO USED FOR FIBER QUILTING FILLING AFTER THE STUFFING SLOTS OF DUVET TYPE QUILTS - ADJUSTABLE FOOT SWITCH CONTROLLING FOR THE MATERIAL INSIDE OF THE STUFFER HOPPER THAT AVOIDS THE MATERIAL TO BALL UP SO THAT THE FINISHED PRODUCT IS RETAINS GOOD ELASTICITY - LOW AIR PRESSURE REQUIRED. - HIGH PRODUCTIVITY QUANTITY AVAILABLE: 1 Learn More -

G-6399 PILLOW FILLING MACHINEREFERENCE NUMBER: G-6399 PILLOW FILLING MACHINE THE PILLOW MACHINE LINE IS ASSEMBLED WITH A FIBER OPENER AND MINI BLOWER STUFFING MACHINES THAT MAINLY USED FOR TEXTILE STUFFING PRODUCTIONS SUCH AS BIG PLUSH TOYS, CUSHIONS AND PILLOWS ETC. IT CAN BE ALSO USED FOR FIBER QUILTING FILLING AFTER THE STUFFING SLOTS OF DUVET TYPE QUILTS - ADJUSTABLE FOOT SWITCH CONTROLLING FOR THE MATERIAL INSIDE OF THE STUFFER HOPPER THAT AVOIDS THE MATERIAL TO BALL UP SO THAT THE FINISHED PRODUCT IS RETAINS GOOD ELASTICITY - LOW AIR PRESSURE REQUIRED QUANTITY AVAILABLE: 1 Learn More

G-6399 PILLOW FILLING MACHINEREFERENCE NUMBER: G-6399 PILLOW FILLING MACHINE THE PILLOW MACHINE LINE IS ASSEMBLED WITH A FIBER OPENER AND MINI BLOWER STUFFING MACHINES THAT MAINLY USED FOR TEXTILE STUFFING PRODUCTIONS SUCH AS BIG PLUSH TOYS, CUSHIONS AND PILLOWS ETC. IT CAN BE ALSO USED FOR FIBER QUILTING FILLING AFTER THE STUFFING SLOTS OF DUVET TYPE QUILTS - ADJUSTABLE FOOT SWITCH CONTROLLING FOR THE MATERIAL INSIDE OF THE STUFFER HOPPER THAT AVOIDS THE MATERIAL TO BALL UP SO THAT THE FINISHED PRODUCT IS RETAINS GOOD ELASTICITY - LOW AIR PRESSURE REQUIRED QUANTITY AVAILABLE: 1 Learn More -

YY-2172 TOY & SMALL PILLOW FILLING MACHINE, CAPACITY 200 KG PER HOURYY-2172 TOY & SMALL PILLOW FILLING MACHINE, CAPACITY 200 KG PER HOUR QUANTITY: 1 Learn More

YY-2172 TOY & SMALL PILLOW FILLING MACHINE, CAPACITY 200 KG PER HOURYY-2172 TOY & SMALL PILLOW FILLING MACHINE, CAPACITY 200 KG PER HOUR QUANTITY: 1 Learn More -

M-3674-A WISE PILLOW MACHINE FILLING MACHINE

M-3674-A WISE PILLOW MACHINE FILLING MACHINEREFERENCE NUMBER: M-3674-A

WISE PILLOW MACHINE FILLING MACHINEPLATE INFO FOR THE HOPPER:

DATE: JUNE/00

MOD. NO.: WK 4×36

PLATE INFO FOR THE FIRST BLOWER:

DATE: JUNE/00

MOD. NO.: 4C 113PLATE INFO FOR THE SECOND BLOWER:

DATE: JUNE/00

MOD. NO.: 4C 113PLATE INFO FOR THE CONTROL PANEL:

DATE: JUNE/2000

MOD. NO.: SYSTEM 1NOTE: THE HOPPER APRON WIDTH: 35 ½” INCHES

AFTER THE HOPPER THERE IS ANOTHER MACHINE WHICH MIGHT BE A FINE OPENER WITH (2) BLOWERS, (2) NOZZLES AND (1) CONTROL PANEL

QUANTITY: 1

Learn More