Search results for: 'Machine+c'

- Related search terms

- machine+cap

- machine+card+0

- Machine+c''

- Machine+card+ro

- machine+ci''

-

F-1362 PILLOW WEIGHT SETTING VACUUM FILLING MACHINEREFERENCE NUMBER: F-1362 PILLOW WEIGHT SETTING VACUUM FILLING MACHINE THE VACUUM FILLING MACHINE IS FOR FABRIC PILLOW AND CUSHION FILLING. SUITABLE MATERIAL IS SILICONIZED STAPLE FIBER. THE VACUUM FILLING MACHINE IS EQUIPPED WITH A FREQUENCY CONVERTER. THE FILLING SPEED IS ADJUSTABLE TO THE FILLING SURFACE IS VERY EVEN. THE FILLING IS CARRIED OUT BY "SUCTION", NOT THE TRADITIONAL "BLOW", WHICH CAN MAKE FILLING MATERIALS GO IN ALL DIRECTIONS AND COME TO THE 4 CORNERS OF THE PILLOW OR CUSHION. THE AFTER-FILLING EFFECT WITH BE BETTER THAN ALL OTHER FILLING. THE LINE CAN SET THE WEIGHT FOR EACH PILLOW/CUSHION APPROXIMATELY. FIBER CARDING MACHINE: DIMENSIONS: 2150 X 900 X 940mm POWER: 4.75kW NET WEIGHT: 600kg FIBER SUCTION AND SILENSOR: DIMENSIONS: 700 X 930 X 2450mm POWER: 7.5kW AIR PRESSURE: 1mpa NET WEIGHT: 300kg VACUUM FILLING MACHINE: DIMENSIONS: 2990 X 1700 X 2450mm AIR PRESSURE: 1mpa NET WEIGHT: 400kg QUANTITY AVAILABLE: 1 Learn More

F-1362 PILLOW WEIGHT SETTING VACUUM FILLING MACHINEREFERENCE NUMBER: F-1362 PILLOW WEIGHT SETTING VACUUM FILLING MACHINE THE VACUUM FILLING MACHINE IS FOR FABRIC PILLOW AND CUSHION FILLING. SUITABLE MATERIAL IS SILICONIZED STAPLE FIBER. THE VACUUM FILLING MACHINE IS EQUIPPED WITH A FREQUENCY CONVERTER. THE FILLING SPEED IS ADJUSTABLE TO THE FILLING SURFACE IS VERY EVEN. THE FILLING IS CARRIED OUT BY "SUCTION", NOT THE TRADITIONAL "BLOW", WHICH CAN MAKE FILLING MATERIALS GO IN ALL DIRECTIONS AND COME TO THE 4 CORNERS OF THE PILLOW OR CUSHION. THE AFTER-FILLING EFFECT WITH BE BETTER THAN ALL OTHER FILLING. THE LINE CAN SET THE WEIGHT FOR EACH PILLOW/CUSHION APPROXIMATELY. FIBER CARDING MACHINE: DIMENSIONS: 2150 X 900 X 940mm POWER: 4.75kW NET WEIGHT: 600kg FIBER SUCTION AND SILENSOR: DIMENSIONS: 700 X 930 X 2450mm POWER: 7.5kW AIR PRESSURE: 1mpa NET WEIGHT: 300kg VACUUM FILLING MACHINE: DIMENSIONS: 2990 X 1700 X 2450mm AIR PRESSURE: 1mpa NET WEIGHT: 400kg QUANTITY AVAILABLE: 1 Learn More -

E-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBERE-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBER FOR POLYESTER STAPLE FIBER OPENING AND FILLING INTO UPHOLSTERY CUSHIONS OR PILLOWS. CAPACITY 250 KGS PER HOUR X 400 HOURS PER MONTH = 100,000 KGS PER MONTH AT 100% EFFICIENCY HOPPER FEED (REF G-3768) WITH 4.5 KW MOTOR FIBER OPENER TRANSFER FAN MIXING MACHINE (SILO WITH FOUR EXITS) FILLING STATION (FAN) , FOUR FILLING FANS WITH NOZZLE CLAMPS AND WITH TABLES SPARE PARTS SUGGESTED Learn More

E-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBERE-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBER FOR POLYESTER STAPLE FIBER OPENING AND FILLING INTO UPHOLSTERY CUSHIONS OR PILLOWS. CAPACITY 250 KGS PER HOUR X 400 HOURS PER MONTH = 100,000 KGS PER MONTH AT 100% EFFICIENCY HOPPER FEED (REF G-3768) WITH 4.5 KW MOTOR FIBER OPENER TRANSFER FAN MIXING MACHINE (SILO WITH FOUR EXITS) FILLING STATION (FAN) , FOUR FILLING FANS WITH NOZZLE CLAMPS AND WITH TABLES SPARE PARTS SUGGESTED Learn More -

M-7753 DOWN PILLOW FILLING MACHINE WITHOUT WEIGHING SYSTEM

M-7753 DOWN PILLOW FILLING MACHINE WITHOUT WEIGHING SYSTEMREFERENCE NUMBER: M-7753

DOWN PILLOW FILLING MACHINE WITHOUT WEIGHING SYSTEM

DOWN PILLOW FILLING MACHINE

WITHOUT WEIGHING SYSTEM

BEST MACHINE IF YOU DON’T NEED EXACT WEIGHT FOR EVERY PILLOW

QUANTITY: 1

Learn More -

M-3674-A WISE PILLOW MACHINE FILLING MACHINE

M-3674-A WISE PILLOW MACHINE FILLING MACHINEREFERENCE NUMBER: M-3674-A

WISE PILLOW MACHINE FILLING MACHINEPLATE INFO FOR THE HOPPER:

DATE: JUNE/00

MOD. NO.: WK 4×36

PLATE INFO FOR THE FIRST BLOWER:

DATE: JUNE/00

MOD. NO.: 4C 113PLATE INFO FOR THE SECOND BLOWER:

DATE: JUNE/00

MOD. NO.: 4C 113PLATE INFO FOR THE CONTROL PANEL:

DATE: JUNE/2000

MOD. NO.: SYSTEM 1NOTE: THE HOPPER APRON WIDTH: 35 ½” INCHES

AFTER THE HOPPER THERE IS ANOTHER MACHINE WHICH MIGHT BE A FINE OPENER WITH (2) BLOWERS, (2) NOZZLES AND (1) CONTROL PANEL

QUANTITY: 1

Learn More -

L-6395 PILLOW STUFFING MACHINE, DOUBLE BELT TYPE (BEMIS TYPE)L-6395 PILLOW STUFFING MACHINE, DOUBLE BELT TYPE (BEMIS TYPE) Capacity one pillow every 10 seconds Voltage: 380v,50hz, 3phases or as per customers request Power: 2.2kw BUT CAN BE MADE ACCORDING TO CUSTOMERS REQUIREMENT QUANTITY: 1 Learn More

L-6395 PILLOW STUFFING MACHINE, DOUBLE BELT TYPE (BEMIS TYPE)L-6395 PILLOW STUFFING MACHINE, DOUBLE BELT TYPE (BEMIS TYPE) Capacity one pillow every 10 seconds Voltage: 380v,50hz, 3phases or as per customers request Power: 2.2kw BUT CAN BE MADE ACCORDING TO CUSTOMERS REQUIREMENT QUANTITY: 1 Learn More -

E-8999 SINGLE NOZZLE PILLOW FILLING MACHINEINVENTORY NUMBER: E-8999 SINGLE NOZZLE PILLOW FILLING MACHINE-NEW DIMENSIONS: 3100 x 1200 x 1020mm VOLTAGE: AS PER CUSTOMER REQUEST POWER: 8.45kw CAPACITY: APPROXIMATELY 90KG/H WEIGHT: 620kg NOZZLE DIAMETER: 70mm OR 100mm QUANTITY AVAILABLE: 1 Learn More

E-8999 SINGLE NOZZLE PILLOW FILLING MACHINEINVENTORY NUMBER: E-8999 SINGLE NOZZLE PILLOW FILLING MACHINE-NEW DIMENSIONS: 3100 x 1200 x 1020mm VOLTAGE: AS PER CUSTOMER REQUEST POWER: 8.45kw CAPACITY: APPROXIMATELY 90KG/H WEIGHT: 620kg NOZZLE DIAMETER: 70mm OR 100mm QUANTITY AVAILABLE: 1 Learn More -

E-8998 DOUBLE NOZZLE PILLOW FILLING MACHINEINVENTORY NUMBER: E-8998 DOUBLE NOZZLE PILLOW FILLING MACHINE -NEW DIMENSIONS: 3300 X 2600 X 1020mm (130" X 102" X 40") VOLTAGE: AS PER CUSTOMER REQUIREMENT POWER: 10.65kw CAPACITY: 150-180kg/H (300 TO 400 LBS PER HOUR) WEIGHT: 710kg (1560 LBS) QUANTITY AVAILABLE: 1 Learn More

E-8998 DOUBLE NOZZLE PILLOW FILLING MACHINEINVENTORY NUMBER: E-8998 DOUBLE NOZZLE PILLOW FILLING MACHINE -NEW DIMENSIONS: 3300 X 2600 X 1020mm (130" X 102" X 40") VOLTAGE: AS PER CUSTOMER REQUIREMENT POWER: 10.65kw CAPACITY: 150-180kg/H (300 TO 400 LBS PER HOUR) WEIGHT: 710kg (1560 LBS) QUANTITY AVAILABLE: 1 Learn More -

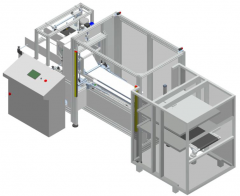

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More -

G-2254 PILLOW & CUSHION FILLING LINE: CARDED FIBER SYSTEMREFERENCE NUMBER: G-2254 PILLOW & CUSHION FILLING LINE: (CARDED FIBER SYSTEM) COMPUTERIZED CONTROL SYSTEM WITH FIBER CARDING, FIBER ROLLING, AUTOMATIC FILLING AND ADJUSTABLE FIBER WEIGHT CONTROLS INCLUDES METAL DETECTOR AND OVERLOAD ALARM ROLLING FILLING MACHINE QUANTITY AVAILABLE: 1 Learn More

G-2254 PILLOW & CUSHION FILLING LINE: CARDED FIBER SYSTEMREFERENCE NUMBER: G-2254 PILLOW & CUSHION FILLING LINE: (CARDED FIBER SYSTEM) COMPUTERIZED CONTROL SYSTEM WITH FIBER CARDING, FIBER ROLLING, AUTOMATIC FILLING AND ADJUSTABLE FIBER WEIGHT CONTROLS INCLUDES METAL DETECTOR AND OVERLOAD ALARM ROLLING FILLING MACHINE QUANTITY AVAILABLE: 1 Learn More -

E-9860 FIBER OPENING MACHINEINVENTORY NUMBER: E-9860 FIBER OPENING MACHINE USED TO OPEN POLYESTER FIBERS FOR PILLOW FILLING, PLUSH STUFFED TOY, SOFA, CUSHION, BEDDING, DECORATIVE PILLOW AND QUILT ETC. THE MACHINE IS MAINLY USED FOR OPENING REGULAR OR HOLLOW CONJUGATE SILICONIZED POLYESTER FIBER SHORTER THAN 100mm LENGTH (4 INCHES). HIGH OUTPUT. WITH METAL ALARM SYSTEM PROTECTING THE OPENER ROLLER, AVOIDING DAMAGE TO ROLLS. ASSEMBLED WITH METALLIC SELF-LOCK WIRE SO THAT THE FIBER CAN BE OPENED FOR MORE THAN 98% AND NOT BE DAMAGED. 150KG TO 320KG PRODUCTION PER HOUR DEPENDING ON THE DIFFERENT MACHINE MODELS AND FIBERS. BALANCED ROLLERS. ELECTRONIC OVERLOAD PROTECTION. QUANTITY AVAILABLE: 1 Learn More

E-9860 FIBER OPENING MACHINEINVENTORY NUMBER: E-9860 FIBER OPENING MACHINE USED TO OPEN POLYESTER FIBERS FOR PILLOW FILLING, PLUSH STUFFED TOY, SOFA, CUSHION, BEDDING, DECORATIVE PILLOW AND QUILT ETC. THE MACHINE IS MAINLY USED FOR OPENING REGULAR OR HOLLOW CONJUGATE SILICONIZED POLYESTER FIBER SHORTER THAN 100mm LENGTH (4 INCHES). HIGH OUTPUT. WITH METAL ALARM SYSTEM PROTECTING THE OPENER ROLLER, AVOIDING DAMAGE TO ROLLS. ASSEMBLED WITH METALLIC SELF-LOCK WIRE SO THAT THE FIBER CAN BE OPENED FOR MORE THAN 98% AND NOT BE DAMAGED. 150KG TO 320KG PRODUCTION PER HOUR DEPENDING ON THE DIFFERENT MACHINE MODELS AND FIBERS. BALANCED ROLLERS. ELECTRONIC OVERLOAD PROTECTION. QUANTITY AVAILABLE: 1 Learn More