Search results for: 'Power pla''

- Related search terms

- power bar

- power supply

- power gener

- Power heat

- power generator'

-

E-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBERE-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBER FOR POLYESTER STAPLE FIBER OPENING AND FILLING INTO UPHOLSTERY CUSHIONS OR PILLOWS. CAPACITY 250 KGS PER HOUR X 400 HOURS PER MONTH = 100,000 KGS PER MONTH AT 100% EFFICIENCY HOPPER FEED (REF G-3768) WITH 4.5 KW MOTOR FIBER OPENER TRANSFER FAN MIXING MACHINE (SILO WITH FOUR EXITS) FILLING STATION (FAN) , FOUR FILLING FANS WITH NOZZLE CLAMPS AND WITH TABLES SPARE PARTS SUGGESTED Learn More

E-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBERE-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBER FOR POLYESTER STAPLE FIBER OPENING AND FILLING INTO UPHOLSTERY CUSHIONS OR PILLOWS. CAPACITY 250 KGS PER HOUR X 400 HOURS PER MONTH = 100,000 KGS PER MONTH AT 100% EFFICIENCY HOPPER FEED (REF G-3768) WITH 4.5 KW MOTOR FIBER OPENER TRANSFER FAN MIXING MACHINE (SILO WITH FOUR EXITS) FILLING STATION (FAN) , FOUR FILLING FANS WITH NOZZLE CLAMPS AND WITH TABLES SPARE PARTS SUGGESTED Learn More -

K-3843 KAPOK FILLING MACHINEREFERENCE NUMBER: K-3843 KAPOK FILLING MACHINE STUFFING MACHINE AND BLOWER KAPOK FEEDING HOPPER AIR COMPRESSOR QUANTITY AVAILABLE: 1 Learn More

K-3843 KAPOK FILLING MACHINEREFERENCE NUMBER: K-3843 KAPOK FILLING MACHINE STUFFING MACHINE AND BLOWER KAPOK FEEDING HOPPER AIR COMPRESSOR QUANTITY AVAILABLE: 1 Learn More -

K-5175 AUTOMATIC PILLOW MACHINE WITH HOPPER FEEDREFERENCE NUMBER: K-5175 AUTOMATIC PILLOW MACHINE WITH HOPPER FEED DIMENSIONS: 11700mm X 4000mm X 3000mm POWER: 23.45KW CAPACITY: 8 TO 10 PIECES PER MINUTE LABOR NEED: 1 CONTROL SYSTEM: SIEMENS PLC ELECTRICITY: AS PER CUSTOMER FIBER OPENING RATE: 98%+ WEIGHT: 3650 KG QUANTITY AVAILABLE: 1 Learn More

K-5175 AUTOMATIC PILLOW MACHINE WITH HOPPER FEEDREFERENCE NUMBER: K-5175 AUTOMATIC PILLOW MACHINE WITH HOPPER FEED DIMENSIONS: 11700mm X 4000mm X 3000mm POWER: 23.45KW CAPACITY: 8 TO 10 PIECES PER MINUTE LABOR NEED: 1 CONTROL SYSTEM: SIEMENS PLC ELECTRICITY: AS PER CUSTOMER FIBER OPENING RATE: 98%+ WEIGHT: 3650 KG QUANTITY AVAILABLE: 1 Learn More -

G-0967 PILLOW VACUUM PACKING MACHINEREFERENCE NUMBER: G-0967 PILLOW VACUUM PACKING MACHINE DESCRIPTION: SUITABLE FOR ALL KINDS OF HOME TEXTILE PRODUCS WHICH ARE PACKED WITH PLASTIC BAGS, SUCH AS PILLOWS, CUSHIONS AND PLUSH TOYS, SOFA CUSHION ETC THOSE SOFT STUFFING PRODUCTIONS. THE SUITABLE BAG MATERIAL CAN BE PP, PO & PE, PA, OPP, ETC. HIGH AUTOMATIC LEVEL OF CONTROL IMPORTED. THE SEALING TIME AND COOLING TIME CAN BE ADJUSTED ACCORDING TO THE BAG MATERIAL THICKNESS, NORMALLY IT IS 2 TO 3 SECONDS. EACH SEALING SIDE CAN BE HANDLED BY ONLY ONE OPERATOR. CAPACITY: 3 PIECES PER MINUTE QUANTITY AVAILABLE: 1 Learn More

G-0967 PILLOW VACUUM PACKING MACHINEREFERENCE NUMBER: G-0967 PILLOW VACUUM PACKING MACHINE DESCRIPTION: SUITABLE FOR ALL KINDS OF HOME TEXTILE PRODUCS WHICH ARE PACKED WITH PLASTIC BAGS, SUCH AS PILLOWS, CUSHIONS AND PLUSH TOYS, SOFA CUSHION ETC THOSE SOFT STUFFING PRODUCTIONS. THE SUITABLE BAG MATERIAL CAN BE PP, PO & PE, PA, OPP, ETC. HIGH AUTOMATIC LEVEL OF CONTROL IMPORTED. THE SEALING TIME AND COOLING TIME CAN BE ADJUSTED ACCORDING TO THE BAG MATERIAL THICKNESS, NORMALLY IT IS 2 TO 3 SECONDS. EACH SEALING SIDE CAN BE HANDLED BY ONLY ONE OPERATOR. CAPACITY: 3 PIECES PER MINUTE QUANTITY AVAILABLE: 1 Learn More -

R-1192 CUSHION ROLL BAG MAKING MACHINE OC668, MACHINE SIZE 3200 × 1250 × 1800mm

R-1192 CUSHION ROLL BAG MAKING MACHINE OC668, MACHINE SIZE 3200 × 1250 × 1800mmREFERENCE NUMBER: R-1192

CUSHION ROLL BAG MAKING MACHINE OC668, MACHINE SIZE 3200 × 1250 × 1800mm

CUSHION ROLL BAG MAKING MACHINEOC668

THIS MACHINE IS SUITABLE FOR HIGH-DENSITY POLYETHYLENE LONGEVITY ETHYLENE (HDPE)

LOW DENSITY POLYETHYLENE (LDPE) AND POLYPROPYLENE (PP) SEALING

MODEL: 500mm

BAG LAYER: SINGLE LAYER

BAG WIDTH: 100 TO 400mm

BAG LENGTH: 100 TO 1000mm

BAG SPEED: 50 TO 120PCS/MIN

Learn More -

V-1212-A PILLOW COMPRESSION/PACKING MACHINE – new model Aug 2020 (800 x 800 mm) {31.5 x 31.5”} WITH DOUBLE BAND SEALINGV-1212-A PILLOW COMPRESSION/PACKING MACHINE – new model Aug 2020 (800 x 800 mm) {31.5 x 31.5”} WITH DOUBLE BAND SEALING

V-1212-A PILLOW COMPRESSION/PACKING MACHINE – new model Aug 2020 (800 x 800 mm) {31.5 x 31.5”} WITH DOUBLE BAND SEALINGV-1212-A PILLOW COMPRESSION/PACKING MACHINE – new model Aug 2020 (800 x 800 mm) {31.5 x 31.5”} WITH DOUBLE BAND SEALING DIMENSIONS: 1200 x 1150 x 1600mm

SHIPPING DIMENSIONS: 1220 WIDTH x 1110 LENGTH x 2060mm HEIGHT

NET WEIGHT: 110 KGS

GROSS WEIGHT 320 KG

PRESSURE: 0.6 MPa = 87 PSI

VIDEO AVAILABLE

QUANTITY: 1

Learn More

DIMENSIONS: 1200 x 1150 x 1600mm

SHIPPING DIMENSIONS: 1220 WIDTH x 1110 LENGTH x 2060mm HEIGHT

NET WEIGHT: 110 KGS

GROSS WEIGHT 320 KG

PRESSURE: 0.6 MPa = 87 PSI

VIDEO AVAILABLE

QUANTITY: 1

Learn More

-

L-5578 DOUBLE PORT FILLING MACHINE, MODEL P-8G

L-5578 DOUBLE PORT FILLING MACHINE, MODEL P-8GREFERENCE NUMBER: L-5578

DOUBLE PORT FILLING MACHINE, MODEL P-8G

MODEL P-8G

VOLTAGE 220V 50/60HZ

AIR DELIVERY SPEED 0.8M³/MIN

POWER 1.7KW

FILLING MATERIALS DOWN 70%-90%

QUANTITY: 1

Learn More -

L-5577 DOUBLE PORT FILLING MACHINE, MODEL P-6G

L-5577 DOUBLE PORT FILLING MACHINE, MODEL P-6GREFERENCE NUMBER: L-5577

DOUBLE PORT FILLING MACHINE, MODEL P-6G

MODEL P-6G

VOLTAGE 220V 50/60HZ

AIR DELIVERY SPEED 0.8M³/MIN

POWER 1.7KW

FILLING MATERIALS DOWN 70%-90%

QUANTITY: 1

Learn More -

L-5576 SINGLE PORT FILLING MACHINE, MODEL P-3G

L-5576 SINGLE PORT FILLING MACHINE, MODEL P-3GREFERENCE NUMBER: L-5576

SINGLE PORT FILLING MACHINE, MODEL P-3G

VOLTAGE 220V 50/60HZ

AIR DELIVERY SPEED 0.5M³/MIN

POWER 1.7KW

FILLING MATERIALS DOWN 70%-90%

QUANTITY: 2

Learn More -

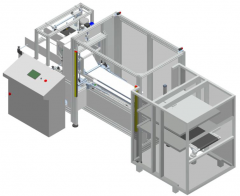

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More