Search results for: 'Weight all a'

-

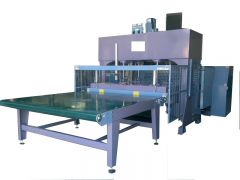

V-1724 MATTRESS WRAPPING WITH PRESSING UNIT AND ROLLING UP – NEW

V-1724 MATTRESS WRAPPING WITH PRESSING UNIT AND ROLLING UP – NEWFLATTEN ALL TYPES OF MATTRESSES AND ROLL UP THE FLAT POCKET SPRING MATTRESSES.

FLATTENING AND ROLLING MATTRESSES HAS THE ADVANTAGE OF MINIMIZING THE STORAGE AREA AND

FACILITATE THE TRANSPORTATION AND LOWER TRANSPORTATION COSTS.

PRODUCTION CAPACITY: 3 MATTRESSES PER MINUTE FOR NORMAL PACKING.

MATTRESS SIZE: MIN. 700 X 1900mm TO MAX. 2100 X 2100mm

MATTRESS HEIGHT: 50mm TO 400mm

PRESSING SYSTEM: PNEUMATIC FOR NORMAL PACKING, HYDRAULIC SYSTEM FOR FLATTENING AND ROLL PACKING

PNEUMATIC PRESSURE: 482 KGS (8 BARS)

HYDRAULIC PRESSURE: 65 TON

WIDTH OF FILM ROLLS: MIN. 2200 mm TO MAX. 2650 mm

MAX. DIAMETER OF FILM ROLLS: 320mm

MAX. WEIGHT OF FILM ROLLS: 200 KGS

TYPE OF NYLON: PE FILM

THICKNESS OF FILM: 50 TO 150 MICRON (5 TO 15)

POWER REQUIREMENTS: 3 PHASE 380 V OR AS PER CUSTOMER

TOTAL ELECTRIC DRAW: 20 KW

WEIGHT: APPROX. 10 TONS

NUMBER OF OPERATORS: 1

QUALITY STANDARD: CE

WARRANTY: 2 YEARS

FINAL ROLL PACKING TUBE DIAMETER: 250 TO 400 mm

YouTube Video 1: https://youtu.be/7e3-3FtaQdE

YouTube Video 2: https://youtu.be/LrmcQ18A1zM

QUANTITY: 1

Learn More -

V-0052 ADHESIVE APPLICATION MACHINE (FOR FOAM, MATTRESSES)REFERENCE NUMBER: V-0052 ADHESIVE APPLICATION MACHINE (FOR FOAM, MATTRESSES) QUANTITY AVAILABLE: 1 Learn More

V-0052 ADHESIVE APPLICATION MACHINE (FOR FOAM, MATTRESSES)REFERENCE NUMBER: V-0052 ADHESIVE APPLICATION MACHINE (FOR FOAM, MATTRESSES) QUANTITY AVAILABLE: 1 Learn More -

L-7136 MATTRESS DURABILITY COMPREHENSIVE TESTER

L-7136 MATTRESS DURABILITY COMPREHENSIVE TESTERABLE TO DO ROLLING TESTS ON MATTRESSES

DURABILITY TEST FOR THE BED SURFACE:

1. USES INDEPENDENT CONTROL SYSTEM. PLC CONTROL SEPARATELY. COOPERATE WITH COLOR TOUCH SCREEN. IT IS

CONVENIENT AND VISUAL TO OPERATE. THE TESTING PROCESS AND THE RUNNING STATUS BE CLEAR TO US, TEST TIMES CAN

BE SET FREELY.

2. SPECIAL LIFT DEVICE IS CONVENIENT TO LIFT UP THE HEAVY ROLLER AND EASY TO MOVE IT TO THE TEST AREA OF THE

MATTRESS. THEN PUT DOWN THE ROLLER AND MAKE ITS OWN WEIGHT FULLY LOAD TO THE SURFACE OF THE MATTRESS.

3.ROLLER CAN MOVE UP AND DOWN IN THE TESTING PROCESS, TO ADAPT TO CONCAVE AND CONVEX SURFACE OF THE

MATTRESS.

4. WHEN DOING DURABILITY TEST OF EDGE, ROLLER CAN BE MOVED TO THE “PARKING” AREA BEHIND THE INSTRUMENT.

5. DURABILITY TEST FOR THE EDGE IS DRIVEN BY SERVO MOTOR; IT IS QUIET, STEADY AND RELIABLE TO OPERATE.

6. INCORPORATES ADVANCED PHOTOELECTRIC SENSE TECHNOLOGY. THE BEGINNING POSITION OF THE CENTER LINE OF THE

CUSHION SURFACE RETURN TO THE HOME POSITION AUTOMATICALLY.

DURABILITY TEST FOR BED EDGE :

ADOPT INDEPENDENT CONTROL SYSTEM, USING DEDICATED HIGH-PRECISION AND HIGH INTELLIGENT ARAM CONTROLLER

AND SPECIAL TEST SOFTWARE. IT CAN RUN UNDER WINDOWS SYSTEM ON PC, IT IS OPERATED ALL BY SOFTWARE, THE

INTERFACE OF SOFTWARE IS EASY TO OPERATE.

SPECIAL TEST SOFTWARE ON PC, WINDOWS OPERATING PAGE, A HIGH DEGREE OF COMPATIBILITY.

TEST PROGRAM HAS ALREADY BEEN SET ON THE SOFTWARE ON PC ACCORDING TO THE TEST REQUIREMENT. A KEY TO TEST.

IT IS CONVENIENT FOR OPERATOR TO LEARN AND SAVE THE TRAINING TIME.

THE CURVE WINDOW OF TEST SOFTWARE DISPLAY THE VALUES OF FORCE AND SHIFT IN REAL TIME, COORDINATE MODEL.

LOADING CUSHION ON THE EDGE AND LOADING CUSHION WHICH IS USED FOR MEASURING USE GENERIC CONNECTION

HEAD THAT CAN BE IN INTERCHANGED. SHARING A SET OF DRIVING DEVICE, SAVE SPACE AND COST.

ADJUSTABLE RACK. THE PRESSURE PLATE CAN BE ADJUSTED THE POSITION ALONG THE DIRECTION OF X AND Y. IT CAN

MEASURE EACH POINT OF THE MATTRESS. IT IS DIFFERENT FROM THE TRADITION WAY TO SEPARATE. THE TEST CAN BE

FINISHED WITHOUT MOVING THE SAMPLE.

SAVE A LOT OF TESTING TIME, GREATLY REDUCES THE WORKING INTENSITY, OPERATORS CAN ACHIEVE SINGLE OPERATION,

SAVE THE COMPANY COST.

FORCE SENSOR AVOIDS DAMAGE TO THE CORE COMPONENTS BECAUSE IT CAN MAKE PROTECTION WHEN IT IS OVERLOAD.ROLLING TEST SPEED: 16±2CYCLES PER MINUTE (OR SPECIFIED BY CUSTOMER)

Learn More

CYLINDER ROLLER: 1400N, THE MIDDLE DIAMETER: 300mm, BOTH ENDS DIAMETER: 250mm, LENGTH: 1000

HEXAGON STYLE WOODEN ROLLER: SIZE AS STANDARD REQUIREMENT

COUNTER: 0~999999 CAN BE SET.

THE CONTROL WAY OF ROLLING: TOUCH SCREEN + PLC CONTROL

LOADING CUSHION ON THE EDGE: BUTTOCKS SHAPE, 380mm X 495mm

LOADING PARTS ON THE EDGE: THE MIDPOINT ON THE LONG EDGE OF THE MATTRESS.200 mm FROM EDGE.

LOADING FORCE ON THE EDGE: 1000N

LOADING TIME ON THE EDGE: 3S

POSITION OF MEASUREMENT: MATTRESS CENTER, LEFT AND RIGHT ARE BOTH 250mm, THE MIDPOINT ON THE LONG EDGE

OF THE MATTRESS 200 mm INWARD.

LOADING PLATE OF MEASUREMENT: DIAMETER 355mm, RADIUS OF CURVATURE OF THE END R800mm

CAPACITY OF FORCE SENSOR: 2KN

LOADING SPEED OF MEASUREMENT: 90±5mm/MIN

STROKE: 500mm

DRIVE MOTOR: SERVO MOTOR -

V-1053 POCKET COILER AND ASSEMBLER, NEW

V-1053 POCKET COILER AND ASSEMBLER, NEWREFERENCE NUMBER: V-1053

POCKET COILER AND ASSEMBLER, NEW

MODEL 12PA AUTO POCKET SPRING PRODUCTION LINE

MODEL 12PA AUTO POCKET SPRING PRODUCTION LINE IS MADE UP OF MODEL-12P POCKET SPRING MACHINE AND MODEL-08A AUTO POCKET SPRING ASSEMBLING MACHINE.

COMPLETELY AUTOMATIC, IT CAN FINISH ALL THE PROCESS OF PRODUCTION FROM POCKET SPRING TO MATTRESS.

EASY TO OPERATE, HIGH EFFICIENCY, AND LOW NOISE.

THE PRODUCTION LINE HAS A SMALL FOOT PRINT ON THE PLANT FLOOR.

THE PRODUCTION LINE IS CONTROLLED BY SERVO MOTORS, SO ACCURACY IS HIGH.

THE CONTROL PARAMETERS CAN BE SET BY THE CUSTOMER FOR DIVERSE DEMANDS.

AUTO STOP WHEN RUN OUT OF MATERIALS. (WITH CE CERTIFICATE)

TECHNICAL SPECIFICATIONS:

DESIGNATION MODEL 12P + MODEL 08A

PRODUCT EFFICIENCY 70 coils / min

SPRING DIAMETER End 45mm-60mm; Center 60mm-80mm

SPRING HEIGHT 80mm-120mm / 120mm-180mm / 160mm-220mm

STEEL WIRE DIAMETER 1.8mm-2.2mm

TOP AND BOTTOM With and without

NON-WOVEN

MAXIMUM POWER 32KW

SPACE DIMENSION (L X W X H) 9500mm x 3000mm x 1850mm

WEIGHT 4000kgs

Learn More -

K-4681 WRAPPING MANUAL FOR MATTRESSESREFERENCE NUMBER: K-4681 WRAPPING MANUAL FOR MATTRESSES MANUAL WELDING BAR TO CLOSE ONE SIDE OF THE MATTRESS QUANTITY AVAILABLE: 1 Learn More

K-4681 WRAPPING MANUAL FOR MATTRESSESREFERENCE NUMBER: K-4681 WRAPPING MANUAL FOR MATTRESSES MANUAL WELDING BAR TO CLOSE ONE SIDE OF THE MATTRESS QUANTITY AVAILABLE: 1 Learn More -

K-4679 WRAPPING MANUAL FOR MATTRESSESREFERENCE NUMBER: K-4679 WRAPPING MANUAL FOR MATTRESSES SEMI-AUTOMATIC PACKAGING MACHINE FOR BAGGING MATTRESSES ON 4 SIDES COMPLETE WITH STAND MATTRESS QUANTITY AVAILABLE: 1 Learn More

K-4679 WRAPPING MANUAL FOR MATTRESSESREFERENCE NUMBER: K-4679 WRAPPING MANUAL FOR MATTRESSES SEMI-AUTOMATIC PACKAGING MACHINE FOR BAGGING MATTRESSES ON 4 SIDES COMPLETE WITH STAND MATTRESS QUANTITY AVAILABLE: 1 Learn More