Search results for: 'pillow c'

- Related search terms

- pillow+b

- pillow co

- pillow+machine

- PILLOW+PA

- pillow p

-

G-6401 PILLOW FILLING MACHINEREFERENCE NUMBER: G-6401 PILLOW FILLING MACHINE THE PILLOW MACHINE LINE IS ASSEMBLED WITH A FIBER OPENER AND MINI BLOWER STUFFING MACHINES THAT MAINLY USED FOR TEXTILE STUFFING PRODUCTIONS SUCH AS BIG PLUSH TOYS, CUSHIONS AND PILLOWS ETC. IT CAN BE ALSO USED FOR FIBER QUILTING FILLING AFTER THE STUFFING SLOTS OF DUVET TYPE - ADJUSTABLE FOOT SWITCH CONTROLLING FOR THE MATERIAL INSIDE OF THE STUFFER HOPPER THAT AVOIDS THE MATERIAL TO BALL UP SO THAT THE FINISHED PRODUCT IS RETAINS GOOD ELASTICITY - LOWER AIR PRESSURE REQUIRED. - HIGH PRODUCTIVITY QUANTITY AVAILABLE: 1 Learn More

G-6401 PILLOW FILLING MACHINEREFERENCE NUMBER: G-6401 PILLOW FILLING MACHINE THE PILLOW MACHINE LINE IS ASSEMBLED WITH A FIBER OPENER AND MINI BLOWER STUFFING MACHINES THAT MAINLY USED FOR TEXTILE STUFFING PRODUCTIONS SUCH AS BIG PLUSH TOYS, CUSHIONS AND PILLOWS ETC. IT CAN BE ALSO USED FOR FIBER QUILTING FILLING AFTER THE STUFFING SLOTS OF DUVET TYPE - ADJUSTABLE FOOT SWITCH CONTROLLING FOR THE MATERIAL INSIDE OF THE STUFFER HOPPER THAT AVOIDS THE MATERIAL TO BALL UP SO THAT THE FINISHED PRODUCT IS RETAINS GOOD ELASTICITY - LOWER AIR PRESSURE REQUIRED. - HIGH PRODUCTIVITY QUANTITY AVAILABLE: 1 Learn More -

G-6400 HEAVY DUTY PILLOW FILLING MACHINEREFERENCE NUMBER: G-6400 HEAVY DUTY PILLOW FILLING MACHINE THE PILLOW MACHINE LINE IS ASSEMBLED WITH A FIBER OPENER AND MINI BLOWER STUFFING MACHINES THAT MAINLY USED FOR TEXTILE STUFFING PRODUCTIONS SUCH AS BIG PLUSH TOYS, CUSHIONS AND PILLOWS ETC. IT CAN BE ALSO USED FOR FIBER QUILTING FILLING AFTER THE STUFFING SLOTS OF DUVET TYPE QUILTS - ADJUSTABLE FOOT SWITCH CONTROLLING FOR THE MATERIAL INSIDE OF THE STUFFER HOPPER THAT AVOIDS THE MATERIAL TO BALL UP SO THAT THE FINISHED PRODUCT IS RETAINS GOOD ELASTICITY - LOW AIR PRESSURE REQUIRED. - HIGH PRODUCTIVITY QUANTITY AVAILABLE: 1 Learn More

G-6400 HEAVY DUTY PILLOW FILLING MACHINEREFERENCE NUMBER: G-6400 HEAVY DUTY PILLOW FILLING MACHINE THE PILLOW MACHINE LINE IS ASSEMBLED WITH A FIBER OPENER AND MINI BLOWER STUFFING MACHINES THAT MAINLY USED FOR TEXTILE STUFFING PRODUCTIONS SUCH AS BIG PLUSH TOYS, CUSHIONS AND PILLOWS ETC. IT CAN BE ALSO USED FOR FIBER QUILTING FILLING AFTER THE STUFFING SLOTS OF DUVET TYPE QUILTS - ADJUSTABLE FOOT SWITCH CONTROLLING FOR THE MATERIAL INSIDE OF THE STUFFER HOPPER THAT AVOIDS THE MATERIAL TO BALL UP SO THAT THE FINISHED PRODUCT IS RETAINS GOOD ELASTICITY - LOW AIR PRESSURE REQUIRED. - HIGH PRODUCTIVITY QUANTITY AVAILABLE: 1 Learn More -

G-6399 PILLOW FILLING MACHINEREFERENCE NUMBER: G-6399 PILLOW FILLING MACHINE THE PILLOW MACHINE LINE IS ASSEMBLED WITH A FIBER OPENER AND MINI BLOWER STUFFING MACHINES THAT MAINLY USED FOR TEXTILE STUFFING PRODUCTIONS SUCH AS BIG PLUSH TOYS, CUSHIONS AND PILLOWS ETC. IT CAN BE ALSO USED FOR FIBER QUILTING FILLING AFTER THE STUFFING SLOTS OF DUVET TYPE QUILTS - ADJUSTABLE FOOT SWITCH CONTROLLING FOR THE MATERIAL INSIDE OF THE STUFFER HOPPER THAT AVOIDS THE MATERIAL TO BALL UP SO THAT THE FINISHED PRODUCT IS RETAINS GOOD ELASTICITY - LOW AIR PRESSURE REQUIRED QUANTITY AVAILABLE: 1 Learn More

G-6399 PILLOW FILLING MACHINEREFERENCE NUMBER: G-6399 PILLOW FILLING MACHINE THE PILLOW MACHINE LINE IS ASSEMBLED WITH A FIBER OPENER AND MINI BLOWER STUFFING MACHINES THAT MAINLY USED FOR TEXTILE STUFFING PRODUCTIONS SUCH AS BIG PLUSH TOYS, CUSHIONS AND PILLOWS ETC. IT CAN BE ALSO USED FOR FIBER QUILTING FILLING AFTER THE STUFFING SLOTS OF DUVET TYPE QUILTS - ADJUSTABLE FOOT SWITCH CONTROLLING FOR THE MATERIAL INSIDE OF THE STUFFER HOPPER THAT AVOIDS THE MATERIAL TO BALL UP SO THAT THE FINISHED PRODUCT IS RETAINS GOOD ELASTICITY - LOW AIR PRESSURE REQUIRED QUANTITY AVAILABLE: 1 Learn More -

F-1361 PILLOW WEIGHT SETTING FILLING MACHINEREFERENCE NUMBER: F-1361 PILLOW WEIGHT SETTING FILLING MACHINE FILLING MACHINES WITH PADDING DEVICES ENSURE HIGH SPEED AND TOP QUALITY FILLING. THE OPERATORS CAN SET THE WEIGHT OF EACH PILLOW/CUSHION APPROXIMATELY FIBER CARDING MACHINE: DIMENSIONS: 2150 X 1150 X 980 POWER: 6.35kW NET WEIGHT: 800kg CAPACITY: APPROX. 160 TO 190kg PER HOUR VOLTAGE: AS PER CUSTOMER OFFERS MORE SAFETY: THE FIBER CARDING MACHINE HAS AN OVERLOADING ALARM SYSTEM TO AVOID THE MACHINE BEING DAMAGED SAVES ON COSTS: IF AN ADDITIONAL BALE OPENING MACHINE IS ADDED, ONLY ONE PERSON IS NEEDED TO RUN THE WHOLE LINE WITH TWO FILLER HEADS FILLING MACHINE: DIMENSIONS: 3350 X 1900 X 1450 POWER: 4.74kW NET WEIGHT: 400kg AIR PRESSURE: 1mpa CAPACITY: APPROX. 160 TO 190kg PER HOUR VOLTAGE: AS PER CUSTOMER QUANTITY AVAILABLE: 1 Learn More

F-1361 PILLOW WEIGHT SETTING FILLING MACHINEREFERENCE NUMBER: F-1361 PILLOW WEIGHT SETTING FILLING MACHINE FILLING MACHINES WITH PADDING DEVICES ENSURE HIGH SPEED AND TOP QUALITY FILLING. THE OPERATORS CAN SET THE WEIGHT OF EACH PILLOW/CUSHION APPROXIMATELY FIBER CARDING MACHINE: DIMENSIONS: 2150 X 1150 X 980 POWER: 6.35kW NET WEIGHT: 800kg CAPACITY: APPROX. 160 TO 190kg PER HOUR VOLTAGE: AS PER CUSTOMER OFFERS MORE SAFETY: THE FIBER CARDING MACHINE HAS AN OVERLOADING ALARM SYSTEM TO AVOID THE MACHINE BEING DAMAGED SAVES ON COSTS: IF AN ADDITIONAL BALE OPENING MACHINE IS ADDED, ONLY ONE PERSON IS NEEDED TO RUN THE WHOLE LINE WITH TWO FILLER HEADS FILLING MACHINE: DIMENSIONS: 3350 X 1900 X 1450 POWER: 4.74kW NET WEIGHT: 400kg AIR PRESSURE: 1mpa CAPACITY: APPROX. 160 TO 190kg PER HOUR VOLTAGE: AS PER CUSTOMER QUANTITY AVAILABLE: 1 Learn More -

J-2968 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT, FOR FEATHERJ-2968 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT, FOR FEATHER SILO CAPACITY: 4.4m3 AUTOMATIC PRE-WEIGHING UNIT: 1, 300 LITER CAPACITY FILLING NOZZLES: 1 OUTPUT CAPACITY: UP TO 400 FILLINGS PER HOUR FILLING WEIGHT ACCURACY: UP TO 1 GRAM (UP TO 2% OF THE TOTAL WEIGHT) EXPECTED OUTPUT: 3 PILLOWS PER MINUTE WITH 2 LBS FEATHER PILLOWS VOLTAGE: 480 VOLTS (+/- 10%) PHASE: 3-PHASE + N + PE FREQUENCY: 60 Hz (+/- 2%) VOLTAGE AUXILIARY CIRCUITS: 24 VDC / 24 VAC INSTALLED POWER: 5.2 KW – 16 AMPS OPERATING PRESSURE: 6 BAR AIR CONSUMPTION: 50 LITERS PER MINUTE NOISE: < 70 Db QUANTITY: 1 Learn More

J-2968 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT, FOR FEATHERJ-2968 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT, FOR FEATHER SILO CAPACITY: 4.4m3 AUTOMATIC PRE-WEIGHING UNIT: 1, 300 LITER CAPACITY FILLING NOZZLES: 1 OUTPUT CAPACITY: UP TO 400 FILLINGS PER HOUR FILLING WEIGHT ACCURACY: UP TO 1 GRAM (UP TO 2% OF THE TOTAL WEIGHT) EXPECTED OUTPUT: 3 PILLOWS PER MINUTE WITH 2 LBS FEATHER PILLOWS VOLTAGE: 480 VOLTS (+/- 10%) PHASE: 3-PHASE + N + PE FREQUENCY: 60 Hz (+/- 2%) VOLTAGE AUXILIARY CIRCUITS: 24 VDC / 24 VAC INSTALLED POWER: 5.2 KW – 16 AMPS OPERATING PRESSURE: 6 BAR AIR CONSUMPTION: 50 LITERS PER MINUTE NOISE: < 70 Db QUANTITY: 1 Learn More -

K-3843 KAPOK FILLING MACHINEREFERENCE NUMBER: K-3843 KAPOK FILLING MACHINE STUFFING MACHINE AND BLOWER KAPOK FEEDING HOPPER AIR COMPRESSOR QUANTITY AVAILABLE: 1 Learn More

K-3843 KAPOK FILLING MACHINEREFERENCE NUMBER: K-3843 KAPOK FILLING MACHINE STUFFING MACHINE AND BLOWER KAPOK FEEDING HOPPER AIR COMPRESSOR QUANTITY AVAILABLE: 1 Learn More -

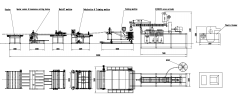

M-3674-A WISE PILLOW MACHINE FILLING MACHINE

M-3674-A WISE PILLOW MACHINE FILLING MACHINEREFERENCE NUMBER: M-3674-A

WISE PILLOW MACHINE FILLING MACHINEPLATE INFO FOR THE HOPPER:

DATE: JUNE/00

MOD. NO.: WK 4×36

PLATE INFO FOR THE FIRST BLOWER:

DATE: JUNE/00

MOD. NO.: 4C 113PLATE INFO FOR THE SECOND BLOWER:

DATE: JUNE/00

MOD. NO.: 4C 113PLATE INFO FOR THE CONTROL PANEL:

DATE: JUNE/2000

MOD. NO.: SYSTEM 1NOTE: THE HOPPER APRON WIDTH: 35 ½” INCHES

AFTER THE HOPPER THERE IS ANOTHER MACHINE WHICH MIGHT BE A FINE OPENER WITH (2) BLOWERS, (2) NOZZLES AND (1) CONTROL PANEL

QUANTITY: 1

Learn More -

K-9222-A ORMONT BLOWER AND HOPPER YEAR 1996

K-9222-A ORMONT BLOWER AND HOPPER YEAR 1996REFERENCE NUMBER: K-9222-A

ORMONT BLOWER AND HOPPER YEAR 1996

ORMONT PILLOW FILLER AND HOPPER

YEAR 1996

ORMONT CORPORATION SHREDDER

TYPE: TRP

SIZE: 11

HP: 11

RPM: 1750

VOLTS: 575

PHASE: 3

CYCLE: 60

AMPS: -

SERV: 80388

FRAME: 1143T

MOTOR INFO:

BRAND: LEESON

HP: 15

VOLTS: 208-230/460

RPM: 1765

PLATE INFO:

ORMONT CORPORATION BLOWER – ONE NOZZLE

TYPE: FG

SIZE: 36

HP: 15

RPM: 1750

VOLTS: 220

PHASE: 3

CYCLE: 60

AMPS: 22

SERV: 80488

FRAME: 254T

QUANTITY: 1

Learn More -

J-5381 MACHINE TO PRODUCE PILLOW FILLING OF POE/EVAJ-5381 MACHINE TO PRODUCE PILLOW FILLING OF POE/EVA TO FILL PILLOWS WITH POE/EVA WITH DENSITY 20 TO 90 DENSITY (KGS/CUBIC METER) WITH THICKNESS BETWEEN 10mm AND 200mm QUANTITY: 1 Learn More

J-5381 MACHINE TO PRODUCE PILLOW FILLING OF POE/EVAJ-5381 MACHINE TO PRODUCE PILLOW FILLING OF POE/EVA TO FILL PILLOWS WITH POE/EVA WITH DENSITY 20 TO 90 DENSITY (KGS/CUBIC METER) WITH THICKNESS BETWEEN 10mm AND 200mm QUANTITY: 1 Learn More -

T-9663 AUTOMATIC SINGLE QUILT JACKET BAG COTTON GOOSE DOWN FEATHER COMFORTER FILLING MACHINE DOWN JACKETT-9663 AUTOMATIC SINGLE QUILT JACKET BAG COTTON GOOSE DOWN FEATHER COMFORTER FILLING MACHINE DOWN JACKET ADAPTATION RANGE: MAINLY FOR LARGE AND SMALL CELLS FILLED WITH DOWN COTTON, DOWN AND BEDDING DUVET FILLING, AND CAN BE FILLED WITH AIRTIGHT FABRICS PACKED WEIGHT: 43.55 KG PACKED DIMENSIONS: 630 x 770 x 700mm Learn More

T-9663 AUTOMATIC SINGLE QUILT JACKET BAG COTTON GOOSE DOWN FEATHER COMFORTER FILLING MACHINE DOWN JACKETT-9663 AUTOMATIC SINGLE QUILT JACKET BAG COTTON GOOSE DOWN FEATHER COMFORTER FILLING MACHINE DOWN JACKET ADAPTATION RANGE: MAINLY FOR LARGE AND SMALL CELLS FILLED WITH DOWN COTTON, DOWN AND BEDDING DUVET FILLING, AND CAN BE FILLED WITH AIRTIGHT FABRICS PACKED WEIGHT: 43.55 KG PACKED DIMENSIONS: 630 x 770 x 700mm Learn More