Search results for: 'pre n'

- Related search terms

- Pre needl

- pressure tank

- pre nee

- pre needle

- pre needle p

-

TT-4358 CARDING + CROSS LAPPING + ANDRITZ SPUNLACE + 2X FLEISSNER OVEN, WIDTH 3500mm, YEAR 2007TT-4358 CARDING + CROSS LAPPING + ANDRITZ SPUNLACE + 2X FLEISSNER OVEN, WIDTH 3500mm, YEAR 2007 CARDING + CROSS LAPPING + ANDRITZ SPUNLACE + 2X FLEISSNER OVEN YEAR: 2007 AVAILABLY: FIRST / SECOND QUARTER 2024 Learn More

TT-4358 CARDING + CROSS LAPPING + ANDRITZ SPUNLACE + 2X FLEISSNER OVEN, WIDTH 3500mm, YEAR 2007TT-4358 CARDING + CROSS LAPPING + ANDRITZ SPUNLACE + 2X FLEISSNER OVEN, WIDTH 3500mm, YEAR 2007 CARDING + CROSS LAPPING + ANDRITZ SPUNLACE + 2X FLEISSNER OVEN YEAR: 2007 AVAILABLY: FIRST / SECOND QUARTER 2024 Learn More -

TT-4132 PROFESSIONAL ALPACA WOOL TOP MAKING SPINNING MACHINE, CAPACITY 40 TO 70 KG PER HOURTT-4132 PROFESSIONAL ALPACA WOOL TOP MAKING SPINNING MACHINE, CAPACITY 40 TO 70 KG PER HOUR BRAND: PASEN CARDING MACHINES CONDITION: NEW QUANTITY: 1 Learn More

TT-4132 PROFESSIONAL ALPACA WOOL TOP MAKING SPINNING MACHINE, CAPACITY 40 TO 70 KG PER HOURTT-4132 PROFESSIONAL ALPACA WOOL TOP MAKING SPINNING MACHINE, CAPACITY 40 TO 70 KG PER HOUR BRAND: PASEN CARDING MACHINES CONDITION: NEW QUANTITY: 1 Learn More -

YY-3068 1 TO 3mm ROPE TWISTING MACHINEYY-3068 1 TO 3mm ROPE TWISTING MACHINE ASK FOR MORE INFO! Learn More

YY-3068 1 TO 3mm ROPE TWISTING MACHINEYY-3068 1 TO 3mm ROPE TWISTING MACHINE ASK FOR MORE INFO! Learn More -

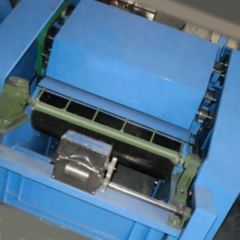

YY-3035 WOOL FIBER OPENING MACHINE & WEIGHING FEEDER & SEMI WORSTED CARDING MACHINEYY-3035 WOOL FIBER OPENING MACHINE & WEIGHING FEEDER & SEMI WORSTED CARDING MACHINE Learn More

YY-3035 WOOL FIBER OPENING MACHINE & WEIGHING FEEDER & SEMI WORSTED CARDING MACHINEYY-3035 WOOL FIBER OPENING MACHINE & WEIGHING FEEDER & SEMI WORSTED CARDING MACHINE Learn More -

TT-3748 TRUTZSCHLER BLOW ROOM WITH TC5 CARDING MACHINE, CAN SIZE 100 X 110mm, YEAR 2012TT-3748 TRUTZSCHLER BLOW ROOM WITH TC5 CARDING MACHINE, CAN SIZE 100 X 110mm, YEAR 2012 TRUTZSCHLER BLOW ROOM WITH TC5 CARDING MACHINE YEAR 2012 CAN SIZE 100 X 110mm Learn More

TT-3748 TRUTZSCHLER BLOW ROOM WITH TC5 CARDING MACHINE, CAN SIZE 100 X 110mm, YEAR 2012TT-3748 TRUTZSCHLER BLOW ROOM WITH TC5 CARDING MACHINE, CAN SIZE 100 X 110mm, YEAR 2012 TRUTZSCHLER BLOW ROOM WITH TC5 CARDING MACHINE YEAR 2012 CAN SIZE 100 X 110mm Learn More -

TT-3053 SCHLAFHORST 338 AUTOMATIC WINDING WITH 60 SPINDLES, YEAR 2007 WITH THERMO-SPLICER DEVICETT-3053 SCHLAFHORST 338 AUTOMATIC WINDING WITH 60 SPINDLES, YEAR 2007 WITH THERMO-SPLICER DEVICE QUANTITY: 1 Learn More

TT-3053 SCHLAFHORST 338 AUTOMATIC WINDING WITH 60 SPINDLES, YEAR 2007 WITH THERMO-SPLICER DEVICETT-3053 SCHLAFHORST 338 AUTOMATIC WINDING WITH 60 SPINDLES, YEAR 2007 WITH THERMO-SPLICER DEVICE QUANTITY: 1 Learn More -

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More -

T-7740 FOR CARDING MACHINE, WORKING WIDTH 2500mm, YEAR 1980T-7740 FOR CARDING MACHINE, WORKING WIDTH 2500mm, YEAR 1980 THE MACHINE IS COMPLETE STILL RUNNING RIGID CLOTHING IN GOOD CONDITION MACHINE NICELY MAINTAINED QUANTITY: 1 Learn More

T-7740 FOR CARDING MACHINE, WORKING WIDTH 2500mm, YEAR 1980T-7740 FOR CARDING MACHINE, WORKING WIDTH 2500mm, YEAR 1980 THE MACHINE IS COMPLETE STILL RUNNING RIGID CLOTHING IN GOOD CONDITION MACHINE NICELY MAINTAINED QUANTITY: 1 Learn More -

INDUSTRIAL ELECTROSPINNING MACHINEREFERENCE NUMBER: A-2471 INDUSTRIAL ELECTROSPINNING MACHINE A MASS PRODUCTION MACHINE OF ELECTROSPINNING. ALUMINUM FRAME STRUCTURE MAKES IT POSSIBLE FOR EXTENDING DIFFERENT FUNCTIONS. THE SPINNERET USED IS MULTI-NEEDLE ARRAYS, FROM 64 TO 384 NEEDLES ARE EQUIPPED. THE LENGTH AND WIDTH CAN BE MADE ACCORDING TO CUSTOMER'S REQUIREMENT. ROLL TO ROLL COLLECTOR AND CONTINUOUS COLLECTOR CAN BE USED BASED ON THE THICKNESS OF REQUIRED FIBER SHEET. FOR SOLUTIONS, A MULTI-CHANNEL PUMP WILL BE SUPPLIED FOR LONG TIME PRODUCTION OR NONE-STOP PRODUCTION. FEATURES: - EQUIPPED WITH BOTH POSITIVE & NEGATIVE HIGH VOLTAGE SUPPLY DEVICES - EQUIPPED WITH UNWINDING & WINDING MACHINES - CONTINUOUS ELECTROSPINNING & WINDING - ALUMINUM ALLOY FRAME STRUCTURE, MULTI-FUNCTIONS EXPANSIBLE - MULTI-NEEDLES IN ARRAYS. 16 NEEDLES X N ROWS, UP TO 384 NEEDLES - SPINNERET MOVING MACHINERY ENSURES EVEN FIBER SHEET - ONLINE AUTO-CLEAN DEVICE FOR NEEDLES - THICKNESS OF THE FIBER SHEET IS CONTROLLABLE - CE & FCC CERTIFICATE SPINNERET STANDARD:16 NEEDLES X 8 GROUPS =128 NEEDLES (THE NUMBER OF NEEDLES CAN BE ADJUSTED FREELY ACCORDING TO THE REQUIREMENTS OF USE) X-Y-Z MOTION SYSTEM - THE NOZZLE CAN BE MOVED UP AND DOWN IN THE Z DIRECTION THROUGH THE TOUCH SCREEN CONTROL TO DETERMINE THE APPROPRIATE SPINNING DISTANCE. - THE NOZZLE CAN MOVE BACK AND FORTH ALONG THE YAXIS DIRECTION OF THE TANGENT DIRECTION OF THE RECEIVING FILM TO PREPARE A UNIFORM FIBER FILM. - THE NOZZLE AUTOMATIC ONLINE CLEANING DEVICE SCANS ALONG THE X-AXIS DIRECTION. COLLECTOR - STAINLESS STEEL PLATE / MESH SERVES AS A CARRIER FOR THE FIBER MEMBRANE SUBSTRATE. - CONNECTED WITH NEGATIVE HIGH VOLTAGE. - RECEIVER BOARD WIDTH: 500 mm - SPINNING DISTANCE: 80 TO 300 mm ADJUSTABLE WINDER AND UNWINDER - AUTOMATICALLY CALCULATE THE ROLL DIAMETER OF THE LOADED MATERIAL AND CONTROL THE TENSION BETWEEN THE UNWINDING AND SPINNING SECTIONS. - CONSTANT FEEDING SPEED. THE FEEDING SPEED RANGE IS 0 TO 5000 mm / min. - ONLINE HOT PRESSING FUNCTION MODULE. AFTER THE SPINNING IS COMPLETED, BEFORE THE WINDING, A TEMPERATURE-CONTROLLED HOT PRESSING DEVICE (ROOM TEMPERATURE TO 60 ° C) IS USED FOR HOT PRESSING. (OPTIONAL THIRD LAYER MATERIAL STICKING AND REWINDING DEVICE). - CAN BE OPERATED BY TOUCH SCREEN. - DO NOT USE METAL FILM AS THE RECEIVING CARRIER. SYRINGE PUMP - 200ML X 4N CHANNEL - FLOW RATE: 0.1ML / H TO 1280 ML / H - SPECIALLY DESIGNED FOR ELECTRO-SPINNING AND RESISTANT TO HIGH VOLTAGE. HIGH VOLTAGE DEVICE -0 TO 50KV, DIGITAL DISPLAY --50KV ~ 0 KV, DIGITAL DISPLAY -OUTPUT CURRENT: <1 MA -CONTINUOUSLY ADJUSTABLE CONTROL SYSTEM -PLC CONTROL SYSTEM, 7-INCH TOUCH SCREEN. -CONTROL THE MOVEMENT OF THE NOZZLE. -CONTROL THE NOZZLE TO MOVE UP AND DOWN. -YOU CAN SET THE MOVEMENT TIME, STROKE AND SPEED OF THE NOZZLE. -CONTROL THE FREQUENCY OF NOZZLE CLEANING. -SPINNING PROCESS PARAMETER RECORDS. ENVIRONMENTAL CONTROL SYSTEM -PROVIDE INTERFACE TO LET IN DRY AMBIENT HUMIDITY AIR. -AN EXTERNAL DEHUMIDIFIER CAN BE USED TO CONTROL THE AMBIENT HUMIDITY. THE EXTERNAL DEHUMIDIFIER NEEDS TO BE SELECTED ACCORDING TO THE SIZE OF THE WORKSHOP. THIS EQUIPMENT DOES NOT INCLUDE THIS DEHUMIDIFIER. EXHAUST SYSTEM -BOTTOM UP, AND FOUR FANS ARE PUMPED AT THE SAME TIME. -THE DISCHARGE VOLUME OF A SINGLE UNIT IS 5 TO 150 M3 / H, AND THE RATE IS ADJUSTABLE. THE COMBINED DISCHARGE VOLUME OF THE TWO EXHAUST FANS IS 10 TO 300M3 / H. THE EXTRACTOR IS DRAWN FROM THE MIDDLE. IN THIS WAY, THE HIGH-SPEED AIR VENTILATION MINIMIZES THE RELATIVE DISTURBANCE TO THE SPINNING. THE EXHAUST FAN IS A SILENT EXHAUST FAN. SAFETY -AUTOMATIC POWER-OFF DEVICE FOR OPENING THE DOOR. -RESIDUAL STATIC ELECTRICITY REMOVAL DEVICE. -EMERGENCY STOP SWITCH. -GROUND AT MULTIPLE POINTS. -ALARM DEVICE AFTER THE CONTROL PARAMETERS EXCEED THE LIMIT. CHAMBER -THE CHAMBER IS MADE OF ALUMINUM ALLOY FRAME. -THE FRONT AND SIDE WINDOWS OF THE CABINET ARE MADE OF TEMPERED GLASS. -MULTI-POINT TEMPERATURE AND HUMIDITY COLLECTION AND DISPLAY. -THE PROCESS CAN BE OBSERVED WITH THE NAKED EYE. -AIR INLET: HOT AND DRY AIR CAN BE INTRODUCED TO QUICKLY ADJUST THE HUMIDITY INSIDE THE CHAMBER. POWER SOURCE -220 VOLTS AND 50/60 Hz -TOTAL POWER: 10KW NUMBER OF NEEDLES: 128 NEEDLES (THE NUMBER OF NEEDLES CAN BE ARBITRARILY REDUCED ACCORDING TO THE SOLVENT USAGE) FLOW RATE OF EACH NEEDLE: (~ 3ML ± 50%) / HOUR TOTAL FLOW OF THE WHOLE MACHINE: ABOUT (400ML ± 50%) / HOUR SOLUTION CONCENTRATION: 10 TO 20% 8 HOURS SOLUTION PROCESSING CAPACITY: ABOUT (3L ± 50%) / 8 HOURS SOLID CONTENT (WEIGHT OF FIBER PRODUCED): (300G ± 50%) / 8 HOURS ACCORDING TO THE APPROXIMATE PRODUCTION OF FIBER MATERIAL WITH A GRAM WEIGHT OF 2GSM. WINDING AND UNWINDING SPEED: 50M / H MATERIAL WIDTH: 0.5 METERS FABRIC AREA PRODUCED PER HOUR: 25 SQUARE METERS FABRIC AREA PRODUCED IN 8 HOURS: 200 SQUARE METERS FABRIC AREA PRODUCED IN 24 HOURS: 600 SQUARE METERS BASED ON THE PRODUCTION OF FIBER MATERIAL WITH A GRAMMAGE OF 0.02G / ㎡, APPROXIMATELY: WINDING AND UNWINDING SPEED: 5000M / H MATERIAL WIDTH: 0.5 METERS FABRIC AREA PRODUCED PER HOUR: 2500 SQUARE METERS FABRIC AREA PRODUCED IN 8 HOURS: 20,000 SQUARE METERS FABRIC AREA PRODUCED IN 24 HOURS: ABOUT 60,000 SQUARE METERS Learn More

INDUSTRIAL ELECTROSPINNING MACHINEREFERENCE NUMBER: A-2471 INDUSTRIAL ELECTROSPINNING MACHINE A MASS PRODUCTION MACHINE OF ELECTROSPINNING. ALUMINUM FRAME STRUCTURE MAKES IT POSSIBLE FOR EXTENDING DIFFERENT FUNCTIONS. THE SPINNERET USED IS MULTI-NEEDLE ARRAYS, FROM 64 TO 384 NEEDLES ARE EQUIPPED. THE LENGTH AND WIDTH CAN BE MADE ACCORDING TO CUSTOMER'S REQUIREMENT. ROLL TO ROLL COLLECTOR AND CONTINUOUS COLLECTOR CAN BE USED BASED ON THE THICKNESS OF REQUIRED FIBER SHEET. FOR SOLUTIONS, A MULTI-CHANNEL PUMP WILL BE SUPPLIED FOR LONG TIME PRODUCTION OR NONE-STOP PRODUCTION. FEATURES: - EQUIPPED WITH BOTH POSITIVE & NEGATIVE HIGH VOLTAGE SUPPLY DEVICES - EQUIPPED WITH UNWINDING & WINDING MACHINES - CONTINUOUS ELECTROSPINNING & WINDING - ALUMINUM ALLOY FRAME STRUCTURE, MULTI-FUNCTIONS EXPANSIBLE - MULTI-NEEDLES IN ARRAYS. 16 NEEDLES X N ROWS, UP TO 384 NEEDLES - SPINNERET MOVING MACHINERY ENSURES EVEN FIBER SHEET - ONLINE AUTO-CLEAN DEVICE FOR NEEDLES - THICKNESS OF THE FIBER SHEET IS CONTROLLABLE - CE & FCC CERTIFICATE SPINNERET STANDARD:16 NEEDLES X 8 GROUPS =128 NEEDLES (THE NUMBER OF NEEDLES CAN BE ADJUSTED FREELY ACCORDING TO THE REQUIREMENTS OF USE) X-Y-Z MOTION SYSTEM - THE NOZZLE CAN BE MOVED UP AND DOWN IN THE Z DIRECTION THROUGH THE TOUCH SCREEN CONTROL TO DETERMINE THE APPROPRIATE SPINNING DISTANCE. - THE NOZZLE CAN MOVE BACK AND FORTH ALONG THE YAXIS DIRECTION OF THE TANGENT DIRECTION OF THE RECEIVING FILM TO PREPARE A UNIFORM FIBER FILM. - THE NOZZLE AUTOMATIC ONLINE CLEANING DEVICE SCANS ALONG THE X-AXIS DIRECTION. COLLECTOR - STAINLESS STEEL PLATE / MESH SERVES AS A CARRIER FOR THE FIBER MEMBRANE SUBSTRATE. - CONNECTED WITH NEGATIVE HIGH VOLTAGE. - RECEIVER BOARD WIDTH: 500 mm - SPINNING DISTANCE: 80 TO 300 mm ADJUSTABLE WINDER AND UNWINDER - AUTOMATICALLY CALCULATE THE ROLL DIAMETER OF THE LOADED MATERIAL AND CONTROL THE TENSION BETWEEN THE UNWINDING AND SPINNING SECTIONS. - CONSTANT FEEDING SPEED. THE FEEDING SPEED RANGE IS 0 TO 5000 mm / min. - ONLINE HOT PRESSING FUNCTION MODULE. AFTER THE SPINNING IS COMPLETED, BEFORE THE WINDING, A TEMPERATURE-CONTROLLED HOT PRESSING DEVICE (ROOM TEMPERATURE TO 60 ° C) IS USED FOR HOT PRESSING. (OPTIONAL THIRD LAYER MATERIAL STICKING AND REWINDING DEVICE). - CAN BE OPERATED BY TOUCH SCREEN. - DO NOT USE METAL FILM AS THE RECEIVING CARRIER. SYRINGE PUMP - 200ML X 4N CHANNEL - FLOW RATE: 0.1ML / H TO 1280 ML / H - SPECIALLY DESIGNED FOR ELECTRO-SPINNING AND RESISTANT TO HIGH VOLTAGE. HIGH VOLTAGE DEVICE -0 TO 50KV, DIGITAL DISPLAY --50KV ~ 0 KV, DIGITAL DISPLAY -OUTPUT CURRENT: <1 MA -CONTINUOUSLY ADJUSTABLE CONTROL SYSTEM -PLC CONTROL SYSTEM, 7-INCH TOUCH SCREEN. -CONTROL THE MOVEMENT OF THE NOZZLE. -CONTROL THE NOZZLE TO MOVE UP AND DOWN. -YOU CAN SET THE MOVEMENT TIME, STROKE AND SPEED OF THE NOZZLE. -CONTROL THE FREQUENCY OF NOZZLE CLEANING. -SPINNING PROCESS PARAMETER RECORDS. ENVIRONMENTAL CONTROL SYSTEM -PROVIDE INTERFACE TO LET IN DRY AMBIENT HUMIDITY AIR. -AN EXTERNAL DEHUMIDIFIER CAN BE USED TO CONTROL THE AMBIENT HUMIDITY. THE EXTERNAL DEHUMIDIFIER NEEDS TO BE SELECTED ACCORDING TO THE SIZE OF THE WORKSHOP. THIS EQUIPMENT DOES NOT INCLUDE THIS DEHUMIDIFIER. EXHAUST SYSTEM -BOTTOM UP, AND FOUR FANS ARE PUMPED AT THE SAME TIME. -THE DISCHARGE VOLUME OF A SINGLE UNIT IS 5 TO 150 M3 / H, AND THE RATE IS ADJUSTABLE. THE COMBINED DISCHARGE VOLUME OF THE TWO EXHAUST FANS IS 10 TO 300M3 / H. THE EXTRACTOR IS DRAWN FROM THE MIDDLE. IN THIS WAY, THE HIGH-SPEED AIR VENTILATION MINIMIZES THE RELATIVE DISTURBANCE TO THE SPINNING. THE EXHAUST FAN IS A SILENT EXHAUST FAN. SAFETY -AUTOMATIC POWER-OFF DEVICE FOR OPENING THE DOOR. -RESIDUAL STATIC ELECTRICITY REMOVAL DEVICE. -EMERGENCY STOP SWITCH. -GROUND AT MULTIPLE POINTS. -ALARM DEVICE AFTER THE CONTROL PARAMETERS EXCEED THE LIMIT. CHAMBER -THE CHAMBER IS MADE OF ALUMINUM ALLOY FRAME. -THE FRONT AND SIDE WINDOWS OF THE CABINET ARE MADE OF TEMPERED GLASS. -MULTI-POINT TEMPERATURE AND HUMIDITY COLLECTION AND DISPLAY. -THE PROCESS CAN BE OBSERVED WITH THE NAKED EYE. -AIR INLET: HOT AND DRY AIR CAN BE INTRODUCED TO QUICKLY ADJUST THE HUMIDITY INSIDE THE CHAMBER. POWER SOURCE -220 VOLTS AND 50/60 Hz -TOTAL POWER: 10KW NUMBER OF NEEDLES: 128 NEEDLES (THE NUMBER OF NEEDLES CAN BE ARBITRARILY REDUCED ACCORDING TO THE SOLVENT USAGE) FLOW RATE OF EACH NEEDLE: (~ 3ML ± 50%) / HOUR TOTAL FLOW OF THE WHOLE MACHINE: ABOUT (400ML ± 50%) / HOUR SOLUTION CONCENTRATION: 10 TO 20% 8 HOURS SOLUTION PROCESSING CAPACITY: ABOUT (3L ± 50%) / 8 HOURS SOLID CONTENT (WEIGHT OF FIBER PRODUCED): (300G ± 50%) / 8 HOURS ACCORDING TO THE APPROXIMATE PRODUCTION OF FIBER MATERIAL WITH A GRAM WEIGHT OF 2GSM. WINDING AND UNWINDING SPEED: 50M / H MATERIAL WIDTH: 0.5 METERS FABRIC AREA PRODUCED PER HOUR: 25 SQUARE METERS FABRIC AREA PRODUCED IN 8 HOURS: 200 SQUARE METERS FABRIC AREA PRODUCED IN 24 HOURS: 600 SQUARE METERS BASED ON THE PRODUCTION OF FIBER MATERIAL WITH A GRAMMAGE OF 0.02G / ㎡, APPROXIMATELY: WINDING AND UNWINDING SPEED: 5000M / H MATERIAL WIDTH: 0.5 METERS FABRIC AREA PRODUCED PER HOUR: 2500 SQUARE METERS FABRIC AREA PRODUCED IN 8 HOURS: 20,000 SQUARE METERS FABRIC AREA PRODUCED IN 24 HOURS: ABOUT 60,000 SQUARE METERS Learn More -

R-6443 YARN SINGEING MACHINE

R-6443 YARN SINGEING MACHINEYARN SINGEING MACHINE

Learn More

MODEL Q488

PRODUCT FEATURES:

FREQUENCY CONVERSION SPEED REGULATION DEVICE, CONVENIENT ADJUSTM

ENT WINDING LINEAR SPEED IS HIGH

TAPER TYPE CONE OR PLAIN CONE TYPE;

HIGH QUALITY OF METALLIC GROOVED DRUM THROUGH DYNAMICALLY BALANCED, GROOVED DRUM AXLE WITH HIGH

ACCURACY OF MANUFACTURE HAS PREMIX TYPE AIR/GAS MIXED BOX AND NEW TYPE BURNER, FLAME STABILIZATION, HIGH BURNING TEMPERATURE, EVEN

SINGEING, LOW GAS CONSUMPTION;

AUTOMATIC STOP MOTION

DUST BLOW-EXHAUST APPARATUS AND DUST REMOVAL BY VENTILATION DEVICE;

PLC CONTROL SYSTEM;

MAIN TECHNICAL PARAMETER:

EACH MACHINE HAS 72 SPINDLES (DOUBLE-FACED)

SPINDLE DISTANCE IS 288mm GAUGE, CAN BE PACKAGE, TAPER TUBE, PARALLEL TUBE;

TUBE SIZE, PAPER TUBE IS 3° 30

PLASTIC TUBE IS 5 ° 57′, WOODEN TUBE ISΦ 25.4 × 147.5 × Φ 8.4

GROOVE DRUM MATERIAL IS ALUMINIUM ALLOY

WINDING SPEED 200 TO 750mm, 200 TO 8200mm

MOTOR POWER 14.14KW

DIMENSIONS (LWH) 13117 × 1850 × 2840mm

MACHINE WEIGHT: 4550 KGS

QUANTITY: 1