Search results for: 'Reference Number:''

- Related search terms

- Reference

- Reference Number: J-'

- reference number -v

- reference number -v-2

- reference number -v-21

-

P-4924 DILO OM25 FINISHING NEEDLE LOOM YEAR 1979 WIDTH 2500mm DOUBLE BOARD DOWNSTROKE 15,000 NEEDLES

P-4924 DILO OM25 FINISHING NEEDLE LOOM YEAR 1979 WIDTH 2500mm DOUBLE BOARD DOWNSTROKE 15,000 NEEDLESP-4924 DILO OM25 FINISHING NEEDLE LOOM YEAR 1979 WIDTH 2500mm DOUBLE BOARD DOWNSTROKE 15,000 NEEDLES

DILO

TYPE: NL32968

FINISHING NEEDLE LOOM

YEAR: 1979

WORKING WIDTH: 2500mm

DOUBLE BOARD DOWNSTROKE

TOTAL 15,000 NEEDLESQUANTITY: 1

Learn More -

P-4923 DILO DV25 PRE-NEEDLE LOOM YEAR 1979 WIDTH 2500mm SINGLE BOARD DOWNSTROKE 1800 NEEDLES

P-4923 DILO DV25 PRE-NEEDLE LOOM YEAR 1979 WIDTH 2500mm SINGLE BOARD DOWNSTROKE 1800 NEEDLESP-4923 DILO DV25 PRE-NEEDLE LOOM YEAR 1979 WIDTH 2500mm SINGLE BOARD DOWNSTROKE 1800 NEEDLES

DILO

TYPE: DV25

PRE-NEEDLE LOOM

YEAR: 1979

WORKING WIDTH: 2500mm

SINGLE BOARD DOWNSTROKE

TOTAL 1800 NEEDLESQUANTITY: 1

Learn More -

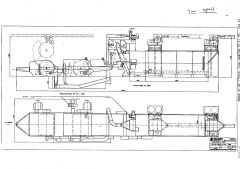

M-1696 MARGASA COMPLETE RECYCLING/TEARING LINE, YEAR 2012, WORKING WIDTH 1500mm

M-1696 MARGASA COMPLETE RECYCLING/TEARING LINE, YEAR 2012, WORKING WIDTH 1500mmM-1696 MARGASA COMPLETE RECYCLING/TEARING LINE, YEAR 2012, WORKING WIDTH 1500mm

2 ROTARY CUTTERS TYPE CMT-900, WORKING WIDTH 900mm, INCLUDING FEEDING CONVEYORS.

Learn More

1 ELECTRONIC METAL DETECTOR, MOUNTED ON FEEDING CONVEYOR OF THE 1ST CUTTER.

1 PNEUMATIC MATERIAL TRANSPORT WITH SPECIAL FAN FOR RAGS ETC.

1 STATIONARY ZIG-ZAG HUMP MAGNET MOUNTED IN TUBE FOR MATERIAL TRANSPORT.

2 MIXING/ RELAXING STORAGE BINS FOR CUTTED RAGS WITH SPRAYING ROOM

IN FRONT OF:

1 FEEDING MACHINE TYPE CCS-1500, WORKING WIDTH 1500mm, AUTOMATIC PNEUMATIC FEEDING FROM STORAGE BINS, ELECTRONIC LEVEL CONTROL AND DOSING CONVEYOR TO TEARING LINE.

1 RAG TEARING LINE WITH 4 SECTIONS TYPE MASTER MCM-1550-DD, WORKING WIDTH 1500mm, TAMBOUR DIAM. 1000mm.

1 ELECTRONIC CONTROL PANEL FOR THE WHOLE LINE INCL. TOUCH SCREEN AND INVERTER DRIVER FOR SEVERAL MOTORS.

6 FILTER UNITS.

- ALL EQUIPMENT “AS NEW” SINCE RUNNING ONLY A FEW HOURS.

- CAPACITY UP TO 1000KG/HR. -

M-0033 ROLANDO COMPLETE TEARING LINE YEAR 1994 WIDTH 2000mm - 2 CYLINDERS

M-0033 ROLANDO COMPLETE TEARING LINE YEAR 1994 WIDTH 2000mm - 2 CYLINDERSM-0033 ROLANDO COMPLETE TEARING LINE YEAR 1994 WIDTH 2000mm - 2 CYLINDERS

WORKING WIDTH 2000mm

Learn More

YEAR 1994

CONSISTING OF:

LOADING INSTALLATION

LIQUID RESP. OIL SPRAYING UNIT

AUTOMATIC FEEDING RA1/6mm 2000

TEARING MACHINE RM9 WITH 2 CYLINDERS, 2000mm -

C-3796 MARGASA 4-DRUM TEARING LINE, WORKING WIDTH 900mm TO 1500mm, YEAR 2012

C-3796 MARGASA 4-DRUM TEARING LINE, WORKING WIDTH 900mm TO 1500mm, YEAR 2012C-3796 MARGASA 4-DRUM TEARING LINE, WORKING WIDTH 900mm TO 1500mm, YEAR 2012

MARGASA 4-DRUM TEARING LINE

YEAR: 2012

WORKING WIDTH: 1500mmCONSISTING OF:

MARGASA CMT-900 ROTARY CUTTERS

WORKING WIDTH: 900mm

QUANTITY: 2METAL DETECTOR

QUANTITY: 1PNEUMATIC TRANSPORT

QUANTITY: 1MAGNETIC DUCT

QUANTITY: 1BIG STORAGE BOX

QUANTITY: 1

FEEDING

QUANTITY: 1MARGASA MASTER MCM-1500-DD 4-DRUM TEARING MACHINE

WORKING WIDTH: 1500mm

DRUM DIAMETER: 1000mm

WITH:

PRESSING ROLLER

WITH A LARGE DIAMETER TO COMPACT THE MATERIAL

BEFORE THE FIRST FEED ROLLER OF THE TEARING MACHINE

BEATERS THAT ELIMINATE THE FOREIGN SUBSTANCES

SUCH AS PLASTICS

WOODS

AND BUTTONS

THAT DUE TO WEIGHT HAVE FALLEN ON THE RETURN APRON

RETURN LATTICE

WITH MOTOR-REDUCER OF 1.5 KW

THAT DRIVES THE BIT RETURN LATTICES

OF THE MATERIAL TO BE RECYCLED

QUANTITY: 1TAKES 4 CONTAINERS TO LOAD

QUANTITY: 1 LINE

Learn More -

R-2243 SULZER P7300HP LOOMS, WIDTH 3600mm, YEAR 2008, CAM

R-2243 SULZER P7300HP LOOMS, WIDTH 3600mm, YEAR 2008, CAMR-2243 SULZER P7300HP LOOMS, WIDTH 3600mm, YEAR 2008, CAM

SULZER P7300HP

WIDTH: 3600mm

MODEL: P7300HP

TYPE V8 B360 N 2 EP D12 R

YEAR: 2008

WITH IRON PROJECTILE FEEDER - LAST GENERATION (NO CARBON)

AUTOMATIC LUBRICATION

WITH LED LIGHT AND WITH A WEFT TENSIONER SYSTEM CALLED “COBRA”

10 HEALD FRAMES

8 CAMS (2 LOOMS 3/1 - 2 LOOMS 2/2)

10000 HEDDLES

10000 DROPPERS

THERE ARE TWO DIFFERENT TAKE UP ROLLERS: THE ONES WHICH ARE “UNDERGROUND” WITH INSPECTING MACHINE (THESE ARE IN 3600mm)

AND “NORMAL” ONES WHICH ARE 3900mm – CAN CHOOSE ANY ONE

WEFT FEEDERS NOT INCLUDED

LOOMS ALREADY STOPPED AT WAREHOUSE

INSPECTION POSSIBLE

TOP CONDITIONQUANTITY: 4

Learn More -

H-1305 BATT FEEDING SYSTEM - WORKING WIDTH 3000mm

H-1305 BATT FEEDING SYSTEM - WORKING WIDTH 3000mmH-1305 BATT FEEDING SYSTEM - WORKING WIDTH 3000mm

WORKING WIDTH: 3000mm

CONTROL SYSTEM INCLUDEDCOMPOSITION OF THE MACHINE:

- LOWER PVC INCLINED CONVEYOR BELT FOR THE TRANSPORT OF THE WEB FROM THE CROSS LAPPER TO THE ENTRANCE OF THE NEEDLE LOOM.

- UPPER PVC COMPRESSION BELT FOR THE PRE-COMPRESSION OF THE WEB BEFORE ENTERING THE FEEDING ROLLS.

- LOWER PVC CONVEYOR AND UPPER PVC BELT DRIVEN BY ONE GEARBOX MOTOR WITH INDEPENDENT FREQUENCY INVERTER.

- PAIR OF FEEDING ROLLS WITH PLASTIC FINGERS TO GUIDE THE COMPRESSED WEB CLOSE TO FIRST NEEDLE ZONE OF THE PRE-NEEDLE LOOM. ROLLER PAIR DRIVEN BY GEARBOX MOTOR WITH INDEPENDENT FREQUENCY INVERTER.

- BATT FEEDING SYSTEM INSTALLED ON RAIL SYSTEM AND EASY REMOVABLE FOR MAINTENANCE OF THE NEEDLE LOOMTECHNICAL DATA:

ELECTRICAL INFORMATION:

ELECTRIC: MAIN VOLTAGE 400 V, 50 HZ, 3 PH.

CONTROL VOLTAGE: DC - 24 V / AC - 230 V

OTHER INFORMATION:

AIR PRESSURE (CONSTANT): MIN. 6 BAR (AT SITE)

OPERATOR SIDE LEFT OR RIGHT (IN WEB RUNNING DIRECTION)

LACQUER COATING:

MAIN COLOR OF THE MACHINES: RAL 7035 (LIGHT GREY)

CONTROL CABINET AND CONTROL DESK RAL 7035 (LIGHT GREY)

LABELING: ENGLISH

TECHNICAL DOCUMENTATION: ONE TIME ON CD-ROM (FURTHER SETS AVAILABLE AT ADDITIONAL COST)

LANGUAGE FOR OPERATING INSTRUCTIONS: ENGLISH

LANGUAGE FOR FURTHER DOCUMENTATION (SPARE PART LISTS, WIRING DIAGRAM, ETC): ENGLISHENVIRONMENTAL CONDITIONS:

INSTALLATION HEIGHT ABOVE SEA LEVEL: LESS THAN OR EQUAL TO 1,000 METERS

TEMPERATURE: 24° C (±2° C)

RELATIVE HUMIDITY: 65% (±5%)

ABSOLUTE WATER CONTENT: 9 TO 12 G/KG DRY AIR

NOTE: PLEASE MAKE SURE THAT THE TEMPERATURE INSIDE THE CONTROL CABINET DOES NOT EXCEED 450 CENTIGRADE. IN CASE OF EXCESSIVE ROOM TEMPERATURES WE RECOMMEND AN AIR-CONDITIONING SYSTEM FOR THE CONTROL CABINETS TO AVOID MALFUNCTION OF ELECTRICAL COMPONENTSQUANTITY: 1

Learn More -

P-3505 DORNIER AIRJET LABEL LOOMS YEAR 2000 JACQUARD

P-3505 DORNIER AIRJET LABEL LOOMS YEAR 2000 JACQUARDP-3505 DORNIER AIRJET LABEL LOOMS YEAR 2000 JACQUARD

DORNIER

AIRJET LABEL LOOMS

YEAR: 2000

WITH STAUBLI JACQUARD CX880

CONTROLLER JC5

1152 HOOKS TAFFETA WEAVING 8x20QUANTITY: 2 SETS

Learn More -

A-1790 TECTEX CROSS LAPPER, 2.5 METER x 4.0 METER

A-1790 TECTEX CROSS LAPPER, 2.5 METER x 4.0 METERA-1790 TECTEX CROSS LAPPER, 2.5 METER x 4.0 METER

BRAND: TECTEX

SPEED: 50 METER PER MINUTE

COMPLETE OVERHAULED BY COMPANY BEMATIC

WITH NEW CABLES AN NEW CONTROL OPERATOR PANEL BEMATICQUANTITY: 1

Learn More -

C-4354 FULL-AUTO HIGH SPEED WET TISSUE FOLDING MACHINE Y-2700(A) AND FULL-AUTO WET TISSUE PACKING MACHINE Y-360, CAPACITY 40 TO 120 PCS/PACKAGE

C-4354 FULL-AUTO HIGH SPEED WET TISSUE FOLDING MACHINE Y-2700(A) AND FULL-AUTO WET TISSUE PACKING MACHINE Y-360, CAPACITY 40 TO 120 PCS/PACKAGEREFERENCE NUMBER: C-4354

FULL-AUTO HIGH SPEED WET TISSUE FOLDING MACHINE Y-2700(A) AND FULL-AUTO WET TISSUE PACKING MACHINE Y-360, CAPACITY 40 TO 120 PCS/PACKAGE

DETAILS:

Y-2700A+360 FULL AUTOMATIC WET TISSUE FOLDING AND PACKING MACHINE

MAKING 40PCS TO 120PCS/PACK WET WIPES

IS A MACHINE THAT CAN SLITTING THE BIG JUMBO RAW MATERIAL, FOLDING, WETTING, CUTTING IN LENGTH

STACKING THEN TRANSFER TO PACKING MACHINE FOR PACKING FROM RAW MATERIAL TO FINISH PRODUCT ALL THE STEPS ARE FINISHED ON MACHINE

THE PROCESS IS QUICK AND CLEAN

THE FOLDING MACHINE AND PACKING MACHINE CAN BE COMBINE TOGETHER TO BE A FULL AUTOMATIC LINE OR CAN BE SEPARATED WHEN NEEDED THAT CAN MAX USE THE MACHINES AND MAKE MORE OUTPUT

QUANTITY: 1

Learn More