Search results for: 'Machin'''

-

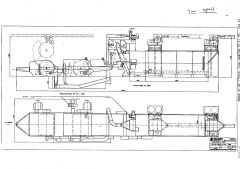

AUTOMATEX, SPINNBAU NEEDLE PUNCH LINEREFERENCE NUMBER: T-6840 AUTOMATEX, SPINNBAU NEEDLE PUNCH LINE BRAND: AUTOMATEX, SPINNBAU NEEDLE PUNCH LINE CONSISTING OF: BLEND LINE, 60” WIDE, 4 HOPPERS WITH 12 HEAVY DUTY EXTENDED APRONS & NEW ELECTRONIC WEIGHING SYSTEM (2016). ALL MACHINES COMPLETELY RECONDITIONED IN 2016. OMMI STACK RESERVE, AUTOMATIC COMBO 332, YEAR 2000 SPINNBAU CARD, 2500mm, DOUBLE DOFFER, YEAR 1995, REPORTED ~1500 TO 1800 PPH CAPACITY DEPENDING UPON PRODUCT. AUTOMATEX FA/3000 TC CROSSLAPPER, YEAR 1997, AC DRIVES. BATT DRAFTER, 12 ROLLS. AUTOMATEX PR-100/T PRE-NEEDLER, 60mm STROKE, YEAR 1997 DRAFTER, 5 ROLLS. AUTOMATEX AG 154/TB NEEDLE LOOM, QUAD PUNCH, 50mm STROKE, YEAR 1997 FOUR ROLL STRETCH. METAL DETECTOR. ENTEX TENTER WITH VERTICAL IR HEAT BANKS, YEAR 1997 WINDER, YEAR 1997 PERKINS 4 ROLL CALENDER, NO STEEL ROLLS OR HEAT SYSTEM INCLUDED BUT MIGHT BE NEGOTIATED. EHHARDT+LEIMER GUIDER MODEL SE 11062, YEAR 2013 ENTEC WINDER, YEAR 1997 FINISHED WIDTH REPORTED OF 210" BUT COULD GO WIDER. LINE RAN PRIMARILY GEOTEXTILE & BEDDING PRODUCTS FROM 4.5 TO 10 OZ/YD. QUANTITY: 1 Learn More

AUTOMATEX, SPINNBAU NEEDLE PUNCH LINEREFERENCE NUMBER: T-6840 AUTOMATEX, SPINNBAU NEEDLE PUNCH LINE BRAND: AUTOMATEX, SPINNBAU NEEDLE PUNCH LINE CONSISTING OF: BLEND LINE, 60” WIDE, 4 HOPPERS WITH 12 HEAVY DUTY EXTENDED APRONS & NEW ELECTRONIC WEIGHING SYSTEM (2016). ALL MACHINES COMPLETELY RECONDITIONED IN 2016. OMMI STACK RESERVE, AUTOMATIC COMBO 332, YEAR 2000 SPINNBAU CARD, 2500mm, DOUBLE DOFFER, YEAR 1995, REPORTED ~1500 TO 1800 PPH CAPACITY DEPENDING UPON PRODUCT. AUTOMATEX FA/3000 TC CROSSLAPPER, YEAR 1997, AC DRIVES. BATT DRAFTER, 12 ROLLS. AUTOMATEX PR-100/T PRE-NEEDLER, 60mm STROKE, YEAR 1997 DRAFTER, 5 ROLLS. AUTOMATEX AG 154/TB NEEDLE LOOM, QUAD PUNCH, 50mm STROKE, YEAR 1997 FOUR ROLL STRETCH. METAL DETECTOR. ENTEX TENTER WITH VERTICAL IR HEAT BANKS, YEAR 1997 WINDER, YEAR 1997 PERKINS 4 ROLL CALENDER, NO STEEL ROLLS OR HEAT SYSTEM INCLUDED BUT MIGHT BE NEGOTIATED. EHHARDT+LEIMER GUIDER MODEL SE 11062, YEAR 2013 ENTEC WINDER, YEAR 1997 FINISHED WIDTH REPORTED OF 210" BUT COULD GO WIDER. LINE RAN PRIMARILY GEOTEXTILE & BEDDING PRODUCTS FROM 4.5 TO 10 OZ/YD. QUANTITY: 1 Learn More -

R-5864 YAMADA SINGLE END SIZING WITH 20 SPINDLES, YEAR 2006

R-5864 YAMADA SINGLE END SIZING WITH 20 SPINDLES, YEAR 2006REFERENCE NUMBER: R-5864

Learn More

YAMADA SINGLE END SIZING

MODEL: YS-6

YEAR: 2006

QUANTITY: 1 -

L-1502 DOUBLE COLUMN COMPUTER CONTROLLED ELECTRONIC UTM MODEL UE2410 TENSILE TESTER (FOR FOAM OR FABRIC)

L-1502 DOUBLE COLUMN COMPUTER CONTROLLED ELECTRONIC UTM MODEL UE2410 TENSILE TESTER (FOR FOAM OR FABRIC)REFERENCE NUMBER: L-1502

Learn More

MODEL: UE2410

QUANTITY: 1 -

R-1170 DELL’ ORCO VILLANI RAG TEARING LINE + BALE PRESS, YEAR 1989 TO 1999

R-1170 DELL’ ORCO VILLANI RAG TEARING LINE + BALE PRESS, YEAR 1989 TO 1999R-1170 DELL’ ORCO VILLANI RAG TEARING LINE + BALE PRESS, YEAR 1989 TO 1999

DETAILS:

DELL’ ORCA VILLANI RAG TEARING LINE + BALLING MACHINE

COMPOSED BY:

ITEM 001

DELL’ ORCA VILLANI CUTTERS

YEAR: 1989

QUANTITY: 2ITEM 002

DELL’ ORCA VILLANI MIXING ROOMS + BIN EMPTIER

TYPE: FA/3030/T

QUANTITY: 2ITEM 003

DELL’ ORCA VILLANI VOLUMATIC FEEDER

MODEL: CARICATORE

TYPE: CS/1600

YEAR: 1999

QUANTITY: 1ITEM 004

DELL’ ORCA VILLANI RAG TEARING MACHINE

4 CYLINDERS

YEAR: 1999

WIDTH: 1500mm

EACH DRUM MODEL: M/1500

TYPE: SFILACCIATRICE

QUANTITY: 1ITEM 005

DELL’ ORCA VILLANI VOLUMATIC FEEDER

MODEL: CARICATORE

TYPE: CS/1600

YEAR: 1989

QUANTITY: 1ITEM 006

DELL’ ORCA VILLANI RAG TEARING MACHINE

3 CYLINDERS

YEAR: 1989

WIDTH: 1500mm

EACH DRUM MODEL: M/1500

TYPE: SFILACCIATRICE

QUANTITY: 1ITEM 007

DELL’ ORCA VILLANI BALE PRESS

TYPE: RA/100

WITH 2 CHAMBERS (ROTATIVE SYSTEM)

WITH WEIGHING DEVICE (SCALE FOR KG OF EACH BALE)

QUANTITY: 1ITEM 008

DELL’ ORCA VILLANI DUST COLLECTING INSTALLATION

WITH BAGS TO COLLECT THE DUST

QUANTITY: 1QUANTITY: 1 LINE

Learn More -

M-1696 MARGASA COMPLETE RECYCLING/TEARING LINE, YEAR 2012, WORKING WIDTH 1500mm

M-1696 MARGASA COMPLETE RECYCLING/TEARING LINE, YEAR 2012, WORKING WIDTH 1500mmM-1696 MARGASA COMPLETE RECYCLING/TEARING LINE, YEAR 2012, WORKING WIDTH 1500mm

2 ROTARY CUTTERS TYPE CMT-900, WORKING WIDTH 900mm, INCLUDING FEEDING CONVEYORS.

Learn More

1 ELECTRONIC METAL DETECTOR, MOUNTED ON FEEDING CONVEYOR OF THE 1ST CUTTER.

1 PNEUMATIC MATERIAL TRANSPORT WITH SPECIAL FAN FOR RAGS ETC.

1 STATIONARY ZIG-ZAG HUMP MAGNET MOUNTED IN TUBE FOR MATERIAL TRANSPORT.

2 MIXING/ RELAXING STORAGE BINS FOR CUTTED RAGS WITH SPRAYING ROOM

IN FRONT OF:

1 FEEDING MACHINE TYPE CCS-1500, WORKING WIDTH 1500mm, AUTOMATIC PNEUMATIC FEEDING FROM STORAGE BINS, ELECTRONIC LEVEL CONTROL AND DOSING CONVEYOR TO TEARING LINE.

1 RAG TEARING LINE WITH 4 SECTIONS TYPE MASTER MCM-1550-DD, WORKING WIDTH 1500mm, TAMBOUR DIAM. 1000mm.

1 ELECTRONIC CONTROL PANEL FOR THE WHOLE LINE INCL. TOUCH SCREEN AND INVERTER DRIVER FOR SEVERAL MOTORS.

6 FILTER UNITS.

- ALL EQUIPMENT “AS NEW” SINCE RUNNING ONLY A FEW HOURS.

- CAPACITY UP TO 1000KG/HR. -

M-0033 ROLANDO COMPLETE TEARING LINE YEAR 1994 WIDTH 2000mm - 2 CYLINDERS

M-0033 ROLANDO COMPLETE TEARING LINE YEAR 1994 WIDTH 2000mm - 2 CYLINDERSM-0033 ROLANDO COMPLETE TEARING LINE YEAR 1994 WIDTH 2000mm - 2 CYLINDERS

WORKING WIDTH 2000mm

Learn More

YEAR 1994

CONSISTING OF:

LOADING INSTALLATION

LIQUID RESP. OIL SPRAYING UNIT

AUTOMATIC FEEDING RA1/6mm 2000

TEARING MACHINE RM9 WITH 2 CYLINDERS, 2000mm -

C-3796 MARGASA 4-DRUM TEARING LINE, WORKING WIDTH 900mm TO 1500mm, YEAR 2012

C-3796 MARGASA 4-DRUM TEARING LINE, WORKING WIDTH 900mm TO 1500mm, YEAR 2012C-3796 MARGASA 4-DRUM TEARING LINE, WORKING WIDTH 900mm TO 1500mm, YEAR 2012

MARGASA 4-DRUM TEARING LINE

YEAR: 2012

WORKING WIDTH: 1500mmCONSISTING OF:

MARGASA CMT-900 ROTARY CUTTERS

WORKING WIDTH: 900mm

QUANTITY: 2METAL DETECTOR

QUANTITY: 1PNEUMATIC TRANSPORT

QUANTITY: 1MAGNETIC DUCT

QUANTITY: 1BIG STORAGE BOX

QUANTITY: 1

FEEDING

QUANTITY: 1MARGASA MASTER MCM-1500-DD 4-DRUM TEARING MACHINE

WORKING WIDTH: 1500mm

DRUM DIAMETER: 1000mm

WITH:

PRESSING ROLLER

WITH A LARGE DIAMETER TO COMPACT THE MATERIAL

BEFORE THE FIRST FEED ROLLER OF THE TEARING MACHINE

BEATERS THAT ELIMINATE THE FOREIGN SUBSTANCES

SUCH AS PLASTICS

WOODS

AND BUTTONS

THAT DUE TO WEIGHT HAVE FALLEN ON THE RETURN APRON

RETURN LATTICE

WITH MOTOR-REDUCER OF 1.5 KW

THAT DRIVES THE BIT RETURN LATTICES

OF THE MATERIAL TO BE RECYCLED

QUANTITY: 1TAKES 4 CONTAINERS TO LOAD

QUANTITY: 1 LINE

Learn More -

R-2243 SULZER P7300HP LOOMS, WIDTH 3600mm, YEAR 2008, CAM

R-2243 SULZER P7300HP LOOMS, WIDTH 3600mm, YEAR 2008, CAMR-2243 SULZER P7300HP LOOMS, WIDTH 3600mm, YEAR 2008, CAM

SULZER P7300HP

WIDTH: 3600mm

MODEL: P7300HP

TYPE V8 B360 N 2 EP D12 R

YEAR: 2008

WITH IRON PROJECTILE FEEDER - LAST GENERATION (NO CARBON)

AUTOMATIC LUBRICATION

WITH LED LIGHT AND WITH A WEFT TENSIONER SYSTEM CALLED “COBRA”

10 HEALD FRAMES

8 CAMS (2 LOOMS 3/1 - 2 LOOMS 2/2)

10000 HEDDLES

10000 DROPPERS

THERE ARE TWO DIFFERENT TAKE UP ROLLERS: THE ONES WHICH ARE “UNDERGROUND” WITH INSPECTING MACHINE (THESE ARE IN 3600mm)

AND “NORMAL” ONES WHICH ARE 3900mm – CAN CHOOSE ANY ONE

WEFT FEEDERS NOT INCLUDED

LOOMS ALREADY STOPPED AT WAREHOUSE

INSPECTION POSSIBLE

TOP CONDITIONQUANTITY: 4

Learn More -

H-1305 BATT FEEDING SYSTEM - WORKING WIDTH 3000mm

H-1305 BATT FEEDING SYSTEM - WORKING WIDTH 3000mmH-1305 BATT FEEDING SYSTEM - WORKING WIDTH 3000mm

WORKING WIDTH: 3000mm

CONTROL SYSTEM INCLUDEDCOMPOSITION OF THE MACHINE:

- LOWER PVC INCLINED CONVEYOR BELT FOR THE TRANSPORT OF THE WEB FROM THE CROSS LAPPER TO THE ENTRANCE OF THE NEEDLE LOOM.

- UPPER PVC COMPRESSION BELT FOR THE PRE-COMPRESSION OF THE WEB BEFORE ENTERING THE FEEDING ROLLS.

- LOWER PVC CONVEYOR AND UPPER PVC BELT DRIVEN BY ONE GEARBOX MOTOR WITH INDEPENDENT FREQUENCY INVERTER.

- PAIR OF FEEDING ROLLS WITH PLASTIC FINGERS TO GUIDE THE COMPRESSED WEB CLOSE TO FIRST NEEDLE ZONE OF THE PRE-NEEDLE LOOM. ROLLER PAIR DRIVEN BY GEARBOX MOTOR WITH INDEPENDENT FREQUENCY INVERTER.

- BATT FEEDING SYSTEM INSTALLED ON RAIL SYSTEM AND EASY REMOVABLE FOR MAINTENANCE OF THE NEEDLE LOOMTECHNICAL DATA:

ELECTRICAL INFORMATION:

ELECTRIC: MAIN VOLTAGE 400 V, 50 HZ, 3 PH.

CONTROL VOLTAGE: DC - 24 V / AC - 230 V

OTHER INFORMATION:

AIR PRESSURE (CONSTANT): MIN. 6 BAR (AT SITE)

OPERATOR SIDE LEFT OR RIGHT (IN WEB RUNNING DIRECTION)

LACQUER COATING:

MAIN COLOR OF THE MACHINES: RAL 7035 (LIGHT GREY)

CONTROL CABINET AND CONTROL DESK RAL 7035 (LIGHT GREY)

LABELING: ENGLISH

TECHNICAL DOCUMENTATION: ONE TIME ON CD-ROM (FURTHER SETS AVAILABLE AT ADDITIONAL COST)

LANGUAGE FOR OPERATING INSTRUCTIONS: ENGLISH

LANGUAGE FOR FURTHER DOCUMENTATION (SPARE PART LISTS, WIRING DIAGRAM, ETC): ENGLISHENVIRONMENTAL CONDITIONS:

INSTALLATION HEIGHT ABOVE SEA LEVEL: LESS THAN OR EQUAL TO 1,000 METERS

TEMPERATURE: 24° C (±2° C)

RELATIVE HUMIDITY: 65% (±5%)

ABSOLUTE WATER CONTENT: 9 TO 12 G/KG DRY AIR

NOTE: PLEASE MAKE SURE THAT THE TEMPERATURE INSIDE THE CONTROL CABINET DOES NOT EXCEED 450 CENTIGRADE. IN CASE OF EXCESSIVE ROOM TEMPERATURES WE RECOMMEND AN AIR-CONDITIONING SYSTEM FOR THE CONTROL CABINETS TO AVOID MALFUNCTION OF ELECTRICAL COMPONENTSQUANTITY: 1

Learn More -

M-3290 FEHRER NL42 NEEDLE LOOM YEAR 1985 WIDTH 2700mm – QUATTRO PUNCH

M-3290 FEHRER NL42 NEEDLE LOOM YEAR 1985 WIDTH 2700mm – QUATTRO PUNCHREFERENCE NUMBER: M-3290

FEHRER NL42 NEEDLE LOOM YEAR 1985 WIDTH 2700mm – QUATTRO PUNCH

MAKE: FEHRER

TYPE: NL42

YEAR: 1985

WORKING WIDTH 2700mm

QUATTRO PUNCH

TWO BOARDS UP AND TWO BOARDS DOWN

NEEDLES: 4 X 7500 N/M

WEIGHT: CA. 22TO

DIMENSIONS: 3900mm X 2300mm X 2600mm

COMPLETE WITH CONTROL SYSTEM

COMPLETE WITH FEEDING SYSTEM

DC MAIN DRIVE

GOOD CONDITION

OVERHAULED 2 GEARBOXES

MACHINE IS STILL IN OPERATION

QUANTITY: 1

Learn More