Search results for: 'Belt'

- Related search terms

- belt knitting

- belt tensioner

- belt sander

- belt cleaner primary

- belt RACK

-

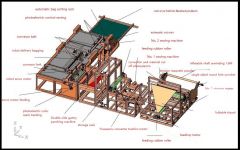

SPINNBAU CARDING LINE, YEAR 2013REFERENCE NUMBER: T-6848 SPINNBAU CARDING LINE, YEAR 2013 BRAND: SPINNBAU SHORT DESCRIPTION: CARDING LINE YEAR: 2013 INSTALLED 2014 LIKE NEW, LITTLE RUN TIME 4 HOPPER TEMAFA BLEND LINE, 1600mm WIDE, 1 WITH CONDENSER FED FROM TRIM MACHINE CARDING WILLOW – 800mm WIDE FEED BELT AND 1200mm WIDE – TEMAFA TEMAFA MIXMASTER BLENDING BIN – 3000mm WIDE X 8000mm LONG X 4600mm HIGH (FILL HEIGHT 3000mm). 72 CUBIC METER CAPACITY. TEMAFA FINE OPENER – 2000mm WIDE WITH PINS 3000mm SPINNBAU CARD FEEDING UNIT – FEED TRUNK, VIBRATING CHUTE, WEIGHT BELT 708mm BREAST SECTION WITH 3 WORKERS AND STRIPPERS, 1500mm MAIN WITH 5 W/S AND (2) 708mm DOFFERS. 1 FOUNDATIONS AND PLATFORMS. DILO PROFILINE – BATT WEIGHT CONTROL SYSTEM MAHLO WEIGHT MEASURING UNIT – QUALISCAN CMS-12 DILO LAYER CROSSLAPPER – TYPE DLS 30/60 – 3000mm INFEED AND UP TO 6000mm LAYDOWN. MAX WEB HEIGHT 650mm. MAXIMUM SPEED 125M/MIN. SPINNBAU LAP DRAFTER TYPE VST 19 – MAX 6000mm WORKING WIDTH. 9 ROLLER PAIRS. LIFTING DEVICE TO ALLOW FOR 600mm CLEARANCE. 159mm ROLLER DIAMETER. INFEED HEIGHT 650 mm BRUCKNER THERMOBONDING OVEN – 5000mm OVEN WITH 3 HEATING AND 2 COOLING ZONE. MAGNETIC BELT. 3 NATURAL GAS MAXON BURNER. SLITTING – 9 POSITION BRUCKNER CRUSH CUTTER SLITTING HEADS. PNEUMATIC LIFTING. 450mm KNIFE DIAMETER CROSS CUTTER – ROTARY CUTTER STYLE WITH CLAMPING. CAPABLE OF 3 CUTS/MINUTES FOR MATERIALS UP TO 200mm THICK. WINDING – ASCENDING BATCH STYLE WINDER. MAX ROLL DIAMETER OF 1200mm. 3000mm DRIVEN FEED CONVEYOR. MANDREL GUIDANCE SYSTEM, MANUALLY ADJUSTABLE BRAKE SYSTEM FOR CONTROLLING TENSILE FORCE AND COMPACTION. TEMAFA FILTER HOUSE – TFS 50. MAX FLOW 50,000 CUBIC METER/H ELECTRICL INFO – 3 X 480V/60Hz. CONTROLS 110V AC/24 DC. SIEMENS PLC QUANTITY: 1 Learn More

SPINNBAU CARDING LINE, YEAR 2013REFERENCE NUMBER: T-6848 SPINNBAU CARDING LINE, YEAR 2013 BRAND: SPINNBAU SHORT DESCRIPTION: CARDING LINE YEAR: 2013 INSTALLED 2014 LIKE NEW, LITTLE RUN TIME 4 HOPPER TEMAFA BLEND LINE, 1600mm WIDE, 1 WITH CONDENSER FED FROM TRIM MACHINE CARDING WILLOW – 800mm WIDE FEED BELT AND 1200mm WIDE – TEMAFA TEMAFA MIXMASTER BLENDING BIN – 3000mm WIDE X 8000mm LONG X 4600mm HIGH (FILL HEIGHT 3000mm). 72 CUBIC METER CAPACITY. TEMAFA FINE OPENER – 2000mm WIDE WITH PINS 3000mm SPINNBAU CARD FEEDING UNIT – FEED TRUNK, VIBRATING CHUTE, WEIGHT BELT 708mm BREAST SECTION WITH 3 WORKERS AND STRIPPERS, 1500mm MAIN WITH 5 W/S AND (2) 708mm DOFFERS. 1 FOUNDATIONS AND PLATFORMS. DILO PROFILINE – BATT WEIGHT CONTROL SYSTEM MAHLO WEIGHT MEASURING UNIT – QUALISCAN CMS-12 DILO LAYER CROSSLAPPER – TYPE DLS 30/60 – 3000mm INFEED AND UP TO 6000mm LAYDOWN. MAX WEB HEIGHT 650mm. MAXIMUM SPEED 125M/MIN. SPINNBAU LAP DRAFTER TYPE VST 19 – MAX 6000mm WORKING WIDTH. 9 ROLLER PAIRS. LIFTING DEVICE TO ALLOW FOR 600mm CLEARANCE. 159mm ROLLER DIAMETER. INFEED HEIGHT 650 mm BRUCKNER THERMOBONDING OVEN – 5000mm OVEN WITH 3 HEATING AND 2 COOLING ZONE. MAGNETIC BELT. 3 NATURAL GAS MAXON BURNER. SLITTING – 9 POSITION BRUCKNER CRUSH CUTTER SLITTING HEADS. PNEUMATIC LIFTING. 450mm KNIFE DIAMETER CROSS CUTTER – ROTARY CUTTER STYLE WITH CLAMPING. CAPABLE OF 3 CUTS/MINUTES FOR MATERIALS UP TO 200mm THICK. WINDING – ASCENDING BATCH STYLE WINDER. MAX ROLL DIAMETER OF 1200mm. 3000mm DRIVEN FEED CONVEYOR. MANDREL GUIDANCE SYSTEM, MANUALLY ADJUSTABLE BRAKE SYSTEM FOR CONTROLLING TENSILE FORCE AND COMPACTION. TEMAFA FILTER HOUSE – TFS 50. MAX FLOW 50,000 CUBIC METER/H ELECTRICL INFO – 3 X 480V/60Hz. CONTROLS 110V AC/24 DC. SIEMENS PLC QUANTITY: 1 Learn More -

H-1305 BATT FEEDING SYSTEM - WORKING WIDTH 3000mm

H-1305 BATT FEEDING SYSTEM - WORKING WIDTH 3000mmH-1305 BATT FEEDING SYSTEM - WORKING WIDTH 3000mm

WORKING WIDTH: 3000mm

CONTROL SYSTEM INCLUDEDCOMPOSITION OF THE MACHINE:

- LOWER PVC INCLINED CONVEYOR BELT FOR THE TRANSPORT OF THE WEB FROM THE CROSS LAPPER TO THE ENTRANCE OF THE NEEDLE LOOM.

- UPPER PVC COMPRESSION BELT FOR THE PRE-COMPRESSION OF THE WEB BEFORE ENTERING THE FEEDING ROLLS.

- LOWER PVC CONVEYOR AND UPPER PVC BELT DRIVEN BY ONE GEARBOX MOTOR WITH INDEPENDENT FREQUENCY INVERTER.

- PAIR OF FEEDING ROLLS WITH PLASTIC FINGERS TO GUIDE THE COMPRESSED WEB CLOSE TO FIRST NEEDLE ZONE OF THE PRE-NEEDLE LOOM. ROLLER PAIR DRIVEN BY GEARBOX MOTOR WITH INDEPENDENT FREQUENCY INVERTER.

- BATT FEEDING SYSTEM INSTALLED ON RAIL SYSTEM AND EASY REMOVABLE FOR MAINTENANCE OF THE NEEDLE LOOMTECHNICAL DATA:

ELECTRICAL INFORMATION:

ELECTRIC: MAIN VOLTAGE 400 V, 50 HZ, 3 PH.

CONTROL VOLTAGE: DC - 24 V / AC - 230 V

OTHER INFORMATION:

AIR PRESSURE (CONSTANT): MIN. 6 BAR (AT SITE)

OPERATOR SIDE LEFT OR RIGHT (IN WEB RUNNING DIRECTION)

LACQUER COATING:

MAIN COLOR OF THE MACHINES: RAL 7035 (LIGHT GREY)

CONTROL CABINET AND CONTROL DESK RAL 7035 (LIGHT GREY)

LABELING: ENGLISH

TECHNICAL DOCUMENTATION: ONE TIME ON CD-ROM (FURTHER SETS AVAILABLE AT ADDITIONAL COST)

LANGUAGE FOR OPERATING INSTRUCTIONS: ENGLISH

LANGUAGE FOR FURTHER DOCUMENTATION (SPARE PART LISTS, WIRING DIAGRAM, ETC): ENGLISHENVIRONMENTAL CONDITIONS:

INSTALLATION HEIGHT ABOVE SEA LEVEL: LESS THAN OR EQUAL TO 1,000 METERS

TEMPERATURE: 24° C (±2° C)

RELATIVE HUMIDITY: 65% (±5%)

ABSOLUTE WATER CONTENT: 9 TO 12 G/KG DRY AIR

NOTE: PLEASE MAKE SURE THAT THE TEMPERATURE INSIDE THE CONTROL CABINET DOES NOT EXCEED 450 CENTIGRADE. IN CASE OF EXCESSIVE ROOM TEMPERATURES WE RECOMMEND AN AIR-CONDITIONING SYSTEM FOR THE CONTROL CABINETS TO AVOID MALFUNCTION OF ELECTRICAL COMPONENTSQUANTITY: 1

Learn More -

V-1360 SANTEX THERMOBONDING COMPRESSION OVEN FOR NONWOVENS ON ROLL, 80 TO 400 G/M, YEAR 1986

V-1360 SANTEX THERMOBONDING COMPRESSION OVEN FOR NONWOVENS ON ROLL, 80 TO 400 G/M, YEAR 1986V-1360 SANTEX THERMOBONDING COMPRESSION OVEN FOR NONWOVENS ON ROLL, 80 TO 400 G/M, YEAR 1986

WORKING WIDTH: 2500mm

ROLL FACE WIDTH: WORKING WIDTH + 50mm

MATERIAL FIBERS: NONWOVEN WEB OF POLYESTER OR DIFFERENT FIBERS MIXED WITH 10 TO 25% POLYESTER BI-COMPONENT BINDER FIBERS OR DIFFERENT BINDER FIBERS

MACHINE SPEED: 1 TO 20 M/MIN. (OTHERS UPON REQUEST)

COMPOSITION OVEN: 2 HEATING ZONES OF 2 M EACH + 1 COOLING SECTIONQUANTITY: 1

Learn More -

M-3729 BEMATIC THERMOBONDING LINE, WIDTH 2500mm, YEAR 2012

M-3729 BEMATIC THERMOBONDING LINE, WIDTH 2500mm, YEAR 2012M-3729 BEMATIC THERMOBONDING LINE, WIDTH 2500mm, YEAR 2012

THERMOBONDING LINE

MAKE: BEMATIC

YEAR: 2012

WIDTH: 2500mmOFFER 001

BEMATIC AC-1500 BALE OPENERSOFFER 002

BEMATIC AF-700 OPENER/MIXEROFFER 003

BEMATIC BLOW SM-2000 FEEDING TOWER AND MIXEROFFER 004

BEMATIC BCV VOLUMETRIC HOPPER FEEDEROFFER 005

BEMATIC HI 91 CARDOFFER 006

TEXNOLOGY EVOLUTION CROSSLAPPEROFFER 007

BOMBI MECCANICA TFP/2N/3/FB OVENOFFER 008

BOMBI MECCANICA TG2.9/3 SLITTING AND CROSS-CUTTING UNITQUANTITY: 1 LINE

Learn More -

C-2459 FEHRER AIRLAY NONWOVEN LINE, WIDTH 2200mm, YEAR 1992REFERENCE NUMBER: C-2459 FEHRER AIRLAY NONWOVEN LINE, WIDTH 2200mm, YEAR 1992 SPECIFICATIONS: 1 PC. AIRLAY NONWOVEN LINE FEHRER V 21 K 12 2200 MM WORKING WIDTH, YEAR OF CONSTRUCTION 1992, SECOND-HAND THE LINE IS CONSISTING OF: 1 PC. CHUTE FEEDER TEMAFA WITH CONDENSER. 1 PC. WEIGHTING UNIT KUKLA WITH CONTINUOUS BELT. 1 PC. FEEDING UNIT, CONTINUOUS BELT TYPE FEHRER - FEEDING V 21. 1 PC. WEB FORMING UNIT FEHRER V 21. 2200 mm WORKING WIDTH. 1 PC. AERODYNAMIC CARD FEHRER K 12, 2200 mm WORKING WIDTH. 1 PC. NEEDLE LOOM FEHRER NL 9 S, 2200 mm WORKING WIDTH. SINGLE BOARD DOWN STROKE MACHINE, 3000 NEEDLES/M. MAX. 1500 STROKES/MIN. WITH OUTLET ROLLERS. 1 PC. WINDER WITH LONGITUDINAL CUTTER. (NO CROSS CUTTER AVAILABLE.) 1 PC. COMPLETE DUST COLLECTION UNIT. THE V 21 K 12 LINE IS SUITABLE FOR A WEIGHT RANGE OF APPROX. 400 TO 2000 GR/SWM AND A CAPACITY OF UP TO 600 KG/H, DEPENDING ON FIBERS. THE CONTROL PANELS, FILTERS ETC. ARE IN A GOOD CONDITION. 1 PC. RANDOM CARDING MACHINE FEHRER K 12 (REF. NO. 2133817). 2300 mm WORKING WIDTH, YEAR OF CONSTRUCTION UNFORTUNATELY NOT KNOWN. WITH OPENING MACHINE K 12. WITH ONE ASSELIN NEEDLE LOOM MODEL 169, STROKE HEIGHT 0-30 MM. 2.800 mm WORKING WIDTH. WITH ONE FEHRER NEEDLE LOOM NL 12, 1200 STROKES/MIN. 60 mm STROKE HEIGHT, 2.400 mm WORKING WIDTH. INCL. CUTTING AND ROLLING SECTION. THE LINE CONSISTS OF K 12 SECTION ONLY. V 21 SECTION IS NOT INCLUDED. PREVIOUSLY USED FOR 200 TO 2000 GR/SQM. THE MINIMUM IS 200 GR/SQM. MAINLY USED TO PRODUCE HIGH QUALITY MATTRESS MATERIAL IN A SQM-RANGE OF 300-1200 G/SQM MADE FROM JUTE FIBRES. IN GENERAL ALMOST ALL TYPES OF FIBERS CAN BE PROCESSED. IT IS A GOOD MACHINE FOR NATURAL FIBERS. 1 PC. AIRLAY LINE ROLANDO / FEHRER V21/K12 (REF. NO. 2226950). 4400 MM WORKING WIDTH. THE LINE IS CONSISTING OF: - HOPPER FEEDER ROLANDO, CASTING IRON. - CHEMINEE FEEDER WITH AUTOMATIC REGULATED FEEDING ROLANDO. - SQUARE METER MEASURING UNIT AND CONTROL SYSTEM MADE BY FEHRER TYPE E-PW. - OPENER FEHRER V 21, 4400 MM WORKING WIDTH. - RANDOM CARDING MACHINE FEHRER K 12, 4400 MM WORKING WIDTH. THE LINE HAS WORKED ON 1000 GR / SQM AND UP. QUANTITY AVAILABLE: 1 Learn More

C-2459 FEHRER AIRLAY NONWOVEN LINE, WIDTH 2200mm, YEAR 1992REFERENCE NUMBER: C-2459 FEHRER AIRLAY NONWOVEN LINE, WIDTH 2200mm, YEAR 1992 SPECIFICATIONS: 1 PC. AIRLAY NONWOVEN LINE FEHRER V 21 K 12 2200 MM WORKING WIDTH, YEAR OF CONSTRUCTION 1992, SECOND-HAND THE LINE IS CONSISTING OF: 1 PC. CHUTE FEEDER TEMAFA WITH CONDENSER. 1 PC. WEIGHTING UNIT KUKLA WITH CONTINUOUS BELT. 1 PC. FEEDING UNIT, CONTINUOUS BELT TYPE FEHRER - FEEDING V 21. 1 PC. WEB FORMING UNIT FEHRER V 21. 2200 mm WORKING WIDTH. 1 PC. AERODYNAMIC CARD FEHRER K 12, 2200 mm WORKING WIDTH. 1 PC. NEEDLE LOOM FEHRER NL 9 S, 2200 mm WORKING WIDTH. SINGLE BOARD DOWN STROKE MACHINE, 3000 NEEDLES/M. MAX. 1500 STROKES/MIN. WITH OUTLET ROLLERS. 1 PC. WINDER WITH LONGITUDINAL CUTTER. (NO CROSS CUTTER AVAILABLE.) 1 PC. COMPLETE DUST COLLECTION UNIT. THE V 21 K 12 LINE IS SUITABLE FOR A WEIGHT RANGE OF APPROX. 400 TO 2000 GR/SWM AND A CAPACITY OF UP TO 600 KG/H, DEPENDING ON FIBERS. THE CONTROL PANELS, FILTERS ETC. ARE IN A GOOD CONDITION. 1 PC. RANDOM CARDING MACHINE FEHRER K 12 (REF. NO. 2133817). 2300 mm WORKING WIDTH, YEAR OF CONSTRUCTION UNFORTUNATELY NOT KNOWN. WITH OPENING MACHINE K 12. WITH ONE ASSELIN NEEDLE LOOM MODEL 169, STROKE HEIGHT 0-30 MM. 2.800 mm WORKING WIDTH. WITH ONE FEHRER NEEDLE LOOM NL 12, 1200 STROKES/MIN. 60 mm STROKE HEIGHT, 2.400 mm WORKING WIDTH. INCL. CUTTING AND ROLLING SECTION. THE LINE CONSISTS OF K 12 SECTION ONLY. V 21 SECTION IS NOT INCLUDED. PREVIOUSLY USED FOR 200 TO 2000 GR/SQM. THE MINIMUM IS 200 GR/SQM. MAINLY USED TO PRODUCE HIGH QUALITY MATTRESS MATERIAL IN A SQM-RANGE OF 300-1200 G/SQM MADE FROM JUTE FIBRES. IN GENERAL ALMOST ALL TYPES OF FIBERS CAN BE PROCESSED. IT IS A GOOD MACHINE FOR NATURAL FIBERS. 1 PC. AIRLAY LINE ROLANDO / FEHRER V21/K12 (REF. NO. 2226950). 4400 MM WORKING WIDTH. THE LINE IS CONSISTING OF: - HOPPER FEEDER ROLANDO, CASTING IRON. - CHEMINEE FEEDER WITH AUTOMATIC REGULATED FEEDING ROLANDO. - SQUARE METER MEASURING UNIT AND CONTROL SYSTEM MADE BY FEHRER TYPE E-PW. - OPENER FEHRER V 21, 4400 MM WORKING WIDTH. - RANDOM CARDING MACHINE FEHRER K 12, 4400 MM WORKING WIDTH. THE LINE HAS WORKED ON 1000 GR / SQM AND UP. QUANTITY AVAILABLE: 1 Learn More -

C-2478 AIRLAY LINE WITH THERMOBONDING OVEN CORMATEX / SICAM, WIDTH 1300mm, YEAR 2010 TO 2011REFERENCE NUMBER: C-2478 AIRLAY LINE WITH THERMOBONDING OVEN CORMATEX / SICAM, WIDTH 1300mm, YEAR 2010 TO 2011 SPECIFICATIONS: AIRLAY LINE WITH THERMOBONDING OVEN CORMATEX / SICAM WORKING WIDTH 1300mm YEAR OF CONSTRUCTION 2010 to 2011. THE AIRLAY LINE IS CONSISTING OF THE FOLLOWING COMPONENTS: BALE OPENER WITH SCALE TO MEASURE THE WEIGHT. CONVEYOR BELT. OPENER. AIRLAY UNIT. CONVEYOR BELT. THERMOBONDING OVEN. EDGE TRIM UNIT. PANEL CUTTER, FULLY AUTOMATIC. LOADING DEVICE TO LOAD READY MADE PANELS ONTO A PALETTE. THE THERMOBONDING OVEN IS MADE BY SICAM AND IS GAS HEATED. QUANTITY AVAILABLE: 1 Learn More

C-2478 AIRLAY LINE WITH THERMOBONDING OVEN CORMATEX / SICAM, WIDTH 1300mm, YEAR 2010 TO 2011REFERENCE NUMBER: C-2478 AIRLAY LINE WITH THERMOBONDING OVEN CORMATEX / SICAM, WIDTH 1300mm, YEAR 2010 TO 2011 SPECIFICATIONS: AIRLAY LINE WITH THERMOBONDING OVEN CORMATEX / SICAM WORKING WIDTH 1300mm YEAR OF CONSTRUCTION 2010 to 2011. THE AIRLAY LINE IS CONSISTING OF THE FOLLOWING COMPONENTS: BALE OPENER WITH SCALE TO MEASURE THE WEIGHT. CONVEYOR BELT. OPENER. AIRLAY UNIT. CONVEYOR BELT. THERMOBONDING OVEN. EDGE TRIM UNIT. PANEL CUTTER, FULLY AUTOMATIC. LOADING DEVICE TO LOAD READY MADE PANELS ONTO A PALETTE. THE THERMOBONDING OVEN IS MADE BY SICAM AND IS GAS HEATED. QUANTITY AVAILABLE: 1 Learn More -

M-1027 NEEDLE PUNCHING PLANT COMPLETE WITH 6 FEHRER NEEDLE LOOMS YEAR 1993REFERENCE NUMBER: M-1027 NEEDLE PUNCHING PLANT COMPLETE WITH 6 FEHRER NEEDLE LOOMS YEAR 1993 ARTIFICIAL LEATHER PRODUCING AND OTHER HIGH/EXTRA-HIGH DENSITY PRODUCING NONWOVEN NEEDLE PUNCHING LINE COMPLETE WITH 6 SETS FEHRER NEEDLE PUNCHING LOOMS YEAR: 1993 PLANT IS RUNNING CAN BE INSPECTED QUANTITY AVAILABLE: 1 Learn More

M-1027 NEEDLE PUNCHING PLANT COMPLETE WITH 6 FEHRER NEEDLE LOOMS YEAR 1993REFERENCE NUMBER: M-1027 NEEDLE PUNCHING PLANT COMPLETE WITH 6 FEHRER NEEDLE LOOMS YEAR 1993 ARTIFICIAL LEATHER PRODUCING AND OTHER HIGH/EXTRA-HIGH DENSITY PRODUCING NONWOVEN NEEDLE PUNCHING LINE COMPLETE WITH 6 SETS FEHRER NEEDLE PUNCHING LOOMS YEAR: 1993 PLANT IS RUNNING CAN BE INSPECTED QUANTITY AVAILABLE: 1 Learn More -

T-7952 SAMHWA CROSS LAPPER, WIDTH 2700mm, YEAR 2017T-7952 SAMHWA CROSS LAPPER, WIDTH 2700mm, YEAR 2017 NOMINAL VOLTAGE: 400V, 50Hz DRIVE: AC SERVO DRIVE CONTROL SYSTEM: ONBOARD TOUCH - SCREEN CONTROL PANEL QUANTITY: 1 Learn More

T-7952 SAMHWA CROSS LAPPER, WIDTH 2700mm, YEAR 2017T-7952 SAMHWA CROSS LAPPER, WIDTH 2700mm, YEAR 2017 NOMINAL VOLTAGE: 400V, 50Hz DRIVE: AC SERVO DRIVE CONTROL SYSTEM: ONBOARD TOUCH - SCREEN CONTROL PANEL QUANTITY: 1 Learn More -

J-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY -FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLEJ-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY-FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLE CAPACITY: 15 TO 36 PIECES PER MINUTE FABRIC WEIGHT: 60 TO 160gsm FOR NONWOVEN FABRIC BAG AUTOMATIC BOTTOM SEWING, SIDE SEWING, AUTOMATIC CUTTING PLC CONTROLLED SERVO MOTOR DRIVEN QUANTITY: 1 Learn More

J-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY -FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLEJ-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY-FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLE CAPACITY: 15 TO 36 PIECES PER MINUTE FABRIC WEIGHT: 60 TO 160gsm FOR NONWOVEN FABRIC BAG AUTOMATIC BOTTOM SEWING, SIDE SEWING, AUTOMATIC CUTTING PLC CONTROLLED SERVO MOTOR DRIVEN QUANTITY: 1 Learn More -

SANTEX THERMOBONDING OVEN FOR HIGH DENSITY NONWOVENS, WORKING WIDTH 2600mmREFERENCE NUMBER: J-2912 SANTEX THERMOBONDING OVEN FOR HIGH DENSITY NONWOVENS, WORKING WIDTH 2600mm -CURRENTLY PROCESSING VIRGIN AND RECYCLED PET MAKE: SANTEX FOR PROCESSING HIGH DENSITY NONWOVENS FOR AUTOMOTIVE INDUSTRY, SOUND ABSORBENT MATERIALS, BEDDING AND FURNITURE WADDING YEAR: 1996 (PERMANENTLY OVERHAULED SO IN GOOD CONDITION) WORKING WIDTH: 2500mm (WEB WIDTH) CAPACITY: 100 TO 4000 gr/m2 WITH MODIFICATIONS TO ALLOW PROCESSING OF 4000 gr/m2 TO 25mm HEIGHT, INLET HEIGHT 5 TO 100mm WITH DOUBLE COMPRESSION GLASS-FIBER BELT GAS HEATED, SINGLE BURNER COOLING ZONE FLOORSPACE REQUIRED (FOR FULLY ERECTED OVEN) APPROXIMATE LENGTH: 9000mm + 3000mm INTAKE TRANSPORT BAND WIDTH: 5500mm HEIGHT: 3500mm + SPACE FOR FANS AND PIPING HEATING CHAMBER LENGTH: APPROXIMATELY 5000mm BURNER BTU (OR KILOCALORIES): INFORMATION COMING SOON IT IS POSSIBLE TO FEED THE OVEN WITH THE WEB WIDTH OF 2600mm, WHICH WILL ALLOW FOR THE TRIMMED WIDTH OF 2500mm AND TAKING OUT TWO PANELS EACH OF 1220mm FROM THIS STATUS: CURRENTLY RUNNING AND POSSIBLE TO SEE UNTIL END OF JUNE, 2020 QUANTITY: 1 Learn More

SANTEX THERMOBONDING OVEN FOR HIGH DENSITY NONWOVENS, WORKING WIDTH 2600mmREFERENCE NUMBER: J-2912 SANTEX THERMOBONDING OVEN FOR HIGH DENSITY NONWOVENS, WORKING WIDTH 2600mm -CURRENTLY PROCESSING VIRGIN AND RECYCLED PET MAKE: SANTEX FOR PROCESSING HIGH DENSITY NONWOVENS FOR AUTOMOTIVE INDUSTRY, SOUND ABSORBENT MATERIALS, BEDDING AND FURNITURE WADDING YEAR: 1996 (PERMANENTLY OVERHAULED SO IN GOOD CONDITION) WORKING WIDTH: 2500mm (WEB WIDTH) CAPACITY: 100 TO 4000 gr/m2 WITH MODIFICATIONS TO ALLOW PROCESSING OF 4000 gr/m2 TO 25mm HEIGHT, INLET HEIGHT 5 TO 100mm WITH DOUBLE COMPRESSION GLASS-FIBER BELT GAS HEATED, SINGLE BURNER COOLING ZONE FLOORSPACE REQUIRED (FOR FULLY ERECTED OVEN) APPROXIMATE LENGTH: 9000mm + 3000mm INTAKE TRANSPORT BAND WIDTH: 5500mm HEIGHT: 3500mm + SPACE FOR FANS AND PIPING HEATING CHAMBER LENGTH: APPROXIMATELY 5000mm BURNER BTU (OR KILOCALORIES): INFORMATION COMING SOON IT IS POSSIBLE TO FEED THE OVEN WITH THE WEB WIDTH OF 2600mm, WHICH WILL ALLOW FOR THE TRIMMED WIDTH OF 2500mm AND TAKING OUT TWO PANELS EACH OF 1220mm FROM THIS STATUS: CURRENTLY RUNNING AND POSSIBLE TO SEE UNTIL END OF JUNE, 2020 QUANTITY: 1 Learn More