Search results for: 'pre n'

- Related search terms

- Pre needl

- pressure tank

- pre nee

- pre needl

- pre needle p

-

M-5147 COTTON PAD MAKING MACHINEREFERENCE NUMBER: M-5147 (1212NDTYXX11) L COTTON PAD MAKING MACHINE PUT ON MAKE-UP THE COTTON AND KAPOK PRODUCTION PROCESS: THE EQUIPMENT IS DIVIDES CUTS THE GOOD DEGREASING TO LAP, THE ADHESIVE-BONDED CLOTH OR THE GAUZE, LAYING ASIDE RAW MATERIAL AFTER THE COMPACTION, THE HEATING EMBOSSES, ROLLS CUTS PROCESS ONE TIME TO COMPLETE. MAIN FEATURE THE HIGH SPEED PUNCH PRESS REVOLVING BLANKING PRINCIPLE OF WORK, THE TECHNOLOGY IS MATURE, THE WORK IS STABLE, THE SERVICE WORK LOAD ARE FEW, OUTPUT MODE: THE PIPELINE ARRANGEMENT OUTPUT, THE CODE FALLS NEATLY, THE BAGGING IS CONVENIENT, A PERSON THEN OPERATES THE COMPLETE MACHINE, BIG REDUCED ARTIFICIAL AMOUNT OF USE; THE GOOD MAN-MACHINE OPERATION CONTACT SURFACE, MAY UNFOLD THE REAL TIME OPERATION INFORMATION, IS ADVANTAGEOUS FOR THE PRODUCTION MONITORING; THE MOLD REPLACEMENT IS CONVENIENT, THE CONSTRUCTION COST IS LOWER THAN GREATLY ROLLS CUTS THE CARVING FLOWER CUTTER BAR, MOREOVER AFTER THE MOLD WEARS, EASY TO REPAIR, DOES NOT NEED TO DISCARD THE REPLACEMENT, SAVES THE MAINTENANCE COST. PUT ON MAKE-UP THE COTTON AND KAPOK MAJOR TECHNIQUE PARAMETER: PRODUCTION SPEED: 20--30M/MIN PRODUCTION SPECIFICATION: MAY ACCORDING TO THE REQUEST ADJUSTMENT TOTAL POWER: 5KW MACHINE DIMENSION: 3.5M*1.7M*2.5M MODEL: A QUANTITY: 1 Learn More

M-5147 COTTON PAD MAKING MACHINEREFERENCE NUMBER: M-5147 (1212NDTYXX11) L COTTON PAD MAKING MACHINE PUT ON MAKE-UP THE COTTON AND KAPOK PRODUCTION PROCESS: THE EQUIPMENT IS DIVIDES CUTS THE GOOD DEGREASING TO LAP, THE ADHESIVE-BONDED CLOTH OR THE GAUZE, LAYING ASIDE RAW MATERIAL AFTER THE COMPACTION, THE HEATING EMBOSSES, ROLLS CUTS PROCESS ONE TIME TO COMPLETE. MAIN FEATURE THE HIGH SPEED PUNCH PRESS REVOLVING BLANKING PRINCIPLE OF WORK, THE TECHNOLOGY IS MATURE, THE WORK IS STABLE, THE SERVICE WORK LOAD ARE FEW, OUTPUT MODE: THE PIPELINE ARRANGEMENT OUTPUT, THE CODE FALLS NEATLY, THE BAGGING IS CONVENIENT, A PERSON THEN OPERATES THE COMPLETE MACHINE, BIG REDUCED ARTIFICIAL AMOUNT OF USE; THE GOOD MAN-MACHINE OPERATION CONTACT SURFACE, MAY UNFOLD THE REAL TIME OPERATION INFORMATION, IS ADVANTAGEOUS FOR THE PRODUCTION MONITORING; THE MOLD REPLACEMENT IS CONVENIENT, THE CONSTRUCTION COST IS LOWER THAN GREATLY ROLLS CUTS THE CARVING FLOWER CUTTER BAR, MOREOVER AFTER THE MOLD WEARS, EASY TO REPAIR, DOES NOT NEED TO DISCARD THE REPLACEMENT, SAVES THE MAINTENANCE COST. PUT ON MAKE-UP THE COTTON AND KAPOK MAJOR TECHNIQUE PARAMETER: PRODUCTION SPEED: 20--30M/MIN PRODUCTION SPECIFICATION: MAY ACCORDING TO THE REQUEST ADJUSTMENT TOTAL POWER: 5KW MACHINE DIMENSION: 3.5M*1.7M*2.5M MODEL: A QUANTITY: 1 Learn More -

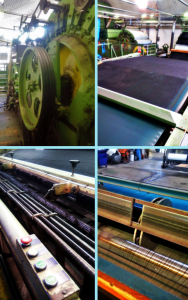

GEO-TEXTILE NON-WOVEN PUNCH LINE 5500mm MODEL T-550KB-110 BALE OPENER (2 SETS) KS-130 PRE OPENER (1 SET) HM-200 BIG CAPACITY BLENDER (1 SET) KS-130 FINE OPENER (1 SET) GM-220 VIBRATING HOPPER (1 SET) SL-250 CARDING MACHINE (C2D2) (1 SET) PW-600 CROSS LAPPER (1 SET) JL-590 BATT FEEDER (1 SET) GY-580 HIGH SPEED PRE-NEEDLE LOOM (1 SET) GS-570 HIGH SPEED UPWARD PUNCH NEEDLE LOOM (1 SET) GX-570 HIGH SPEED DOWNWARD PUNCH NEEDLE LOOM (1 SET) CJ-550 WINDER (1 SET) ELECTRIC CONTROL CABINET (1 SET) MOTORS: TECO (TAIWAN) INVERTERS: EMERSON PLC+TOUCH SCREEN: MITSUBISHI Learn More

GEO-TEXTILE NON-WOVEN PUNCH LINE 5500mm MODEL T-550KB-110 BALE OPENER (2 SETS) KS-130 PRE OPENER (1 SET) HM-200 BIG CAPACITY BLENDER (1 SET) KS-130 FINE OPENER (1 SET) GM-220 VIBRATING HOPPER (1 SET) SL-250 CARDING MACHINE (C2D2) (1 SET) PW-600 CROSS LAPPER (1 SET) JL-590 BATT FEEDER (1 SET) GY-580 HIGH SPEED PRE-NEEDLE LOOM (1 SET) GS-570 HIGH SPEED UPWARD PUNCH NEEDLE LOOM (1 SET) GX-570 HIGH SPEED DOWNWARD PUNCH NEEDLE LOOM (1 SET) CJ-550 WINDER (1 SET) ELECTRIC CONTROL CABINET (1 SET) MOTORS: TECO (TAIWAN) INVERTERS: EMERSON PLC+TOUCH SCREEN: MITSUBISHI Learn More -

M-1520 FEHRER NONWOVEN PRODUCTION LINE WIDTH 4000mm YEAR 1997

M-1520 FEHRER NONWOVEN PRODUCTION LINE WIDTH 4000mm YEAR 1997M-1520 FEHRER NONWOVEN PRODUCTION LINE WIDTH 4000mm YEAR 1997

OFFER 001

MAKE: FEHRER AG

TYPE: V21/R – K12OFFER 002

REUKE BALE OPENER 1OFFER 003

REUKE BALE OPENER 2OFFER 004

REUKE BALE OPENER 3OFFER 005

REUKE MIXING BELTOFFER 006

LTG FILTRATION SYSTEMOFFER 007

HERGETH FEEDING BOX WITH CONDENSEROFFER 008

KUKLA WEIGH BAROFFER 009

FEHRER AG PRE – WEB FORMING HEADOFFER 010

FEHRER AG RANDOM CARDOFFER 011

SCHOTT & MEISSNER THERMOBONDING OVENOFFER 012

SCHIRP CROSS / LENGTHS CUTTEROFFER 013

KSM STACKERQUANTITY: 1

Learn More -

T-7944 HERGETH CARDING MACHINE AND CROSS LAPPER, WIDTH 2500mm, YEAR 1988T-7944 HERGETH CARDING MACHINE AND CROSS LAPPER, WIDTH 2500mm, YEAR 1988 ITEM 001 HERGETH CARDING MACHINE PRESENT STATUS: DECOMMISSIONED IN WORKING ORDER QUANTITY: 1 ITEM 002 HERGETH CROSS - LAPPER PRESENT STATUS: DECOMMISSIONED IN WORKING ORDER QUANTITY: 1 Learn More

T-7944 HERGETH CARDING MACHINE AND CROSS LAPPER, WIDTH 2500mm, YEAR 1988T-7944 HERGETH CARDING MACHINE AND CROSS LAPPER, WIDTH 2500mm, YEAR 1988 ITEM 001 HERGETH CARDING MACHINE PRESENT STATUS: DECOMMISSIONED IN WORKING ORDER QUANTITY: 1 ITEM 002 HERGETH CROSS - LAPPER PRESENT STATUS: DECOMMISSIONED IN WORKING ORDER QUANTITY: 1 Learn More -

T-7942 KIRLOSKAR CENTRAL COMPRESSOR, YEAR 2019T-7942 KIRLOSKAR CENTRAL COMPRESSOR, YEAR 2019 CONDITION: FULLY OPERATIONAL QUANTITY: 1 Learn More

T-7942 KIRLOSKAR CENTRAL COMPRESSOR, YEAR 2019T-7942 KIRLOSKAR CENTRAL COMPRESSOR, YEAR 2019 CONDITION: FULLY OPERATIONAL QUANTITY: 1 Learn More -

NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7REFERENCE NUMBER: T-6989 NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7 ITEM 001 PRODUCTION PLANT OF NON-WOVEN FABRIC PLANT IS COMPLETE IN AN EXCELLENT STATE OF MAINTENANCE WITH DRUMS OF 2000mm IN DIAMETER LIKE THE SAME DIAMETER DOFFERS, HIGH WORK 2200mm, 2500 X 4200mm, ALL MACHINES ARE ELECTRONICALLY MANAGED BY PLC, WEIGHT SCALE WITH LOAD CELLS, IT IS THERE IS ALSO THE COMPLETE AUTOMATED FIBER PREPARATION IN ADDITION, THERE IS 1 LOOM FOR NONWOVEN MALIWATT WITH THREAD AND 1 MALIVLIES LOOM WITHOUT SEWING THREAD INTERTWINES THE FIBERS AND PRODUCES A NON-WOVEN FABRIC ALSO USED FOR THE PRODUCTION OF ANTI-COVID-19 FACIAL MASKS FABRIC PRODUCTION PLANTS IN BLOCK FABRIC OR FOR SINGLE UNITS IN GOOD CONDITION AND STILL IN PRODUCTION TODAY THE DESCRIPTION OF THE PLANTS BELOW: ITEM 002 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1980 FOR MODEL CARD WORKING HEIGHT 2200mm DRUM DIAMETER 1700mm DOFFER 1270mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, PLANT IN GOOD CONDITION QUANTITY: 2 ITEM 003 MALIWATT 3600 TYPE 14013 GAUGE 7 YEAR OF CONSTRUCTION 1981 CARD MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC AT THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 004 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 OCTIR MODEL CARD WORKING HEIGHT 2500mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% LENGTH FIBER 60mm, 3.4 DTEX, IMPLANT IN EXCELLENT CONDITION QUANTITY: 1 ITEM 005 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 CARD FOR MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC ON THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 006 MALIWATT 3600 TYPE 14011 GAUGE 14 YEAR OF CONSTRUCTION 1976 BOISSON MODEL CARD WORKING HEIGHT 2000mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, NENCINI CROSS LAPPER, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, IMPLANT IN FAIR GENERAL CONDITION QUANTITY: 1 DESCRIPTION: ALL PRODUCTION LINES ARE FULLY FUNCTIONAL AND ARE STILL PRODUCTION ALL THE PLANTS ARE COMPOSED OF FORWARD TRAIN AND ONE CARD DOES NOT HAVE FIBER CROSSING AND THE PRODUCTION OF ARTICLES WITH MELANGE COLORS IS PROBLEMATIC, ANOTHER HANDICAP THAT I HAVE DETECTED THE PLANT DOES NOT HAVE FIBER PREPARATION AND STORAGE, THERE ARE BALES AND SILOS OPENERS WITH FEEDING CONVEYORS BUT THE FIBER USED IS NOT WELL MIXED, CURRENTLY THEY PRODUCE NON-WOVEN FABRICS FOR PRINTING. ALL MALIWATTS THE ELECTRICAL SYSTEM AND THE ELECTRONIC BAR HEATING SYSTEM HAVE BEEN REBUILT; THE CROSS LAPPERS HAVE ALSO BEEN UPDATED IN THE ELECTRONICS. THE SELLER SELLS THE PLANT IS NOT PROFITABLE AND THEY PLAN TO REINVEST IN DIFFERENT PRODUCTIONS IN ADDITION, THERE ARE ALSO VARIOUS ACCESSORIES FOR PRODUCTION SUCH AS BALE OPENERS, CALENDERS, CONVEYOR TROLLEYS ETC. Learn More

NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7REFERENCE NUMBER: T-6989 NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7 ITEM 001 PRODUCTION PLANT OF NON-WOVEN FABRIC PLANT IS COMPLETE IN AN EXCELLENT STATE OF MAINTENANCE WITH DRUMS OF 2000mm IN DIAMETER LIKE THE SAME DIAMETER DOFFERS, HIGH WORK 2200mm, 2500 X 4200mm, ALL MACHINES ARE ELECTRONICALLY MANAGED BY PLC, WEIGHT SCALE WITH LOAD CELLS, IT IS THERE IS ALSO THE COMPLETE AUTOMATED FIBER PREPARATION IN ADDITION, THERE IS 1 LOOM FOR NONWOVEN MALIWATT WITH THREAD AND 1 MALIVLIES LOOM WITHOUT SEWING THREAD INTERTWINES THE FIBERS AND PRODUCES A NON-WOVEN FABRIC ALSO USED FOR THE PRODUCTION OF ANTI-COVID-19 FACIAL MASKS FABRIC PRODUCTION PLANTS IN BLOCK FABRIC OR FOR SINGLE UNITS IN GOOD CONDITION AND STILL IN PRODUCTION TODAY THE DESCRIPTION OF THE PLANTS BELOW: ITEM 002 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1980 FOR MODEL CARD WORKING HEIGHT 2200mm DRUM DIAMETER 1700mm DOFFER 1270mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, PLANT IN GOOD CONDITION QUANTITY: 2 ITEM 003 MALIWATT 3600 TYPE 14013 GAUGE 7 YEAR OF CONSTRUCTION 1981 CARD MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC AT THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 004 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 OCTIR MODEL CARD WORKING HEIGHT 2500mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% LENGTH FIBER 60mm, 3.4 DTEX, IMPLANT IN EXCELLENT CONDITION QUANTITY: 1 ITEM 005 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 CARD FOR MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC ON THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 006 MALIWATT 3600 TYPE 14011 GAUGE 14 YEAR OF CONSTRUCTION 1976 BOISSON MODEL CARD WORKING HEIGHT 2000mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, NENCINI CROSS LAPPER, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, IMPLANT IN FAIR GENERAL CONDITION QUANTITY: 1 DESCRIPTION: ALL PRODUCTION LINES ARE FULLY FUNCTIONAL AND ARE STILL PRODUCTION ALL THE PLANTS ARE COMPOSED OF FORWARD TRAIN AND ONE CARD DOES NOT HAVE FIBER CROSSING AND THE PRODUCTION OF ARTICLES WITH MELANGE COLORS IS PROBLEMATIC, ANOTHER HANDICAP THAT I HAVE DETECTED THE PLANT DOES NOT HAVE FIBER PREPARATION AND STORAGE, THERE ARE BALES AND SILOS OPENERS WITH FEEDING CONVEYORS BUT THE FIBER USED IS NOT WELL MIXED, CURRENTLY THEY PRODUCE NON-WOVEN FABRICS FOR PRINTING. ALL MALIWATTS THE ELECTRICAL SYSTEM AND THE ELECTRONIC BAR HEATING SYSTEM HAVE BEEN REBUILT; THE CROSS LAPPERS HAVE ALSO BEEN UPDATED IN THE ELECTRONICS. THE SELLER SELLS THE PLANT IS NOT PROFITABLE AND THEY PLAN TO REINVEST IN DIFFERENT PRODUCTIONS IN ADDITION, THERE ARE ALSO VARIOUS ACCESSORIES FOR PRODUCTION SUCH AS BALE OPENERS, CALENDERS, CONVEYOR TROLLEYS ETC. Learn More -

C-3929 TEMAFA FIBER BLENDING AND PREPERATION LINE, YEAR 1988

C-3929 TEMAFA FIBER BLENDING AND PREPERATION LINE, YEAR 1988C-3929 TEMAFA FIBER BLENDING AND PREPERATION LINE, YEAR 1988

TEMAFA FIBER BLENDING AND PREPERATION LINE

BRAND: TEMAFA

YEAR: 1988QUANTITY: 1

Learn More -

C-3946 SPINNBAU CARDING MACHINE, WIDTH 3000mm, YEAR 1989

C-3946 SPINNBAU CARDING MACHINE, WIDTH 3000mm, YEAR 1989C-3946 SPINNBAU CARDING MACHINE, WIDTH 3000mm, YEAR 1989

SPINNBAU CARDING MACHINE

BRAND: SPINNBAU

YEAR: 1989

WIDTH: 3000mmQUANTITY: 1

Learn More -

A-1876 END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mm

A-1876 END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mmREFERENCE NUMBER: A-1876

END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mmPRODUCT TO BE PROCESSED: NEEDLEPUNCHED NONWOVENS

PRODUCT WIDTH: 4.000 MMWORKING SPEED: 1 – 20 M/MIN

QUANTITY: 1

Learn More -

C-1158 CARDING MACHINE HOUGET DUESBERG BOSSON WITH CROSS LAPPER BOSTALO, WIDTH 2200MMREFERENCE NUMBER: C-1158 CARDING MACHINE HOUGET DUESBERG BOSSON WITH CROSS LAPPER BOSTALO, WIDTH 2200MM SPECIFICATIONS: HOUGET DUESBERG BOSSON CARDING MACHINE -HDB BELGIUM 2200 MM WORKING WIDTH RIGID CARD CLOTHING QUANTITY AVAILABLE: 1 Learn More

C-1158 CARDING MACHINE HOUGET DUESBERG BOSSON WITH CROSS LAPPER BOSTALO, WIDTH 2200MMREFERENCE NUMBER: C-1158 CARDING MACHINE HOUGET DUESBERG BOSSON WITH CROSS LAPPER BOSTALO, WIDTH 2200MM SPECIFICATIONS: HOUGET DUESBERG BOSSON CARDING MACHINE -HDB BELGIUM 2200 MM WORKING WIDTH RIGID CARD CLOTHING QUANTITY AVAILABLE: 1 Learn More