Search results for: 'Automatic 4 s'

- Related search terms

- automatic

- automatic Ver'

- automatic te

- automatic V''

- AUTOMATIC P'

-

J-3671 AUTOMATIC MATTRESS PACKING MACHINEJ-3671 AUTOMATIC MATTRESS PACKING MACHINE PRODUCTION CAPACITY: 30 SECONDS PER MATTRESS WITH PNEUMATIC PRESS WITH AUTOMATIC SIZING SYSTEM WITH AUTOMATIC WATER-COOLING SYSTEM (GIVES A BETTER SEAL) POWER REQUIREMENT: 6.5 KW / 380 VOLTS QUANTITY: 1 Learn More

J-3671 AUTOMATIC MATTRESS PACKING MACHINEJ-3671 AUTOMATIC MATTRESS PACKING MACHINE PRODUCTION CAPACITY: 30 SECONDS PER MATTRESS WITH PNEUMATIC PRESS WITH AUTOMATIC SIZING SYSTEM WITH AUTOMATIC WATER-COOLING SYSTEM (GIVES A BETTER SEAL) POWER REQUIREMENT: 6.5 KW / 380 VOLTS QUANTITY: 1 Learn More -

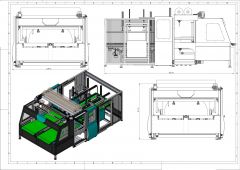

M-6042 VACUUM PRESSING AND ROLLING UP MATTRESSES LINE

M-6042 VACUUM PRESSING AND ROLLING UP MATTRESSES LINEREFERENCE NUMBER: M-6042 (880699GY7RX) L

VACUUM PRESSING AND ROLLING UP MATTRESSES LINECOMPLETE LINE FOR VACUUM PRESSING AND ROLLING UP MATTRESSES

PRODUCTION: 3 MATTRESSES PER MINUTE

CAN WORK: VISCO / POLYURETHANE / LATEX / BONNELL SPRING / POCKET SPRING / ETC.QUANTITY: 1

Learn More -

M-3489 AUTOMATIC MATTRESS WRAPPER SINGLE/QUEEN/KING (88” WIDE)REFERENCE NUMBER: M-3489 (880NWTYXX7)-D AUTOMATIC MATTRESS WRAPPER SINGLE/QUEEN/KING (88” WIDE) GOOD FOR 18”-20” HIGH MATTRESS AUTOMATIC MATTRESS WRAPPER SINGLE/QUEEN/KING WITH 14 ROLLERS AT THE ENTRANCE CONVEYOR WIDTH OF ROLLERS: 86” WITH (2) SEALERS: LENGTH 100” MAX. DISTANCE BETWEEN THE SEALERS: 80 ¾” MAX. HEIGHT OF SEALERS FROM TABLE: APPROX. 9” THIS WRAPPER HAS A FIXED HEIGHT OF 17” IT INCLUDES (1) METAL TABLE AT THE END OF THE ENTRANCE WIDTH OF TABLE: 72” DEPTH OF TABLE: 51” WRAPPER EXIT WIDTH: 83” MAX. DISTANCE BETWEEN RIGHT AND LEFT SIDE OF THE BAGGER: 89 ½” MAX. WORKING HEIGHT: 17” (430mm) THE INSIDE DISTANCE BETWEEN THE RIGHT SEALER AND LEFT SEALER: 76 ½” QUANTITY AVAILABLE: 1 Learn More

M-3489 AUTOMATIC MATTRESS WRAPPER SINGLE/QUEEN/KING (88” WIDE)REFERENCE NUMBER: M-3489 (880NWTYXX7)-D AUTOMATIC MATTRESS WRAPPER SINGLE/QUEEN/KING (88” WIDE) GOOD FOR 18”-20” HIGH MATTRESS AUTOMATIC MATTRESS WRAPPER SINGLE/QUEEN/KING WITH 14 ROLLERS AT THE ENTRANCE CONVEYOR WIDTH OF ROLLERS: 86” WITH (2) SEALERS: LENGTH 100” MAX. DISTANCE BETWEEN THE SEALERS: 80 ¾” MAX. HEIGHT OF SEALERS FROM TABLE: APPROX. 9” THIS WRAPPER HAS A FIXED HEIGHT OF 17” IT INCLUDES (1) METAL TABLE AT THE END OF THE ENTRANCE WIDTH OF TABLE: 72” DEPTH OF TABLE: 51” WRAPPER EXIT WIDTH: 83” MAX. DISTANCE BETWEEN RIGHT AND LEFT SIDE OF THE BAGGER: 89 ½” MAX. WORKING HEIGHT: 17” (430mm) THE INSIDE DISTANCE BETWEEN THE RIGHT SEALER AND LEFT SEALER: 76 ½” QUANTITY AVAILABLE: 1 Learn More -

M-3011 PORTER AUTOMATIC LABEL SEWERREFERENCE NUMBER: M-3011 (770KIDEXX6) PORTER AUTOMATIC LABEL SEWER AUTOMATIC LABEL SEWER MODEL: PALS-4000 QUANTITY AVAILABLE: 1 Learn More

M-3011 PORTER AUTOMATIC LABEL SEWERREFERENCE NUMBER: M-3011 (770KIDEXX6) PORTER AUTOMATIC LABEL SEWER AUTOMATIC LABEL SEWER MODEL: PALS-4000 QUANTITY AVAILABLE: 1 Learn More -

M-3006 AUTOMATIC MATTRESS WRAPPER SINGLE/QUEEN/KING (88” WIDE)

M-3006 AUTOMATIC MATTRESS WRAPPER SINGLE/QUEEN/KING (88” WIDE)REFERENCE NUMBER: M-3006

AUTOMATIC MATTRESS WRAPPER SINGLE/QUEEN/KING (88” WIDE)

AUTOMATIC MATTRESS WRAPPER

SINGLE/QUEEN/KING

WITH 14 ROLLERS AT THE ENTRANCE CONVEYOR

WIDTH OF ROLLERS: 86”

WITH (2) SEALERS: LENGTH 100”

MAX. DISTANCE BETWEEN THE SEALERS: 80 ¾”

MAX. HEIGHT OF SEALERS FROM TABLE: APPROX. 9”

THIS WRAPPER HAS A FIXED HEIGHT OF 17”

IT INCLUDES (1) METAL TABLE AT THE END OF THE ENTRANCE

WIDTH OF TABLE: 72”

DEPTH OF TABLE: 51”

WRAPPER EXIT WIDTH: 83”

MAX. DISTANCE BETWEEN RIGHT AND LEFT SIDE OF THE BAGGER: 89 ½”

MAX. WORKING HEIGHT: 17” (430mm)

THE INSIDE DISTANCE BETWEEN THE RIGHT SEALER AND LEFT SEALER: 76 ½”

Learn More -

G-3653 AUTOMATIC POCKET SPRING PRODUCTION LINE

G-3653 AUTOMATIC POCKET SPRING PRODUCTION LINEREFERENCE NUMBER: G-3653

AUTOMATIC POCKET SPRING PRODUCTION LINE

MODEL 08PA AUTOMATIC POCKET SPRING PRODUCTION LINE

MAIN PARAMETER:

PART OF MACHINE: SL-08P+SL-08A

DIMENSIONS(L×W×H): 9.75×1.4×1.85M (EXCEPT THE WORKTABLE)

COIL SHAPE: CYLINDRICAL OR BARREL

SPRING DIAMETER: TOP & BOTTOM Φ45-60Mmm CENTER Φ60-80mm

SPRING HEIGHT (INSIDE THE NON-WOVEN): 130 TO 180mm

STEEL WIRE DIAMETER: Φ1.8 TO Φ2.2Mmm

POCKETED WIDTH OF NON-WOVEN FABRIC: 410 TO 520mm

TYPE OF SEALING: ULTRASONIC

PRODUCTION: 65 PCS/MINUTE

POWER REQUIREMENT: 21 KW

COMPRESSED AIR PRESSURE: 6KGS/CM³

WEIGHT: APPROX. 3.3 TONS

Learn More -

J-3787 HUAJIAN AND VEYSEL KUTUKLU BONELL COILERS AND ASSEMBLERS FOR MATTRESS SPRINGSJ-3787 HUAJIAN AND VEYSEL KUTUKLU BONELL COILERS AND ASSEMBLERS FOR MATTRESS SPRINGS ITEM 001 MAKE: HUAJIAN QUANTITY: 2 ITEM 002 MAKE: VEYSEL KUTUKLU QUANTITY: 2 ITEM 003 MAKE: VEYSEL KUTUKLU ITEM 004 MAKE: VEYSEL KUTUKLU QUANTITY: 1 ITEM 005 MAKE: VEYSEL KUTUKLU QUANTITY: 1 ITEM 006 MAKE: VEYSEL KUTUKLU QUANTITY: 1 Learn More

J-3787 HUAJIAN AND VEYSEL KUTUKLU BONELL COILERS AND ASSEMBLERS FOR MATTRESS SPRINGSJ-3787 HUAJIAN AND VEYSEL KUTUKLU BONELL COILERS AND ASSEMBLERS FOR MATTRESS SPRINGS ITEM 001 MAKE: HUAJIAN QUANTITY: 2 ITEM 002 MAKE: VEYSEL KUTUKLU QUANTITY: 2 ITEM 003 MAKE: VEYSEL KUTUKLU ITEM 004 MAKE: VEYSEL KUTUKLU QUANTITY: 1 ITEM 005 MAKE: VEYSEL KUTUKLU QUANTITY: 1 ITEM 006 MAKE: VEYSEL KUTUKLU QUANTITY: 1 Learn More -

AA-1177 3D FULL PACK – AUTOMATIC MATTRESS COMPRESS AND ROLL PACKING MACHINEAA-1177 3D FULL PACK – AUTOMATIC MATTRESS COMPRESS AND ROLL PACKING MACHINE INNOVATIVE PACKAGING SYSTEM USER FRIENDLY MACHINE SAVING SHIPPING AND STORAGE COSTS Learn More

AA-1177 3D FULL PACK – AUTOMATIC MATTRESS COMPRESS AND ROLL PACKING MACHINEAA-1177 3D FULL PACK – AUTOMATIC MATTRESS COMPRESS AND ROLL PACKING MACHINE INNOVATIVE PACKAGING SYSTEM USER FRIENDLY MACHINE SAVING SHIPPING AND STORAGE COSTS Learn More -

J-2172 COMPLETE MATTRESS PLANT AVAILABLE – 2000 TO 3000 MATTRESSES PER DAY

J-2172 COMPLETE MATTRESS PLANT AVAILABLE – 2000 TO 3000 MATTRESSES PER DAYSee all pictures: https://ibb.co/album/gpK9bF

#1 GRIBETZ MPLUS PATTERN LINK 90 TACK AND JUMP 3 BAR WITH PANEL CUTTER 4 POS CREEL

#2 GRIBETZ GI4300 TACK AND JUMP 90" 3 BAR WITH PANEL CUTTER 3 POS CREEL

# 3 EMCO 2 BAR 1X3 WITH PANEL CUTTER, YEAR 2001 (FOR PARTS)

#4 EMCO COMPUSTITCH 3 BAR

WITH JAMES CASH K-10 PANEL CUTTER#5 GRIBETZ GI2300 90" SET UP FOR BORDERS 4 POS CREEL

#6 EMCO 9000 COMPUSTITCH 1X3X6 BUT RUNNING 1X6

WITH BORDER CUTTER JAMES CASH K-10 1997#7 EMCO 9000 COMPUSTITCH 3 BAR 1 POSITION CREEL

WITH BORDER CUTTER JAMES CASH K-10#8 GRIBETZ 3 BAR 92"

WITH JAMES CASH K-12#9 TAPE EDGE WITH SINGER 300UX6 STEEL TABLE 55 X 81

#10 ATLANTA ATTACHEMENT TAPE EDGE WITH SINGER 300UX5 WITH STAINLESS STEEL TABLE 60 X 80

#11 ATLANTA ATTACHEMENT TAPE EDGE WITH SINGER 300UX5 WITH STAINLESS STEEL TABLE 60 X 80

#12 ATLANTA ATTACHEMENT TAPE EDGE WITH PFAFF 5625 WITH STAINLESS STEEL TABLE 60 X 80

#13 ATLANTA ATTACHEMENT TAPE EDGE WITH SINGER 300UX6 WITH STAINLESS STEEL TABLE 60 X 80

#14 PORTER TAPE EDGE PFAFF DISSASSEMBLED HEAD TABLE SIZE 60 X 82

#15 ATLANTA ATTACHMENT TAPE EDGE WITH PFAFF 5625 STAINLESS STEEL TABLE 59 X 79

#16 ATLANTA ATTACHEMENT TAPE EDGE WITH SINGERS 300UX5 STAINLESS STEEL TABLE 60 X 80 16"H

#17 BUILD UP TABLES MOSTLY 60 X 80 OF WHICH 15 ARE GLOBAL SYSTEMS AND 2 ARE HOME MADE

#19 ? SMALL BALER CONSOLIDATED MODEL STDS-2 36' WIDE X 18" FRONT TO BACK X 50"H

#20 SCREW UNBALER ATLANTA ATTACHMENT FOR 18 INNERSPRING CAPACITY

#21 PIQUA BALER 58 X 31 X 54" TALL 220 VOLT

#22 SCREW UNBALER WBSCO

#23 CART FOR INNERSPRING BALE

#24 GRIBETZ PANEL CUTTER ( I HAVE ALL THE INFO ALREADY)

#25 LAMINATOR GRIBETZ STRATA WITH HOT ROLL AND FELT BLANDET FOR LAMINATING WITH WEB SUBSTRATE (ROTARY HEAT PRESS) MODEL GLM011 220 VOLT , 2 POS CREEL

#26 HORIZONTAL FOAM CUTTER ESCO MODEL HTX 51-88 PU+

88" WIDE , X 118" LONG , KNIFE GRINDERS , SUCTION TABLE

TOUCH SCREEN PANEL , ELECTRICAL CONTROL PANEL

AUTOMATIC LUBRICATION BINKS MODEL 80-600 SG2 PLUS#27 VERTICAL FOAM CUTTER MODEL EL-4

112" WIDE

OUTSIDE TABLE 73"

INSIDE TABLE 74"

FENCE 8" PLUS 16 " EXTENSION

68" THROAT

112" OVERALL HEIGHT

194" TOTAL RAIL WIDTH#28 PORTER SERGER FLANGER MODEL 4000 WITH AIR FLOTATION TABLE

220 VOLT#29 ATLANTA ATTACHMENT JUKI SERGER FLANGER MODEL MO6916G BELT DRIVE WITH AIR FLOTATION TABLE

#30 ATLANTA ATTACHEMENT JUKI SERGER FLANGER MODEL MO6916G BELT DRIVE WITH AIR FLOTATION TABLE

#31 SINGER LONG ARM REPAIR 25"

#32 ATLANTA ATTACHEMENT RUFFLER

MODEL 13XXMF#33 ATLANTA ATTATCHMENT 9 NEEDLE SEWING MACHINE (MULTINEEDLE) MODEL 4000D

#34 SINGLE NEEDLE SIT DOWN MACHINES OF WHICH 3 ARE PORTER

#35 AVANCE EMBROIDERY MACHINE

#36 GALKIN "X" SEWING MACHINE FOR HANDLES

GAP5OBT-3 , JUKI MODEL LK1900CV#37 ATLANTA ATTACHMENT DOUBLE BORDER SERGER 25" OPENING , PEGASUS HEAD

MODEL E521-130 AND EX5203-M03#38 ATLANTA ATTACHMENT BINDER FOR HANDLE MAKING

#39 ANDERSON MULTISLITTER 10 BLADES 92" WIDE

#40 ANDERSON STAND ALONE PANEL CUTTER 103"WIDE WITH 2 EDGE SLITTERS AND ONE CROSS CUTTER

WITH 1049 HOURS ON THE CLOCK#41 CONVEYOR FOR SEW DEPARTMENTE 34" WIDE OVER 100 FEET LONG

#42 TOYOTA FORKLIFTS 6270 LBS CAPACITY MODEL 71CCUT5 (TWO)

ONE NISSAN FORKLIFT

ONE CATERPILLAR FORKLIFT#43 ONE GLUE STATION 4 GUNS , SABA GUNS , NOT THERE (BELONG TO SABA)

#44 240 FEET LONG CONVEYOR FEEDING MATTRESS WRAPPING DEPARTMENT

#45 TWO MERELLO WRAPPERS 20 INCH MAX HEIGHT X 88 " WIDE, YEAR 2016

#46 TECNOMAC (ITALY) MATTRESS ROLL AND PACK MACHINE MODEL TK381 YEAR 2015

Learn More

400 VOLT X 50HZ X 30 KW

8 BAR AIR PRESSURE -

T-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTET-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTE TECHNICAL PARAMETERS FUNCTION: EMBOSSING, CUTTING, FOLDING OF PET PAD FOLDING METHOD: 1/3 IN THE WIDTH DIRECTION, 2 TIMES IN THE LENGTH DIRECTION RAW MATERIAL WIDTH: HYDROPHILIC CLOTH WIDTH ≦ 600mm (SLIGHTLY SMALLER THAN THE WIDTH OF THE CAST FILM) WATER ABSORPTION LAYER WIDTH = HYDROPHILIC CLOTH WIDTH: 50 TO 60mm CAST FILM WIDTH ≦ 600mm PRODUCT UNFOLDED SIZE: 400 X 600mm; 500 X 700mm; 600 X 900mm FOLDED SIZE: 135 X 200mm; 170 X 250mm; 200 X 300mm SPEED: 120 TO 150 PIECES PER MINUTE FINISHED PRODUCT LENGTH: LENGTH ERROR ≦ 5mm THE POSITION OF THE ABSORBENT LAYER: THE SAME LENGTH AS THE HYDROPHILIC CLOTH AND CAST FILM WATER-ABSORBING LAMINATED PATTERN: DIAMOND PATTERN (CUSTOMIZABLE) NUMBER OF FOLDING LAYERS: 3 LAYERS EACH FOLD WIDTH: 135 TO 200mm APPLICABLE RAW MATERIALS: HYDROPHILIC NON-WOVEN FABRIC ABOUT 20 GSM WATER ABSORPTION LAYER 0.5 TO 3mm CAST FILM ABOUT 25 GSM SSS SPUNBOND WEIGHT: 13 TO 15 GSM THE INNER DIAMETER OF THE RAW MATERIAL CORE: 3 INCHES (75mm) RAW MATERIAL DIAMETER: NON-WOVEN FABRIC ≦ 700mm WATER ABSORPTION LAYER ≦ 1200mm CAST FILM ≦ 400mm MACHINE SIZE (L X W X H) MACHINE: 15000 X 2000 X 1700mm VOLTAGE: 380V/50Hz POWER: 12KW (WITHOUT WOOD PULP SECTION) NET WEIGHT: 6T AIR COMPRESSOR: ≥ 0.6MPA 1.2m³/MINUTE, 15KW (CUSTOMER FURNISHES) NONWOVEN ROLL MAXIMUM DIAMETER: 650mm FILM ROLL DIAMETER: 450mm REQUIRES 2 40 FOOT HQ CONTAINERS Learn More

T-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTET-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTE TECHNICAL PARAMETERS FUNCTION: EMBOSSING, CUTTING, FOLDING OF PET PAD FOLDING METHOD: 1/3 IN THE WIDTH DIRECTION, 2 TIMES IN THE LENGTH DIRECTION RAW MATERIAL WIDTH: HYDROPHILIC CLOTH WIDTH ≦ 600mm (SLIGHTLY SMALLER THAN THE WIDTH OF THE CAST FILM) WATER ABSORPTION LAYER WIDTH = HYDROPHILIC CLOTH WIDTH: 50 TO 60mm CAST FILM WIDTH ≦ 600mm PRODUCT UNFOLDED SIZE: 400 X 600mm; 500 X 700mm; 600 X 900mm FOLDED SIZE: 135 X 200mm; 170 X 250mm; 200 X 300mm SPEED: 120 TO 150 PIECES PER MINUTE FINISHED PRODUCT LENGTH: LENGTH ERROR ≦ 5mm THE POSITION OF THE ABSORBENT LAYER: THE SAME LENGTH AS THE HYDROPHILIC CLOTH AND CAST FILM WATER-ABSORBING LAMINATED PATTERN: DIAMOND PATTERN (CUSTOMIZABLE) NUMBER OF FOLDING LAYERS: 3 LAYERS EACH FOLD WIDTH: 135 TO 200mm APPLICABLE RAW MATERIALS: HYDROPHILIC NON-WOVEN FABRIC ABOUT 20 GSM WATER ABSORPTION LAYER 0.5 TO 3mm CAST FILM ABOUT 25 GSM SSS SPUNBOND WEIGHT: 13 TO 15 GSM THE INNER DIAMETER OF THE RAW MATERIAL CORE: 3 INCHES (75mm) RAW MATERIAL DIAMETER: NON-WOVEN FABRIC ≦ 700mm WATER ABSORPTION LAYER ≦ 1200mm CAST FILM ≦ 400mm MACHINE SIZE (L X W X H) MACHINE: 15000 X 2000 X 1700mm VOLTAGE: 380V/50Hz POWER: 12KW (WITHOUT WOOD PULP SECTION) NET WEIGHT: 6T AIR COMPRESSOR: ≥ 0.6MPA 1.2m³/MINUTE, 15KW (CUSTOMER FURNISHES) NONWOVEN ROLL MAXIMUM DIAMETER: 650mm FILM ROLL DIAMETER: 450mm REQUIRES 2 40 FOOT HQ CONTAINERS Learn More