Search results for: 'Automatic d'

- Related search terms

- automatic+V

- automatic cuttin

- automatic+cuttin

- Automatic+du

- AUTOMATIC P'

-

L-7134 PP NONWOVEN FABRIC PRODUCTION LINE, SPUNBONDED, MELT BLOWN

L-7134 PP NONWOVEN FABRIC PRODUCTION LINE, SPUNBONDED, MELT BLOWNEFFECTIVE WIDTH: 1600mm

DAILY OUTPUT: 10,000 KGS PER DAY

WEIGHT RANGE: 10 TO 150 GSM

FILAMENT DIAMETER: 1.6 TO 2.0 DENIER

SPEED: 350 TO 400 METERS PER MINUTE

RAW MATERIAL: POLYPROPYLENE (PP)

DIMENSIONS: 35,000 X 15,000 X 11,000mm

VOLTAGE: 380 VOLTS, 3 PHASECONSISTING OF:

SPUNBOND EQUIPMENT

PP VACUUM SUCTION MACHINE (2)

7800 TO 900 KGS PER HOUR

AIR CAPACITY: 300 CUBIC METERS PER HOUR

POWER: 7.5 KWMASTER BATCH DOSING UNIT (2)

ACCURACY: 0.01%EXTRUDER (2)

DIAMETER: 130mm

SINGLE SCREW (2)

HEATING SYSTEM: ELECTRICITY

MOTOR: 75 KWMELT FILTRATION MACHINE (2)

PIPE SIZE: 50mm

FILTER AREA: 3.5 SQUARE METERS

MELT FLOW: 650 KGS PER HOUR

DOUBLE FILTRATION CHAMBERMELTING PUMP (2)

40 RPM

FLOW CAPACITY: 400 KGS PER HOUR

POWER: 7.5 KWSPINNING BEAM (2)

DIMENSIONS: 1900 X 256mm

HANGER TYPE MELT DISTRIBUTION

HEATING SYSTEM: OIL

WORKING TEMPERATURE: 200 TO 260 CELSIUSSPINNERET (4)

HARDNESS: 30

SIZE: 1900mm LONG X 256mm WIDE

HOLE DIAMETER 0.45mm

HOLE QUANTITY: 6500 HOLE PER METERQUENCHING UNIT (2)

WORKING TEMP: 20 CELSIUS

AIR FLOW CAPACITY: 12,000 CUBIC METERS/H

AIR PRESSURE: 6500

FILTER SIZE: 80#FILAMENT DRAFT UNITS (2)

AIR PRESSURE: 5020PA

AIR FLOW CAPACITY: 12,000 CUBIC METERS/H

INSIDE TEMP: 10 TO 25 CELSIUS

FILAMENT FINENESS: 1.6 TO 2.0 DENIERMELT BLOWN EQUIPMENT

VACUUM SUCTION MACHINE (2)

LOAD CAPACITY: 700 TO 900 KGS PER HOUR

AIR CAPACITY: 300 CUBIC METERS/H

POWER: 7.5 KWMASTER BATCH DOSING UNIT (2)

4 HOPPERS

200 KGS HOPPER LOADEXTRUDER

DIAMETER: 105mm

SINGLE SCREW

MOTOR: 18.5 KWMELT FILTER

DOUBLE CYLINDER

HYDRAULIC

MELT FLOW CAPACITY: 450 KGS/HR

FILTER SIZE: 150mm DIAMETER

ELECTRIC HEATINGMELTING PUMP

SPEED: 40 RPM

MELT FLOW CAPACITY: 450 KGS PER HOUR

POWER: 7.5 KWMELT BLOWN DIE SPINNARET

SPINNERET HOLE SIZE: 0.32 TO 0.35mm

HOLE DISTANCE: 40 TO 42 PER INCH

FABRIC WEIGHT: 2 TO 200 GSMHIGH PRESSURE AIR BLOWER

AIR FLOW CAPACITY: 70 TO 100 CUBIC METERS PER MINUTE

AIR PRESSURE: 100 KPA

POWER: 200 KWWEB FORMING MACHINE

SPEED: 100 METERS PER MINUTEELECTRIC TREATMENT

VOLTAGE: 220 VOLTS, 50 Hz

INPUT CURRENT: 3A

OUTPUT VOLTAGE: 60 KV

TREAT WEB WIDTH: 1.6 METERSHOT AIR HEATING MACHINE

WORKING TEMP: 350 CELSIUS

PRESSURE: 0.8 KPA

HEATING: ELECTRIC

POWER: 200 KWTHERMAL CALENDER

PROCESSING SPEED: 400 METERS PER MINUTE

ROLLER SIZE: 2000mm LONG, 520mm DIAMETER

EMBOSSING ROLLER: 1

LINEAR PRESSURE: 30 TO 125 N/mm

HEATING SYSTEM: OILHYDROPHILIC MACHINE

SPEED: 400 METERS PER MINUTE

FEEDING SYSTEM: DOUBLE KISSING ROLLER

KISS ROLLER DIAMETER: 215mm

LIQUID TANK: 200 KGS WITH HEAT/WARM AND MIXDRYING SYSTEM:

INFRARED + HOT AIR

DRIVE ROLL SIZE: 150mm

HEATING EQUIPMENT: QUARTZ HEATER, HOT AIR BLOWER, EXHAUST AIR BLOWERINSPECTION MACHINE

EFFECTIVE WIDTH: 1600mm

INSPECTION SPEED: 400 METERS PER MINUTE

INSPECT GSM: 10 TO 40 GSMAUTOMATIC WINDING MACHINE

SPEED: 400 METERS PER MINUTE

ROLLER DIAMETER: 2000mm

ROLLER EXCHANGE SYSTEM: AUTOMATIC

FABRIC INSPECTOR: ONLINE

POWER: 15 KWHIGH SPEED SLITTING MACHINE

PROCESS SPEED: 800 METERS PER MIN

ROLL DIAMETER: MAX 1500mm

SLITTING WIDTH: 80mm

PAPER TUBE SIZE: 76mm DIAMETER

AUTO TENSILE CONTROL: AVAILABLE ONLINE

METER COUNTING: AVAILABLE ONLINEOIL HEATER (4)

HEATING POWER: 60 KW

MOTOR POWER: 7.5 KW

OIL PUMP FLOW: 30 CUBIC METERS PER SECOND

PRESSURE: 0.4 KPAWATER CHILLER

DRIVE SYSTEM: SCREW

COOLING CAPACITY: 300,000 CALORIES

TEMP: 0 TO 20 CELSIUS

POWER: 110 KWAIR BLOWER

SPEED: 1450 RPM

AIR BLOW CAPACITY: 12,000 CUBIC METERS PER HOUR

PRESSURE: 5200 PA

POWER: 30 KW x 3, 45 KW x 1AIR COMPRESSOR

DRIVE SYSTEM: SCREW

PRESSURE: 0.8 KPA

POWER: 15 KWHEATING SYSTEM: ELECTRIC

TEMP: 350 CELSIUS

HEATING TIME: 6 TO 8 HOURS

POWER: 4 KWULTRASONIC CLEANING MACHINE

3mm THICK

SIZE: 2000 X 500mm

FREQUENCY VIBRATION: 100 KHZ

TEMP: 40 CELSIUSELECTRONIC PANEL BOARD

PLATFORM

Learn More -

V-1813 N95 MASK MAKING MACHINE, ROTARY ULTRASONIC DIE CUTTING

V-1813 N95 MASK MAKING MACHINE, ROTARY ULTRASONIC DIE CUTTINGA. SEMI-AUTOMATIC N95 FACE MASK MACHINE

30 TO 45PCS/MIN

MAXIMUM ROLL DIAMETER: 600mm

NUMBER OF ROLLS FEEDING THE MACHINE: 4 ROLLS OR 4 LAYERS

WIDTH OF THE ROLL: 230mm

TOTAL KW OF THIS MACHINE: 3KW

FREQUENCY (KHZ) OF THE ROTARY ULTRASONIC DIE: 15KHZ 2600W

DIAMETER OF THE ROTARY DIE: 74mm

FLOOR SPACE DIMENSIONS OF THIS MACHINE: 3000mm X 1500mm

MACHINE WEIGHT: 400KGS

PACKING DIMENSIONS OF THE MACHINE: 1600mm X 1000mm X 1700mm(L X W X H)

HEIGHT OF THE MACHINE: 1960mmB. N95 EARLOOP MACHINE

15 TO 20PCS/MIN

NUMBER OF PAIRS OF EAR LOOPS DONE PER MINUTE: 15 TO 20PCS/MIN

FLOOR SPACE DIMENSIONS OF THE MACHINE: 1200mm X 1000mm

MACHINE WEIGHT: 350KGS

PACKING DIMENSIONS OF THE MACHINE: 1200mm X 1000mm X 1500mm(L X W X H)

HEIGHT OF THE MACHINE: 1300mm

SPOT WELDING IS USED TO ADHERE THE CLIP TO THE MESK. NO GLUE IS USED.C. N95 SEALING MACHINE

15 TO 20PCS/MIN

TOTAL KW OF THE MACHINE: 20K 2600W

FREQUENCY (KHZ) OF THE ROTARY ULTRASONIC DIE: 20K

FLOOR SPACE DIMENSIONS OF THE MACHINE: 600mm X 600mm

MACHINE WEIGHT: 100KGS

PACKING DIMENSIONS OF THE MACHINE: 700mm X 700mm X 1300mm (L X W X H)

HEIGHT OF THE MACHINE: 1200mmD. N95 NOSE CLIP MACHINE

15 TO 20PCS/MIN

15 TO 20PCS/MIN

SEE VIDEO OF HOW THE CLIOP IS ATTACHED TO THE MASK.

DIMENSIONS OF THE MACHINE: 500mm X 500mm

WEIGHT OF THE MACHINE: 20KGS

https://youtu.be/4IGKM5TxsqYPACKED: IN ONE WOODEN CASE,

Learn More

PACKAGE SIZE: 2000mm X 1500mm X 1900mm (L X W X H),

GROSS WEIGHT: ABOUT 1000KGS

WARRANTY OF MACHINE:1.5 YEARS

LEAD TIME IS 12 DAYS AFTER ORDER IS CONFIRMED -

J-2778 SEMI-AUTOMATIC FACE MASK MACHINE FOR MASS 175 x 95mm – 200 PER MINUTE (Air Freight Available)

J-2778 SEMI-AUTOMATIC FACE MASK MACHINE FOR MASS 175 x 95mm – 200 PER MINUTE (Air Freight Available)SEMI-AUTOMATIC FACE MASK MACHINE

PRODUCES BLANK MASKS WITH NO EAR STRAPS (see our J-2779 for ear strap machine)

MASK DIMENSIONS: 175 x 95mm

CAPACITY: 150 TO 200 PIECES PER MINUTE

WEIGHT: 650 KGS

DIMENSIONS (L x W x H): 3400 x 800 x 2020mm

MATERIAL: NONWOVEN/ MELT-BLOWN FABRIC

VOLTAGE: 220 VOLTS / 380 VOLTS

POWER: 6 KWWITH ADJUSTABLE SPEED

CONSISTENT PRODUCT QUALITY

CONVENIENT OPERATION

USES ULTRASONIC WELDING TO FORM MASKSLEAD TIME: 5 DAYS FROM RECEIPT OF PAYMENT

PACKAGE 1 BY WOODEN BOX: 2400 X 1000 X 1300mm

Learn More

PACKAGE 2 BY WOODEN BOX: 2150 X 700 X 2300 mm

TOTAL WEIGHT IS EXPECTED TO BE AROUND 650KGS -

J-2765 3-LAYER FACE MASK PRODUCTION MACHINE – 150 MASKS PER MINUTE

J-2765 3-LAYER FACE MASK PRODUCTION MACHINE – 150 MASKS PER MINUTECAPACITY: 100 TO 150 MASKS PER MINUTE

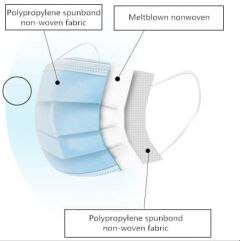

PRODUCES MASKS WITH 3 LAYERS OF POLYPROPYLENE NONWOVEN MATERIAL

AIR PRESSURE: 0.6 MPa, AIR CONSUMPTION 300 LITERS PER MINUTE

CONTROLLED BY PLC, OPERATED BY LCD TOUCH SCREEN

USES ULTRASONIC WELDING FOR EAR STRAPS

VOLTAGE: AS PER CUSTOMER

TOTAL POWER: 11 KW

DIMENSIONS: 6850 x 3520 x 1990mm

WEIGHT: ≤ 5000kgMASK SURFACE LAYER, FILTER LAYER AND BOTTOM LAYER CAN BE ALIGNED AND FED TO THE MACHINE AUTOMATICALLY

BOTH SIDES ARE SYMMETRICAL WITH ULTRASONIC PROCESS STATIONS FOR EAR STRAP WELDING

AFTER WELDING, THE MASKS ARE COUNTED AND PILED TOGETHER AUTOMATICALLY

MASKS ARE DISTRIBUTED EVENLY TO TWO SETS OF EAR STRAP STATIONS BY AUTOMATIC TRANSMISSION SYSTEM, CONTROLLED BY PLC

NOSE CLIPS CAN BE AUTOMATICALLY FED, CUT AND ULTRASONICALLY WELDEDTHE CUP TYPE MASK PRODUCTION LINE CAN BE SENT BY AIR, THERE ARE TOTAL 5 WOODEN CASES, SIZES AND WEIGHT AS BELOW:

1. 2500 X 1100 X 1000mm, 1PC, 250KGS

2. 2200 X 1000 X 1500mm, 1PC, 1100KGS

3. 3000 X 1200 X 1500mm, 1PC, 1100KGS

4. 3000 X 1200 X 1500mm, 1PC, 1100KGS

5. 1900 X 700 X 1150mm, 1PC, 250KGSIF CUSTOMER NEEDS MASK BAGGING MACHINE TO CONNECT WITH DISPOSABLE MASK PRODUCTION LINE, THERE WILL BE ANOTHER TWO WOODEN CASES EXTRA, BUT WILL CANCEL THE FIFTH WOODEN CASE, SIZES AND WEIGHT AS BELOW:

1. 1580mm X 840MM X 1510 mm,1PCS, 340KG

Learn More

2. 2540 mm X 540 mm X 1510 mm,1PCS, 80KG -

Y-2003 FULLY AUTOMATIC N95 FACE MASK MACHINE, 35 MASKS PER MINUTE

Y-2003 FULLY AUTOMATIC N95 FACE MASK MACHINE, 35 MASKS PER MINUTECAPACITY: 30-35 MASKS PER MINUTE

HIGH STABILITY, LOW FAILURE RATE

COMPUTER CONTROLLED OPERATIONS DRIVEN BY PLC

WITH AUTOMATIC TENSION CONTROL

VOLTAGE: 380 VOLTS, +5%, 50 Hz (OR AS PER CUSTOMER)

TOTAL POWER: ABOUT 15 KW

DIMENSIONS: L 10500 x W 1500 x H 2200mmQUANTITY: 1

Learn More -

V-1807 AUTOMATIC FACE MASK WITH OUTER EAR LOOP MACHINE, 120 MASKS PER MINUTE, FLAT TYPE

V-1807 AUTOMATIC FACE MASK WITH OUTER EAR LOOP MACHINE, 120 MASKS PER MINUTE, FLAT TYPEI. FUNCTION

Learn More

THE MACHINE IS FULLY AUTOMATIC EAR TO LOOP MASK MAKING MACHINE. THIS MACHINE INCLUDES ONE SET OF CS-175 AND 2 SETS CS-WD175 AND BY A UNIT OF AUTOMATED DISPENSER. MASK BODIES PRODUCED ON THE MASK MACHINE CAN BE ALLOCATED ONTO 2 SETS OF SUBSEQUENT MACHINES CONTROLLED BY PLC AT THE SPEED OF 0 TO 120 PIECES PER MINUTE. ALL OF OPERATIONS OF THE MACHINE ARE CONTROLLED THROUGH TOUCH SCREEN OR PLCS.

II. PROCESS

AFTER THE MACHINE MAKES THE MASK BODY, THE CONVEYOR BELT STRUCTURE TRANSPORTS THE MASK BODY PIECE TO THE CONNECTING CONVEYOR. THROUGH THE CONNECTION CONVEYOR MASK PLATE TO THE CONVEYOR BELT, AGAIN THROUGH THE CONVEYOR BELT THE MASK IS TRANSPORTED TO THE EAR PIECE SECTION TO THE FRONT OF THE MACHINE ABOVE THE FIRST MASK PLATE, FINALLY THROUGH THE CYLINDER DOWN THE MASK ONTO MASK EAR MACHINE DISC, FOLLOWED UP BY EAR MASKS FOR THE EARS OF THE BELT WELDING MACHINE AND THEN IT’S COMPLETE.

III. FEATURES:

1. MACHINE FRAME IS MADE OF ALUMINUM ALLOY, PREVENTED FROM RUST;

2. THE MACHINE CAN MAKE 1 TO 3 TYPES OF MASK BLANKS ACCORDING TO WHAT THE CUSTOMER REQUIRES.

3. THE SIZE OF THE MASK BLANK AND THE FOLDING LOCATION CAN BE ADJUSTED;

4. THE DIRECTION OF THE EAR LOOP IS OUTSIDE;

5. A COMPUTER PROGRAM CONTROL AND PHOTOELECTRIC DETECTION ACHIEVES A HIGH RELIABILITY AND LOW FAILURE RATE. -

J-2763 SEMI-AUTOMATIC MASK PRODUCTION LINE WITH PACKING, 100 3-LAYER MASKS PER MINUTE - NEW

J-2763 SEMI-AUTOMATIC MASK PRODUCTION LINE WITH PACKING, 100 3-LAYER MASKS PER MINUTE - NEWCOMPOSED OF

SEMI-AUTOMATIC MASK PRODUCTION MACHINE

MASK DIMENSIONS: 17.5 x 9.5mm

CAPACITY: 80 TO 100 PIECES PER MINUTE

3 LAYERS

WITH ULTRASONIC SEALING

MATERIAL: POLYPROPYLENE FABRIC

TOTAL POWER CONSUMPTION: 3 KW

POWER SUPPLY: 220 VOLTS, 50 OR 60 Hz

DIMENSIONS: 3300mm x 630mm x 1850mm

QUANTITY: 1EAR LOOP ULTRASONIC WELDING MACHINES

QUANTITY: 4MASK PACKING MACHINE

Learn More

QUANTITY: 1