Search results for: 'Mate'

- Related search terms

- material of c channel

- material panel veneer

- materi bei

-

L-7129 NONWOVEN SMS PRODUCTION LINE, 1600mm, SPUNBONDED, MELT BLOWN

L-7129 NONWOVEN SMS PRODUCTION LINE, 1600mm, SPUNBONDED, MELT BLOWNPP CHIPS FOR MELTBLOWN: 1200 TO 2000

FABRIC WIDTH: 1600mm

2 SPINNING BEAMS FOR SPUNBOND & 1 FOR MELTBLOWN

BASIC WEIGHT: SMS 9 TO 80 GRAMS PER SQUARE METER

SS: 15 TO 100 GRAMS PER SQUARE METERPRODUCT:

SMS LAMINATED NONWOVEN FABRIC

SS SPUNBOND NONWOVEN FABRIC SS

M MELTBLOWN NONWOVEN FABRIC MTO MAKE HYGENIC FABRICS SUCH AS BABY DIAPERS, SANITARY NAPKINS, ADULT DIAPERS, MEDICAL OPERATION SUITS, OPERATION CAPS, OPERATIONS SHOES, MASKS, ETC.

CONSISTING OF:

3 X FEEDING SYSTEMS

AUTOMATIC VACUUM SUCTION FOR BOTH MAIN MATERIAL AND ADDITIVES

CAPACITY (SB + MB) 2 X 520 KGS/H, (SB) 2 X 200 KGS/HR

WITH THREE HOPPERS, THREE SUPPLIYING DEVICESSPUNBOND SYSTEM

2 X EXTRUDERS

DIAMETER: 150mm

CAPACITY: 450 KGS/HR

L/D 30:1

DRIVE POWER: 110 KW

HEATING POWER: 90 KW2 X RECYCLING SYSTEMS

DIAMETER: 105mm

CAPACITY: 100 KGS PER HOUR

L/D: 15:12 X MELT FILTERS

WORKING TEMPERATURE: UP TO 280 CELSIUS

FILTRATION CAPACITY: 520 KGS PER HOUR2 X METERING PUMPS

TYPE: GEAR PUMP

FLOW VOLUME: 250 ML/R

DESIGNING TEMPERATURE: 280 CELSIUS2 X MELT PIPELINES

WITH STATIC MIXER2 X MONOMER EXHAUSTER

INCLUDING BLOWER, CHILLER, PIPELINE, VALVE, INSULATION, ETC2 X SPINNING BEAMS

SINGLE COAT-HANGER MELT DISTRIBUTION

DESIGNING PRESSURE: 9MPA

WORKING TEMPERATURE: MAX 280 CELSIUS4 X SPINNERETS

HOLE DIAMETER: 0.45mm

L/D: 5:1

15,500 HOLESMELTBLOWN SYSTEM

1 X EXTRUDER

DIAMETER 120mm

CAPACITY: 280 KGS/HR

L/D: 30:1

DRIVE POWER: 75 KW

HEATING POWER: 80 KW1 X MELT FILTER

FILTRATION PRECISION: 20 TO 60 MICROMETERS

FILTRATION: 280 KGS PER HOUR1 X METERING PUMP

GEAR PUMP

MAX. FLOW VOLUME: 100ML/R

DESIGNED TEMPERATURE: 300 CELSIUS1 X MELT PIPELINE

WITH STATIC MIXER1 X SPINNING BEAM

INCLUDING STRETCHING CHANNEL, NOZZLE, ETC. WITH INSULATION MATERIAL

DESIGNED PRESSURE: 6 MPA2 X SPINNING DIE PACKS

COMPACT DIE PACKS

HOLE DIAMETER: 0.35mm

L/D: 12:1

# OF HOLES: 42HPI1 X SCREW BLOWER

INCLUDING MUFFLE, PRESSURE REDUCER VALVE, PIPELINE, ETC.

POWER: 200 KW1 X HOT AIR SYSTEM

FLOW VOLUME: 6000 CUBIC METERS PER HOUR

WORKING TEMP: MAX 350 CELSIUS

INCLUDING HEATER, STAINLESS STEEL PIPELINE, ETC.

POWER: 290 KW1 X OFF-LINE CONVEYOR

RANGE OF SPEED: 5 TO 100 METERS PER MINUTE1 X CONVEYOR

MECHANICAL SPEED: MAX 400 METERS PER MINUTE

BELT WIDTH AND PENETRATION

3800±10mm, 10000 CUBIC METERS PER H.M21 X CALENDAR

DOUBLE ROLLS HEATED BY OIL

PROCESS SPEED: 350 METERS PER MINUTE

EMBOSSING WIDTH: UP TO 2000mm

MAX LINEAR PRESSURE: 110 DAN/C

MAX. TEMP OF EMBOSSING ROLLER, 180 CELSIUS1 X WINDER

ONLINE CHANGING ROLL, ONLINE EDGE CUTTING, TENSION CONTROL

MAX. LINEAR SPEED: 350 METERS PER MINUTE

WIDTH: 1600mm

WIND DIAMETER: MAX 1500mm1 X SLITTER

MAX. LINE SPEED: 600 METERS PER MINUTE

MAX. WIND DIAMETER: 1200mm

MIN. SLITTING WIDE: 120mm

22 CIRCULAR BLADES1 X STEEL PLATFORM

1 X ELECTRICAL CONTROL SYSTEM

2 X OIL OVEN

1 X AIR CONDITIONING SYSTEM

1 X WATER COOLING SYSTEM

1 X CLEANING EQUIPMENTS FOR DIE PACK

1 X AUXILIARY PLATFORM

1 X AUXILIARY EQUIPMENTS

1 X LABORATORY TESTING DEVICE

Learn More -

L-7134 PP NONWOVEN FABRIC PRODUCTION LINE, SPUNBONDED, MELT BLOWN

L-7134 PP NONWOVEN FABRIC PRODUCTION LINE, SPUNBONDED, MELT BLOWNEFFECTIVE WIDTH: 1600mm

DAILY OUTPUT: 10,000 KGS PER DAY

WEIGHT RANGE: 10 TO 150 GSM

FILAMENT DIAMETER: 1.6 TO 2.0 DENIER

SPEED: 350 TO 400 METERS PER MINUTE

RAW MATERIAL: POLYPROPYLENE (PP)

DIMENSIONS: 35,000 X 15,000 X 11,000mm

VOLTAGE: 380 VOLTS, 3 PHASECONSISTING OF:

SPUNBOND EQUIPMENT

PP VACUUM SUCTION MACHINE (2)

7800 TO 900 KGS PER HOUR

AIR CAPACITY: 300 CUBIC METERS PER HOUR

POWER: 7.5 KWMASTER BATCH DOSING UNIT (2)

ACCURACY: 0.01%EXTRUDER (2)

DIAMETER: 130mm

SINGLE SCREW (2)

HEATING SYSTEM: ELECTRICITY

MOTOR: 75 KWMELT FILTRATION MACHINE (2)

PIPE SIZE: 50mm

FILTER AREA: 3.5 SQUARE METERS

MELT FLOW: 650 KGS PER HOUR

DOUBLE FILTRATION CHAMBERMELTING PUMP (2)

40 RPM

FLOW CAPACITY: 400 KGS PER HOUR

POWER: 7.5 KWSPINNING BEAM (2)

DIMENSIONS: 1900 X 256mm

HANGER TYPE MELT DISTRIBUTION

HEATING SYSTEM: OIL

WORKING TEMPERATURE: 200 TO 260 CELSIUSSPINNERET (4)

HARDNESS: 30

SIZE: 1900mm LONG X 256mm WIDE

HOLE DIAMETER 0.45mm

HOLE QUANTITY: 6500 HOLE PER METERQUENCHING UNIT (2)

WORKING TEMP: 20 CELSIUS

AIR FLOW CAPACITY: 12,000 CUBIC METERS/H

AIR PRESSURE: 6500

FILTER SIZE: 80#FILAMENT DRAFT UNITS (2)

AIR PRESSURE: 5020PA

AIR FLOW CAPACITY: 12,000 CUBIC METERS/H

INSIDE TEMP: 10 TO 25 CELSIUS

FILAMENT FINENESS: 1.6 TO 2.0 DENIERMELT BLOWN EQUIPMENT

VACUUM SUCTION MACHINE (2)

LOAD CAPACITY: 700 TO 900 KGS PER HOUR

AIR CAPACITY: 300 CUBIC METERS/H

POWER: 7.5 KWMASTER BATCH DOSING UNIT (2)

4 HOPPERS

200 KGS HOPPER LOADEXTRUDER

DIAMETER: 105mm

SINGLE SCREW

MOTOR: 18.5 KWMELT FILTER

DOUBLE CYLINDER

HYDRAULIC

MELT FLOW CAPACITY: 450 KGS/HR

FILTER SIZE: 150mm DIAMETER

ELECTRIC HEATINGMELTING PUMP

SPEED: 40 RPM

MELT FLOW CAPACITY: 450 KGS PER HOUR

POWER: 7.5 KWMELT BLOWN DIE SPINNARET

SPINNERET HOLE SIZE: 0.32 TO 0.35mm

HOLE DISTANCE: 40 TO 42 PER INCH

FABRIC WEIGHT: 2 TO 200 GSMHIGH PRESSURE AIR BLOWER

AIR FLOW CAPACITY: 70 TO 100 CUBIC METERS PER MINUTE

AIR PRESSURE: 100 KPA

POWER: 200 KWWEB FORMING MACHINE

SPEED: 100 METERS PER MINUTEELECTRIC TREATMENT

VOLTAGE: 220 VOLTS, 50 Hz

INPUT CURRENT: 3A

OUTPUT VOLTAGE: 60 KV

TREAT WEB WIDTH: 1.6 METERSHOT AIR HEATING MACHINE

WORKING TEMP: 350 CELSIUS

PRESSURE: 0.8 KPA

HEATING: ELECTRIC

POWER: 200 KWTHERMAL CALENDER

PROCESSING SPEED: 400 METERS PER MINUTE

ROLLER SIZE: 2000mm LONG, 520mm DIAMETER

EMBOSSING ROLLER: 1

LINEAR PRESSURE: 30 TO 125 N/mm

HEATING SYSTEM: OILHYDROPHILIC MACHINE

SPEED: 400 METERS PER MINUTE

FEEDING SYSTEM: DOUBLE KISSING ROLLER

KISS ROLLER DIAMETER: 215mm

LIQUID TANK: 200 KGS WITH HEAT/WARM AND MIXDRYING SYSTEM:

INFRARED + HOT AIR

DRIVE ROLL SIZE: 150mm

HEATING EQUIPMENT: QUARTZ HEATER, HOT AIR BLOWER, EXHAUST AIR BLOWERINSPECTION MACHINE

EFFECTIVE WIDTH: 1600mm

INSPECTION SPEED: 400 METERS PER MINUTE

INSPECT GSM: 10 TO 40 GSMAUTOMATIC WINDING MACHINE

SPEED: 400 METERS PER MINUTE

ROLLER DIAMETER: 2000mm

ROLLER EXCHANGE SYSTEM: AUTOMATIC

FABRIC INSPECTOR: ONLINE

POWER: 15 KWHIGH SPEED SLITTING MACHINE

PROCESS SPEED: 800 METERS PER MIN

ROLL DIAMETER: MAX 1500mm

SLITTING WIDTH: 80mm

PAPER TUBE SIZE: 76mm DIAMETER

AUTO TENSILE CONTROL: AVAILABLE ONLINE

METER COUNTING: AVAILABLE ONLINEOIL HEATER (4)

HEATING POWER: 60 KW

MOTOR POWER: 7.5 KW

OIL PUMP FLOW: 30 CUBIC METERS PER SECOND

PRESSURE: 0.4 KPAWATER CHILLER

DRIVE SYSTEM: SCREW

COOLING CAPACITY: 300,000 CALORIES

TEMP: 0 TO 20 CELSIUS

POWER: 110 KWAIR BLOWER

SPEED: 1450 RPM

AIR BLOW CAPACITY: 12,000 CUBIC METERS PER HOUR

PRESSURE: 5200 PA

POWER: 30 KW x 3, 45 KW x 1AIR COMPRESSOR

DRIVE SYSTEM: SCREW

PRESSURE: 0.8 KPA

POWER: 15 KWHEATING SYSTEM: ELECTRIC

TEMP: 350 CELSIUS

HEATING TIME: 6 TO 8 HOURS

POWER: 4 KWULTRASONIC CLEANING MACHINE

3mm THICK

SIZE: 2000 X 500mm

FREQUENCY VIBRATION: 100 KHZ

TEMP: 40 CELSIUSELECTRONIC PANEL BOARD

PLATFORM

Learn More -

J-2788 SEMI-AUTOMATIC DISPOSABLE FLAT MASK PRODUCTION LINE

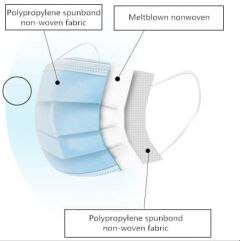

J-2788 SEMI-AUTOMATIC DISPOSABLE FLAT MASK PRODUCTION LINE3 LAYER MASKS CONSTRUCTED OF NONWOVEN AND MELTBLOWN FABRIC

MASK DIMENSIONS: 175 x 95mm (ADULT) & 145 x 90mm (CHILD)---COMPOSED OF TWO MACHINES, AS BELOW

1) AUTOMATIC MASK LAYER MAKING AND CUTTING MACHINE

CAPACITY: 200 TO 300 PIECES PER MINUTE

INCLUDES

• MATERIAL FEEDING FRAME

• MACHINE FRAME

• ALUMINUM NOSE STRIP INSERTION

• ULTRASONIC WELDING

• CONVEYOR

DIMENSIONS: 4600 x 500 x 2100mm

WEIGHT: 300 KGS

POWER: 220 VOLTS, 50 Hz (OR AS PER CUSTOMER)

2) MANUAL EAR BAND WELDING MACHINE

CAPACITY: 30 TO 40 PIECES PER MINUTE

INCLUDES

• WORKBENCH

• LIGHT

• AIR CYLINDER

• ULTRASONIC GENERATOR

• CONTROL SYSTEM

DIMENSIONS: 800 x 500 x 1000mm

WEIGHT: 43 KGS

POWER: 380 VOLTS, 50 Hz (OR AS PER CUSTOMER)WARRANTY: 1 YEAR FOR MAJOR COMPONENTS, LIFELONG SERVICE FOR THE USER

QUANTITY: 1 COMPLETE SEMI-AUTOMATIC LINE

Learn More -

J-2765 3-LAYER FACE MASK PRODUCTION MACHINE – 150 MASKS PER MINUTE

J-2765 3-LAYER FACE MASK PRODUCTION MACHINE – 150 MASKS PER MINUTECAPACITY: 100 TO 150 MASKS PER MINUTE

PRODUCES MASKS WITH 3 LAYERS OF POLYPROPYLENE NONWOVEN MATERIAL

AIR PRESSURE: 0.6 MPa, AIR CONSUMPTION 300 LITERS PER MINUTE

CONTROLLED BY PLC, OPERATED BY LCD TOUCH SCREEN

USES ULTRASONIC WELDING FOR EAR STRAPS

VOLTAGE: AS PER CUSTOMER

TOTAL POWER: 11 KW

DIMENSIONS: 6850 x 3520 x 1990mm

WEIGHT: ≤ 5000kgMASK SURFACE LAYER, FILTER LAYER AND BOTTOM LAYER CAN BE ALIGNED AND FED TO THE MACHINE AUTOMATICALLY

BOTH SIDES ARE SYMMETRICAL WITH ULTRASONIC PROCESS STATIONS FOR EAR STRAP WELDING

AFTER WELDING, THE MASKS ARE COUNTED AND PILED TOGETHER AUTOMATICALLY

MASKS ARE DISTRIBUTED EVENLY TO TWO SETS OF EAR STRAP STATIONS BY AUTOMATIC TRANSMISSION SYSTEM, CONTROLLED BY PLC

NOSE CLIPS CAN BE AUTOMATICALLY FED, CUT AND ULTRASONICALLY WELDEDTHE CUP TYPE MASK PRODUCTION LINE CAN BE SENT BY AIR, THERE ARE TOTAL 5 WOODEN CASES, SIZES AND WEIGHT AS BELOW:

1. 2500 X 1100 X 1000mm, 1PC, 250KGS

2. 2200 X 1000 X 1500mm, 1PC, 1100KGS

3. 3000 X 1200 X 1500mm, 1PC, 1100KGS

4. 3000 X 1200 X 1500mm, 1PC, 1100KGS

5. 1900 X 700 X 1150mm, 1PC, 250KGSIF CUSTOMER NEEDS MASK BAGGING MACHINE TO CONNECT WITH DISPOSABLE MASK PRODUCTION LINE, THERE WILL BE ANOTHER TWO WOODEN CASES EXTRA, BUT WILL CANCEL THE FIFTH WOODEN CASE, SIZES AND WEIGHT AS BELOW:

1. 1580mm X 840MM X 1510 mm,1PCS, 340KG

Learn More

2. 2540 mm X 540 mm X 1510 mm,1PCS, 80KG -

Y-2004 FACE MASK MACHINE, 120 MASKS PER MINUTE, FOR MASKS WITH 1 TO 4 LAYERS

Y-2004 FACE MASK MACHINE, 120 MASKS PER MINUTE, FOR MASKS WITH 1 TO 4 LAYERSCAPACITY: 100 TO 120 PER MINUTE

AUTOMATIC CONVEYING

CUT OFF THE BRIDGE OF THE NOSE

MASK EDGE WELDING

FOLDING

ULTRASONIC FUSION

WITH AUTOMATED MOLDING AND CUTTING

IT CAN BE USED AS A MASK WITH 1-4 LAYERS OF CLOTH ( THE ACTIVATED CARBON MATERIAL CAN BE

ADDED IN THE MIDDLE )

RATED POWER 10KW ( INCLUDING WELDING MACHINE)

DIMENSIONS: SIZE (L) 6500 x 3500 (W) x 1950 (H) mmQUANTITY: 1

Learn More -

V-1806 HALF AUTOMATIC FACE MASK WITH INNER EAR LOOP PACKING MACHINE

V-1806 HALF AUTOMATIC FACE MASK WITH INNER EAR LOOP PACKING MACHINEI. FUNCTION

Learn More

THIS MACHINE IS USED TO PACK DISPOSABLE SURGICAL FACE MASK WITH THE SIZE OF 190 X 65mm. IT CAN ALSO BE USED TO PACK OTHER PRODUCTS SUCH AS WET TISSUE.

II. FEATURES:

1. ONE SET OF INK TO INJECT PRINTER IS INCLUDED; IT CAN BE USED TO PRINT THE DATA AND OTHER INFORMATION.

2. THE AIR COMPRESSOR EQUIPMENT IS OPTIONAL.

3. PACKING MATERIAL: SINGLE TO SIDE HEAT TO SEALING PACKAGING FILM MATERIALS, SUCH AS OPP, CPP, OPP COMPOSITE PE, PET COMPOSITE PE, SINGLE TO LAYER OR COMPOSITE PACKAGING FILM MATERIALS.

4. BAG FORM: BACK TO SEALED PACKING, CAN BE CUSTOMIZED.

5. VERTICAL/HORIZONTAL SEAL: RETICULATED PACKAGING/VERTICAL AND RETICULATED PACKAGING.

III. SPECIFICATION:

NAME: PILLOW PACKING MACHINE

TYPE KD TO 350

APPLICATION: FOR ALL KINDS OF OPP HEAT TO SEALING FILM, COMPOSITE FILM, SPRAY FILM PAPER, ALUMINUM FOIL FILM, ALUMINUM PLASTIC COMPOSITE FILM

MACHINE SIZE: 4600 X 850 X 1500

PACKING SPEED: 60 TO 220 BAG/MIN

MAX. PACKING SIZE: 330mm, 150mm, 80mm. LENGTH: 330mm, WIDTH: 150mm, HEIGHT: 80mm

MIN. PACKING SIZE: 50mm, 10mm, 5mm. LENGTH: 50mm, WIDTH: 10mm, HEIGHT: 5mm

ELECTRICAL: AC220V, 2.7KW

AIR PRESSURE 0.5 TO 0.7 MPA

AIR CONSUMPTION: >0.36 (M3/H)

(DB) NOISE: 60 TO 70DB

MACHINE WEIGHT: 550KG

MOTOR FREQUENCY ADJUST: 0 TO 50HZ

AUTOMATIC CONTROL

AUTOMATIC PRINTING

STANDARD: GMP STANDARD, PACKAGING MACHINE ENTERPRISE STANDARD

APPROVAL: ISO9001:2000, CE ISO:2000 -

J-2733 COMPLETE AUTOMATIC PRODUCTION LINE FOR FACE MASKS – 140,000 PIECES PER 24-HOUR DAY

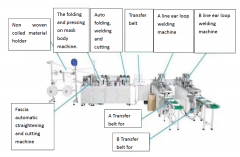

J-2733 COMPLETE AUTOMATIC PRODUCTION LINE FOR FACE MASKS – 140,000 PIECES PER 24-HOUR DAYPRODUCES FLAT MASKS AUTOMATICALLY: COILS STOCK, FOLDS AND PRESSES, MOLDS MASK, CUTS, LOADS AND WELDS EAR LOOPS, FINISHED PRODUCTS EXIT THE MACHINE

Learn More

MASKS ARE COMFORTABLE, NO PRESSURE, EASY TO WEAR AND PROVIDE GOOD FILTRATION

LINE FEATURES

ULTRASONIC WELDING MACHINE

HIGH SPEED PRODUCTION: 120,000 TO 140,000 PIECES PER 24-HOUR DAY

-APPROXIMATELY 90 TO 110 PIECES PER MINUTE

MODULAR AND PERSONNEL-FRIENDLY DESIGN WITH EASY MAINTENANCE

AUTOMATIC STOP AND ALARM FEATURE FOR MATERIAL BREAKAGE AND OTHER EXCEPTIONS, WITH ON-SCREEN HELP FOR CORRECTING THE BREAKAGE/EXCEPTIONS

DIMENSIONS: 6500mm LENGTH x 2500mm WIDTH x 1950mm HEIGHT

WEIGHT: </= 5000 KG

POWER: 220 VOLTS +/- 5% , 50 Hz, GROUND PROTECTION (OR AS PER CUSTOMER)

TOTAL KW: APPROXIMATELY 8.8 KW

AIR: 0.4 TO 0.6 MP (CLEAN AIR AFTER DEWATER, OIL-LESS, FILTRATION AND PRESSURE)

MAIN ACCESSORY: AIRTAC AIR CYLINDER

QUANTITY: 1 COMPLETE LINE (2 SETS CURRENTLY AVAILABLE MARCH 17TH)