Search results for: 'used S'

- Related search terms

- used fo

- Used Ga

- used foam gr

- used+foam+cutting+machine

- Used+Gas+Turbine+Generator

-

A-2611 ULTRAVIOLET AGING TESTING CHAMBER BOX TYPEA-2611 ULTRAVIOLET AGING TESTING CHAMBER BOX TYPE FLUORESCENT UV LAMP IS IMPORTED FOR THIS ACCELERATED AGING TEST CHAMBER. CAN SIMULATE HARM BY SUNLIGHT, RAINWATER AND DEW. UV WEATHER RESISTANCE CHAMBER USE FLUORESCENT UV LAMP TO SIMULATES THE EFFECT OF SUNLIGHT, CONDENSATION MOISTURE IS USED TO SIMULATE DEW. THE TESTED MATERIAL IS PLACED IN A LOOP PROGRAM THAT ALTERNATES LIGHT AND MOISTURE AT A CERTAIN TEMPERATURE. THE MATERIAL WAS TESTED FOR ACCELERATED WEATHERABILITY. UV CHAMBER CAN RE-CREATE HAZARDS THAT OCCUR OUTDOORS FOR MONTHS OR YEARS.THE TYPES OF HAZARDS INCLUDE: DISCOLORATION, CHALKINESS, POWDER LIGHT, CRACKING, TURBIDITY, BUBBLES, BRITTLE, STRENGTH, DECAY, OXIDATION, ETC. THIS MACHINE INCLUDES SPRAY DEVICE. Learn More

A-2611 ULTRAVIOLET AGING TESTING CHAMBER BOX TYPEA-2611 ULTRAVIOLET AGING TESTING CHAMBER BOX TYPE FLUORESCENT UV LAMP IS IMPORTED FOR THIS ACCELERATED AGING TEST CHAMBER. CAN SIMULATE HARM BY SUNLIGHT, RAINWATER AND DEW. UV WEATHER RESISTANCE CHAMBER USE FLUORESCENT UV LAMP TO SIMULATES THE EFFECT OF SUNLIGHT, CONDENSATION MOISTURE IS USED TO SIMULATE DEW. THE TESTED MATERIAL IS PLACED IN A LOOP PROGRAM THAT ALTERNATES LIGHT AND MOISTURE AT A CERTAIN TEMPERATURE. THE MATERIAL WAS TESTED FOR ACCELERATED WEATHERABILITY. UV CHAMBER CAN RE-CREATE HAZARDS THAT OCCUR OUTDOORS FOR MONTHS OR YEARS.THE TYPES OF HAZARDS INCLUDE: DISCOLORATION, CHALKINESS, POWDER LIGHT, CRACKING, TURBIDITY, BUBBLES, BRITTLE, STRENGTH, DECAY, OXIDATION, ETC. THIS MACHINE INCLUDES SPRAY DEVICE. Learn More -

TT-1040 COMPUTERIZED TENSILE TESTING MACHINE, 150KNTT-1040 COMPUTERIZED TENSILE TESTING MACHINE, 150KN COMPUTERIZED TENSILE TESTING MACHINE KEY SPECIFICATION: CAPACITY: KGF 3000, 5000, 10000, 15000 KN 30, 50, 100, 150 UNIT: LOAD N, KN, G, KG, TON, LB DISPLACEMENT: mm, CM, INCH LOAD RESOLUTION: 1/20,000 LOAD ACCURACY: ±1% (±0.5% OPTIONAL) LOAD AMPLIFICATION: X 1, X 2, X 5, X 10 AUTO RANGE TESTING WIDTH (mm): 560 (800 OPTIONAL) CROSSHEAD TRAVEL (mm): 980 (1480 OPTIONAL) TESTING STROKE: CROSSHEAD TRAVEL MINUS UPPER/LOWER GRIPS AND GRIPPING LENGTH TEST SPEED RANGE (mm/MIN): 0.5~500 OR 0.2~200, 0.2~200 OR 0.5~500 MAXIMUM FORCE AT FULL SPEED (KGF): 1000, 2000 MAXIMUM SPEED AT FULL LOAD (mm/MIN): 100, 50 SPEED ACCURACY: ±0.5% SERVO CONTROL DISPLACEMENT RESOLUTION: 0.001 DRIVING METHOD: AC SERVO MOTOR POWER SPECIFICATIONS: 3Ø, 220VAC, 50/60Hz (380/415V OPTIONAL) CONSUMPTION: 3000 KGF 30 KN 5000 KGF 50 KN 10000 KGF 100 KN 15000 KGF 150 KN 2 KVA, 3 KVA, 5 KVA, 10 KVA DIMENSIONS FRAME (mm): 1300 X 600 X 2130 1540 X 600 X 2130 1300 X 600 X 2630 1540 X 600 X 2630 CONTROL BOX (mm) COMPUTER TYPE 1200 X 600 X 740 MICRO-COMPUTER TYPE 660 X 600 X 740 WEIGHT (KG) FRAME 800, CONTROL BOX 100 FRAME 1200, CONTROL BOX 100 STANDARD ACCESSORIES: TENSILE GRIPS X 1 SET, NECESSARY TOOLS X 1 SET, OPERATIONAL MANUAL X 1 COPY, CERTIFICATE OF CALIBRATION X 1 COPY Learn More

TT-1040 COMPUTERIZED TENSILE TESTING MACHINE, 150KNTT-1040 COMPUTERIZED TENSILE TESTING MACHINE, 150KN COMPUTERIZED TENSILE TESTING MACHINE KEY SPECIFICATION: CAPACITY: KGF 3000, 5000, 10000, 15000 KN 30, 50, 100, 150 UNIT: LOAD N, KN, G, KG, TON, LB DISPLACEMENT: mm, CM, INCH LOAD RESOLUTION: 1/20,000 LOAD ACCURACY: ±1% (±0.5% OPTIONAL) LOAD AMPLIFICATION: X 1, X 2, X 5, X 10 AUTO RANGE TESTING WIDTH (mm): 560 (800 OPTIONAL) CROSSHEAD TRAVEL (mm): 980 (1480 OPTIONAL) TESTING STROKE: CROSSHEAD TRAVEL MINUS UPPER/LOWER GRIPS AND GRIPPING LENGTH TEST SPEED RANGE (mm/MIN): 0.5~500 OR 0.2~200, 0.2~200 OR 0.5~500 MAXIMUM FORCE AT FULL SPEED (KGF): 1000, 2000 MAXIMUM SPEED AT FULL LOAD (mm/MIN): 100, 50 SPEED ACCURACY: ±0.5% SERVO CONTROL DISPLACEMENT RESOLUTION: 0.001 DRIVING METHOD: AC SERVO MOTOR POWER SPECIFICATIONS: 3Ø, 220VAC, 50/60Hz (380/415V OPTIONAL) CONSUMPTION: 3000 KGF 30 KN 5000 KGF 50 KN 10000 KGF 100 KN 15000 KGF 150 KN 2 KVA, 3 KVA, 5 KVA, 10 KVA DIMENSIONS FRAME (mm): 1300 X 600 X 2130 1540 X 600 X 2130 1300 X 600 X 2630 1540 X 600 X 2630 CONTROL BOX (mm) COMPUTER TYPE 1200 X 600 X 740 MICRO-COMPUTER TYPE 660 X 600 X 740 WEIGHT (KG) FRAME 800, CONTROL BOX 100 FRAME 1200, CONTROL BOX 100 STANDARD ACCESSORIES: TENSILE GRIPS X 1 SET, NECESSARY TOOLS X 1 SET, OPERATIONAL MANUAL X 1 COPY, CERTIFICATE OF CALIBRATION X 1 COPY Learn More -

V-1820 MASK AND RESPIRATOR FIELD TESTER

V-1820 MASK AND RESPIRATOR FIELD TESTERMAINLY USED FOR VISUAL FIELD TESTING OF MASKS AND RESPIRATORS, WHICH IS USEFUL FOR MASK AND RESPIRATOR MANUFACTURERS, QUALITY SUPERVISORS, SCIENTIFIC RESEARCH, AND FOR TESTING PRIOR TO SELLING MASKS.

FEATURES:

1. THE EQUIPMENT IS COMPOSED OF A SEMI-ARC BOW, RECORDING DEVICE, SEAT FRAME AND TEST HEAD DIE.

2. SEMI-ARC BOW: THE RADIUS IS 300 TO 340 mm

CAN BE ROTATED AROUND THE HORIZONTAL RADIUS PLANE PASSING THROUGH THE POINT 0°, AND A SCALE EXTENDING TO THE 90° ARC BOW EVERY 5° FROM 0° ON BOTH SIDES, EQUIPPED WITH SLIDING WHITE VISUAL STANDARD.

3. RECORDING DEVICE: THE RECORDING NEEDLE IS CONNECTED WITH THE VISUAL STANDARD THROUGH COMPONENTS SUCH AS AXLE WHEEL, AND THE DIRECTION AND ANGLE OF THE VISUAL STANDARD ARE RECORDED ON THE VISUAL FIELD DRAWING CORRESPONDINGLY.

4. SEAT FRAME: USED TO SUPPORT SEMI-CIRCULAR ARC BOW AND FIXED RECORDING DEVICE.

5. TEST THE HEAD MOLD: A STANDARD HEAD MOLD, THE TWO EYE HOLES OF THE HEAD MOLD ARE EQUIPPED WITH SMALL LIGHT BULBS, THE POSITION OF THE BULB AND THE POSITION OF THE HEAD MOLD ARE ACCORDING TO THE REQUIREMENTS OF GB 2890. THE TEST HEAD DIE MUST BE INSTALLED ON THE WORKBENCH IN SUCH A WAY THAT THE LEFT AND RIGHT EYES ARE PLACED AT THE CENTER OF THE SEMICIRCULAR ARCH AND THE "0" POINT IS DIRECTLY SEEN.MAIN INDICATORS

Learn More

1. SEMI-CIRCULAR ARC RADIUS: 335mm.

2. LEFT AND RIGHT FIELD OF VIEW: ≤120°.

3. BULB DISTANCE: THE VERTEX OF THE BULB IS CONNECTED AFTER THE TWO EYE POINTS (7±0.5).

APPLICABLE STANDARDS: GB/T 32610-2016, GB 2626-2019, GB2890-2009 -

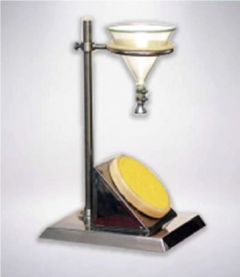

T-6548 FABRIC SURFACE WETTING TESTER

T-6548 FABRIC SURFACE WETTING TESTERREFERENCE NUMBER: T-6548

FABRIC SURFACE WETTING TESTER

INSTRUMENT TECHNICAL DESCRIPTION:

WATER TESTER IS TO INSTALL THE SAMPLE ON THE SAMPLE HOLDER AND MAKE AN ANGLE OF 45 ° WITH THE LEVEL. THE CENTER OF THE SAMPLE IS LOCATED AT A SPECIFIED DISTANCE BELOW THE NOZZLE. THE SAMPLE IS SPRAYED WITH A SPECIFIED VOLUME OF DISTILLED OR DEIONIZED WATER. BY COMPARING THE APPEARANCE OF THE SAMPLE WITH THE EVALUATION STANDARDS AND PICTURES TO DETERMINE ITS WATER-SOAKING GRADE, IT IS SUITABLE FOR MEASURING VARIOUS WATER-SOAKING TESTS ON THE SURFACE OF FABRICS WITH OR WITHOUT WATER RESISTANCE AND WATER REPELLENT FINISHING. THIS INSTRUMENT IS NOT SUITABLE FOR MEASURING THE WATER PERMEABILITY OF FABRICS, SO IT CANNOT BE USED TO PREDICT THE RAINPROOF PERMEABILITY OF FABRICS.

STANDARD:

GB19082-2009 TECHNICAL REQUIREMENTS FOR MEDICAL PRIMARY PROTECTIVE CLOTHINGGB / T4745 SURFACE MOISTURE RESISTANCE TEST

THE MAIN TECHNICAL INDICATORS OF THE INSTRUMENT:

GLASS FUNNEL: φ150mm

MEASURING CUP: 500ML

SAMPLE SUPPORT ANGLE: 45 °

INSTRUMENT CONFIGURATION:

1. ONE HOST

2. A GLASS FUNNEL

3. 500ML MEASURING CUP

QUANTITY: 1

Learn More -

T-6549 CONSTANT TEMPERATURE AND HUMIDITY CHAMBER -FABRIC WATER VAPOR TRANSMISSION RATE

T-6549 CONSTANT TEMPERATURE AND HUMIDITY CHAMBER -FABRIC WATER VAPOR TRANSMISSION RATEREFERENCE NUMBER: T-6549

CONSTANT TEMPERATURE AND HUMIDITY CHAMBER -FABRIC WATER VAPOR TRANSMISSION RATE

TESTING METER (WITH MOISTURE PERMEABLE CUP)

TECHNICAL DESCRIPTION OF THE INSTRUMENT:

IT IS MAINLY USED TO MEASURE THE MOISTURE PERMEABILITY OF ALL KINDS OF FABRICS, INCLUDING PERMEABLE COATED FABRICS. STRUCTURE PRINCIPLE: ADOPT COMPUTER CONTROL, CREATING A CONSTANT TEMPERATURE, AND HUMIDITY TEST ENVIRONMENT, TEST ENVIRONMENT IN THE CONSTANT TEMPERATURE, AND HUMIDITY, MOISTURE VAPOR TRANSMISSION CUP, PLACED 6 SAMPLE INTO THE GLASS AND THE RUBBER GASKET SEAL, THE CONTAINING HYGROSCOPIC AGENT OR WATER SEAL IS SPECIFIED BY THE WET CUP PLACED IN THE FABRIC SAMPLE TEMPERATURE AND HUMIDITY OF THE ENVIRONMENT, THE SEAL MOISTURE VAPOR TRANSMISSION CUP ACCORDING TO A CERTAIN TIME (INCLUDING SAMPLE AND HYGROSCOPIC AGENT OR WATER) TO CALCULATE THE MOISTURE TRANSMISSION QUALITY CHANGE.

TESTING STANDARD:

GB19082-2009 MEDICAL PRIMARY PROTECTIVE CLOTHING

TECHNICAL REQUIREMENTS GUIDELINES FOR THE SELECTION OF YY-T1498-2016 MEDICAL PROTECTIVE CLOTHING

GB/T12704.1 DETERMINATION OF MOISTURE PERMEABILITY OF FABRICS --HYGROSCOPIC METHOD

DETAILED TECHNICAL SPECIFICATIONS AND CONFIGURATION:

TECHNICAL INDICATORS:

1. TEMPERATURE CONTROL RANGE: -40°C ~ 150°C;RESOLUTION; 0.1 °C

2. HUMIDITY CONTROL RANGE: 50%RH ~ 95% RH±5%

3. SPEED RANGE: 2mm ~ 60mm/MIN

4. CONTROL PRECISION: TEMPERATURE <0.1°C; HUMIDITY + / -1% RH OR LESS

5. CYCLIC WIND SPEED: 0.02 ~ 0.5M/S, 0.3 ~ 0.5M/S

6. TIME CONTROL: 1 ~ 9999H

7. MOISTURE PERMEABLE AREA: 2827 mm 2 (DIAMETER IS 60 mm --NATIONAL STANDARD)

8. QUANTITY OF PERMEABLE CUPS: 6 GB;

9. DRYING BOX CONTROL TEMPERATURE: ROOM TEMPERATURE ~ 199 °C

10. TEST TIME: 1 ~ 999H

11. DRYING BOX STUDIO SIZE: 490 X 400 X 215mm

INSTRUMENT CONFIGURATION:

1. ONE MAIN MACHINE

QUANTITY: 1

Learn More -

TT-1041UNIVERSAL TENSILE STRENGTH TESTER, 50KNTT-1041UNIVERSAL TENSILE STRENGTH TESTER, 50KN 50KN TENSILE STRENGTH TEST KEY SPECIFICATIONS: CAPACITY KGF 5000, 10000, 15000 KN 50, 100, 150 UNIT: LOAD N, KN, G, KG, TON, LB DISPLACEMENT: mm, CM, INCH LOAD RESOLUTION: 1/20,000 LOAD ACCURACY: ±1% (±0.5% OPTIONAL) LOAD AMPLIFICATION: X 1, X 2, X 5, X 10 AUTO RANGE TESTING WIDTH (mm): 800 CROSSHEAD TRAVEL (mm): 1480 TESTING STROKE: CROSSHEAD TRAVEL MINUS UPPER/LOWER GRIPS AND GRIPPING LENGTH TEST SPEED RANGE (mm/MIN): 0.5~500 OR 0.2~200 MAXIMUM FORCE AT FULL SPEED (KGF): 2000 MAXIMUM SPEED AT FULL LOAD (mm/MIN): 100 SPEED ACCURACY: ±0.5% SERVO CONTROL DISPLACEMENT RESOLUTION (mm): 0.001 DRIVING METHOD: AC SERVO MOTOR POWER: SPECIFICATIONS 3Ø, 220VAC, 50/60Hz (380/415V OPTIONAL) CAPACITY: 5000KGF, 10000KGF, 15000KGF 50KN, 100KN, 150KN CONSUMPTION: 3KVA DIMENSIONS: FRAME (mm) 1540 X 600 X 2130 CONTROL BOX (mm): COMPUTER TYPE 1200 X 600 X 740 MICRO-COMPUTER TYPE 660 X 600 X 740 WEIGHT (KG): FRAME 800, CONTROL BOX 100 STANDARD ACCESSORIES: TENSILE GRIPS X 1 SET, NECESSARY TOOLS X 1 SET, OPERATIONAL MANUAL X 1 COPY, CERTIFICATE OF CALIBRATION X 1 COPY QUANTITY: 1 Learn More

TT-1041UNIVERSAL TENSILE STRENGTH TESTER, 50KNTT-1041UNIVERSAL TENSILE STRENGTH TESTER, 50KN 50KN TENSILE STRENGTH TEST KEY SPECIFICATIONS: CAPACITY KGF 5000, 10000, 15000 KN 50, 100, 150 UNIT: LOAD N, KN, G, KG, TON, LB DISPLACEMENT: mm, CM, INCH LOAD RESOLUTION: 1/20,000 LOAD ACCURACY: ±1% (±0.5% OPTIONAL) LOAD AMPLIFICATION: X 1, X 2, X 5, X 10 AUTO RANGE TESTING WIDTH (mm): 800 CROSSHEAD TRAVEL (mm): 1480 TESTING STROKE: CROSSHEAD TRAVEL MINUS UPPER/LOWER GRIPS AND GRIPPING LENGTH TEST SPEED RANGE (mm/MIN): 0.5~500 OR 0.2~200 MAXIMUM FORCE AT FULL SPEED (KGF): 2000 MAXIMUM SPEED AT FULL LOAD (mm/MIN): 100 SPEED ACCURACY: ±0.5% SERVO CONTROL DISPLACEMENT RESOLUTION (mm): 0.001 DRIVING METHOD: AC SERVO MOTOR POWER: SPECIFICATIONS 3Ø, 220VAC, 50/60Hz (380/415V OPTIONAL) CAPACITY: 5000KGF, 10000KGF, 15000KGF 50KN, 100KN, 150KN CONSUMPTION: 3KVA DIMENSIONS: FRAME (mm) 1540 X 600 X 2130 CONTROL BOX (mm): COMPUTER TYPE 1200 X 600 X 740 MICRO-COMPUTER TYPE 660 X 600 X 740 WEIGHT (KG): FRAME 800, CONTROL BOX 100 STANDARD ACCESSORIES: TENSILE GRIPS X 1 SET, NECESSARY TOOLS X 1 SET, OPERATIONAL MANUAL X 1 COPY, CERTIFICATE OF CALIBRATION X 1 COPY QUANTITY: 1 Learn More -

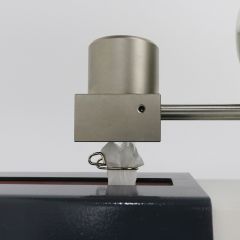

T-9594 MANUAL CROCKMETER RUBBING FASTNESS TESTERT-9594 MANUAL CROCKMETER RUBBING FASTNESS TESTER KEY SPECIFICATION: RUBBING HEAD DIAMETER: 16mm VERTICAL PRESSURE: 9N±0.2N RUBBING HEAD TRACK: 104±3mm DIMENSIONS: 660 X 160mm X 215mm (L X W X H) WEIGHT: 6KG ACCESSORIES: STANDARDS ACCESSORIES 1BOX: RUBBING CLOTH 2PC: SANDPAPER 2PC: RINGS OPTIONAL ACCESSORIES: GRAY SCALE FOR STAINING Learn More

T-9594 MANUAL CROCKMETER RUBBING FASTNESS TESTERT-9594 MANUAL CROCKMETER RUBBING FASTNESS TESTER KEY SPECIFICATION: RUBBING HEAD DIAMETER: 16mm VERTICAL PRESSURE: 9N±0.2N RUBBING HEAD TRACK: 104±3mm DIMENSIONS: 660 X 160mm X 215mm (L X W X H) WEIGHT: 6KG ACCESSORIES: STANDARDS ACCESSORIES 1BOX: RUBBING CLOTH 2PC: SANDPAPER 2PC: RINGS OPTIONAL ACCESSORIES: GRAY SCALE FOR STAINING Learn More -

YY-2183 OZONE AGING TEST CHAMBER, TEMPERATURE RANGE RT +10°C ~ 60°CYY-2183 OZONE AGING TEST CHAMBER, TEMPERATURE RANGE RT +10°C ~ 60°C DETAILS: IT IS WIDELY USED TO MEASURE QUALITY CONTROL; RUBBER & PLASTICS; AUTOMOBILE PRODUCTION; WIRES AND CABLES; PACKING MATERIALS; INSTRUMENTS AND MEASURING DEVICES; MEDICAL EQUIPMENT; CIVILIAN NUCLEAR ENERGY; CIVIL AVIATION; COLLEGES AND UNIVERSITIES; RESEARCH LABORATORIES; INSPECTION ARBITRATION, AND TECHNICAL SUPERVISION DEPARTMENTS AND OTHER PRODUCTS. CORRESPONDING STANDARDS: JIS K 6259, ASTM1149, ASTM1171, ISO1431, DIN53509, GB/T13642, GB/T 7762-2003, GB 2951. QUANTITY: 1 Learn More

YY-2183 OZONE AGING TEST CHAMBER, TEMPERATURE RANGE RT +10°C ~ 60°CYY-2183 OZONE AGING TEST CHAMBER, TEMPERATURE RANGE RT +10°C ~ 60°C DETAILS: IT IS WIDELY USED TO MEASURE QUALITY CONTROL; RUBBER & PLASTICS; AUTOMOBILE PRODUCTION; WIRES AND CABLES; PACKING MATERIALS; INSTRUMENTS AND MEASURING DEVICES; MEDICAL EQUIPMENT; CIVILIAN NUCLEAR ENERGY; CIVIL AVIATION; COLLEGES AND UNIVERSITIES; RESEARCH LABORATORIES; INSPECTION ARBITRATION, AND TECHNICAL SUPERVISION DEPARTMENTS AND OTHER PRODUCTS. CORRESPONDING STANDARDS: JIS K 6259, ASTM1149, ASTM1171, ISO1431, DIN53509, GB/T13642, GB/T 7762-2003, GB 2951. QUANTITY: 1 Learn More -

TT-1044 SERVO CONTROL UNIVERSAL TESTING MACHINE, 20KNTT-1044 SERVO CONTROL UNIVERSAL TESTING MACHINE, 20KN KEY SPECIFICATIONS: MAX. CAPACITY: 10N, 20N, 50N, 100N, 200N, 500N, 1KN, 2KN, 5KN,10KN,20KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTION: 0.5mm TEST SPEED: 0.001-500mm/MIN OR 0.001-1000mm/MIN (OPTION), CAN SET BY COMPUTER, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 400W DIMENSIONS: 720 X 620 X 1400mm (W X D X H) WEIGHT: 150KG POWER SUPPLY: 220V 50/60Hz 10A STANDARD ACCESSORIES: 1 SET OF GRIPS ENGLISH OPERATION SOFTWARE CABLE CONNECT WITH PC LOAD CELL OPTION ACCESSORIES: DESKTOP COMPUTER UNIVERSAL COMPRESSION TESTING MACHINE SOFTWARE FUNCTION: TEST & CONTROL SYSTEM IS DESIGNED FOR PC ELECTRONIC UNIVERSAL TESTING MACHINES, PC HYDRAULIC UNIVERSAL TESTING MACHINES AND PC COMPRESSION TESTERS. CAN CONDUCT TENSILE, COMPRESSION, BENDING, SHEARING, TEARING AND PEELING TEST; USE PC AND INTERFACE BOARD FOR DATA COLLECTION, PRESERVATION, PROCESSING AND PRINTING TEST RESULT; CAN CALCULATE MAX FORCE, YIELD STRENGTH, AVERAGE PEELING FORCE, MAX DEFORMATION, YIELD POINT, ELASTIC MODULUS AND OTHER PARAMETERS. CAN CONDUCT CURVE GRAPHICS PROCESSING, MULTI-SENSOR SUPPORT, VIDEO AND IMAGE INTERFACE, FLEXIBLE DATA PROCESSING, MS-ACCESS DATABASE SUPPORT, MAKING MORE POWERFUL FUNCTION OF SYSTEM. QUANTITY: 1 Learn More

TT-1044 SERVO CONTROL UNIVERSAL TESTING MACHINE, 20KNTT-1044 SERVO CONTROL UNIVERSAL TESTING MACHINE, 20KN KEY SPECIFICATIONS: MAX. CAPACITY: 10N, 20N, 50N, 100N, 200N, 500N, 1KN, 2KN, 5KN,10KN,20KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTION: 0.5mm TEST SPEED: 0.001-500mm/MIN OR 0.001-1000mm/MIN (OPTION), CAN SET BY COMPUTER, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 400W DIMENSIONS: 720 X 620 X 1400mm (W X D X H) WEIGHT: 150KG POWER SUPPLY: 220V 50/60Hz 10A STANDARD ACCESSORIES: 1 SET OF GRIPS ENGLISH OPERATION SOFTWARE CABLE CONNECT WITH PC LOAD CELL OPTION ACCESSORIES: DESKTOP COMPUTER UNIVERSAL COMPRESSION TESTING MACHINE SOFTWARE FUNCTION: TEST & CONTROL SYSTEM IS DESIGNED FOR PC ELECTRONIC UNIVERSAL TESTING MACHINES, PC HYDRAULIC UNIVERSAL TESTING MACHINES AND PC COMPRESSION TESTERS. CAN CONDUCT TENSILE, COMPRESSION, BENDING, SHEARING, TEARING AND PEELING TEST; USE PC AND INTERFACE BOARD FOR DATA COLLECTION, PRESERVATION, PROCESSING AND PRINTING TEST RESULT; CAN CALCULATE MAX FORCE, YIELD STRENGTH, AVERAGE PEELING FORCE, MAX DEFORMATION, YIELD POINT, ELASTIC MODULUS AND OTHER PARAMETERS. CAN CONDUCT CURVE GRAPHICS PROCESSING, MULTI-SENSOR SUPPORT, VIDEO AND IMAGE INTERFACE, FLEXIBLE DATA PROCESSING, MS-ACCESS DATABASE SUPPORT, MAKING MORE POWERFUL FUNCTION OF SYSTEM. QUANTITY: 1 Learn More -

TT-1043 UNIVERSAL TESTING MACHINE FOR TENSILE TEST, 30KNTT-1043 UNIVERSAL TESTING MACHINE FOR TENSILE TEST, 30KN KEY SPECIFICATIONS: MAX. CAPACITY: 10N, 20N, 50N, 100N, 200N, 500N, 1KN, 2KN, 5KN, 10KN, 20KN, 30KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTIO: 0.5mm TEST SPEED: 0.001-500mm/MIN, CAN SET BY COMPUTER, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS WALKING SPACE: 1000mm (IT CAN BE CUSTOM-TAILOR ACCORDING TO THEIR REQUIREMENTS) FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 400W DIMENSIONS: 720 X 620 X 1400mm (W X D X H) WEIGHT: 150KG POWER SUPPLY: 220V 50/60Hz 10A STANDARDS: BS EN ISO 13934-1, 13934-2, 13937-2, 13937-3, 13937-4, 13935-1, 13935-2, BS 3320, 4303. ASTM D 434, 558, 2256, 2261, 2731, 3936, 4533, 4964, 5034, 5035, 5735. ISO 2062, 5082, 9073.4, 10321, 13919. ASTM882, ASTM638 STANDARD ACCESSORIES: ENGLISH OPERATION SOFTWARE 1PC CABLE CONNECT WITH PC 1PC LOAD CELL 1PC OPTION ACCESSORIES: DESKTOP COMPUTER 1PC QUANTITY: 1 Learn More

TT-1043 UNIVERSAL TESTING MACHINE FOR TENSILE TEST, 30KNTT-1043 UNIVERSAL TESTING MACHINE FOR TENSILE TEST, 30KN KEY SPECIFICATIONS: MAX. CAPACITY: 10N, 20N, 50N, 100N, 200N, 500N, 1KN, 2KN, 5KN, 10KN, 20KN, 30KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTIO: 0.5mm TEST SPEED: 0.001-500mm/MIN, CAN SET BY COMPUTER, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS WALKING SPACE: 1000mm (IT CAN BE CUSTOM-TAILOR ACCORDING TO THEIR REQUIREMENTS) FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 400W DIMENSIONS: 720 X 620 X 1400mm (W X D X H) WEIGHT: 150KG POWER SUPPLY: 220V 50/60Hz 10A STANDARDS: BS EN ISO 13934-1, 13934-2, 13937-2, 13937-3, 13937-4, 13935-1, 13935-2, BS 3320, 4303. ASTM D 434, 558, 2256, 2261, 2731, 3936, 4533, 4964, 5034, 5035, 5735. ISO 2062, 5082, 9073.4, 10321, 13919. ASTM882, ASTM638 STANDARD ACCESSORIES: ENGLISH OPERATION SOFTWARE 1PC CABLE CONNECT WITH PC 1PC LOAD CELL 1PC OPTION ACCESSORIES: DESKTOP COMPUTER 1PC QUANTITY: 1 Learn More