Search results for: 'machine+trai+0'

-

TT-5852 MASCOTT PLUS 25-30 CROSSLAPPER AND MONO_1AB_27-3000 NEEDLE LOOMTT-5852 MASCOTT PLUS 25-30 CROSSLAPPER AND MONO_1AB_27-3000 NEEDLE LOOM Learn More

TT-5852 MASCOTT PLUS 25-30 CROSSLAPPER AND MONO_1AB_27-3000 NEEDLE LOOMTT-5852 MASCOTT PLUS 25-30 CROSSLAPPER AND MONO_1AB_27-3000 NEEDLE LOOM Learn More -

TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024 1. MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET 2. 1 UNIT 400 V 3. 2 UNITS 6.3 KV Learn More

TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024 1. MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET 2. 1 UNIT 400 V 3. 2 UNITS 6.3 KV Learn More -

TT-6597 MTU OPEN TYPE NATURAL GAS GENERATORS, 1.5 MW, 50Hz EXCELLENT FULL DESCRIPTION OF A GENERATORTT-6597 MTU OPEN TYPE NATURAL GAS GENERATORS, 1.5 MW, 50Hz EXCELLENT FULL DESCRIPTION OF A GENERATOR QUANTITY: 10 Learn More

TT-6597 MTU OPEN TYPE NATURAL GAS GENERATORS, 1.5 MW, 50Hz EXCELLENT FULL DESCRIPTION OF A GENERATORTT-6597 MTU OPEN TYPE NATURAL GAS GENERATORS, 1.5 MW, 50Hz EXCELLENT FULL DESCRIPTION OF A GENERATOR QUANTITY: 10 Learn More -

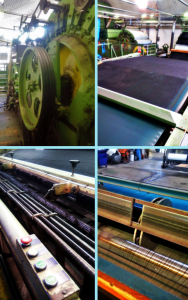

NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7REFERENCE NUMBER: T-6989 NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7 ITEM 001 PRODUCTION PLANT OF NON-WOVEN FABRIC PLANT IS COMPLETE IN AN EXCELLENT STATE OF MAINTENANCE WITH DRUMS OF 2000mm IN DIAMETER LIKE THE SAME DIAMETER DOFFERS, HIGH WORK 2200mm, 2500 X 4200mm, ALL MACHINES ARE ELECTRONICALLY MANAGED BY PLC, WEIGHT SCALE WITH LOAD CELLS, IT IS THERE IS ALSO THE COMPLETE AUTOMATED FIBER PREPARATION IN ADDITION, THERE IS 1 LOOM FOR NONWOVEN MALIWATT WITH THREAD AND 1 MALIVLIES LOOM WITHOUT SEWING THREAD INTERTWINES THE FIBERS AND PRODUCES A NON-WOVEN FABRIC ALSO USED FOR THE PRODUCTION OF ANTI-COVID-19 FACIAL MASKS FABRIC PRODUCTION PLANTS IN BLOCK FABRIC OR FOR SINGLE UNITS IN GOOD CONDITION AND STILL IN PRODUCTION TODAY THE DESCRIPTION OF THE PLANTS BELOW: ITEM 002 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1980 FOR MODEL CARD WORKING HEIGHT 2200mm DRUM DIAMETER 1700mm DOFFER 1270mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, PLANT IN GOOD CONDITION QUANTITY: 2 ITEM 003 MALIWATT 3600 TYPE 14013 GAUGE 7 YEAR OF CONSTRUCTION 1981 CARD MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC AT THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 004 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 OCTIR MODEL CARD WORKING HEIGHT 2500mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% LENGTH FIBER 60mm, 3.4 DTEX, IMPLANT IN EXCELLENT CONDITION QUANTITY: 1 ITEM 005 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 CARD FOR MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC ON THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 006 MALIWATT 3600 TYPE 14011 GAUGE 14 YEAR OF CONSTRUCTION 1976 BOISSON MODEL CARD WORKING HEIGHT 2000mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, NENCINI CROSS LAPPER, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, IMPLANT IN FAIR GENERAL CONDITION QUANTITY: 1 DESCRIPTION: ALL PRODUCTION LINES ARE FULLY FUNCTIONAL AND ARE STILL PRODUCTION ALL THE PLANTS ARE COMPOSED OF FORWARD TRAIN AND ONE CARD DOES NOT HAVE FIBER CROSSING AND THE PRODUCTION OF ARTICLES WITH MELANGE COLORS IS PROBLEMATIC, ANOTHER HANDICAP THAT I HAVE DETECTED THE PLANT DOES NOT HAVE FIBER PREPARATION AND STORAGE, THERE ARE BALES AND SILOS OPENERS WITH FEEDING CONVEYORS BUT THE FIBER USED IS NOT WELL MIXED, CURRENTLY THEY PRODUCE NON-WOVEN FABRICS FOR PRINTING. ALL MALIWATTS THE ELECTRICAL SYSTEM AND THE ELECTRONIC BAR HEATING SYSTEM HAVE BEEN REBUILT; THE CROSS LAPPERS HAVE ALSO BEEN UPDATED IN THE ELECTRONICS. THE SELLER SELLS THE PLANT IS NOT PROFITABLE AND THEY PLAN TO REINVEST IN DIFFERENT PRODUCTIONS IN ADDITION, THERE ARE ALSO VARIOUS ACCESSORIES FOR PRODUCTION SUCH AS BALE OPENERS, CALENDERS, CONVEYOR TROLLEYS ETC. Learn More

NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7REFERENCE NUMBER: T-6989 NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7 ITEM 001 PRODUCTION PLANT OF NON-WOVEN FABRIC PLANT IS COMPLETE IN AN EXCELLENT STATE OF MAINTENANCE WITH DRUMS OF 2000mm IN DIAMETER LIKE THE SAME DIAMETER DOFFERS, HIGH WORK 2200mm, 2500 X 4200mm, ALL MACHINES ARE ELECTRONICALLY MANAGED BY PLC, WEIGHT SCALE WITH LOAD CELLS, IT IS THERE IS ALSO THE COMPLETE AUTOMATED FIBER PREPARATION IN ADDITION, THERE IS 1 LOOM FOR NONWOVEN MALIWATT WITH THREAD AND 1 MALIVLIES LOOM WITHOUT SEWING THREAD INTERTWINES THE FIBERS AND PRODUCES A NON-WOVEN FABRIC ALSO USED FOR THE PRODUCTION OF ANTI-COVID-19 FACIAL MASKS FABRIC PRODUCTION PLANTS IN BLOCK FABRIC OR FOR SINGLE UNITS IN GOOD CONDITION AND STILL IN PRODUCTION TODAY THE DESCRIPTION OF THE PLANTS BELOW: ITEM 002 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1980 FOR MODEL CARD WORKING HEIGHT 2200mm DRUM DIAMETER 1700mm DOFFER 1270mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, PLANT IN GOOD CONDITION QUANTITY: 2 ITEM 003 MALIWATT 3600 TYPE 14013 GAUGE 7 YEAR OF CONSTRUCTION 1981 CARD MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC AT THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 004 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 OCTIR MODEL CARD WORKING HEIGHT 2500mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% LENGTH FIBER 60mm, 3.4 DTEX, IMPLANT IN EXCELLENT CONDITION QUANTITY: 1 ITEM 005 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 CARD FOR MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC ON THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 006 MALIWATT 3600 TYPE 14011 GAUGE 14 YEAR OF CONSTRUCTION 1976 BOISSON MODEL CARD WORKING HEIGHT 2000mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, NENCINI CROSS LAPPER, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, IMPLANT IN FAIR GENERAL CONDITION QUANTITY: 1 DESCRIPTION: ALL PRODUCTION LINES ARE FULLY FUNCTIONAL AND ARE STILL PRODUCTION ALL THE PLANTS ARE COMPOSED OF FORWARD TRAIN AND ONE CARD DOES NOT HAVE FIBER CROSSING AND THE PRODUCTION OF ARTICLES WITH MELANGE COLORS IS PROBLEMATIC, ANOTHER HANDICAP THAT I HAVE DETECTED THE PLANT DOES NOT HAVE FIBER PREPARATION AND STORAGE, THERE ARE BALES AND SILOS OPENERS WITH FEEDING CONVEYORS BUT THE FIBER USED IS NOT WELL MIXED, CURRENTLY THEY PRODUCE NON-WOVEN FABRICS FOR PRINTING. ALL MALIWATTS THE ELECTRICAL SYSTEM AND THE ELECTRONIC BAR HEATING SYSTEM HAVE BEEN REBUILT; THE CROSS LAPPERS HAVE ALSO BEEN UPDATED IN THE ELECTRONICS. THE SELLER SELLS THE PLANT IS NOT PROFITABLE AND THEY PLAN TO REINVEST IN DIFFERENT PRODUCTIONS IN ADDITION, THERE ARE ALSO VARIOUS ACCESSORIES FOR PRODUCTION SUCH AS BALE OPENERS, CALENDERS, CONVEYOR TROLLEYS ETC. Learn More -

M-5300 UNDER PAD PRODUCTION LINEREFERENCE NUMBER: M-5300 (131342BVGT12UF) L UNDER PAD PRODUCTION LINE UNDER PAD PRODUCTION LINE MODEL: 100CD PRODUCTS TO BE PRODUCED: 3 SIZES OF DISPOSABLE UNDER PAD (SIZE: 600x900mm, 600x600mm, 600x400mm) MECHANICAL DRIVING SYSTEM WITH INVERTER CONTROL PRODUCT STRUCTURE: FLUFF +SAP; TOP TISSUE; BOTTOM TISSUE; TOP SHEET; BACK SHEET QUANTITY AVAILABLE: 1 Learn More

M-5300 UNDER PAD PRODUCTION LINEREFERENCE NUMBER: M-5300 (131342BVGT12UF) L UNDER PAD PRODUCTION LINE UNDER PAD PRODUCTION LINE MODEL: 100CD PRODUCTS TO BE PRODUCED: 3 SIZES OF DISPOSABLE UNDER PAD (SIZE: 600x900mm, 600x600mm, 600x400mm) MECHANICAL DRIVING SYSTEM WITH INVERTER CONTROL PRODUCT STRUCTURE: FLUFF +SAP; TOP TISSUE; BOTTOM TISSUE; TOP SHEET; BACK SHEET QUANTITY AVAILABLE: 1 Learn More -

TT-8593 GE TM2500GEN08 MOBILE GAS TURBINE GENERATOR, 10.5KV, YEAR 2025TT-8593 GE TM2500GEN08 MOBILE GAS TURBINE GENERATOR, 10.5KV, YEAR 2025 1. GE TM2500GEN08 2. YEAR: JUNE 2025 3. 10.5KV 4. DUAL FREQUENCY 5. DUAL FUEL 6. DRY LOW EMISSION 7. HOURS: 0 8. WARRANTY: ONE YEAR QUANTITY: 1 Learn More

TT-8593 GE TM2500GEN08 MOBILE GAS TURBINE GENERATOR, 10.5KV, YEAR 2025TT-8593 GE TM2500GEN08 MOBILE GAS TURBINE GENERATOR, 10.5KV, YEAR 2025 1. GE TM2500GEN08 2. YEAR: JUNE 2025 3. 10.5KV 4. DUAL FREQUENCY 5. DUAL FUEL 6. DRY LOW EMISSION 7. HOURS: 0 8. WARRANTY: ONE YEAR QUANTITY: 1 Learn More -

TT-2227 TRANSPORT TRAILERS, 10 X 60 TON PLUS TRUCK TRACTORS, 10 X 8 X 8 FOR TOWING THESE TRAILERS, ALMOST NEW, ONLY 500 MILESTT-2227 TRANSPORT TRAILERS, 10 X 60 TON PLUS TRUCK TRACTORS, 10 X 8 X 8 FOR TOWING THESE TRAILERS, ALMOST NEW, ONLY 500 MILES TOTAL QUANTITY: 20 Learn More

TT-2227 TRANSPORT TRAILERS, 10 X 60 TON PLUS TRUCK TRACTORS, 10 X 8 X 8 FOR TOWING THESE TRAILERS, ALMOST NEW, ONLY 500 MILESTT-2227 TRANSPORT TRAILERS, 10 X 60 TON PLUS TRUCK TRACTORS, 10 X 8 X 8 FOR TOWING THESE TRAILERS, ALMOST NEW, ONLY 500 MILES TOTAL QUANTITY: 20 Learn More -

YY-1357 HORIZONTAL CONTINUOUS FOAMING MACHINE, 21000 KG PER HOURYY-1357 HORIZONTAL CONTINUOUS FOAMING MACHINE, 21000 KG PER HOUR MAIN TECHNICAL SPECIFICATION: 1.TOTAL LENGTH: 35000mm × WIDTH 4500mm × HEIGHT 3000mm 2. FOAMING WIDTH 1000mm TO APPROXIMATELY 2300mm 3.FOAMING HEIGHT: 1200mm 4.FOAMING DENSITY: 8 KG PER m3 TO APPROXIMATELY 80 KG PER m3 5.FOAMING SPEED: 0 TO 6.8 METERS PER MINUTE 6.MAX TOTAL OUTPUT: 80 LITERS TO 350 LITERS PER MINUTE 7.MATERIAL SPRAYING METHOD: TROUGH 8.ALL KINDS OF VALVES, PIPES AND SPARE PARTS 9.THE MEMBRANE AUTOMATICALLY RECEIVES THE VOLUME INSTALLMENT (TO USE THE NEWEST INSTALLMENT, TO GUARANTEE THAT IT RECEIVES VOLUME SIDE PAPER SMOOTHLY); 10.USES ENVIRONMENTALLY-FRIENDLY EQUIPMENT TO PURIFY EXHAUST GAS, NO POLLUTION PRESENT 11. RESPONSIBLE FOR ELECTRICAL, MECHANICAL MAINTENANCE PERSONNEL TRAINING 12.THE BLOCK CUTTER MACHINE CUTS THE BUN LENGTH USING ROTARY ENCODER AND THICKNESS GAUGE TO SETUP AND CONTROL 13. MIXING HEAD FRAME PLUS OVERHAUL STAND, LADDER AND BARRICADE 14.MIXING HEAD IS GERMAN PRECISION TECHNOLOGY 15.FOAMING OVEN, DECLINING BOARD AND OVEN INNER CONVEYOR MACHINE PARTS 16. MIXING HEAD SIZE: Φ100mm 18.MIXING HEAD MOTOR: 30 KW 19.TOTAL POWER: ABOUT 80 KW Learn More

YY-1357 HORIZONTAL CONTINUOUS FOAMING MACHINE, 21000 KG PER HOURYY-1357 HORIZONTAL CONTINUOUS FOAMING MACHINE, 21000 KG PER HOUR MAIN TECHNICAL SPECIFICATION: 1.TOTAL LENGTH: 35000mm × WIDTH 4500mm × HEIGHT 3000mm 2. FOAMING WIDTH 1000mm TO APPROXIMATELY 2300mm 3.FOAMING HEIGHT: 1200mm 4.FOAMING DENSITY: 8 KG PER m3 TO APPROXIMATELY 80 KG PER m3 5.FOAMING SPEED: 0 TO 6.8 METERS PER MINUTE 6.MAX TOTAL OUTPUT: 80 LITERS TO 350 LITERS PER MINUTE 7.MATERIAL SPRAYING METHOD: TROUGH 8.ALL KINDS OF VALVES, PIPES AND SPARE PARTS 9.THE MEMBRANE AUTOMATICALLY RECEIVES THE VOLUME INSTALLMENT (TO USE THE NEWEST INSTALLMENT, TO GUARANTEE THAT IT RECEIVES VOLUME SIDE PAPER SMOOTHLY); 10.USES ENVIRONMENTALLY-FRIENDLY EQUIPMENT TO PURIFY EXHAUST GAS, NO POLLUTION PRESENT 11. RESPONSIBLE FOR ELECTRICAL, MECHANICAL MAINTENANCE PERSONNEL TRAINING 12.THE BLOCK CUTTER MACHINE CUTS THE BUN LENGTH USING ROTARY ENCODER AND THICKNESS GAUGE TO SETUP AND CONTROL 13. MIXING HEAD FRAME PLUS OVERHAUL STAND, LADDER AND BARRICADE 14.MIXING HEAD IS GERMAN PRECISION TECHNOLOGY 15.FOAMING OVEN, DECLINING BOARD AND OVEN INNER CONVEYOR MACHINE PARTS 16. MIXING HEAD SIZE: Φ100mm 18.MIXING HEAD MOTOR: 30 KW 19.TOTAL POWER: ABOUT 80 KW Learn More -

TT-7562 CATERPILLAR 816B, YEAR 1989, RECONDITIONED, 17,330 HOURSTT-7562 CATERPILLAR 816B, YEAR 1989, RECONDITIONED, 17,330 HOURS 1. MACHINE HOURS: 17,330 2. CATERPILLAR DEALER REBUILT THE COMPLETE DRIVE TRAIN AT 15,384 HOURS 3. ENGINE, TORQUE, TRANSMISSION, TRANSFER CASE, BOTH DIFFERENTIALS, 4. ALL FINAL DRIVES, REAR AXLE OSCILLATION & HYDRAULIC PUMPS ETC. 5. REBUILD / REPAIR RECORDS ARE AVAILABLE. 6. ALL NEEDED REPAIRS & SERVICING HAS BEEN COMPLETED BY MARCEL EQUIPMENT SINCE ARRIVING IN OUR YARD. QUANTITY: 1 Learn More

TT-7562 CATERPILLAR 816B, YEAR 1989, RECONDITIONED, 17,330 HOURSTT-7562 CATERPILLAR 816B, YEAR 1989, RECONDITIONED, 17,330 HOURS 1. MACHINE HOURS: 17,330 2. CATERPILLAR DEALER REBUILT THE COMPLETE DRIVE TRAIN AT 15,384 HOURS 3. ENGINE, TORQUE, TRANSMISSION, TRANSFER CASE, BOTH DIFFERENTIALS, 4. ALL FINAL DRIVES, REAR AXLE OSCILLATION & HYDRAULIC PUMPS ETC. 5. REBUILD / REPAIR RECORDS ARE AVAILABLE. 6. ALL NEEDED REPAIRS & SERVICING HAS BEEN COMPLETED BY MARCEL EQUIPMENT SINCE ARRIVING IN OUR YARD. QUANTITY: 1 Learn More -

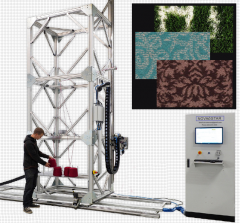

T-7649 NOVASTAR ROBOT HANDTUFTING MACHINET-7649 NOVASTAR ROBOT HANDTUFTING MACHINE ITEM 001 NOVASTAR ROBOT HANDTUFT STAR6.2-6X4 MACHINE IS COMPLETE AND INCLUDES ALL NECESSARY ACCESSORIES. 10000 X 4400mm PRODUCTION AREA INCLUDING FOLLOWING PARTS 1 PC MOVEABLE FRAME 10850 X 5850mm 2 PCS HOLDERS FOR FRAMES 1 UNIT CREEL WITH 6 SENSORS 1 PC YARNDETECTOR FOR TUFTHEAD 2 SET NEEDLES, 8 PCS DIAMETER 5mm, 8 PCS DIAMETER 6mm 10 PCS BLADE 2 PCS ANVIL 1 PC TOOLKIT FOR TUFTUNIT 1 TOOL FOR STRECHING OF BACKING BLADES, 10 PCS ANVIL, 2 PCS 1 SET FEED WHEELS, 2 PCS QUANTITY: 1 UNIT ITEM 002 FRAME 6000 X 4000mm (6850 X 4850) QUANTITY: 2 ITEM 003 SPARE PART KIT QUANTITY: 1 ITEM 004 NOVASTAR TUFT CAD, PLUG IN YOU NEED A LICENSE OF COREL DRAW 2020 Learn More

T-7649 NOVASTAR ROBOT HANDTUFTING MACHINET-7649 NOVASTAR ROBOT HANDTUFTING MACHINE ITEM 001 NOVASTAR ROBOT HANDTUFT STAR6.2-6X4 MACHINE IS COMPLETE AND INCLUDES ALL NECESSARY ACCESSORIES. 10000 X 4400mm PRODUCTION AREA INCLUDING FOLLOWING PARTS 1 PC MOVEABLE FRAME 10850 X 5850mm 2 PCS HOLDERS FOR FRAMES 1 UNIT CREEL WITH 6 SENSORS 1 PC YARNDETECTOR FOR TUFTHEAD 2 SET NEEDLES, 8 PCS DIAMETER 5mm, 8 PCS DIAMETER 6mm 10 PCS BLADE 2 PCS ANVIL 1 PC TOOLKIT FOR TUFTUNIT 1 TOOL FOR STRECHING OF BACKING BLADES, 10 PCS ANVIL, 2 PCS 1 SET FEED WHEELS, 2 PCS QUANTITY: 1 UNIT ITEM 002 FRAME 6000 X 4000mm (6850 X 4850) QUANTITY: 2 ITEM 003 SPARE PART KIT QUANTITY: 1 ITEM 004 NOVASTAR TUFT CAD, PLUG IN YOU NEED A LICENSE OF COREL DRAW 2020 Learn More