Search results for: '12.5*16'

-

TT-2995 BALONEY SLITTER, CUTTING WIDTH 3 TO 1600mm (64 INCHES) – ONE (SINGLE) SHAFT ACCURACY ± 0.1mmTT-2995 BALONEY SLITTER, CUTTING WIDTH 3 TO 1600mm (64 INCHES) – ONE (SINGLE) SHAFT ACCURACY ± 0.1mm BALONEY SLITTER APPLICATION: USE FOR MELT-BLOWN FABRIC, NON-WOVEN FABRIC, FOAM TAPE, MASKING TAPE, ETC. ROLLER WIDTH: 1700mm CUTTING WIDTH: 3mm TO 1600mm (UP TO 64 INCHES) PAPER CORE I.D.: 76.2mm OR CHANGEABLE CUTTING DIAMETER: MAXIMUM 550mm (21.6 INCHES) POWER SOURCE: PLEASE ADVISE VOLTAGE REQUIRED AIR SOURCE: 5 KG (SUPPLIED BY USER) QUANTITY: 1 Learn More

TT-2995 BALONEY SLITTER, CUTTING WIDTH 3 TO 1600mm (64 INCHES) – ONE (SINGLE) SHAFT ACCURACY ± 0.1mmTT-2995 BALONEY SLITTER, CUTTING WIDTH 3 TO 1600mm (64 INCHES) – ONE (SINGLE) SHAFT ACCURACY ± 0.1mm BALONEY SLITTER APPLICATION: USE FOR MELT-BLOWN FABRIC, NON-WOVEN FABRIC, FOAM TAPE, MASKING TAPE, ETC. ROLLER WIDTH: 1700mm CUTTING WIDTH: 3mm TO 1600mm (UP TO 64 INCHES) PAPER CORE I.D.: 76.2mm OR CHANGEABLE CUTTING DIAMETER: MAXIMUM 550mm (21.6 INCHES) POWER SOURCE: PLEASE ADVISE VOLTAGE REQUIRED AIR SOURCE: 5 KG (SUPPLIED BY USER) QUANTITY: 1 Learn More -

YY-2409 SLOT DIE COATING MACHINE, MAXIMUM COATING WIDTH 1550mm (61 INCHES)YY-2409 SLOT DIE COATING MACHINE, MAXIMUM COATING WIDTH 1550mm (61 INCHES) APPLICATION: 1. HOT MELT SENSITIVE PRESSURE ADHESIVE COATING AND LAMINATION LINE, FOR COATING, LAMINATION, PEELING, REWINDING FUNCTION. 2. APPLICATION MATERIAL: PET, PVC, PAPER ETC. MACHINE FEATURES: 1. THIS MACHINE INCLUDES MICROCOMPUTER PLC, TOUCH SCREEN CONTROL, SIMPLE OPERATION AND HIGH AUTOMATION; 2. USING HIGH WEAR-RESISTANT ALLOY STEEL SLOT DIE, WITH COATING CONTROL ACCURACY AND GOOD SERVICE LIFE; 3. AN OVERALL COATING ADJUSTMENT BRACKET IS INCLUDED, AND THE REPEAT POSITIONING ACCURACY IS PRECISE; 4. AUTOMATICALLY TRACKS AND DISPLAYS AND STORES THE AMOUNT OF GLUE NEEDED, MAKING THE OPERATION AND USE CONVENIENT AND FAST; 5. THE FIRST UNWINDING IS EQUIPPED WITH A WEB GUIDING DEVICE, WITH A HIGH-PERFORMANCE INFRARED SENSOR AND ELECTRIC CONTROLLER TO ENSURE THE EVEN LET OFF OF THE MATERIAL ROLL; 6. THE HEATING TEMPERATURE IS ALL CENTRALLY CONTROLLED BY PLC; 7. THE AMOUNT OF GLUE SUPPLIED BY THE METERING PUMP FOR THE COATING WIDTH IS INPUT BY THE WORKER, AND THE AMOUNT OF GLUE SUPPLIED WILL BE AUTOMATICALLY CALCULATED AND SUPPLIED TO THE DIE SLOT. QUANTITY: 1 Learn More

YY-2409 SLOT DIE COATING MACHINE, MAXIMUM COATING WIDTH 1550mm (61 INCHES)YY-2409 SLOT DIE COATING MACHINE, MAXIMUM COATING WIDTH 1550mm (61 INCHES) APPLICATION: 1. HOT MELT SENSITIVE PRESSURE ADHESIVE COATING AND LAMINATION LINE, FOR COATING, LAMINATION, PEELING, REWINDING FUNCTION. 2. APPLICATION MATERIAL: PET, PVC, PAPER ETC. MACHINE FEATURES: 1. THIS MACHINE INCLUDES MICROCOMPUTER PLC, TOUCH SCREEN CONTROL, SIMPLE OPERATION AND HIGH AUTOMATION; 2. USING HIGH WEAR-RESISTANT ALLOY STEEL SLOT DIE, WITH COATING CONTROL ACCURACY AND GOOD SERVICE LIFE; 3. AN OVERALL COATING ADJUSTMENT BRACKET IS INCLUDED, AND THE REPEAT POSITIONING ACCURACY IS PRECISE; 4. AUTOMATICALLY TRACKS AND DISPLAYS AND STORES THE AMOUNT OF GLUE NEEDED, MAKING THE OPERATION AND USE CONVENIENT AND FAST; 5. THE FIRST UNWINDING IS EQUIPPED WITH A WEB GUIDING DEVICE, WITH A HIGH-PERFORMANCE INFRARED SENSOR AND ELECTRIC CONTROLLER TO ENSURE THE EVEN LET OFF OF THE MATERIAL ROLL; 6. THE HEATING TEMPERATURE IS ALL CENTRALLY CONTROLLED BY PLC; 7. THE AMOUNT OF GLUE SUPPLIED BY THE METERING PUMP FOR THE COATING WIDTH IS INPUT BY THE WORKER, AND THE AMOUNT OF GLUE SUPPLIED WILL BE AUTOMATICALLY CALCULATED AND SUPPLIED TO THE DIE SLOT. QUANTITY: 1 Learn More -

TT-2093 CONVEYOR PRESSING MACHINE FOR DOWN JACKETSTT-2093 CONVEYOR PRESSING MACHINE FOR DOWN JACKETS ITEM 001 WORKING AREA: 1900 X 1000mm ITEM 002 WORKING AREA: 3800 X 1000mm CONVEYOR PRESSING MACHINE FOR DOWN JACKETS STABLE PERFORMANCE AND SMALL VIBRATION WORK SPEED: 2.9M/MIN TO 13M/MIN 3 TO 5 TIMES OF MANUAL PRESSING FREQUENCY SPEED CONTROL+DIGITAL DISPLAY+EASY TO OPERATE Learn More

TT-2093 CONVEYOR PRESSING MACHINE FOR DOWN JACKETSTT-2093 CONVEYOR PRESSING MACHINE FOR DOWN JACKETS ITEM 001 WORKING AREA: 1900 X 1000mm ITEM 002 WORKING AREA: 3800 X 1000mm CONVEYOR PRESSING MACHINE FOR DOWN JACKETS STABLE PERFORMANCE AND SMALL VIBRATION WORK SPEED: 2.9M/MIN TO 13M/MIN 3 TO 5 TIMES OF MANUAL PRESSING FREQUENCY SPEED CONTROL+DIGITAL DISPLAY+EASY TO OPERATE Learn More -

T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008 YEAR 2008, PILOT RUN YEAR 2009, STOPPED PRODUCTION YEAR 2017 FILM MACHINE EXTRUDER: BATTENFELD EXTRUDER DIAMETER 4.5” (115mm) L/D RATIO 24:1 460V 3P 60Hz 125HP AC VECTOR MOTOR RESIN TEMPARETURE: 230°C (446 DEGREEF) OUTPUT: MAX 180KG/H (400 LBS/H) PRESSURE RATINGS ARE: BARREL 20,000PSI BARREL CLAMP 10,000PSI RUPTURED DISC 7,500PSI Learn More

T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008 YEAR 2008, PILOT RUN YEAR 2009, STOPPED PRODUCTION YEAR 2017 FILM MACHINE EXTRUDER: BATTENFELD EXTRUDER DIAMETER 4.5” (115mm) L/D RATIO 24:1 460V 3P 60Hz 125HP AC VECTOR MOTOR RESIN TEMPARETURE: 230°C (446 DEGREEF) OUTPUT: MAX 180KG/H (400 LBS/H) PRESSURE RATINGS ARE: BARREL 20,000PSI BARREL CLAMP 10,000PSI RUPTURED DISC 7,500PSI Learn More -

A-2611 ULTRAVIOLET AGING TESTING CHAMBER BOX TYPEA-2611 ULTRAVIOLET AGING TESTING CHAMBER BOX TYPE FLUORESCENT UV LAMP IS IMPORTED FOR THIS ACCELERATED AGING TEST CHAMBER. CAN SIMULATE HARM BY SUNLIGHT, RAINWATER AND DEW. UV WEATHER RESISTANCE CHAMBER USE FLUORESCENT UV LAMP TO SIMULATES THE EFFECT OF SUNLIGHT, CONDENSATION MOISTURE IS USED TO SIMULATE DEW. THE TESTED MATERIAL IS PLACED IN A LOOP PROGRAM THAT ALTERNATES LIGHT AND MOISTURE AT A CERTAIN TEMPERATURE. THE MATERIAL WAS TESTED FOR ACCELERATED WEATHERABILITY. UV CHAMBER CAN RE-CREATE HAZARDS THAT OCCUR OUTDOORS FOR MONTHS OR YEARS.THE TYPES OF HAZARDS INCLUDE: DISCOLORATION, CHALKINESS, POWDER LIGHT, CRACKING, TURBIDITY, BUBBLES, BRITTLE, STRENGTH, DECAY, OXIDATION, ETC. THIS MACHINE INCLUDES SPRAY DEVICE. Learn More

A-2611 ULTRAVIOLET AGING TESTING CHAMBER BOX TYPEA-2611 ULTRAVIOLET AGING TESTING CHAMBER BOX TYPE FLUORESCENT UV LAMP IS IMPORTED FOR THIS ACCELERATED AGING TEST CHAMBER. CAN SIMULATE HARM BY SUNLIGHT, RAINWATER AND DEW. UV WEATHER RESISTANCE CHAMBER USE FLUORESCENT UV LAMP TO SIMULATES THE EFFECT OF SUNLIGHT, CONDENSATION MOISTURE IS USED TO SIMULATE DEW. THE TESTED MATERIAL IS PLACED IN A LOOP PROGRAM THAT ALTERNATES LIGHT AND MOISTURE AT A CERTAIN TEMPERATURE. THE MATERIAL WAS TESTED FOR ACCELERATED WEATHERABILITY. UV CHAMBER CAN RE-CREATE HAZARDS THAT OCCUR OUTDOORS FOR MONTHS OR YEARS.THE TYPES OF HAZARDS INCLUDE: DISCOLORATION, CHALKINESS, POWDER LIGHT, CRACKING, TURBIDITY, BUBBLES, BRITTLE, STRENGTH, DECAY, OXIDATION, ETC. THIS MACHINE INCLUDES SPRAY DEVICE. Learn More -

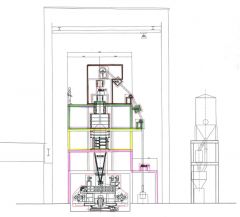

H-1261 GOOSE FEATHER CLEANING MACHINE

H-1261 GOOSE FEATHER CLEANING MACHINEH-1261 GOOSE FEATHER CLEANING MACHINE

LIST OF COMPONENTS FOR THE GOOSE FEATHER CLEANING MACHINE:

1) RINSING MACHINE OF THE TYPE 2000 (STAINLESS STEEL USED FOR IT)

EXTERIOR DIMENSION: 4000×2000×2600×Ф1800MM

QUANTITY: 12) GOOSE FEATHER ADDING MACHINE

EXTERIOR DIMENSION: 4000×1800×3300MM

QUANTITY: 13) WATER TANK

EXTERIOR DIMENSION: Ф1930MM×2440MM

QUANTITY: 14) DEWATERING MACHINE FLAT PLATE TYPE (BEING EQUIPPED WITH VARIABLE FREQUENCY CONTROL) - 2 SETS

QUANTITY: 25)DRYER OF THE TYPE 2000 (BEING EQUIPPED WITH ELECTRONIC WEIGHING)

EXTERIOR DIMENSION: 4500×2100×2900MM

QUANTITY: 16)GOOSE FEATHER ADDING MACHINE FOR DRYER(STAINLESS STEEL USED FOR IT AND ELECTRONIC WEIGHING INCLUDED)

EXTERIOR DIMENSION: 1500×1200×3600MM

QUANTITY: 17)THE COOLER OF THE TYPE 4700(STEEL & WOOD STRUCTURE, OPTIMIZED MOISTURE PROOF PANEL)

EXTERIOR DIMENSION: 4700×2350×2600×Ф2000MM

QUANTITY: 18) SORTING EQUIPMENT

QUANTITY: 29) POWER DISTRIBUTION CABINET

QUANTITY: 2RINSING MACHINE: TYPE 2000

1. EXTERIOR DIMENSION: 4000×2000×2600×Ф1800MM DIAMETER

2.THE MATERIAL OF 14MM IN THICKNESS STAINLESS STEEL IS USED FOR THE WALL FOR WASHING MACHINE AND 5MM IN THICKNESS FOR BARREL

3. THE MATERIAL OF AISI 1045 IS USED FOR THE SPINDLE OF THE SQUARE SHAPE(SPECIFICATION =108MMX108MM). WRAPPED WITH 2MM STAINLESS STEEL IN THE OUTER.

10MM IN THICKNESS STAINLESS STEEL IS FOR HOOP OF VANE.

4MM IN THICKNESS STAINLESS STEEL WHICH IS FOLDED IS FOR VANE.

HOOP SCREW OF M14 X 70 (HIGH STRENGTH GRADE) ARE USED.

THE BEARING HOUSING &BEARING OF UKP318 IS USED FOR THE SPINDLE.4.THE SIEVE OF 1.5MM IN THICKNESS STAINLESS STEEL IS USED FOR WACHING MACHINE.THE HOLE IS 1.8MM IN DIAMETER. HOLE SPACING 3.8MM .THE STAINLESS STEEL OF 2MM IS USED FOR THE OBLIQUE OF OUTPUTTING THE GOOSE FEATHER.THE OUTLET NEAR DEWATERING MACHINE FOR GOOSE FEATHER CAN BE TURNED UPWARD. FOR GOOSE FEATHER.

5.THE PIPE FOR WATER INLET IS 114MM IN DIAMETER

6.THE POWER OF FAN: 7.5KW AND SPEED: 2900R/M

7.THE PIPE FOR FEEDING GOOSE FEATHER IS 250MM IN DIAMETER.

8.THE REDUCER FOR THE SPINDLE: JZQ-400. THE POWER OF MOTOR IS 15KW AND OUTPUT SPEED IS 42 R/M

9.EXTERIOR DIMENSION OF THE BOTTOM FOR WASHING MACHINE: WIDTH=1600MM;LENGTH=3500MM.ONE SIEVE OF 1MM IN THICKNESS FOR IT.

WATER TANK

1. THE DIMENSION OF TANK: Ф1930MM×2440MM

2.THE STAINLESS STEELOF 2MM IN THICKNESS FOR ITS BARREL AND 3MM FOR THE BOTTOM.THE COVER IS CONSTUCTED WITH ANGLE IRON OF STAINLESS STEEL AND INNER COVER 2MM STAINLESS STEEL PLATE.

DEWATERING MACHINE OF TYPE 1600

1. ONE SETS OF RINSING MACHING OF THE TYPE 2000 IS EQUIPPED WITH TWO SETS DEWATERING MACHINE OF THE TYPE 1600

2.THE POWER OF MOTOR=11KW-17KW.DOUBLE SPEED MOTOR WITH VARIABLE FREQUENCY CONTROL.

DRYER OF TYPE 2000

1. EXTERIOR DIMENSION: 4500×2100×2900×Ф1800MM(DIAMETER)

2. THE MATERIAL OF 14MM IN THICKNESS STAINLESS STEEL(Q345R) IS USED FOR THE WALL FOR WASHING MACHINE. 10MM STAINLESS STEEL(Q345R) IS USED FOR INNER COVER OF THE BARREL AND 10MM STAINLESS STEEL (Q345R) PLATE FOR OUTER COVER OF THE BARREL.

3. THE INNER WALL OF WIND PLATE IS 0.5MM IN THICKNESS AND THE HOLE 1.5MM IN DIAMETER STAINLESS STEEL. 3MM COLD ROLLED PLATE IS USED FOR THE OUTER GATE.

4. THE SEAMLESS PIPE OF Ф108MM×10MM IS FOR THE MAIN SPINDLE.THE STEEL PLATE OF 10MM IN THICKNESS IS FOR THE VANE.THE WIDTH OF THE VANE IS 80MM. HOOP SCREW IS M12X70

6. THERE ARE FOUR INLET OF 1.5INCH IN DIAMETER FOR STEAM.

RELIEF VALVE FROM 3 KILO TO 7 (1 SETS)

THE PRESSURE GAGE (0-16 KILO) (2 SETS)

THE THERMOMETER (0-150 DEGREE) (1 SETS)

THERE ARE THREE DRAIN HOLE OF 1.5 INCH IN DIAMETER AT THE BOTTOM6. THERE ARE TWO LAYERS FOR GOOSE FEATHER ADDING FOR DRYER: 1.5×1.2×3.6M.THEY ARE MADE WITH STAINLESS STEEL.THE SPECIFICATION OF CHARGING SPOUT ON THE TOP OF DRYER IS 1.55 X 0.55M.

7. THE OUTLET FOR GOOSE FEATHER OF DRYER CAN BE TURNED UPWARD.THE PIPE FOR OUTPUTTING GOOSE FEATHER IS 300MM IN DIAMETER.

8. TWO FANS ARE EQUIPPED FOR PRECISE WASHING LINE.THE POWER OF FAN FOR ADDING GOOSE FEATHER IS 7.5KW,SPEED: 2900R/M.WHICH IS USED TOGETHER WITH GOOSE ADDING MACHINE OF WASHING MACHINE.THE POWER OF FAN FOR DRYER IS 5.5KW,SPEED IS 2900 R/M.

9. MAIN SHAFT SPEED REDUCER FOR BELT BRIDGE MOTOR 7.5KW.OUTPUT SPEED IS 52 R/M

THE COOLER IS OF TYPE 47001. EXTERIOR DIMENSION: 4700×2350×2600×Ф2000MM DIAMETER

2. THE EXTERIOR IS CONSTRUCTED WITH THE WHOLE WOOD STRUCTURE.THE MATERIAL OF STEEL WITH 4# ANGLE STEEL AND 30X30 SQUARE TUBE IS FOR THE INNER SKELETON.

3. THE SEAMLESS PIPE OF Ф108MM×10MM IS FOR THE MAIN SPINDLE.THE STEEL PLATE OF 14MM IN THICKNESS IS FOR THE VANE.THE WIDTH OF THE VANE IS 80MM. HOOP SCREW IS M16X70

4. THE DIAMETER OF WIND PIPE: MAIN PIPE IS 300MM IN DIAMETER AND BRANCH IS 250MM IN DIAMETER.THERE ARE FOUR AIR OUTLET OF 300MM IN DIAMETER EQUIPPED EQUALLY SPACE.

5. ONE SIEVE IS EQUIPPED FOR THE COOLER.THE SIEVE IS MADE WITH 0.6MM IN THICKNESS GALVANIZED STEEL SHEET.THE HEIGHT OF HOLE IS 1.1MM.THE SCREEN FRAME IS MADE WITH 3# ANGLE STEEL.

6.THERE ARE TWO SORTING BOX WHICH IS CONSTRUCTED WITH STEEL FRAME AND WOODEN STRUCTURE. SIEVE 14 MESH GALVANIZED MESH BOLD

7. ONE FAN IS FOR THE COOLER.THE POWER OF THE FAN IS 11KW AND OUTPUT SPEED IS 2900 R/M

8. THE MOTOR FOR THE MAIN SPINDLE IS 15KW (6 POLE).THE SPEED OF 140 R/M IS FOR THE COOLER.

QUANTITY: 1

Learn More -

P-3201 CARDING AND NEEDLING LINE, WIDTH 6000mm, YEAR 2005

P-3201 CARDING AND NEEDLING LINE, WIDTH 6000mm, YEAR 2005P-3201 CARDING AND NEEDLING LINE, WIDTH 6000mm, YEAR 2005

OFFER 001

CARDING AND NEELDING LINE

YEAR: 2005 (STARTED AT 2006)

WIDTH: 6000mmCONSISTS OF:

OFFER 002

FALUBAZ FEEDING AND MIXING LINEOFFER 003

FOR CARDING MACHINE WMZ+ZOFFER 004

AUTOMATEX CROSS LAPPER FA 5000/TC AUTOMATEOFFER 005

ASSELIN GILL BOXOFFER 006

AUTOMATEX NEEDLING MACHINE PR 160/TOFFER 007

AUTOMATEX NEEDLING MACHINE AG 160/TBOFFER 008

BELMATEX COMPENSATOR WITH WINDERQUANTITY: 1 LINE

Learn More -

M-5491 SULZER MODEL P7200 B390 F4 J D1 – JACQUARD LX-1600 AND CX-870REFERENCE NUMBER: M-5491 SULZER MODEL P7200 B390 F4 J D1 – JACQUARD LX-1600 AND CX-870 YEAR 6X 1997, 2X 1998 WORKING WIDTH 3900 MM/ 153” (4) STAUBLI E-JACQUARD LX-1600 YEAR 2000 3072 HOOKS CONTROLLER JC-5 (M/C 1997) (4) STAUBLI E-JACQUARD CX-870 YEAR 2000/01 2688 HOOKS CONTROLLER JC-5 (M/C 1997/98) GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER QUANTITY AVAILABLE: 8 Learn More

M-5491 SULZER MODEL P7200 B390 F4 J D1 – JACQUARD LX-1600 AND CX-870REFERENCE NUMBER: M-5491 SULZER MODEL P7200 B390 F4 J D1 – JACQUARD LX-1600 AND CX-870 YEAR 6X 1997, 2X 1998 WORKING WIDTH 3900 MM/ 153” (4) STAUBLI E-JACQUARD LX-1600 YEAR 2000 3072 HOOKS CONTROLLER JC-5 (M/C 1997) (4) STAUBLI E-JACQUARD CX-870 YEAR 2000/01 2688 HOOKS CONTROLLER JC-5 (M/C 1997/98) GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER QUANTITY AVAILABLE: 8 Learn More -

M-5364 VOLKMANN VTS-07 TFO TWISTERS YEAR 1999 WITH 160 SPINDLESREFERENCE NUMBER: M-5364 (220WDFAXX1) L VOLKMANN VTS-07 TFO TWISTERS YEAR 1999 WITH 160 SPINDLES VOLKMANN 2X1 TWISTERS MODEL VTS-07 YEAR 1999 160 SPINDLES EACH FEEDING TUBES LENGTH 250mm CAN DIAMETER 128mm OUTPUT 6” 4°20, GAUGE 225mm AIR THREADING DEVICE WITH 1 SMIT DOUBLE MACHINE (NEW MACHINE NOT BEING INSTALLED) ASSEMBLY WINDER MODEL SESB/24, WITH 24 HEADS FOR ASSEMBLING UP TO 2 PLIES WITH CREEL IN MACHINE, DELIVERY TRAVERSE 6”, 4°20, WITH MESDAN WATER SPLICER QUANTITY AVAILABLE: 2 Learn More

M-5364 VOLKMANN VTS-07 TFO TWISTERS YEAR 1999 WITH 160 SPINDLESREFERENCE NUMBER: M-5364 (220WDFAXX1) L VOLKMANN VTS-07 TFO TWISTERS YEAR 1999 WITH 160 SPINDLES VOLKMANN 2X1 TWISTERS MODEL VTS-07 YEAR 1999 160 SPINDLES EACH FEEDING TUBES LENGTH 250mm CAN DIAMETER 128mm OUTPUT 6” 4°20, GAUGE 225mm AIR THREADING DEVICE WITH 1 SMIT DOUBLE MACHINE (NEW MACHINE NOT BEING INSTALLED) ASSEMBLY WINDER MODEL SESB/24, WITH 24 HEADS FOR ASSEMBLING UP TO 2 PLIES WITH CREEL IN MACHINE, DELIVERY TRAVERSE 6”, 4°20, WITH MESDAN WATER SPLICER QUANTITY AVAILABLE: 2 Learn More -

M-5376 VOLKMANN VTS-08.6 YEAR 1996 – 160 POSITIONSREFERENCE NUMBER: M-5376 (220SWGEXX1) L VOLKMANN VTS-08.6 YEAR 1996 – 160 POSITIONS VOLKMANN TYPE: VTS-08.6 ORIGIN: GERMANY YEAR: 1996 QUANTITY AVAILABLE: 1 Learn More

M-5376 VOLKMANN VTS-08.6 YEAR 1996 – 160 POSITIONSREFERENCE NUMBER: M-5376 (220SWGEXX1) L VOLKMANN VTS-08.6 YEAR 1996 – 160 POSITIONS VOLKMANN TYPE: VTS-08.6 ORIGIN: GERMANY YEAR: 1996 QUANTITY AVAILABLE: 1 Learn More