Search results for: 'Har'

-

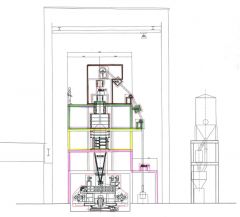

T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008 YEAR 2008, PILOT RUN YEAR 2009, STOPPED PRODUCTION YEAR 2017 FILM MACHINE EXTRUDER: BATTENFELD EXTRUDER DIAMETER 4.5” (115mm) L/D RATIO 24:1 460V 3P 60Hz 125HP AC VECTOR MOTOR RESIN TEMPARETURE: 230°C (446 DEGREEF) OUTPUT: MAX 180KG/H (400 LBS/H) PRESSURE RATINGS ARE: BARREL 20,000PSI BARREL CLAMP 10,000PSI RUPTURED DISC 7,500PSI Learn More

T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008 YEAR 2008, PILOT RUN YEAR 2009, STOPPED PRODUCTION YEAR 2017 FILM MACHINE EXTRUDER: BATTENFELD EXTRUDER DIAMETER 4.5” (115mm) L/D RATIO 24:1 460V 3P 60Hz 125HP AC VECTOR MOTOR RESIN TEMPARETURE: 230°C (446 DEGREEF) OUTPUT: MAX 180KG/H (400 LBS/H) PRESSURE RATINGS ARE: BARREL 20,000PSI BARREL CLAMP 10,000PSI RUPTURED DISC 7,500PSI Learn More -

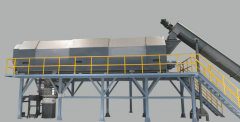

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More -

YY-1228 BAG OPENER, FEEDING PORT SIZE 600 X 800mmYY-1228 BAG OPENER, FEEDING PORT SIZE 600 X 800mm MODEL: APE-60 MOTOR POWER: MAIN SHAFT MOTOR: 4 POLE 2.2 KW, CVT INCORPORATED TO CAPACITY: 2 TONS PERHOUR DIMENSIONS: 1400 X 1000 X 2000mm Learn More

YY-1228 BAG OPENER, FEEDING PORT SIZE 600 X 800mmYY-1228 BAG OPENER, FEEDING PORT SIZE 600 X 800mm MODEL: APE-60 MOTOR POWER: MAIN SHAFT MOTOR: 4 POLE 2.2 KW, CVT INCORPORATED TO CAPACITY: 2 TONS PERHOUR DIMENSIONS: 1400 X 1000 X 2000mm Learn More -

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More -

V-1817 SEMI-AUTOMATIC NOSE CLIP WELDING MACHINE

V-1817 SEMI-AUTOMATIC NOSE CLIP WELDING MACHINESEMI-AUTOMATIC NOSE CLIP WELDING MACHINE FOR NOSE CLIP WELDING FOR DUST MASK RESPIRATORS, IT’S EASY TO OPERATE, FIRM WELDING EFFECT. THIS MACHINE INCORPORATES CONSTANT TEMPERATURE WELDING, WHICH IS NOT HARMFUL TO THE FABRIC, IT’S THE IDEAL MACHINE FOR DUST MASK RESPIRATOR MANUFACTURING.

FEATURES:

1. THIS MACHINE IS EASY TO OPERATE; THE GLUED ALUMINUM NOSE CLIP IS MOVED BY PNEUMATIC THEN WELDED ONTO THE MASK.

2. IT’S HIGH PRECISION AND THE NOSE CLIP WELD IS FIRM.

3. WELDING WITH CONSTANT TEMPERATURE WHICH IS NOT HARMFUL TO THE FABRIC.

ITEM NAME

TECHNICAL PARAMTER

QTY

REMARK

SPECIFICATION

1200mm X 650mm X 1000mm

1

HONGDA

WEIGHT

50KG

EFFICIENCY

8 TO 15PCS/MIN

VOLTAGE

220V/380V

AIR PRESSURE

5KG/CM²

FREQUENCY

20KHZ

POWER

600W

MOLD SERVO MOTOR

SGM7G-09AFC61 4.4KW

1

YASKAWA

ULTRASONIC POWER SERVO MOTOR

SGM7G-13AFC61 1.3KW

2

YASKAWA

MATERIAL PULLING SERVO MOTOR

SGM7G-09AFC61 0.85KW

2

YASKAWA

MATERIAL FEEDING/CORRECTING/INDENTATION MOTOR

130BYG-350A

4

SONGYANG

POUCHING MOTOR

110BYG-350B

4

SONGYANG

110 STEPPER MOTOR

110BYG-350A

10

SONGYANG

UP AND LOWER MOTOR

90BYG-350A

2

SONGYANG

STEPPER MOTOR 56

SY57STH56-2004A

8

SONGYANG

DIRECT CURRENT MOTOR

0.4KW

2

DIRECT CURRENT MOTOR

0.6KW

1

ASYNCHRONOUS THREE-PHASE MOTOR

90S-6

1

0.75KW

FREQUENCY CONVERTER

AVF200-0152

1

1.5KW

MAIN PNEUMATIC COMPONENTS: AIRTAC(TAIWAN); MAIN ELECTRICAL COMPONENTS: PANASONIC(JAPAN), SICK(GERMANY), DONLIM(CHINA&JAPAN), ETC.

EMAIL US FOR PRICE & PICTURES

INCLUDE OUR REFERENCE NUMBER

Learn More -

DORNIER PTV16/S LOOM WITH STAUBLI DOBBY 3800mm YEAR 2005

DORNIER PTV16/S LOOM WITH STAUBLI DOBBY 3800mm YEAR 2005DORNIER PTV16/S YEAR 2005

NOMINAL WIDTH: 3800mm

AT2 CONTROLLER

8 ECS COLOR SELECTORS

STÄUBLI DOBBY WITH MAX 24 HARNESS FRAMES

LET-OFF AND TAKE-UP BOTH ELECTRONIC

WITH 16 HARNESS FRAMES

4 WEFT FEEDERS

6000 HEDDLES/DROPPERS + 1 EXTERNAL BATCHING MOTION + 2 SPLIT BEAMSQUANTITY: 1

Learn More -

L-2987 SIZING MACHINES FOR SALE

L-2987 SIZING MACHINES FOR SALELIST NUMBER: L-2987

Learn More

SIZING MACHINES FOR SALE

REFERENCE NUMBER: P-6749

ROTAL

SIZING MACHINE

YEAR: 1990

QUANTITY: 1

REFERENCE NUMBER: P-7175

BENNINGER ZELL

SIZING

YEAR: 1994

HEAD STOCK WORKING WIDTH: 2800mm

QUANTITY: 1

REFERENCE NUMBER: P-5168

SUCKER

MODEL: MOENUS Z 14

SIZZING MACHINE

WIDTH: 3400mm

BENNINGER

TYPE: BEN DIRECT

WARPER

QUANTITY: 1

REFERENCE NUMBER: P-5818

SUCKER MULLER

SIZING 2 SIZING BOX WIH BENNINGER DIRECT WARPER

YEAR: 1989

WIDTH: 130 INCHES

QUANTITY: 1

REFERENCE NUMBER: P-5586

BENNINGER-ZELL

WARP SIZING LINE

YEAR: 1994

WORKING WIDTH: 3400mm

QUANTITY: 1

REFERENCE NUMBER: C-1229

SUCKER MULLER SIZING MACHINE

MODEL ZG6

YEAR 1984

WORK WIDTH 3000mm

SCHLAFHORST DIRECT WARPING MACHINE MODEL MZD

YEAR 1984

WORK WIDTH 1600mm

QUANTITY: 1

REFERENCE NUMBER: R-1913

SUCKER SIZING

WORKING WIDTH: 3300mm

QUANTITY: 1

REFERENCE NUMBER: R-3193

BENNINGER SIZING MACHINE

TYPE: BEN-SIZE TEC A13

YEAR: 1994

HEADSTOCK WIDTH: 3400mm

QUANTITY: 1

REFERENCE NUMBER: P-3562

WEST POINT

MODEL: 861

SLASHER

YEAR: 1993

HEADWAY WIDTH: 126 INCHES

QUANTITY: 1 -

L-2532 POLYETHYLENE FOAM PLANK PRODUCTION LINE MODEL 180 1000 TO 2000mm WIDTH 2 TO 18mm THICKNESS

L-2532 POLYETHYLENE FOAM PLANK PRODUCTION LINE MODEL 180 1000 TO 2000mm WIDTH 2 TO 18mm THICKNESSREFERENCE NUMBER: L-2532

Learn More

MODEL: 180

1000 TO 2000mm WIDTH -

L-5094 TSUDAKOMA ZAX , WIDTH 2100mm, TERRY TOWEL WEAVING MACHINES, YEAR 1998

L-5094 TSUDAKOMA ZAX , WIDTH 2100mm, TERRY TOWEL WEAVING MACHINES, YEAR 1998L-5094

TSUDAKOMA ZAX , WIDTH 2100mm, TERRY TOWEL WEAVING MACHINES, YEAR 1998

QUANTITY: 13

Learn More -

R-4395 SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

R-4395 SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOURREFERENCE NUMBER: R-4395

SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

MAIN TECHNICAL PARAMETERS:

PROFILES:

THIS LINE IS USED TO PRODUCE CANDIES IN VARIOUS COLORS AND DESIGNS, ESPECIALLY BUBBLE GUM IN X SHAPE, CUBIC, CORRUGATED, CHANNEL STYLE, AND OTHER KINDS.

IT IS DESIGNED TO FACILITATE THE OPERATION WITH RELIABLE PERFORMANCE AND CHANGEABLE CANDY STYLE.

A CORRUGATION-STYLE WRAPPING MACHINE OR A CUTTING/WRAPPING MACHINE CAN BE SUPPLIED IF REQUIRED.

ADVANTAGES:

1) RELIABILITY, EASY CLEANING AND MAINTENANCE

2) ACCURATE CUTTING AND SIMPLE CHANGEOVER

3) EASY OPERATION

4) AUTOMATIC BELT TENSIONING

REFERENCE NUMBER: R-4395

SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

MAIN TECHNICAL PARAMETERS:

PROFILES:

THIS LINE IS USED TO PRODUCE CANDIES IN VARIOUS COLORS AND DESIGNS, ESPECIALLY BUBBLE GUM IN X SHAPE, CUBIC, CORRUGATED, CHANNEL STYLE, AND OTHER KINDS.

IT IS DESIGNED TO FACILITATE THE OPERATION WITH RELIABLE PERFORMANCE AND CHANGEABLE CANDY STYLE.

A CORRUGATION-STYLE WRAPPING MACHINE OR A CUTTING/WRAPPING MACHINE CAN BE SUPPLIED IF REQUIRED.

ADVANTAGES:

1) RELIABILITY, EASY CLEANING AND MAINTENANCE

2) ACCURATE CUTTING AND SIMPLE CHANGEOVER

3) EASY OPERATION

4) AUTOMATIC BELT TENSIONING

Learn More