Search results for: 'Combined'

- Related search terms

- combined o

- combined+o

- combined c

- COMBINED+CYCLE+COMPLETE+POWER+PLANT

- combined+heat+and+power

-

L-3886 CHICKEN FEED PRODUCTION LINE

L-3886 CHICKEN FEED PRODUCTION LINEREFERENCE NUMBER: L-3886

Learn More

1) RECEIVING PROCESS

HEIGHT: 12 METERS

POWER: 1.5 KW

2) GRINDING AND MIXING PROCESS

LENGTH: 1.5 METERS

POWER: 1.5 KW

3) PELLETIZING AND BAGGING PROCESS

CAPACITY: 2 TO 3 TONS PER HOUR, PER UNIT

POWER: 37 KW

4) AUXILIARY PROCESS

POWE: 1.5 KW

5) ELECTRIC CONTROL SYSTEM

POWER: 3 PHASE, 380 VOLTS, 50 Hz -

P-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOS

P-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOSP-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOS

THIS ROASTER OFFERS EXACTLY WHAT CUSTOMERS NEED TO PRODUCE TOP-QUALITY COFFEE. AN INNOVATIVE AND EASY-TO-USE PLC CONTROL SYSTEM ENSURES CONSTANT QUALITY DURING PRODUCTION BUT ALSO RETAINS THE ABILITY TO INFLUENCE THE PROCESSING WHEN NECESSARY. OPTIMIZED PARAMETERS CAN BE SAVED IN THE MACHINE’S MEMORY AND RE-USED. THE MACHINE IS MADE OF STAINLESS STEEL AND OTHER HIGH-QUALITY MATERIALS WHICH PROVIDE SUPERIOR HYGIENE AND MAKE CLEANING COMFORTABLE. THIS ROASTER PROVES THAT DURABILITY AND A MODERN DESIGN CAN BE COMBINED.

THE ROASTER BECOMES A PLUG-AND-PLAY MACHINE BY THE COMBINATION OF SEPARATE COOLING AND HEATING FANS WHICH ALLOW TO ROAST AND COOL AT THE SAME TIME WITH THE INCLUDED CYCLONE. HOT AIR IS THE BEST CHOICE TO ENSURE A UNIFORM ROAST, BECAUSE OF THE HOMOGENOUS HEAT TRANSFER.

THE VARIABLE DRUM SPEED OF THE ROASTING CHAMBER AND THE TWO STEP BURNER ALWAYS DELIVER THE BEST CONDITIONS FOR THE PRODUCT – NO MATTER IF THE BEANS ARE HEAVY AND SMALL AT THE BEGINNING OF THE PROCESS OR IF THEY HAVE ALREADY BECOME LIGHTER TOWARDS TO THE END OF THE ROAST. THE HELICOIDAL BLADES POWERED BY A VARIABLE DRUM SPEED DRIVE OFFER A PERFECT BLENDING AND AN OPTIMAL HEAT EXCHANGE AT ANY TIME OF THE PROCESS. MOREOVER, THE ERGONOMICALLY DESIGNED ROASTER PROVIDES MAXIMUM SAFETY.

THIS ROASTER WAS DESIGNED TO PROVIDE SMALL AND MEDIUM-SIZED COMPANIES WITH A FLEXIBLE HIGH-QUALITY SOLUTION. THE SOPHISTICATED DESIGN OF THE ROASTING MACHINE PLUS MODERN PROCESS TECHNOLOGY ENSURES A HIGH-QUALITY COFFEE PRODUCT THAT IS UNIFORMLY ROASTED – FROM THE SURFACE TO THE CORE OF EVERY SINGLE COFFEE BEAN.

THE COFFEE AND THE HOT AIR TEMPERATURE AS WELL AS THE ROASTING TIME PER BATCH IS PERMANENTLY MONITORED VIA THE TOUCH SCREEN. THE MACHINE’S DESIGN FEATURES AND INSULATING MATERIALS REDUCE INERTIA AND HEAT LOSS TO A MINIMUM, WHICH IMPACTS POSITIVELY ON WORKING ENVIRONMENTS AND FUEL CONSUMPTION.

FEATURES:

AUTOMATIC AND EASY-TO-USE PLC CONTROL SYSTEM WITH INTEGRATED TOUCH PANEL, PARAMETER MEMORY, TEMPERATURE TREND AND SAFETY FEATURES.

GOOD VALUE FOR MONEY.

INDIRECT, CONVECTIVE HOT-AIR SYSTEM FOR UNIFORM ROASTING.

FULL RANGE HEAT CONTROL - BURNER MODULATES BETWEEN 130,000 BTU ALL THE WAY DOWN TO A MERE 20,000 BTU

VARIABLE DRUM SPEEDS OFFER OPTIMAL HEAT TRANSFER AND PRODUCT QUALITY.

FUNCTIONAL AND ATTRACTIVE MACHINE DESIGN MADE OF HIGH-QUALITY MATERIAL.

STATE-OF-THE-ART TECHNOLOGY AND A PLC CONTROL SYSTEM OFFER USER-FRIENDLY AND EFFICIENT COFFEE ROASTING.

A WIDE VARIETY OF GREEN COFFEE CHARACTERISTICS AND BLENDS CAN BE PROCESSED TO HIGH-CLASS COFFEE PRODUCTS.

A USER-FRIENDLY AUTOMATION-PANEL ALLOWS THE PERFECT CONTROL OVER VARIOUS PROCESS PARAMETERS.

UL LISTED AND MADE RIGHT HERE IN MINNEAPOLIS.

GAS CONSUMPTION: RATED AT MAXIMUM - UP TO 150,000BTU (44KW/HR) OPERATES BEST BETWEEN 75 - 80,000 BTUOPTIONAL FEATURES:

PNEUMATIC FEEDER

PNEUMATIC DESTONER/DISCHARGE UNIT

AFTERBURNERQUANTITY: 1

Learn More -

P-5068 SAN FRANCISCAN 12 KILOS 25 POUNDS ROASTER

P-5068 SAN FRANCISCAN 12 KILOS 25 POUNDS ROASTERP-5068 SAN FRANCISCAN 12 KILOS 25 POUNDS ROASTER

INCLUDES ROASTER, AFTERBURNER, AMBIENT AND BEAN TEMPERATURE PROBES WITH DUAL DIGITAL DISPLAY. ALSO, THE

HIGH QUALITY GAS MANIFOLD ALLOWS YOU TO MEASURE THE BTU INPUT. COMES CHAFF COLLECTOR. BOTH THE AFTERBURNER AND CHAFF COLLECTOR ARE COMBINED IN THE CYLINDER BEHIND THE ROASTER. EXCELLENT, AFFORDABLE CHOICE FOR THE CONTINUOUS COFFEE ROASTER. IT ROASTS AND COOLS AT THE SAME TIME. 4 BATCHES/HOUR. MINIMAL MAINTENANCE. PIPES ARE BUILT ON THE EXTERIOR SO EASY TO CLEAN. TERMS: 50% DEPOSIT AND BALANCE PRIOR TO SHIPMENT. ALLOW 60-90 DAYS FOR ASSEMBLY!SPECIFICATIONS:

36 INCHES X 96 INCHES FLOOR SPACE REQUIRED

4 BATCHES/HR =100 LBS/HR

VOLTAGE 220V SINGLE PHASE

AMPS 15 AMPS

BTU 100,000

GAS PRESSURE: 7 INCHES W/C NAT GAS OR 11 INCHES W/C PROPANE

FACE PLATES: 5/8 INCHES STEEL

WEIGHT 1350 LBS ROASTER + AFTERBURNER= 2100 LBSQUANTITY: 1

Learn More -

K-8157 COAL FIRED POWER PLANT (2 X 50MW)

K-8157 COAL FIRED POWER PLANT (2 X 50MW)K-8157 COAL FIRED POWER PLANT (2 X 50MW)

ENERGY BOILERS (CAE)

TURBINE SYSTEMS

STEAM TURBINES (TA) - DSL ARE 50 - 1

-CONDENSING TURBINE WITH TWO ADJUSTABLE OUTLETS, SUCH AS "ACTING" ON A SINGLE LINE OF TREES, DESIGNED TO DRIVE THE AC GENERATOR DIRECT-TYPE TH 60-2

-IS COMPOSED OF TWO BODIES: THE BODY OF HIGH PRESSURE (CIP) AND MEDIUM AND LOW PRESSURE BODY (CMP + CJP)

-HAS TWO ADJUSTABLE OUTLETS (PLUG SOCKETS AND PLUG HEATING) AND FIVE FIXED DOSES REGENERATIVE CIRCUIT FEEDSQUARES OF 600 CARS OVER T/H (WITH BUCKET WHEEL AND ARM LENGTH 12 M) - 4 PCS

-TIP HAMMER CRUSHERS CCA - 160 TO 2 PIECES

- RUBBER BANDS COAL TRANSPORTTHE MAIN EQUIPMENT IS ADDED TO ENSURE PROPER OPERATION FOLLOWING:

- SOLID FUEL STORAGE

- INSTALLATIONS AND INDUSTRIAL WATER SUPPLIES AND WASTEWATER DISCHARGE

- INSTALLATION OF EXHAUST HYDRAULIC SLAG

- WATER TREATMENT STATION

TO USE COAL, WEIGHT 88%, 12% NATURAL GASQUANTITY: 1

Learn More -

C-4005 PACTEC NAGEMA EW10 CUT & VIENNA FOLD TYPE BONBON WRAPPER, WIDTH 16 TO 18mm, YEAR 1990

C-4005 PACTEC NAGEMA EW10 CUT & VIENNA FOLD TYPE BONBON WRAPPER, WIDTH 16 TO 18mm, YEAR 1990C-4005 PACTEC NAGEMA EW10 CUT & VIENNA FOLD TYPE BONBON WRAPPER, WIDTH 16 TO 18mm, YEAR 1990

YEAR: 1990

300/MIN

WITH BATCH ROLLER & ROPE SIZER

REFURBISHED

PRODUCT DIMENSIONS

LENGTH: 25 TO 35mm

WIDTH: 16 TO 18mmQUANTITY: 1

Learn More -

K-0272 CATTLE SLAUGHTER LINE 60 PER HOURREFERENCE NUMBER: K-0272 CATTLE SLAUGHTER LINE 60 PER HOUR SHIFT PRODUCTION: 100 TONS (60 CATTLE PER HOUR) QUANTITY AVAILABLE: 1 Learn More

K-0272 CATTLE SLAUGHTER LINE 60 PER HOURREFERENCE NUMBER: K-0272 CATTLE SLAUGHTER LINE 60 PER HOUR SHIFT PRODUCTION: 100 TONS (60 CATTLE PER HOUR) QUANTITY AVAILABLE: 1 Learn More -

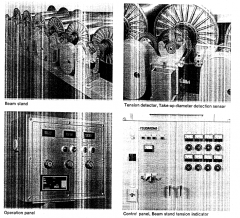

M-5202 KB10 REBEAMER FOR ACETATE WITH DISK BRAKES - TSUDAKOMAREFERENCE NUMBER: M-5202 (1313VTYFXX12) L KB10 REBEAMER FOR ACETATE WITH DISK BRAKES - TSUDAKOMA QUANTITY AVAILABLE: 1 Learn More

M-5202 KB10 REBEAMER FOR ACETATE WITH DISK BRAKES - TSUDAKOMAREFERENCE NUMBER: M-5202 (1313VTYFXX12) L KB10 REBEAMER FOR ACETATE WITH DISK BRAKES - TSUDAKOMA QUANTITY AVAILABLE: 1 Learn More -

M-5004 PILLOW FILLING MACHINESREFERENCE NUMBER: M-5004 (1212CKWDHH11) L PILLOW FILLING MACHINES DIFFERENT CAPACITIES FOR THIS MACHINE 100KG/H, 120KG/H, 220KG/H, 250KG/H FUNCTION OF THE PILLOW FILLING MACHINE: THE SMALL PIECES OF RAW COTTON OPENING INTO A FLUFFY IMITATION SILK, COTTON, AND USED THE WIND SUCTION OUT FROM OPENING MACHINE, IMITATION SILK COTTON BY METAL DUCT INTO THE CUSHION OR PILLOW. OPERATOR CONTROL THE COTTON FILLING TIME. IT WILL CONNECT WITH THE FIBER OPENING MACHINE THE PRODUCTION LINE INCLUDES FIBER OPENING, CONVEYING, MIXED STIRRING AND STUFFING. IT MIXES AND STIRS MANY KINDS OF STUFFING MATERIALS AND THEN FILLS THEM INTO THROW PILLOWS, CUSHIONS, PILLOWS, PET PRODUCTS, BIG PLUSH TOYS, AND OTHERS. THE OPENING RATE OF THE MACHINE IS UP TO 100%, NO DAMAGES TO FIBER CRIMP AND SLIPPERY. THE STUFFED PRODUCT IS FLUFFY, ELASTIC, AND SOFT. REASONABLE AND EFFICIENT STRUCTURAL CONFIGURATION IMPROVES MANUFACTURING EFFICIENCY, SAVES COT FOR CUSTOMERS, AND DECREASES LABOR INTENSITY. ALL WORK TEETH ARE PROCESSED WITH DYNAMIC BALANCE, NO VIBRATION AND LOW NOISE IN THE OPERATION. THE MACHINE CAN BE FREELY COMBINED BASED ON CUSTOMER’S CHOICE OF AN OPENER AND A FILLING MACHINE, SATISFYING DIFFERENT CUSTOMER’S REQUIREMENTS. CE CERTIFICATION (MODEL: 001) PILLOW FILLING MACHINE CAPACITY: 100KG/H POWER: 6.7KW PRESSURE: 0.4 TO 0.8 MPA VOLTAGE: AS PER CUSTOMER REQUIREMENT NET WEIGHT: 680KG DIMENSION: 3200mm x 1500mm x 1330mm (MODEL: 002) PILLOW FILLING MACHINE CAPACITY: 120KG/H POWER: 6.7KW PRESSURE: 0.4 TO 0.8 MPA VOLTAGE: AS PER CUSTOMER REQUIREMENT NET WEIGHT: 700KG DIMENSION: 3500mm x 1500mm x 1330mm (MODEL: 003) PILLOW FILLING MACHINE CAPACITY: 220KG/H POWER: 10.45KW PRESSURE: 0.4 TO 0.8 MPA VOLTAGE: AS PER CUSTOMER REQUIREMENT NET WEIGHT: 900KG DIMENSION: 4000mm x 2200mm x 1200mm (MODEL: 004) PILLOW FILLING MACHINE CAPACITY: 250KG/H POWER: 10.45KW PRESSURE: 0.4 TO 0.8 MPA VOLTAGE: AS PER CUSTOMER REQUIREMENT NET WEIGHT: 1050KG DIMENSION: 4500mm x 2500mm x 2050mm QUANTITY AVAILABLE: 1 Learn More

M-5004 PILLOW FILLING MACHINESREFERENCE NUMBER: M-5004 (1212CKWDHH11) L PILLOW FILLING MACHINES DIFFERENT CAPACITIES FOR THIS MACHINE 100KG/H, 120KG/H, 220KG/H, 250KG/H FUNCTION OF THE PILLOW FILLING MACHINE: THE SMALL PIECES OF RAW COTTON OPENING INTO A FLUFFY IMITATION SILK, COTTON, AND USED THE WIND SUCTION OUT FROM OPENING MACHINE, IMITATION SILK COTTON BY METAL DUCT INTO THE CUSHION OR PILLOW. OPERATOR CONTROL THE COTTON FILLING TIME. IT WILL CONNECT WITH THE FIBER OPENING MACHINE THE PRODUCTION LINE INCLUDES FIBER OPENING, CONVEYING, MIXED STIRRING AND STUFFING. IT MIXES AND STIRS MANY KINDS OF STUFFING MATERIALS AND THEN FILLS THEM INTO THROW PILLOWS, CUSHIONS, PILLOWS, PET PRODUCTS, BIG PLUSH TOYS, AND OTHERS. THE OPENING RATE OF THE MACHINE IS UP TO 100%, NO DAMAGES TO FIBER CRIMP AND SLIPPERY. THE STUFFED PRODUCT IS FLUFFY, ELASTIC, AND SOFT. REASONABLE AND EFFICIENT STRUCTURAL CONFIGURATION IMPROVES MANUFACTURING EFFICIENCY, SAVES COT FOR CUSTOMERS, AND DECREASES LABOR INTENSITY. ALL WORK TEETH ARE PROCESSED WITH DYNAMIC BALANCE, NO VIBRATION AND LOW NOISE IN THE OPERATION. THE MACHINE CAN BE FREELY COMBINED BASED ON CUSTOMER’S CHOICE OF AN OPENER AND A FILLING MACHINE, SATISFYING DIFFERENT CUSTOMER’S REQUIREMENTS. CE CERTIFICATION (MODEL: 001) PILLOW FILLING MACHINE CAPACITY: 100KG/H POWER: 6.7KW PRESSURE: 0.4 TO 0.8 MPA VOLTAGE: AS PER CUSTOMER REQUIREMENT NET WEIGHT: 680KG DIMENSION: 3200mm x 1500mm x 1330mm (MODEL: 002) PILLOW FILLING MACHINE CAPACITY: 120KG/H POWER: 6.7KW PRESSURE: 0.4 TO 0.8 MPA VOLTAGE: AS PER CUSTOMER REQUIREMENT NET WEIGHT: 700KG DIMENSION: 3500mm x 1500mm x 1330mm (MODEL: 003) PILLOW FILLING MACHINE CAPACITY: 220KG/H POWER: 10.45KW PRESSURE: 0.4 TO 0.8 MPA VOLTAGE: AS PER CUSTOMER REQUIREMENT NET WEIGHT: 900KG DIMENSION: 4000mm x 2200mm x 1200mm (MODEL: 004) PILLOW FILLING MACHINE CAPACITY: 250KG/H POWER: 10.45KW PRESSURE: 0.4 TO 0.8 MPA VOLTAGE: AS PER CUSTOMER REQUIREMENT NET WEIGHT: 1050KG DIMENSION: 4500mm x 2500mm x 2050mm QUANTITY AVAILABLE: 1 Learn More -

G-7618-B BABCOCK STENTER FRAME 2800mm YEAR 1992BRAND: BABCOCK PRODUCTION YEAR: 1992 WORKING WIDTH: 2800mm WEAVE + KNIT FABRIC CAN BE WORKED. SPEED OF OPERATION: 0-60 METERS PER MINUTE QUANTITY: 1 Learn More

G-7618-B BABCOCK STENTER FRAME 2800mm YEAR 1992BRAND: BABCOCK PRODUCTION YEAR: 1992 WORKING WIDTH: 2800mm WEAVE + KNIT FABRIC CAN BE WORKED. SPEED OF OPERATION: 0-60 METERS PER MINUTE QUANTITY: 1 Learn More -

MAMMUT 2 HEAD PANEL QUILTING MACHINE2 HEAD PANEL QUILTING MACHINE WITH AUTOMATIC FABRIC FEED Learn More

MAMMUT 2 HEAD PANEL QUILTING MACHINE2 HEAD PANEL QUILTING MACHINE WITH AUTOMATIC FABRIC FEED Learn More