Search results for: 'Reference Number: J'

- Related search terms

- Reference Number:

- Reference Number: J-

- Reference Number'

- Reference Number:'

- reference number -

-

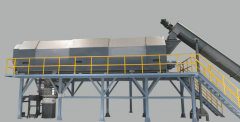

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More -

M-3674-A WISE PILLOW MACHINE FILLING MACHINE

M-3674-A WISE PILLOW MACHINE FILLING MACHINEREFERENCE NUMBER: M-3674-A

WISE PILLOW MACHINE FILLING MACHINEPLATE INFO FOR THE HOPPER:

DATE: JUNE/00

MOD. NO.: WK 4×36

PLATE INFO FOR THE FIRST BLOWER:

DATE: JUNE/00

MOD. NO.: 4C 113PLATE INFO FOR THE SECOND BLOWER:

DATE: JUNE/00

MOD. NO.: 4C 113PLATE INFO FOR THE CONTROL PANEL:

DATE: JUNE/2000

MOD. NO.: SYSTEM 1NOTE: THE HOPPER APRON WIDTH: 35 ½” INCHES

AFTER THE HOPPER THERE IS ANOTHER MACHINE WHICH MIGHT BE A FINE OPENER WITH (2) BLOWERS, (2) NOZZLES AND (1) CONTROL PANEL

QUANTITY: 1

Learn More -

P-1144 NOUVO PIGNONE TP500 TERRY TOWEL LOOMS JACQUARD DOBBY

P-1144 NOUVO PIGNONE TP500 TERRY TOWEL LOOMS JACQUARD DOBBYREFERENCE NUMBER: P-1144

Learn More

NOUVO PIGNONE TP500 TERRY TOWEL LOOMS JACQUARD DOBBY

NOUV PIGNONE TP500

TERRY TOWEL LOOMS

1 SET JACQUARD TYPE 130 INCHES R/S

3 SETS JACQUARD and DOBBY BOTH USE TYPE 130 INCHES R/S

3 SETS JACQUARD and DOBBY BOTH USE TYPE 85 INCHES R/S

2 SETS DOBBY TYPE 85 INCHES R/S

2 SETS DOBBY TYPE 130 INCHES R/S

2 SETS TODO TYING MACHINE

1 SET KAMITU WINDER (8 SPINDLES)

1 SET ACCESSORIES PARTS

QUANTITY: 15 SETS -

K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORYREFERENCE NUMBER: K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORY WORKING FACTORY TO MAKE ELASTIC, RIBBON OR PRINTED LABEL TAPE SUITABLE PRINTING METHODS: ROTARY, SILK-SCREEN, LETTER PRESS, HOT EDGE, STAMPING. NARROW WOVEN EDGE POLYESTER OR SATIN. YOU MAY BUY THIS FACTORY IN PARTS OR ENTIRELY, ACCORDING TO YOUR NEEDS. A THOROUGHLY MODERN PLANT. HUMAN HANDS NEVER TOUCH THE PRODUCT. CONSISTING OF: JACOB MULLER NF LOOMS NEEDLE HEADS PER MACHINE: 6 REED WIDTH: 42 mm MAX. RIBBON WIDTH: APPROX. 40mm MAX. QUANTITY: 68 BENNINGER ERGOTRONIC SECTIONAL WARPER IN PERFECT CONDITION QUANTITY: 1 JACOB MULLER WEBTEX FINISHING MACHINE QUANTITY: 1 JACOB MULLER RAM 500 MEASURING AND ROLLING MACHINE QUANTITY: 1 JACOB MULLER NF AUTOMATIC WINDERS QUANTITY: 78 QUANTITY AVAILABLE: 1 Learn More

K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORYREFERENCE NUMBER: K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORY WORKING FACTORY TO MAKE ELASTIC, RIBBON OR PRINTED LABEL TAPE SUITABLE PRINTING METHODS: ROTARY, SILK-SCREEN, LETTER PRESS, HOT EDGE, STAMPING. NARROW WOVEN EDGE POLYESTER OR SATIN. YOU MAY BUY THIS FACTORY IN PARTS OR ENTIRELY, ACCORDING TO YOUR NEEDS. A THOROUGHLY MODERN PLANT. HUMAN HANDS NEVER TOUCH THE PRODUCT. CONSISTING OF: JACOB MULLER NF LOOMS NEEDLE HEADS PER MACHINE: 6 REED WIDTH: 42 mm MAX. RIBBON WIDTH: APPROX. 40mm MAX. QUANTITY: 68 BENNINGER ERGOTRONIC SECTIONAL WARPER IN PERFECT CONDITION QUANTITY: 1 JACOB MULLER WEBTEX FINISHING MACHINE QUANTITY: 1 JACOB MULLER RAM 500 MEASURING AND ROLLING MACHINE QUANTITY: 1 JACOB MULLER NF AUTOMATIC WINDERS QUANTITY: 78 QUANTITY AVAILABLE: 1 Learn More -

M-5217 NUOVO PIGNONE TERRY TOWEL RAPIER WEAVING LOOMS – 135” & 85” DOBBY AND JACQUARDREFERENCE NUMBER: M-5217 (1313265FEL12UC) L NUOVO PIGNONE TERRY TOWEL RAPIER WEAVING LOOMS – 135” & 85” DOBBY AND JACQUARD NUOVO PIGNONE TERRY TOWEL RAPIER LOOMS 1 SET JACQUARD TYPE, 130” R/S 3 SETS JACQUARD & DOBBY BOTH USE TYPE, 130” R/S 3 SETS JACQUARD & DOBBY BOTH USE TYPE, 85” R/S 2 SETS DOBBY TYPE, 85” R/S 2 SETS DOBBY TYPE, 130” R/S 2 SETS TODO TYING MACHINE 1 SET KAMITU WINDER (8 SPINDLES) 1 SET ACCESSORIES PARTS DELIVERY: WITHIN 1 MONTH AFTER RECEIPT OF CUSTOMER’S PAYMENT QUANTITY AVAILABLE: 15 SETS Learn More

M-5217 NUOVO PIGNONE TERRY TOWEL RAPIER WEAVING LOOMS – 135” & 85” DOBBY AND JACQUARDREFERENCE NUMBER: M-5217 (1313265FEL12UC) L NUOVO PIGNONE TERRY TOWEL RAPIER WEAVING LOOMS – 135” & 85” DOBBY AND JACQUARD NUOVO PIGNONE TERRY TOWEL RAPIER LOOMS 1 SET JACQUARD TYPE, 130” R/S 3 SETS JACQUARD & DOBBY BOTH USE TYPE, 130” R/S 3 SETS JACQUARD & DOBBY BOTH USE TYPE, 85” R/S 2 SETS DOBBY TYPE, 85” R/S 2 SETS DOBBY TYPE, 130” R/S 2 SETS TODO TYING MACHINE 1 SET KAMITU WINDER (8 SPINDLES) 1 SET ACCESSORIES PARTS DELIVERY: WITHIN 1 MONTH AFTER RECEIPT OF CUSTOMER’S PAYMENT QUANTITY AVAILABLE: 15 SETS Learn More -

A-1161 STAUBLI JACQUARD CX 880/2688, 870/2688, DX 110/2688 HOOKS 2400REFERENCE NUMBER: A-1161 (1212GHBXX11) A STAUBLI JACQUARD CX 880/2688, 870/2688, DX 110/2688 HOOKS 2400 (1) STAUBLI JACQUARD CX 880/2688 YEAR 2001 WORKING HOOKS 2400 WITH CONTROLLER JC5 MODULES M4 CARDAN SHAFT AND ACCESSORIES (1) STAUBLI JACQUARD CX 870/2688 YEAR 2000 WORKING HOOKS 2400 WITH CONTROLLER JC5 MODULES M4 CARDAN SHAFT AND ACCESSORIES (1) STAUBLI JACQUARD DX 110/2688 YEAR 2008 WORKING HOOKS 2400 WITH CONTROLLER JC6 MODULES M6 CARDAN SHAFT AND ACCESSORIES QUANTITY AVAILABLE: 3 Learn More

A-1161 STAUBLI JACQUARD CX 880/2688, 870/2688, DX 110/2688 HOOKS 2400REFERENCE NUMBER: A-1161 (1212GHBXX11) A STAUBLI JACQUARD CX 880/2688, 870/2688, DX 110/2688 HOOKS 2400 (1) STAUBLI JACQUARD CX 880/2688 YEAR 2001 WORKING HOOKS 2400 WITH CONTROLLER JC5 MODULES M4 CARDAN SHAFT AND ACCESSORIES (1) STAUBLI JACQUARD CX 870/2688 YEAR 2000 WORKING HOOKS 2400 WITH CONTROLLER JC5 MODULES M4 CARDAN SHAFT AND ACCESSORIES (1) STAUBLI JACQUARD DX 110/2688 YEAR 2008 WORKING HOOKS 2400 WITH CONTROLLER JC6 MODULES M6 CARDAN SHAFT AND ACCESSORIES QUANTITY AVAILABLE: 3 Learn More -

J-1132 STAUBLI JACQUARD MACHINESREFERENCE NUMBER: J-1132 (1212ZMTDXX11) J STAUBLI JACQUARD MACHINES STAUBLI JACQUARD CX 880/2688 YEAR 2001 – 2400 HOOKS MODEL: CX 880/2688 2400 HOOKS YEAR: 2001 CONTROLLER JC5 MODULES M4 CARDAN SHAFT AND ACCESSORIES QUANTITY: 1 STAUBLI JACQUARD CX 870/2688 YEAR 2000 – 2400 HOOKS MODEL: CX 870/2688 2400 HOOKS YEAR: 2000 CONTROLLER JC5 MODULES M4 CARDAN SHAFT AND ACCESSORIES STAUBLI JACQUARD DX 110/2688 YEAR 2008 – 2400 HOOKS MODEL: DX 110/2688 2400 HOOKS YEAR: 2008 CONTROLLER JC6 MODULES M6 CARDAN SHAFT AND ACCESSORIES QUANTITY AVAILABLE: 3 Learn More

J-1132 STAUBLI JACQUARD MACHINESREFERENCE NUMBER: J-1132 (1212ZMTDXX11) J STAUBLI JACQUARD MACHINES STAUBLI JACQUARD CX 880/2688 YEAR 2001 – 2400 HOOKS MODEL: CX 880/2688 2400 HOOKS YEAR: 2001 CONTROLLER JC5 MODULES M4 CARDAN SHAFT AND ACCESSORIES QUANTITY: 1 STAUBLI JACQUARD CX 870/2688 YEAR 2000 – 2400 HOOKS MODEL: CX 870/2688 2400 HOOKS YEAR: 2000 CONTROLLER JC5 MODULES M4 CARDAN SHAFT AND ACCESSORIES STAUBLI JACQUARD DX 110/2688 YEAR 2008 – 2400 HOOKS MODEL: DX 110/2688 2400 HOOKS YEAR: 2008 CONTROLLER JC6 MODULES M6 CARDAN SHAFT AND ACCESSORIES QUANTITY AVAILABLE: 3 Learn More -

M-4677 DORNIER JACQUARD LOOMS YEAR 1994-1996 WIDTH 1900mm-2000mmREFERENCE NUMBER: M-4677 (111123ASMD10RC) L DORNIER JACQUARD LOOMS YEAR 1994-1996 WIDTH 1900mm-2000mm (2) X DORNIER HTV S/8J – WIDTH 2000mm – YEAR 1994 WITH STAUBLI CX860 JACQUARD, JC4 CONTROLLER, 2688 HOOKS (2) X DORNIER HTV S78J – WIDTH 1900mm – YEAR 1996 WITH STAUBLI CX860 JACQUARD, JC4 CONTROLLER, 2688 HOOKS (2) X DORNIER HTV S78J – WIDTH 1900mm – YEAR 1996 WITH STAUBLI CX860 JACQUARD, JC4 CONTROLLER, 2688 HOOKS, WITH FANCY BEAM LOOMS ARE WELL KEPT, RUNNING PRESENTLY INSPECTION & IMMEDIATE DELIVERY AVAILABLE QUANTITY AVAILABLE: 6 Learn More

M-4677 DORNIER JACQUARD LOOMS YEAR 1994-1996 WIDTH 1900mm-2000mmREFERENCE NUMBER: M-4677 (111123ASMD10RC) L DORNIER JACQUARD LOOMS YEAR 1994-1996 WIDTH 1900mm-2000mm (2) X DORNIER HTV S/8J – WIDTH 2000mm – YEAR 1994 WITH STAUBLI CX860 JACQUARD, JC4 CONTROLLER, 2688 HOOKS (2) X DORNIER HTV S78J – WIDTH 1900mm – YEAR 1996 WITH STAUBLI CX860 JACQUARD, JC4 CONTROLLER, 2688 HOOKS (2) X DORNIER HTV S78J – WIDTH 1900mm – YEAR 1996 WITH STAUBLI CX860 JACQUARD, JC4 CONTROLLER, 2688 HOOKS, WITH FANCY BEAM LOOMS ARE WELL KEPT, RUNNING PRESENTLY INSPECTION & IMMEDIATE DELIVERY AVAILABLE QUANTITY AVAILABLE: 6 Learn More -

K-6686 PICANOL GAMMAX WITH STAUBLI JACQUARD WIDTH 3200mm YEAR 2003REFERENCE NUMBER: K-6686 PICANOL GAMMAX WITH STAUBLI JACQUARD WIDTH 3200mm YEAR 2003 PICANOL GAMMAX WORKING WIDTH: 3200mm YEAR: 2003 WITH STAUBLIC JACQUARD 8/J 8 COLORS + JACQUARD 1000mm FLANGE, SUMO MOTOR ELO/ETU WITH STAUBLI JACQUARD CS 960 3072 HOOKS FORMAT (1920 HOOKS INSTALLED) YEAR 1994 (TOTALLY REFURBISHED IN 2003) WITH NEW M4 MODULES AND NEW JC5 CONTROLLER NEW DROPBOX 6 WEFT FEEDERS 2 CLOTH ROLLERS 1 WARP BEAM QUANTITY AVAILABLE: 2 Learn More

K-6686 PICANOL GAMMAX WITH STAUBLI JACQUARD WIDTH 3200mm YEAR 2003REFERENCE NUMBER: K-6686 PICANOL GAMMAX WITH STAUBLI JACQUARD WIDTH 3200mm YEAR 2003 PICANOL GAMMAX WORKING WIDTH: 3200mm YEAR: 2003 WITH STAUBLIC JACQUARD 8/J 8 COLORS + JACQUARD 1000mm FLANGE, SUMO MOTOR ELO/ETU WITH STAUBLI JACQUARD CS 960 3072 HOOKS FORMAT (1920 HOOKS INSTALLED) YEAR 1994 (TOTALLY REFURBISHED IN 2003) WITH NEW M4 MODULES AND NEW JC5 CONTROLLER NEW DROPBOX 6 WEFT FEEDERS 2 CLOTH ROLLERS 1 WARP BEAM QUANTITY AVAILABLE: 2 Learn More -

M-4868 PUB BREWERY 20HLREFERENCE NUMBER: M-4868 (1111275NKG10RX) L PUB BREWERY 20HL SPECIFICATION: 1. MALT HANDLING - CYLINDER-CONIC MALT SILO WITH 25M³ CONTENT, MADE IN FIBRE GLASS / PLASTIC, STANDING OUTDOOR ON STEEL CONSTRUCTION - MALT CONVEYORS / SPIRAL CONVEYOR INTO 1ST FLOOR - 2-ROLLER MALT MILL - GRIST CASE - FALL PIPE IN MASH COPPER (FOR DUST FREE MASHING-IN) - GIBBET-LIFT FOR BAGGED SPECIAL MALTS 2. BREWHOUSE TOWER BREWHOUSE FOR 20 HL / BREW, COMPLETE IN STAINLESS STEEL, BUILT 1994, STEAM HEATED, ISOLATED AND COVERED WITH STAINLESS STEEL SHEET, 2 CRANE EYELET, 2 STAINLESS STEEL PLATFORM, WITH: - MASH- / WORT COPPER WITH BOTTOM HEATING ZONE AND INTERIOR COOKER, SIDEWAYS AGITATOR, MANWAY ENTRANCE HATCH, LIGHTNING, STEAM REGULATION VALVE - LAUTER TUN, WITH STAINLESS STEEL RAKING MACHINE WITH SEW-DRIVE FROM TOP, WITH SPENT GRAINS SLIDER, STAINLESS STEEL FALSE BOTTOM, SPENT GRAINS HATCH, VERTICAL SIGHT GLASS, LIGHTNING, SPRAY HEAD, DOME LID WITH BUILT IN CONTROL CABINET - SPINDLE STATION WITH WASHING TABLE IN STAINLESS STEEL, ABOUT 1,5M WALL ASSEMBLED - HOT WATER TANK, WITH 30 HL, IN STAINLESS STEEL, ISOLATED AND COVERED WITH STAINLESS STEEL SHEET, HEATABLE, WITH MANWAY IN THE WALL, LEVEL DISPLAY - PRESSURE RAISING PUMP - WORT COOLING, 1-STAGE PLATE APPARATUS - WORT AERATION IN STAINLESS STEEL 3. FERMENTING- AND STORAGE TANKS - 5 CCTS, WITH 40 HL NET / 46 HL GROSS CONTENT, ALL TANKS 3 BAR, BUILT 1994, STANDING ON FEET, PI-ISOLATED FULLY WELDED WITH STAINLESS STEEL JACKET, WITH JACKET COOLING FROM CONE BELOW TO ½ WALL 60 LT COOLING JACKET 3 BAR, WITH MANWAY IN THE WALL, 2 OUTLETS WITH BUTTERFLY VALVES, TEMPERATURE SENSOR PT100, SPRAY HEAD, PULLED DOWN CLEANING PIPE WITH BUTTERFLY VALVE, BUNGING ARMATURE, OVER PRESSURE VALVE, SAMPLER, 2 CRANE EYELETS, 2 OF THE TANKS WITH LEVEL DISPLAY - DIGITAL TEMPERATURE CONTROL FOR 5 TANKS IN STAINLESS STEEL CONTROL CABINET - CIRCULATING PUMP IN STAINLESS STEEL, MOBILE, WITH SWITCH - MANY GOOD BEER HOSES - 6 X 10 HL BEER DISPENSING TANKS, MAKE DUO TANK, BUILT 2002, 3,0 / 4,3 BAR, COOL ABLE, ISOLATED WITH STAINLESS STEEL-JACKET FULLY WELDED, FOR INLINE-OPERATION, LYING IN RACK, SCREWED STAINLESS STEEL RACK, WITH PRESSURE ARMATURE, OUTLET ARMATURE WITH REDUCTION TO BARE CONNECTION, MANWAY WITH BIG SIGHT GLASS IN MANWAY LED - PANEL FOR 3 TYPES OF BEER 4. FILLING COMBINED BOTTLE-/KEGGING PLANT, WITH 1 CLEANING TUB, HEATED AND 1 REBUILT KEG: - BOTTLE CLEANING MACHINE FOR CLEANING OF 8 BOTTLES INSIDE AND OUTSIDE, FOR UP TO 2LT BOTTLES - BOTTLE FILLING STATION WITH HUB CYLINDER FROM BELOW, WITH SPLINTER PROTECTION - COMBINED KEG-CLEANING- AND FILLING STATION - BUILT IN CONTROL CABINET WITH SIEMENS S5 CONTROL AND OPERATING CONSOLE OP 7 5. OTHER EQUIPMENT - STEAM BOILER FOR ABOUT F280 KG/H, WITH GAS BURNER, FULLY SERVICED ON 4TH AUGUST 2014, BUILT IN 1994 - CONDENSATE TUB IN STAINLESS STEEL AT WALL AND SECOND SMALL S/S-TUB - WATER TREATMENT - STEAM REGULATION AND CONDENSATE VALVES IN CYCLE - STAINLESS STEEL CHIMNEY PLANT ABOUT 8-10M - AIR COMPRESSOR WITH WIND KETTLE, BUILT 1994 - COOLING PLANT / COLD WATER PLANT, MAKE L&R KÄLTETECHNIK, TYPE: WRK-17/SL/-5, PLANT BUILT 1997, COOLING AGENT R 407 C, WITH NEW COMPRESSOR AND NEW PLATE HEAT EXCHANGER IN 2014 FOR 10,000 € INVESTED, EVAPORATOR WITH 2 VENTILATOR OUTSIDE HANGING ON THE WALL 6.1 OTHERS - ABOUT 100 KETS, MAKE SCHÄFER, PLUS-KEGS, FLAT FITTING IN DIFFERENT SIZES, NEUTRAL - PARTY-KEGS, WITH BAVARIAN TAP, PU-COVERED IN BLACK AND WITH WOOD-OPTIC - ABOUT 800 NEUTRAL CLIP LOCK BOTTLES EACH 1 LT 6.2 DIMENSIONS THE ROOM HEIGHT IN BREWHOUSE AND CCTS IS 4.50M. THE PLANT AS ASSEMBLED ON 10.75 X 4.38M. PLEASE NOTE THAT THE BREWERY IS ONLY AVAILABLE AS A SINGLE SALE QUANTITY AVAILABLE: 1 Learn More

M-4868 PUB BREWERY 20HLREFERENCE NUMBER: M-4868 (1111275NKG10RX) L PUB BREWERY 20HL SPECIFICATION: 1. MALT HANDLING - CYLINDER-CONIC MALT SILO WITH 25M³ CONTENT, MADE IN FIBRE GLASS / PLASTIC, STANDING OUTDOOR ON STEEL CONSTRUCTION - MALT CONVEYORS / SPIRAL CONVEYOR INTO 1ST FLOOR - 2-ROLLER MALT MILL - GRIST CASE - FALL PIPE IN MASH COPPER (FOR DUST FREE MASHING-IN) - GIBBET-LIFT FOR BAGGED SPECIAL MALTS 2. BREWHOUSE TOWER BREWHOUSE FOR 20 HL / BREW, COMPLETE IN STAINLESS STEEL, BUILT 1994, STEAM HEATED, ISOLATED AND COVERED WITH STAINLESS STEEL SHEET, 2 CRANE EYELET, 2 STAINLESS STEEL PLATFORM, WITH: - MASH- / WORT COPPER WITH BOTTOM HEATING ZONE AND INTERIOR COOKER, SIDEWAYS AGITATOR, MANWAY ENTRANCE HATCH, LIGHTNING, STEAM REGULATION VALVE - LAUTER TUN, WITH STAINLESS STEEL RAKING MACHINE WITH SEW-DRIVE FROM TOP, WITH SPENT GRAINS SLIDER, STAINLESS STEEL FALSE BOTTOM, SPENT GRAINS HATCH, VERTICAL SIGHT GLASS, LIGHTNING, SPRAY HEAD, DOME LID WITH BUILT IN CONTROL CABINET - SPINDLE STATION WITH WASHING TABLE IN STAINLESS STEEL, ABOUT 1,5M WALL ASSEMBLED - HOT WATER TANK, WITH 30 HL, IN STAINLESS STEEL, ISOLATED AND COVERED WITH STAINLESS STEEL SHEET, HEATABLE, WITH MANWAY IN THE WALL, LEVEL DISPLAY - PRESSURE RAISING PUMP - WORT COOLING, 1-STAGE PLATE APPARATUS - WORT AERATION IN STAINLESS STEEL 3. FERMENTING- AND STORAGE TANKS - 5 CCTS, WITH 40 HL NET / 46 HL GROSS CONTENT, ALL TANKS 3 BAR, BUILT 1994, STANDING ON FEET, PI-ISOLATED FULLY WELDED WITH STAINLESS STEEL JACKET, WITH JACKET COOLING FROM CONE BELOW TO ½ WALL 60 LT COOLING JACKET 3 BAR, WITH MANWAY IN THE WALL, 2 OUTLETS WITH BUTTERFLY VALVES, TEMPERATURE SENSOR PT100, SPRAY HEAD, PULLED DOWN CLEANING PIPE WITH BUTTERFLY VALVE, BUNGING ARMATURE, OVER PRESSURE VALVE, SAMPLER, 2 CRANE EYELETS, 2 OF THE TANKS WITH LEVEL DISPLAY - DIGITAL TEMPERATURE CONTROL FOR 5 TANKS IN STAINLESS STEEL CONTROL CABINET - CIRCULATING PUMP IN STAINLESS STEEL, MOBILE, WITH SWITCH - MANY GOOD BEER HOSES - 6 X 10 HL BEER DISPENSING TANKS, MAKE DUO TANK, BUILT 2002, 3,0 / 4,3 BAR, COOL ABLE, ISOLATED WITH STAINLESS STEEL-JACKET FULLY WELDED, FOR INLINE-OPERATION, LYING IN RACK, SCREWED STAINLESS STEEL RACK, WITH PRESSURE ARMATURE, OUTLET ARMATURE WITH REDUCTION TO BARE CONNECTION, MANWAY WITH BIG SIGHT GLASS IN MANWAY LED - PANEL FOR 3 TYPES OF BEER 4. FILLING COMBINED BOTTLE-/KEGGING PLANT, WITH 1 CLEANING TUB, HEATED AND 1 REBUILT KEG: - BOTTLE CLEANING MACHINE FOR CLEANING OF 8 BOTTLES INSIDE AND OUTSIDE, FOR UP TO 2LT BOTTLES - BOTTLE FILLING STATION WITH HUB CYLINDER FROM BELOW, WITH SPLINTER PROTECTION - COMBINED KEG-CLEANING- AND FILLING STATION - BUILT IN CONTROL CABINET WITH SIEMENS S5 CONTROL AND OPERATING CONSOLE OP 7 5. OTHER EQUIPMENT - STEAM BOILER FOR ABOUT F280 KG/H, WITH GAS BURNER, FULLY SERVICED ON 4TH AUGUST 2014, BUILT IN 1994 - CONDENSATE TUB IN STAINLESS STEEL AT WALL AND SECOND SMALL S/S-TUB - WATER TREATMENT - STEAM REGULATION AND CONDENSATE VALVES IN CYCLE - STAINLESS STEEL CHIMNEY PLANT ABOUT 8-10M - AIR COMPRESSOR WITH WIND KETTLE, BUILT 1994 - COOLING PLANT / COLD WATER PLANT, MAKE L&R KÄLTETECHNIK, TYPE: WRK-17/SL/-5, PLANT BUILT 1997, COOLING AGENT R 407 C, WITH NEW COMPRESSOR AND NEW PLATE HEAT EXCHANGER IN 2014 FOR 10,000 € INVESTED, EVAPORATOR WITH 2 VENTILATOR OUTSIDE HANGING ON THE WALL 6.1 OTHERS - ABOUT 100 KETS, MAKE SCHÄFER, PLUS-KEGS, FLAT FITTING IN DIFFERENT SIZES, NEUTRAL - PARTY-KEGS, WITH BAVARIAN TAP, PU-COVERED IN BLACK AND WITH WOOD-OPTIC - ABOUT 800 NEUTRAL CLIP LOCK BOTTLES EACH 1 LT 6.2 DIMENSIONS THE ROOM HEIGHT IN BREWHOUSE AND CCTS IS 4.50M. THE PLANT AS ASSEMBLED ON 10.75 X 4.38M. PLEASE NOTE THAT THE BREWERY IS ONLY AVAILABLE AS A SINGLE SALE QUANTITY AVAILABLE: 1 Learn More