Search results for: 'complete li'

- Related search terms

- Complete

- Complete ca

- complete+conveyor

- complete+li

- Complete T

-

L-4869 TRUTZSCHLER LINE, 100” WORKING WIDTH, YEAR 2005 – COMPLETE

L-4869 TRUTZSCHLER LINE, 100” WORKING WIDTH, YEAR 2005 – COMPLETEREFERENCE NUMBER: L-4869

TRUTZSCHLER LINE, 100” WORKING WIDTH, YEAR 2005 – COMPLETE

TRUTZSCHLER

AUTOMATEX DOUBLE NEEDLE LOOM, GRADE “7”

TRUTZSCHLER OPENER/BLOWER, MODEL TF2500

TRUTZSCHLER FORMER, MODEL FD-U 1200

AUTOMATEX DOUBLE NEEDLE LOOM (3 YEAR OLD DC MOTOR AND NEW DC DRIVE)

HOT CALENDERS (INSTEAD OF OVEN)

COOLING ROLLERS

FR SPRAYER

SLITTER

GUILLOTINE

BUNTIUNG MAGNETIC METAL DETECTOR

PAD ROLLING UNIT

QUANTITY: 1

Learn More -

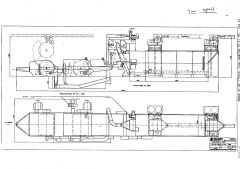

M-0033 ROLANDO COMPLETE TEARING LINE YEAR 1994 WIDTH 2000mm - 2 CYLINDERS

M-0033 ROLANDO COMPLETE TEARING LINE YEAR 1994 WIDTH 2000mm - 2 CYLINDERSM-0033 ROLANDO COMPLETE TEARING LINE YEAR 1994 WIDTH 2000mm - 2 CYLINDERS

WORKING WIDTH 2000mm

Learn More

YEAR 1994

CONSISTING OF:

LOADING INSTALLATION

LIQUID RESP. OIL SPRAYING UNIT

AUTOMATIC FEEDING RA1/6mm 2000

TEARING MACHINE RM9 WITH 2 CYLINDERS, 2000mm -

A-1776 COMPLETE AQUARIUS 24MM DIAMETER BALL LOLLIPOP LINE

A-1776 COMPLETE AQUARIUS 24MM DIAMETER BALL LOLLIPOP LINEREFERENCE NUMBER: A-1776

COMPLETE AQUARIUS 24MM DIAMETER BALL LOLLIPOP LINE

REFUBISHED: 1999

WITH BATCH ROLLER

ROPE SIZER

FORMER AND COOLING FRUM

QUANTITY: 1

Learn More -

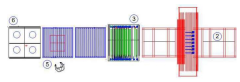

M-3856 COMPLETE BLOW ROOM LINE YEAR 2006

M-3856 COMPLETE BLOW ROOM LINE YEAR 2006REFERENCE NUMBER: M-3856

COMPLETE BLOW ROOM LINE YEAR 2006

TRUMAC BOA 2300 (25 METER)

TRUMAC MFC

TRUMAC MPM 8

TRUMAC ASTA

TRUTSCHLER CLC 3

TRUTSCHLER FDO

TRUTSCHLER LVSA

TRUMAC DX – 1 NO.

WITH VSL FILTERS

QUANTITY: 1

Learn More -

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More -

V-1041 AIRLAY- FELT LINE 2400mmINDEX 1. Technical specification pag.2 2. Line composition pag.3 3. Machines description pag.4 4. Total price of the turn-key plant pag.25 5. Sale terms pag.26 6. Payment terms pag.28 7. General selling terms and conditions pag.29 Learn More

V-1041 AIRLAY- FELT LINE 2400mmINDEX 1. Technical specification pag.2 2. Line composition pag.3 3. Machines description pag.4 4. Total price of the turn-key plant pag.25 5. Sale terms pag.26 6. Payment terms pag.28 7. General selling terms and conditions pag.29 Learn More -

YY-2746 AUTOMATIC ADHESIVE SPREADING LINE, MACHINE N.2 AND 3 AND 5 AND 6, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES)YY-2746 AUTOMATIC ADHESIVE SPREADING LINE, MACHINE N.2 AND 3 AND 5 AND 6, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES) DETAILS: LINE G 7000 S AUTOMATIC LINE WITH SPREADING ROLLERS SUITABLE FOR APPLY COLD SOLVENT PRODUCTS, WATER-BASIC AND ACRYLICS NO. 2 SPREADING ROLLERS COMPLETE OF SPECIAL INFRARED CABIN TO LET FASTER DRY THE GLUE Learn More

YY-2746 AUTOMATIC ADHESIVE SPREADING LINE, MACHINE N.2 AND 3 AND 5 AND 6, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES)YY-2746 AUTOMATIC ADHESIVE SPREADING LINE, MACHINE N.2 AND 3 AND 5 AND 6, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES) DETAILS: LINE G 7000 S AUTOMATIC LINE WITH SPREADING ROLLERS SUITABLE FOR APPLY COLD SOLVENT PRODUCTS, WATER-BASIC AND ACRYLICS NO. 2 SPREADING ROLLERS COMPLETE OF SPECIAL INFRARED CABIN TO LET FASTER DRY THE GLUE Learn More -

TT-6624 MINI SUGAR CRUSHER PLANT, 200 TCD, YEAR 2019TT-6624 MINI SUGAR CRUSHER PLANT, 200 TCD, YEAR 2019 1. MINI SUGAR CRUSHER PLANT 2. 200 TCD 3. MANUFACTURING YEAR 2019 4. PLANT RUNNING 2020 5. PLANTS RUNNING OVER 180 DAYS Learn More

TT-6624 MINI SUGAR CRUSHER PLANT, 200 TCD, YEAR 2019TT-6624 MINI SUGAR CRUSHER PLANT, 200 TCD, YEAR 2019 1. MINI SUGAR CRUSHER PLANT 2. 200 TCD 3. MANUFACTURING YEAR 2019 4. PLANT RUNNING 2020 5. PLANTS RUNNING OVER 180 DAYS Learn More -

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mmM-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

OFFER 001

SPUNBOND PRODUCTION LINE

WORKING WIDTH: 4040mm

WEIGHT: 130 TO 250 G/M2OFFER 002

POLYMER CLEANING GROUPOFFER 003

CRYSTALLIZING GROUPOFFER 004

DRYING GROUPOFFER 005

PNEUMATIC CONVEYING SYSTEMOFFER 006

EXTRUDER HOPPEROFFER 007

EXTRUDEROFFER 008

FILTERING UNITOFFER 009

MELT TRANSFER LINEOFFER 010

SPINNING BEAMOFFER 011

SPINNING PACKSOFFER 012

FILAMENTS QUENCHING SYSTEMOFFER 013

FILAMENTS DRAWING AND DISTRIBUTION SYSTEMOFFER 014

WEB FORMING CONVEYOR BELTOFFER 015

CREEL FOR APPLICATION OF REINFORCING FILAMENTSOFFER 016

PRE-NEEDLING MACHINEOFFER 017

NEEDLING MACHINEOFFER 018

THERMOSETTING UNITOFFER 019

OUTLET CALENDEROFFER 020

FOULARDOFFER 021

BINDER PREPARATION SYSTEMOFFER 022

DRYEROFFER 023

OUTLET CALENDEROFFER 024

AUTOMATIC WINDEROFFER 025

AIR COMPRESSORS (FOR FILAMENTS STRETCHING EJECTORS)OFFER 026

DIATHERMIC OIL HEATING SYSTEMOFFER 027

CHILLED WATER CIRCULATION AND GENERATION SYSTEMOFFER 028

EQUIPMENT FOR CLEANING CYCLE, SPECIAL TOOLSOFFER 029

FIBRE DUST RECOVERY SYSTEMOFFER 030

EDGES RECOVERY SYSTEMOFFER 031

SPINNING SECTION STEEL STRUCTUREOFFER 032

DISTRIBUTION ELECTRIC CABINETSOFFER 033

PROCESS ELECTRIC SYSTEM OF EXISTING MACHINES ACCORDING TO THE ACTUAL LAYOUTOFFER 034

CABLES AND CABLING MATERIALSQUANTITY: 1 LINE

Learn More -

TT-2982 CATERPILLAR 988K XE WHEEL LOADER, YEAR 2019 WITH 6200 HOURSTT-2982 CATERPILLAR 988K XE WHEEL LOADER, YEAR 2019 WITH 6200 HOURS CATERPILLAR 988K XE CURRENT MACHINE HOURS: 6,200 VERY CLEAN, STRAIGHT LOADER RECENTLY REPLACED TIRES QUANTITY: 1 Learn More

TT-2982 CATERPILLAR 988K XE WHEEL LOADER, YEAR 2019 WITH 6200 HOURSTT-2982 CATERPILLAR 988K XE WHEEL LOADER, YEAR 2019 WITH 6200 HOURS CATERPILLAR 988K XE CURRENT MACHINE HOURS: 6,200 VERY CLEAN, STRAIGHT LOADER RECENTLY REPLACED TIRES QUANTITY: 1 Learn More