Search results for: 'die pre'

- Related search terms

- die c

- diesel generator

- Diese

- Diesel G

- pres'

-

YY-2374 DIESEL OIL FIRED STEAM BOILER, RATED EVAPORATION 2.2 T PER HYY-2374 DIESEL OIL FIRED STEAM BOILER, RATED EVAPORATION 2.2 T PER H ASK FOR DETAILS! QUANTITY: 1 Learn More

YY-2374 DIESEL OIL FIRED STEAM BOILER, RATED EVAPORATION 2.2 T PER HYY-2374 DIESEL OIL FIRED STEAM BOILER, RATED EVAPORATION 2.2 T PER H ASK FOR DETAILS! QUANTITY: 1 Learn More -

YY-2372 DIESEL OIL FIRED STEAM BOILER, RATED EVAPORATION 1.5 T PER HYY-2372 DIESEL OIL FIRED STEAM BOILER, RATED EVAPORATION 1.5 T PER H ASK FOR DETAILS! QUANTITY: 1 Learn More

YY-2372 DIESEL OIL FIRED STEAM BOILER, RATED EVAPORATION 1.5 T PER HYY-2372 DIESEL OIL FIRED STEAM BOILER, RATED EVAPORATION 1.5 T PER H ASK FOR DETAILS! QUANTITY: 1 Learn More -

TT-1784 SAMCO 70 DIE CUTTER, CUTTING AREA 22” X 67”, 70 TONSTT-1784 SAMCO 70 DIE CUTTER, CUTTING AREA 22” X 67”, 70 TONS SHUTTLE LOADING TABLE HYDRAULIC TANK OPERATING PRIOR TO DISCONNECT QUANTITY: 1 Learn More

TT-1784 SAMCO 70 DIE CUTTER, CUTTING AREA 22” X 67”, 70 TONSTT-1784 SAMCO 70 DIE CUTTER, CUTTING AREA 22” X 67”, 70 TONS SHUTTLE LOADING TABLE HYDRAULIC TANK OPERATING PRIOR TO DISCONNECT QUANTITY: 1 Learn More -

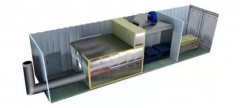

YY-2208 HUMAN CREMATION MACHINE, LIGHT DIESEL FUEL, GAS, NATURAL GAS, LIQUEFIED GASYY-2208 HUMAN CREMATION MACHINE, LIGHT DIESEL FUEL, GAS, NATURAL GAS, LIQUEFIED GAS DETAILS: 1. INCORPORATES EFFICIENT HEAT EXCHANGER AND SPECIAL AIR PATH STRUCTURE, MAKE FULL USE OF WASTE HEAT COMBUSTION FUEL GAS, IMPROVING HEAT UTILIZATION RATE, GOOD ENVIRONMENTAL PROTECTION INDEX, SAVES FUEL AND SHORTENS CREMATION TIME. 2. NEW REFRACTORY MATERIALS (EXCLUSIVE FORMULA) THAT ARE RESISTANT TO HIGH TEMPERATURE WITH LOW SPECIFIC HEAT. GREATLY EXTEND THE SERVICE LIFE. 3. SPECIAL CASTING MATERIAL, HIGH TEMPERATURE RESISTANCE, LONG SERVICE LIFE; SHORTENS THE COOLING CYCLE. THE BRICK STRUCTURE ON BOTH SIDES OF THE ASH PICKING FURNACE DOOR WILL NOT HAVE CRACKS CAUSED BY DESIGN OR QUALITY PROBLEMS GUARANTEED FOR ONE YEAR. REFRACTORY MATERIALS, THE FURNACE CONTACT ARE WITH FLAME HAS PHOSPHORIC ACID A CHARACTERISTIC COMBINATION BRICK WHICH CAN RESIST RAPID COOLING AND RAPID HEAT, AND THE ARCHED ROOF INCORPORATES HIGH ALUMINUM SINTERED MOLDING BRICK. THE FURNACE BODY IS SURROUNDED BY ALUMINUM SILICATE WOOL WITH GOOD HEAT INSULATION AND HEAT PRESERVATION PERFORMANCE. THE THICKNESS IS 180mm. 4. ALL OPERATING SYSTEMS OF THE EQUIPMENT HAVE THREE SETS OF OPERATION FUNCTIONS, NAMELY AUTOMATIC, SEMI-AUTOMATIC AND MANUAL, WHICH CAN BE SWITCH BETWEEN THEM WITHOUT INTERFERENCE. AUTOMATIC CONTROL, TELECOMMUNICATION OPERATION AND ANIMATION DISPLAY. KEEPING THE OPERATOR AWAY FROM THE CREMATION SITE AND PROTECTING THE OPERATOR. AT THE SAME TIME EQUIPPED WITH A STANDBY OPERATING SYSTEM. LOW NOISE MOTOR EQUIPMENT, THERMOCOUPLE RESISTANCE TO HIGH TEMPERATURE. ALL ELECTRICAL CABINETS OF THE EQUIPMENT ARE EXTERNAL. 5. THE OIL SUPPLY SYSTEM INCORPORATES AUTOMATIC CONTROL AND MANUAL CONTROL, AND INCORPORATES OIL PROTECTION TECHNOLOGY, WHICH CAN EFFECTIVELY PREVENT FUEL OIL FROM RUNNING, BUBBLING, LEAKING AND CAUSING FURNACE EXPLOSION ACCIDENTS INCLUDING ANTI-LEAKAGE TECHNOLOGY TO BETTER PROTECT THE PERSONAL SAFETY OF OPERATORS. 6. THE BLOWER, THE INDUCED DRAFT FAN, THE FURNACE DOOR MOTOR, THE BODY CART MOTOR, THE PREPARATORY DOOR MOTOR AND THE FLUE GATE MOTOR ARE ALL INSTALLED WITH AN INTEGRATED DEVICE FOR OVER-CURRENT AND SHORT-CIRCUIT PROTECTION. 7. SPECIAL DIESEL METERING DEVICE, ACCURATE METERING. QUANTITY: 1 Learn More

YY-2208 HUMAN CREMATION MACHINE, LIGHT DIESEL FUEL, GAS, NATURAL GAS, LIQUEFIED GASYY-2208 HUMAN CREMATION MACHINE, LIGHT DIESEL FUEL, GAS, NATURAL GAS, LIQUEFIED GAS DETAILS: 1. INCORPORATES EFFICIENT HEAT EXCHANGER AND SPECIAL AIR PATH STRUCTURE, MAKE FULL USE OF WASTE HEAT COMBUSTION FUEL GAS, IMPROVING HEAT UTILIZATION RATE, GOOD ENVIRONMENTAL PROTECTION INDEX, SAVES FUEL AND SHORTENS CREMATION TIME. 2. NEW REFRACTORY MATERIALS (EXCLUSIVE FORMULA) THAT ARE RESISTANT TO HIGH TEMPERATURE WITH LOW SPECIFIC HEAT. GREATLY EXTEND THE SERVICE LIFE. 3. SPECIAL CASTING MATERIAL, HIGH TEMPERATURE RESISTANCE, LONG SERVICE LIFE; SHORTENS THE COOLING CYCLE. THE BRICK STRUCTURE ON BOTH SIDES OF THE ASH PICKING FURNACE DOOR WILL NOT HAVE CRACKS CAUSED BY DESIGN OR QUALITY PROBLEMS GUARANTEED FOR ONE YEAR. REFRACTORY MATERIALS, THE FURNACE CONTACT ARE WITH FLAME HAS PHOSPHORIC ACID A CHARACTERISTIC COMBINATION BRICK WHICH CAN RESIST RAPID COOLING AND RAPID HEAT, AND THE ARCHED ROOF INCORPORATES HIGH ALUMINUM SINTERED MOLDING BRICK. THE FURNACE BODY IS SURROUNDED BY ALUMINUM SILICATE WOOL WITH GOOD HEAT INSULATION AND HEAT PRESERVATION PERFORMANCE. THE THICKNESS IS 180mm. 4. ALL OPERATING SYSTEMS OF THE EQUIPMENT HAVE THREE SETS OF OPERATION FUNCTIONS, NAMELY AUTOMATIC, SEMI-AUTOMATIC AND MANUAL, WHICH CAN BE SWITCH BETWEEN THEM WITHOUT INTERFERENCE. AUTOMATIC CONTROL, TELECOMMUNICATION OPERATION AND ANIMATION DISPLAY. KEEPING THE OPERATOR AWAY FROM THE CREMATION SITE AND PROTECTING THE OPERATOR. AT THE SAME TIME EQUIPPED WITH A STANDBY OPERATING SYSTEM. LOW NOISE MOTOR EQUIPMENT, THERMOCOUPLE RESISTANCE TO HIGH TEMPERATURE. ALL ELECTRICAL CABINETS OF THE EQUIPMENT ARE EXTERNAL. 5. THE OIL SUPPLY SYSTEM INCORPORATES AUTOMATIC CONTROL AND MANUAL CONTROL, AND INCORPORATES OIL PROTECTION TECHNOLOGY, WHICH CAN EFFECTIVELY PREVENT FUEL OIL FROM RUNNING, BUBBLING, LEAKING AND CAUSING FURNACE EXPLOSION ACCIDENTS INCLUDING ANTI-LEAKAGE TECHNOLOGY TO BETTER PROTECT THE PERSONAL SAFETY OF OPERATORS. 6. THE BLOWER, THE INDUCED DRAFT FAN, THE FURNACE DOOR MOTOR, THE BODY CART MOTOR, THE PREPARATORY DOOR MOTOR AND THE FLUE GATE MOTOR ARE ALL INSTALLED WITH AN INTEGRATED DEVICE FOR OVER-CURRENT AND SHORT-CIRCUIT PROTECTION. 7. SPECIAL DIESEL METERING DEVICE, ACCURATE METERING. QUANTITY: 1 Learn More -

T-9263 2″ AMERICAN 24:1 KUHNE EXTRUDER, 3 BARREL & 3 DIE ZONES, 20 HP MOTOR AND DRIVET-9263 2″ AMERICAN 24:1 KUHNE EXTRUDER, 3 BARREL & 3 DIE ZONES, 20 HP MOTOR AND DRIVE 2″ AMERICAN 24:1 KUHNE EXTRUDER MODEL AK-200 RECONDITIONED VERY GOOD CONDITION QUANTITY: 1 Learn More

T-9263 2″ AMERICAN 24:1 KUHNE EXTRUDER, 3 BARREL & 3 DIE ZONES, 20 HP MOTOR AND DRIVET-9263 2″ AMERICAN 24:1 KUHNE EXTRUDER, 3 BARREL & 3 DIE ZONES, 20 HP MOTOR AND DRIVE 2″ AMERICAN 24:1 KUHNE EXTRUDER MODEL AK-200 RECONDITIONED VERY GOOD CONDITION QUANTITY: 1 Learn More -

T-9989 TRUTZCHLER - TOYOTA - MURATA COMPLETE 37000 SPINDLE RING SPINNING PLANT, YEAR 2018T-9989 TRUTZCHLER - TOYOTA - MURATA COMPLETE 37000 SPINDLE RING SPINNING PLANT, YEAR 2018 WITH THE TOP OF THE LINE UP TRUTZSCHLER BACK PROCESS, TOYOTA RING FRAME AND MURATEC QPRO LINK CORNER Learn More

T-9989 TRUTZCHLER - TOYOTA - MURATA COMPLETE 37000 SPINDLE RING SPINNING PLANT, YEAR 2018T-9989 TRUTZCHLER - TOYOTA - MURATA COMPLETE 37000 SPINDLE RING SPINNING PLANT, YEAR 2018 WITH THE TOP OF THE LINE UP TRUTZSCHLER BACK PROCESS, TOYOTA RING FRAME AND MURATEC QPRO LINK CORNER Learn More -

J-4517 REBUILT/RUNNING CONDITION PELLETIZING LINE, STRAND TYPE, MODEL BCC38 EXTRUDER, 30:1 L/D RATIOJ-4517 REBUILT/RUNNING CONDITION PELLETIZING LINE, STRAND TYPE, MODEL BCC38 EXTRUDER, 30:1 L/D RATIO Learn More

J-4517 REBUILT/RUNNING CONDITION PELLETIZING LINE, STRAND TYPE, MODEL BCC38 EXTRUDER, 30:1 L/D RATIOJ-4517 REBUILT/RUNNING CONDITION PELLETIZING LINE, STRAND TYPE, MODEL BCC38 EXTRUDER, 30:1 L/D RATIO Learn More -

J-4080 AUTOMATIC PUNCHING MACHINE FOR FOAM MATTRESSES, WORKING HEIGHT 200mmJ-4080 AUTOMATIC PUNCHING MACHINE FOR FOAM MATTRESSES, WORKING HEIGHT 200mm OPTIONS CUSTOMIZED DIE TOOL (2 ROWS), HOLE DIAMETER 12mm, HOLE QUANTITY: 152 CUSTOMIZED DIE TOOL (2 ROWS), HOLE DIAMETER 20mm, HOLE QUANTITY: 76 QUANTITY: 1 Learn More

J-4080 AUTOMATIC PUNCHING MACHINE FOR FOAM MATTRESSES, WORKING HEIGHT 200mmJ-4080 AUTOMATIC PUNCHING MACHINE FOR FOAM MATTRESSES, WORKING HEIGHT 200mm OPTIONS CUSTOMIZED DIE TOOL (2 ROWS), HOLE DIAMETER 12mm, HOLE QUANTITY: 152 CUSTOMIZED DIE TOOL (2 ROWS), HOLE DIAMETER 20mm, HOLE QUANTITY: 76 QUANTITY: 1 Learn More -

YY-1136 ULTRAVIOLET STERILIZERYY-1136 ULTRAVIOLET STERILIZER MAINTENANCE OF UV STERILIZER: 1 CHECK REGULARLY TO ENSURE THE NORMAL OPERATION OF THE UV LAMP. 2. AFTER 9000 HOURS OR ONE YEAR OF CONTINUOUS USE, THE ULTRAVIOLET LAMP SHOULD BE REPLACED. WHEN REPLACING A NEW LAMP, FIRST UNPLUG THE POWER SOCKET OF THE LAMP AND TAKE OUT THE ULTRAVIOLET LAMP. PAY ATTENTION NOT TO TOUCH THE QUARTZ GLASS OF THE NEW LAMP WITH YOUR FINGERS, BECAUSE THE STAIN WILL AFFECT THE INTENSITY OF THE LIGHT, AND CAREFULLY PUT THE LAMP INTO THE CHAMBER OF THE STERILIZER. Learn More

YY-1136 ULTRAVIOLET STERILIZERYY-1136 ULTRAVIOLET STERILIZER MAINTENANCE OF UV STERILIZER: 1 CHECK REGULARLY TO ENSURE THE NORMAL OPERATION OF THE UV LAMP. 2. AFTER 9000 HOURS OR ONE YEAR OF CONTINUOUS USE, THE ULTRAVIOLET LAMP SHOULD BE REPLACED. WHEN REPLACING A NEW LAMP, FIRST UNPLUG THE POWER SOCKET OF THE LAMP AND TAKE OUT THE ULTRAVIOLET LAMP. PAY ATTENTION NOT TO TOUCH THE QUARTZ GLASS OF THE NEW LAMP WITH YOUR FINGERS, BECAUSE THE STAIN WILL AFFECT THE INTENSITY OF THE LIGHT, AND CAREFULLY PUT THE LAMP INTO THE CHAMBER OF THE STERILIZER. Learn More -

AA-1191 – SOURCE INFO MELT BLOWN CLOTH PRODUCTION LINE, VERTICAL TYPE (WIDTH: 600mm)AA-1191 – SOURCE INFO MELT BLOWN CLOTH PRODUCTION LINE, VERTICAL TYPE (WIDTH: 600mm) MACHINE PARTS: 1. VACUUM LOADER - 1 SET 2. HOPPER DRYER - 1 SET 3. SINGLE SCREW EXTRUDER - 1 SET 4. HYDRAULIC SCREEN CHANGER - 1 SET 5. METERING PUMP - 1 SET 6. T-DIE - 1 SET 7. BARREL TYPE FORMING MACHINE - 1 SET 8. ELECTROSTATIC ELECTRET DEVICE - 1 SET 9. SLIT AND COILER - 1 SET 10. HOT AIR SYSTEM - 1 SET Learn More

AA-1191 – SOURCE INFO MELT BLOWN CLOTH PRODUCTION LINE, VERTICAL TYPE (WIDTH: 600mm)AA-1191 – SOURCE INFO MELT BLOWN CLOTH PRODUCTION LINE, VERTICAL TYPE (WIDTH: 600mm) MACHINE PARTS: 1. VACUUM LOADER - 1 SET 2. HOPPER DRYER - 1 SET 3. SINGLE SCREW EXTRUDER - 1 SET 4. HYDRAULIC SCREEN CHANGER - 1 SET 5. METERING PUMP - 1 SET 6. T-DIE - 1 SET 7. BARREL TYPE FORMING MACHINE - 1 SET 8. ELECTROSTATIC ELECTRET DEVICE - 1 SET 9. SLIT AND COILER - 1 SET 10. HOT AIR SYSTEM - 1 SET Learn More