Search results for: 'Machine op'

- Related search terms

- Machine f

- MACHINE+S

- machine de

- machine de'

- machine de''

-

YY-2047 AUTOMATIC FOUR-SIDED SEWING MACHINE (BOTH FOR TURN-OVER QUILT PROCESS)YY-2047 AUTOMATIC FOUR-SIDED SEWING MACHINE (BOTH FOR TURN-OVER QUILT PROCESS) DETAILS: MACHINE FEATURES: 1. NEW COMPUTER CONTROL SYSTEM, FRIENDLY HMI, FLEXIBLE CONTROL AND LARGE CAPACITY, ENSURING HIGH-PRECISION RUNNING OF THE MACHINE. 2. LONGITUDINAL SEWING: DOUBLE THREADS CHAINSTITCH (OPTIONAL LOCKSTITCH OR OVERLOCK STITCH). 3. TRAVERSE SEWING: MULTI-NEEDLE CHAINSTITCH SEWING. 4. FULL SERVO MOTOR CONTROL SYSTEM, PROVIDING STRONG AND ACCURATE DRIVING POWER. 5. WITH SCRAP COLLECTION DEVICE TO KEEP THE WORKSHOP CLEAN. QUANTITY: 1 Learn More

YY-2047 AUTOMATIC FOUR-SIDED SEWING MACHINE (BOTH FOR TURN-OVER QUILT PROCESS)YY-2047 AUTOMATIC FOUR-SIDED SEWING MACHINE (BOTH FOR TURN-OVER QUILT PROCESS) DETAILS: MACHINE FEATURES: 1. NEW COMPUTER CONTROL SYSTEM, FRIENDLY HMI, FLEXIBLE CONTROL AND LARGE CAPACITY, ENSURING HIGH-PRECISION RUNNING OF THE MACHINE. 2. LONGITUDINAL SEWING: DOUBLE THREADS CHAINSTITCH (OPTIONAL LOCKSTITCH OR OVERLOCK STITCH). 3. TRAVERSE SEWING: MULTI-NEEDLE CHAINSTITCH SEWING. 4. FULL SERVO MOTOR CONTROL SYSTEM, PROVIDING STRONG AND ACCURATE DRIVING POWER. 5. WITH SCRAP COLLECTION DEVICE TO KEEP THE WORKSHOP CLEAN. QUANTITY: 1 Learn More -

M-5373 OPEN END SPINNING PLANTREFERENCE NUMBER: M-5373 (220RJAMHH1) L OPEN END SPINNING PLANT OPENER – CARDS (2) X RIETER UNIFLOC A1/2 BALE PLUCKER YEAR 1988 (12) X RIETER C4 CARDS YEAR 1988 (12) X RIETER AEROFEED TYPE U CHUTE FEED YEAR 1988 (3) X RIETER UNIMIX B-7/3R MIXER YEAR 1997 (1) X RIETER UNIMIX B-7/3R MIXER YEAR 2000 (1) X RIETER UNIMIX B-7/3R MIXER YEAR 1988 (1) X RIETER UNIMIX B-7/3 MIXER YEAR 1997 (2) X RIETER B-3/3R MIXER-OPENER YEAR 1988 (1) X RIETER B-1 OPENER YEAR 1988 (1) X RIETER B-50 OPENER YEAR 1988 (2) X RIETER B-50 OPENER YEAR 1997 (1) X RIETER ERM-B5/5 OPENER YEAR 1988 (1) X RIETER MONOCYLINDER B 4/1 OPENER YEAR 1988 (1) X RIETER UNIBLEND A80 (3 CHAMBERS) YEAR 1997 (1) X RIETER UNIBLEND A80 (2 CHAMBERS) YEAR 1997 (2) X RIETER UNISTORE A77 YEAR 1997 (1) X RIETER B-2/5 WASTE OPENER YEAR 1988 (1) X TRUTZSCHLER ABGANGOFFNER WASTE OPENER YEAR 1979 (1) X OMMI BLENDER YEAR 1998 DRAW FRAMES (2) X RIETER D1/2 DRAW FRAMES YEAR 1988 ROTOR SPINNING FRAMES (2) X SCHLAFHORST ACO-288 (SE-10) AUTOCORO (240 ROTORS) YEAR 1997 (3) X SCHLAFHORST-SUSSEN ACO-240 (SE-08/SC1-M) AUTOCORO (216 ROTORS) YEAR 1998-1995 (1) X SCHLAFHORST ACO-240 (SE-08) AUTOCORO (216 ROTORS) YEAR 1988 (4) X RIETER R-20 OPEN END (240 ROTORS) YEAR 1997 (4) X RIETER R-20 OPEN END (280 ROTORS) YEAR 1997 MISCELLANEOUS (1) X C+M WASTE PRESS YEAR 2001 (1) X SAN GRATO KALIE V3 PACKING MACHINE YEAR 1988 (1) X ITIPAC VKC/F-O WRAPPING MACHINE YEAR 1995 (1) X DALMEC BOX LIFT (1) X SAN GRATO PELLICANO PACKING MACHINE YEAR 1997 (1) X ITIPAC VKC/F-O WRAPPING MACHINE YEAR 1995 (1) X DALMEC BOX LIFT (1) X LUWA WASTE PRESS (1) X LAROCHE WASTE OPENER (3) X RIETER CONDENSER INFORMATION – DETAILS A. SE-10 AUTOCORO SCHLAFHORST OPEN-END YEAR 1997 MODEL ACO 288 TYPE SRK 240 POSITIONS NOZZLE KN 4 ROTORS T 231 BD YARN PRESENCE DEVICE EXIT CONICAL 4°20 6” TRAVERSE CLEARERS BARCO COROLAB 7 SPINNING BOX SE-10 01 SHUTTLE FOR 240 SPINDLES 02 ASW PIECERS WITH INTERNAL RESERVE WITH WAXING DEVICE BIG BELT FOR WASTE REMOVAL CONE DELIVERY WITH TWO BELTS 2 MAIN MOTOR DRIVEN BY FREQUENCY INVERTER VOLTAGE 380.3.50HZ COMBING ROLLER B 174 WITH ELECTRONIC YARN BREAK DETECTOR B. (4) X AUTOCORO SCHLAFHORST OPEN-END SPINNING MACHINES YEAR 1988/1997 MODEL ACO 240/SC1-M (3 MACHINES), ACO 240 SE08 (1 MACHINE) TYPE SRK 216 POSITIONS FEEDING CANS 500mm x 1160mm WITHOUT WHEELS NOZZLE KN4 ROTORS T 231 BD (1 MACHINE), T 236 BD (1), T 233 BD (1), T 33 (1) EXIT CONICAL 4°20 6” TRAVERSE CLEARERS USTER UPG4 SPINNING BOX THREE MACHINES SC1-M, ONE MACHINE SE08 1 SHUTTLE FOR 216 SPINDLES ONE MACHINE WITH 2 ASW PIECERS, THREE MACHINES WITH 1 ASW PIECER WITH INTERNAL RESERVE WITH WAXING DEVICE BIG BELT FOR THE WASTE REMOVAL CONE DELIVERY WITH TWO BELTS VOLTAGE 380.3.50HZ COMBING ROLLER B174 C. (12) X C4 RIETER CARDING MACHINES YEAR 1988 FEEDING BY CHUTE FEED AEROFEED U WORKING WIDTH 1000mm CARD CLOTHING FOR COTTON REVOLVING FLATS CENTRALIZED WASTE COLLECTION INTERMITTENT FIX FLATS IN ENTRY AND EXIT RIETER AUTOLEVELLER 1850-582 DIGITAL METER COUNTER IN METER MODEL DZ1 COILERS SIZE 1100mm x 1200mm DOFFER DRIVEN BY FREQUENCY INVERTER SAFETY COVERS FOR THE OPERATORS VOLTAGE 380.3.50HZ STATUS: STOPPED QUANTITY AVAILABLE: 1 Learn More

M-5373 OPEN END SPINNING PLANTREFERENCE NUMBER: M-5373 (220RJAMHH1) L OPEN END SPINNING PLANT OPENER – CARDS (2) X RIETER UNIFLOC A1/2 BALE PLUCKER YEAR 1988 (12) X RIETER C4 CARDS YEAR 1988 (12) X RIETER AEROFEED TYPE U CHUTE FEED YEAR 1988 (3) X RIETER UNIMIX B-7/3R MIXER YEAR 1997 (1) X RIETER UNIMIX B-7/3R MIXER YEAR 2000 (1) X RIETER UNIMIX B-7/3R MIXER YEAR 1988 (1) X RIETER UNIMIX B-7/3 MIXER YEAR 1997 (2) X RIETER B-3/3R MIXER-OPENER YEAR 1988 (1) X RIETER B-1 OPENER YEAR 1988 (1) X RIETER B-50 OPENER YEAR 1988 (2) X RIETER B-50 OPENER YEAR 1997 (1) X RIETER ERM-B5/5 OPENER YEAR 1988 (1) X RIETER MONOCYLINDER B 4/1 OPENER YEAR 1988 (1) X RIETER UNIBLEND A80 (3 CHAMBERS) YEAR 1997 (1) X RIETER UNIBLEND A80 (2 CHAMBERS) YEAR 1997 (2) X RIETER UNISTORE A77 YEAR 1997 (1) X RIETER B-2/5 WASTE OPENER YEAR 1988 (1) X TRUTZSCHLER ABGANGOFFNER WASTE OPENER YEAR 1979 (1) X OMMI BLENDER YEAR 1998 DRAW FRAMES (2) X RIETER D1/2 DRAW FRAMES YEAR 1988 ROTOR SPINNING FRAMES (2) X SCHLAFHORST ACO-288 (SE-10) AUTOCORO (240 ROTORS) YEAR 1997 (3) X SCHLAFHORST-SUSSEN ACO-240 (SE-08/SC1-M) AUTOCORO (216 ROTORS) YEAR 1998-1995 (1) X SCHLAFHORST ACO-240 (SE-08) AUTOCORO (216 ROTORS) YEAR 1988 (4) X RIETER R-20 OPEN END (240 ROTORS) YEAR 1997 (4) X RIETER R-20 OPEN END (280 ROTORS) YEAR 1997 MISCELLANEOUS (1) X C+M WASTE PRESS YEAR 2001 (1) X SAN GRATO KALIE V3 PACKING MACHINE YEAR 1988 (1) X ITIPAC VKC/F-O WRAPPING MACHINE YEAR 1995 (1) X DALMEC BOX LIFT (1) X SAN GRATO PELLICANO PACKING MACHINE YEAR 1997 (1) X ITIPAC VKC/F-O WRAPPING MACHINE YEAR 1995 (1) X DALMEC BOX LIFT (1) X LUWA WASTE PRESS (1) X LAROCHE WASTE OPENER (3) X RIETER CONDENSER INFORMATION – DETAILS A. SE-10 AUTOCORO SCHLAFHORST OPEN-END YEAR 1997 MODEL ACO 288 TYPE SRK 240 POSITIONS NOZZLE KN 4 ROTORS T 231 BD YARN PRESENCE DEVICE EXIT CONICAL 4°20 6” TRAVERSE CLEARERS BARCO COROLAB 7 SPINNING BOX SE-10 01 SHUTTLE FOR 240 SPINDLES 02 ASW PIECERS WITH INTERNAL RESERVE WITH WAXING DEVICE BIG BELT FOR WASTE REMOVAL CONE DELIVERY WITH TWO BELTS 2 MAIN MOTOR DRIVEN BY FREQUENCY INVERTER VOLTAGE 380.3.50HZ COMBING ROLLER B 174 WITH ELECTRONIC YARN BREAK DETECTOR B. (4) X AUTOCORO SCHLAFHORST OPEN-END SPINNING MACHINES YEAR 1988/1997 MODEL ACO 240/SC1-M (3 MACHINES), ACO 240 SE08 (1 MACHINE) TYPE SRK 216 POSITIONS FEEDING CANS 500mm x 1160mm WITHOUT WHEELS NOZZLE KN4 ROTORS T 231 BD (1 MACHINE), T 236 BD (1), T 233 BD (1), T 33 (1) EXIT CONICAL 4°20 6” TRAVERSE CLEARERS USTER UPG4 SPINNING BOX THREE MACHINES SC1-M, ONE MACHINE SE08 1 SHUTTLE FOR 216 SPINDLES ONE MACHINE WITH 2 ASW PIECERS, THREE MACHINES WITH 1 ASW PIECER WITH INTERNAL RESERVE WITH WAXING DEVICE BIG BELT FOR THE WASTE REMOVAL CONE DELIVERY WITH TWO BELTS VOLTAGE 380.3.50HZ COMBING ROLLER B174 C. (12) X C4 RIETER CARDING MACHINES YEAR 1988 FEEDING BY CHUTE FEED AEROFEED U WORKING WIDTH 1000mm CARD CLOTHING FOR COTTON REVOLVING FLATS CENTRALIZED WASTE COLLECTION INTERMITTENT FIX FLATS IN ENTRY AND EXIT RIETER AUTOLEVELLER 1850-582 DIGITAL METER COUNTER IN METER MODEL DZ1 COILERS SIZE 1100mm x 1200mm DOFFER DRIVEN BY FREQUENCY INVERTER SAFETY COVERS FOR THE OPERATORS VOLTAGE 380.3.50HZ STATUS: STOPPED QUANTITY AVAILABLE: 1 Learn More -

TT-8178 TETRA PAK FILLING MACHINE A3 FLEX 7500 BPH, YEAR 2016TT-8178 TETRA PAK FILLING MACHINE A3 FLEX 7500 BPH, YEAR 2016 1. BRAND: TETRA PAK® 2. MODEL: A3FLEX 3. YEAR: 2016 4. SPEED: 7500 BPH 5. PRODUCTS: DAIRY, JUICE 6. CONTAINERS: BRIK Learn More

TT-8178 TETRA PAK FILLING MACHINE A3 FLEX 7500 BPH, YEAR 2016TT-8178 TETRA PAK FILLING MACHINE A3 FLEX 7500 BPH, YEAR 2016 1. BRAND: TETRA PAK® 2. MODEL: A3FLEX 3. YEAR: 2016 4. SPEED: 7500 BPH 5. PRODUCTS: DAIRY, JUICE 6. CONTAINERS: BRIK Learn More -

TT-4790 PP MICRO DANLINE TWISTED FIBER CUTTING MACHINE/MULTIFILAMENT YARN CHOPPING MACHINETT-4790 PP MICRO DANLINE TWISTED FIBER CUTTING MACHINE/MULTIFILAMENT YARN CHOPPING MACHINE CONDITION: NEW APPLICATION: LASER CUTTING APPLICABLE MATERIAL: LEATHER PAPER CRYSTAL LASER TYPE: FIBER LASER CUTTING AREA: 400mm X 600mm CNC OR NOT: YES Learn More

TT-4790 PP MICRO DANLINE TWISTED FIBER CUTTING MACHINE/MULTIFILAMENT YARN CHOPPING MACHINETT-4790 PP MICRO DANLINE TWISTED FIBER CUTTING MACHINE/MULTIFILAMENT YARN CHOPPING MACHINE CONDITION: NEW APPLICATION: LASER CUTTING APPLICABLE MATERIAL: LEATHER PAPER CRYSTAL LASER TYPE: FIBER LASER CUTTING AREA: 400mm X 600mm CNC OR NOT: YES Learn More -

G-6521 POTATO CHIPS PRODUCTION LINE 200KG/HREFERENCE NUMBER: G-6521 POTATO CHIPS PRODUCTION LINE 200KG/H 1. WASHING MACHINE 2. PEELING MACHINE 3. TRIMMING MACHINE 4. SLICER FEEDER 5. SLICER 6. WASHING MACHINE 7. BLANCHING MACHINE 8. GAS TYPE CONTINUOUS FRYING MACHINE 9. FLAVORING MACHINE QUANTITY AVAILABLE: 1 Learn More

G-6521 POTATO CHIPS PRODUCTION LINE 200KG/HREFERENCE NUMBER: G-6521 POTATO CHIPS PRODUCTION LINE 200KG/H 1. WASHING MACHINE 2. PEELING MACHINE 3. TRIMMING MACHINE 4. SLICER FEEDER 5. SLICER 6. WASHING MACHINE 7. BLANCHING MACHINE 8. GAS TYPE CONTINUOUS FRYING MACHINE 9. FLAVORING MACHINE QUANTITY AVAILABLE: 1 Learn More -

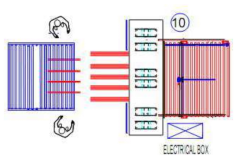

YY-2745 ELECTRONIC AUTOMATIC FILLING MACHINE FOR COVER & AUTOMATIC INSERTION OF FOAM LAYERS INTO COVERS, MACHINE N. 10, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES)YY-2745 ELECTRONIC AUTOMATIC FILLING MACHINE FOR COVER & AUTOMATIC INSERTION OF FOAM LAYERS INTO COVERS, MACHINE N. 10, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES) SPECIFICATION OF THE MACHINE: MAXIMUM WORKING AREA: FROM 700mm TO 2200mm; MAXIMUM HEIGHT: FROM 05CM TO 40CM; KING OF MATERIALS: ANY KIND OF FOAM LAYERS; PRODUCTION: 2 CYCLES/MINUTE; DIMENSIONS: 3500 X 3500 X H2200 mm (WITH ALL OPTIONAL); WEIGHT: 3.250 KG; POWER: 8 KW; POWER SUPPLY: 480V – AC – 60 Hz – 3PHASES; AIR PRESSURE: 6/8 BAR. QUANTITY: 1 Learn More

YY-2745 ELECTRONIC AUTOMATIC FILLING MACHINE FOR COVER & AUTOMATIC INSERTION OF FOAM LAYERS INTO COVERS, MACHINE N. 10, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES)YY-2745 ELECTRONIC AUTOMATIC FILLING MACHINE FOR COVER & AUTOMATIC INSERTION OF FOAM LAYERS INTO COVERS, MACHINE N. 10, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES) SPECIFICATION OF THE MACHINE: MAXIMUM WORKING AREA: FROM 700mm TO 2200mm; MAXIMUM HEIGHT: FROM 05CM TO 40CM; KING OF MATERIALS: ANY KIND OF FOAM LAYERS; PRODUCTION: 2 CYCLES/MINUTE; DIMENSIONS: 3500 X 3500 X H2200 mm (WITH ALL OPTIONAL); WEIGHT: 3.250 KG; POWER: 8 KW; POWER SUPPLY: 480V – AC – 60 Hz – 3PHASES; AIR PRESSURE: 6/8 BAR. QUANTITY: 1 Learn More -

TT-1040 COMPUTERIZED TENSILE TESTING MACHINE, 150KNTT-1040 COMPUTERIZED TENSILE TESTING MACHINE, 150KN COMPUTERIZED TENSILE TESTING MACHINE KEY SPECIFICATION: CAPACITY: KGF 3000, 5000, 10000, 15000 KN 30, 50, 100, 150 UNIT: LOAD N, KN, G, KG, TON, LB DISPLACEMENT: mm, CM, INCH LOAD RESOLUTION: 1/20,000 LOAD ACCURACY: ±1% (±0.5% OPTIONAL) LOAD AMPLIFICATION: X 1, X 2, X 5, X 10 AUTO RANGE TESTING WIDTH (mm): 560 (800 OPTIONAL) CROSSHEAD TRAVEL (mm): 980 (1480 OPTIONAL) TESTING STROKE: CROSSHEAD TRAVEL MINUS UPPER/LOWER GRIPS AND GRIPPING LENGTH TEST SPEED RANGE (mm/MIN): 0.5~500 OR 0.2~200, 0.2~200 OR 0.5~500 MAXIMUM FORCE AT FULL SPEED (KGF): 1000, 2000 MAXIMUM SPEED AT FULL LOAD (mm/MIN): 100, 50 SPEED ACCURACY: ±0.5% SERVO CONTROL DISPLACEMENT RESOLUTION: 0.001 DRIVING METHOD: AC SERVO MOTOR POWER SPECIFICATIONS: 3Ø, 220VAC, 50/60Hz (380/415V OPTIONAL) CONSUMPTION: 3000 KGF 30 KN 5000 KGF 50 KN 10000 KGF 100 KN 15000 KGF 150 KN 2 KVA, 3 KVA, 5 KVA, 10 KVA DIMENSIONS FRAME (mm): 1300 X 600 X 2130 1540 X 600 X 2130 1300 X 600 X 2630 1540 X 600 X 2630 CONTROL BOX (mm) COMPUTER TYPE 1200 X 600 X 740 MICRO-COMPUTER TYPE 660 X 600 X 740 WEIGHT (KG) FRAME 800, CONTROL BOX 100 FRAME 1200, CONTROL BOX 100 STANDARD ACCESSORIES: TENSILE GRIPS X 1 SET, NECESSARY TOOLS X 1 SET, OPERATIONAL MANUAL X 1 COPY, CERTIFICATE OF CALIBRATION X 1 COPY Learn More

TT-1040 COMPUTERIZED TENSILE TESTING MACHINE, 150KNTT-1040 COMPUTERIZED TENSILE TESTING MACHINE, 150KN COMPUTERIZED TENSILE TESTING MACHINE KEY SPECIFICATION: CAPACITY: KGF 3000, 5000, 10000, 15000 KN 30, 50, 100, 150 UNIT: LOAD N, KN, G, KG, TON, LB DISPLACEMENT: mm, CM, INCH LOAD RESOLUTION: 1/20,000 LOAD ACCURACY: ±1% (±0.5% OPTIONAL) LOAD AMPLIFICATION: X 1, X 2, X 5, X 10 AUTO RANGE TESTING WIDTH (mm): 560 (800 OPTIONAL) CROSSHEAD TRAVEL (mm): 980 (1480 OPTIONAL) TESTING STROKE: CROSSHEAD TRAVEL MINUS UPPER/LOWER GRIPS AND GRIPPING LENGTH TEST SPEED RANGE (mm/MIN): 0.5~500 OR 0.2~200, 0.2~200 OR 0.5~500 MAXIMUM FORCE AT FULL SPEED (KGF): 1000, 2000 MAXIMUM SPEED AT FULL LOAD (mm/MIN): 100, 50 SPEED ACCURACY: ±0.5% SERVO CONTROL DISPLACEMENT RESOLUTION: 0.001 DRIVING METHOD: AC SERVO MOTOR POWER SPECIFICATIONS: 3Ø, 220VAC, 50/60Hz (380/415V OPTIONAL) CONSUMPTION: 3000 KGF 30 KN 5000 KGF 50 KN 10000 KGF 100 KN 15000 KGF 150 KN 2 KVA, 3 KVA, 5 KVA, 10 KVA DIMENSIONS FRAME (mm): 1300 X 600 X 2130 1540 X 600 X 2130 1300 X 600 X 2630 1540 X 600 X 2630 CONTROL BOX (mm) COMPUTER TYPE 1200 X 600 X 740 MICRO-COMPUTER TYPE 660 X 600 X 740 WEIGHT (KG) FRAME 800, CONTROL BOX 100 FRAME 1200, CONTROL BOX 100 STANDARD ACCESSORIES: TENSILE GRIPS X 1 SET, NECESSARY TOOLS X 1 SET, OPERATIONAL MANUAL X 1 COPY, CERTIFICATE OF CALIBRATION X 1 COPY Learn More -

YY-2980 MASTER BAG 350 FOR EFFICIENT PRODUCTION OF FLAT BOTTOM PAPER BAG MID-SIZE AND BIG-SIZE PAPER BAGSYY-2980 MASTER BAG 350 FOR EFFICIENT PRODUCTION OF FLAT BOTTOM PAPER BAG MID-SIZE AND BIG-SIZE PAPER BAGS THE IDEAL MACHINE FOR FAST AND EFFICIENT PRODUCTION OF FLAT BOTTOM PAPER BAG MID-SIZE AND BIG-SIZE PAPER BAGS. WITH ITS ADVANCED DESIGN AND HIGH-SPEED CAPABILITIES, IT'S PART OF OUR PAPER BAG MACHINE SERIES, WHICH IS DESIGNED TO PRODUCE A WIDE RANGE OF PAPER BAGS. THIS MACHINE IS CAPABLE OF PRODUCING PAPER BAGS OF VARYING SIZES A T A SPEED OF UP TO 600 BAGS PER MINUTE, MAKING IT AN IDEAL CHOICE FOR BUSINESSES THAT REQUIRE HIGH-VOLUME PRODUCTION, EASY TO OPERATE AND CAN BE CUSTOMIZED TO SUIT YOUR SPECIFIC NEEDS AND REQUIREMENTS. IT IS MADE WITH HIGH-QUALITY MATERIALS THAT ENSURE DURABILITY AND LONGEVITY, MAKING IT A RELIABLE INVESTMENT FOR YOUR BUSINESS. QUANTITY: 1 Learn More

YY-2980 MASTER BAG 350 FOR EFFICIENT PRODUCTION OF FLAT BOTTOM PAPER BAG MID-SIZE AND BIG-SIZE PAPER BAGSYY-2980 MASTER BAG 350 FOR EFFICIENT PRODUCTION OF FLAT BOTTOM PAPER BAG MID-SIZE AND BIG-SIZE PAPER BAGS THE IDEAL MACHINE FOR FAST AND EFFICIENT PRODUCTION OF FLAT BOTTOM PAPER BAG MID-SIZE AND BIG-SIZE PAPER BAGS. WITH ITS ADVANCED DESIGN AND HIGH-SPEED CAPABILITIES, IT'S PART OF OUR PAPER BAG MACHINE SERIES, WHICH IS DESIGNED TO PRODUCE A WIDE RANGE OF PAPER BAGS. THIS MACHINE IS CAPABLE OF PRODUCING PAPER BAGS OF VARYING SIZES A T A SPEED OF UP TO 600 BAGS PER MINUTE, MAKING IT AN IDEAL CHOICE FOR BUSINESSES THAT REQUIRE HIGH-VOLUME PRODUCTION, EASY TO OPERATE AND CAN BE CUSTOMIZED TO SUIT YOUR SPECIFIC NEEDS AND REQUIREMENTS. IT IS MADE WITH HIGH-QUALITY MATERIALS THAT ENSURE DURABILITY AND LONGEVITY, MAKING IT A RELIABLE INVESTMENT FOR YOUR BUSINESS. QUANTITY: 1 Learn More -

TT-1443 COMPLETE SPUNLACE LINE, WORKING WIDTH 3500mm, YEAR 2000TT-1443 COMPLETE SPUNLACE LINE, WORKING WIDTH 3500mm, YEAR 2000 ITEM 001 LAROCHE OPENING & BLENDING SET (COMPRISING OF 4 BALE HOPPER, SET OF FINE OPENER AND FIBRE CONVEYING SYSTEM) QUANTITY: 1 ITEM 002 THIBEAU CARD CA11, WORKING WIDTH 3000mm QUANTITY: 1 ITEM 003 ASSELIN CROSSLAPPER QUANTITY: 1 ITEM 004 RIETER- PERFOJET SPUNLACE MACHINE 3 CYLINDERS/7 INJECTORS WORKING WIDTH 3600mm QUANTITY: 1 ITEM 005 FLEISSNER DRUM DRYER, WORKING WIDTH 3600mm QUANTITY: 1 ITEM 006 BASTIAN AUTOMATIC WINDER, WORKING WIDTH 3600mm QUANTITY: 1 ITEM 007 THIBEAU CARD FEEDER QUANTITY: 1 ITEM 008 ASSELIN WEB-DRAFTER WORKING WIDTH 4400mm QUANTITY: 1 ITEM 009 LOT ELECTRICAL CONTROLS 380V/50Hz QUANTITY: 1 ITEM 010 LOT AUXILIARY EQUIPMENT FOR THE SPUNLACE UNIT QUANTITY: 1 YEAR 2000 DRYER: 8 TYPE, 2 DRUMS Learn More

TT-1443 COMPLETE SPUNLACE LINE, WORKING WIDTH 3500mm, YEAR 2000TT-1443 COMPLETE SPUNLACE LINE, WORKING WIDTH 3500mm, YEAR 2000 ITEM 001 LAROCHE OPENING & BLENDING SET (COMPRISING OF 4 BALE HOPPER, SET OF FINE OPENER AND FIBRE CONVEYING SYSTEM) QUANTITY: 1 ITEM 002 THIBEAU CARD CA11, WORKING WIDTH 3000mm QUANTITY: 1 ITEM 003 ASSELIN CROSSLAPPER QUANTITY: 1 ITEM 004 RIETER- PERFOJET SPUNLACE MACHINE 3 CYLINDERS/7 INJECTORS WORKING WIDTH 3600mm QUANTITY: 1 ITEM 005 FLEISSNER DRUM DRYER, WORKING WIDTH 3600mm QUANTITY: 1 ITEM 006 BASTIAN AUTOMATIC WINDER, WORKING WIDTH 3600mm QUANTITY: 1 ITEM 007 THIBEAU CARD FEEDER QUANTITY: 1 ITEM 008 ASSELIN WEB-DRAFTER WORKING WIDTH 4400mm QUANTITY: 1 ITEM 009 LOT ELECTRICAL CONTROLS 380V/50Hz QUANTITY: 1 ITEM 010 LOT AUXILIARY EQUIPMENT FOR THE SPUNLACE UNIT QUANTITY: 1 YEAR 2000 DRYER: 8 TYPE, 2 DRUMS Learn More -

TT-7165 COMPLETE TEXTILE MILL EQUIPMENT, YEAR 1986 TO 2023TT-7165 COMPLETE TEXTILE MILL EQUIPMENT, YEAR 1986 TO 2023 COMPLETE DENIM TEXTILE MILL EQUIPMENT: WEAVING, SIZING, TWISTING, WINDING, AND FINISHING MACHINERY - INCLUDING CONTINUOUS WASHING, MERCERIZING, AND SANFORIZING. Learn More

TT-7165 COMPLETE TEXTILE MILL EQUIPMENT, YEAR 1986 TO 2023TT-7165 COMPLETE TEXTILE MILL EQUIPMENT, YEAR 1986 TO 2023 COMPLETE DENIM TEXTILE MILL EQUIPMENT: WEAVING, SIZING, TWISTING, WINDING, AND FINISHING MACHINERY - INCLUDING CONTINUOUS WASHING, MERCERIZING, AND SANFORIZING. Learn More