Search results for: 'Operating sy'

- Related search terms

- Operating s

- Operating syste

- Operating system

- Operating sy'A=0

- Operating sy'A=0'

-

YY-3512 SIEMENS SGT-600 DLE GAS TURBINE, YEAR 2011, EMISSION TYPE DLE (DRY LOW EMISSION)YY-3512 SIEMENS SGT-600 DLE GAS TURBINE, YEAR 2011, EMISSION TYPE DLE (DRY LOW EMISSION) MODEL: SGT-600 DLE YEAR: 2011 EMISSION TYPE: DLE (DRY LOW EMISSION) QUANTITY OF SHAFTS: DUAL SHAFTS (MAY DRIVE THE COMPRESSOR) Learn More

YY-3512 SIEMENS SGT-600 DLE GAS TURBINE, YEAR 2011, EMISSION TYPE DLE (DRY LOW EMISSION)YY-3512 SIEMENS SGT-600 DLE GAS TURBINE, YEAR 2011, EMISSION TYPE DLE (DRY LOW EMISSION) MODEL: SGT-600 DLE YEAR: 2011 EMISSION TYPE: DLE (DRY LOW EMISSION) QUANTITY OF SHAFTS: DUAL SHAFTS (MAY DRIVE THE COMPRESSOR) Learn More -

YY-3485 PROCESSING AND PACKAGING LINE FOR COFFEE PODS (ESE Ø44mm)YY-3485 PROCESSING AND PACKAGING LINE FOR COFFEE PODS (ESE Ø44mm) Learn More

YY-3485 PROCESSING AND PACKAGING LINE FOR COFFEE PODS (ESE Ø44mm)YY-3485 PROCESSING AND PACKAGING LINE FOR COFFEE PODS (ESE Ø44mm) Learn More -

TT-6302 TETRA PAK FILLING LINE TBA 19 200ML SLIM 10V, YEAR 2003TT-6302 TETRA PAK FILLING LINE TBA 19 200ML SLIM 10V, YEAR 2003 1. TETRA PAK BOTTLING PLANT 2. YEAR OF CONSTRUCTION 2003 3. CONDITION USED 4. OPERATING HOURS: 38,750 H QUANTITY: 1 Learn More

TT-6302 TETRA PAK FILLING LINE TBA 19 200ML SLIM 10V, YEAR 2003TT-6302 TETRA PAK FILLING LINE TBA 19 200ML SLIM 10V, YEAR 2003 1. TETRA PAK BOTTLING PLANT 2. YEAR OF CONSTRUCTION 2003 3. CONDITION USED 4. OPERATING HOURS: 38,750 H QUANTITY: 1 Learn More -

The TM 2500 Mobile Gas Turbine GeneratorThe TM 2500 Mobile Gas Turbine Generator Standard Description Quantity: 2 Units Available Immediately. Learn More

The TM 2500 Mobile Gas Turbine GeneratorThe TM 2500 Mobile Gas Turbine Generator Standard Description Quantity: 2 Units Available Immediately. Learn More -

TT-4385 CATERPILLAR GAS ENGINE GENERATOR, 4.3 MW, 50Hz, YEAR 2014TT-4385 CATERPILLAR GAS ENGINE GENERATOR, 4.3 MW, 50Hz, YEAR 2014 CATERPILLAR GAS ENGINE GENERATOR 4.3 MW YEAR: 2014 BRAND: CATERPILLAR /USA QUANTITY: 1 Learn More

TT-4385 CATERPILLAR GAS ENGINE GENERATOR, 4.3 MW, 50Hz, YEAR 2014TT-4385 CATERPILLAR GAS ENGINE GENERATOR, 4.3 MW, 50Hz, YEAR 2014 CATERPILLAR GAS ENGINE GENERATOR 4.3 MW YEAR: 2014 BRAND: CATERPILLAR /USA QUANTITY: 1 Learn More -

YY-3017 HONEYWELL MODEL PRO FLOW II POSITION AUTOMATIC PROFILE (2013)YY-3017 HONEYWELL MODEL PRO FLOW II POSITION AUTOMATIC PROFILE (2013) FOURDRINIER PAPER MACHINE PM3: FACE WIDTH: 4.57 METERS, TRIM WIDTH: 4.05 METERS GRADE: BOND, OFFSET, XEROCOPY BASIS WEIGHT: 35 TO 135 GSM MAXIMUM SPEED: 914 METERS ( OPERATING SPEED 700 METERS ) WIRE WIDTH : 4.52 METERS MAXIMUM WINDER SPEED: 2000 METERS/MIN Learn More

YY-3017 HONEYWELL MODEL PRO FLOW II POSITION AUTOMATIC PROFILE (2013)YY-3017 HONEYWELL MODEL PRO FLOW II POSITION AUTOMATIC PROFILE (2013) FOURDRINIER PAPER MACHINE PM3: FACE WIDTH: 4.57 METERS, TRIM WIDTH: 4.05 METERS GRADE: BOND, OFFSET, XEROCOPY BASIS WEIGHT: 35 TO 135 GSM MAXIMUM SPEED: 914 METERS ( OPERATING SPEED 700 METERS ) WIRE WIDTH : 4.52 METERS MAXIMUM WINDER SPEED: 2000 METERS/MIN Learn More -

J-5082 7 SIEMENS SGT 800 UNITS, TOTALING 400 MW, 60 Hz – PACKAGE DEAL ONLY TOTAL: 400 MEGAWATTSJ-5082 7 SIEMENS SGT 800 UNITS, TOTALING 400 MW, 60 Hz – PACKAGE DEAL ONLY TOTAL: 400 MEGAWATTS MAKE: SIEMENS MODEL: SGT 800 TOTALLING 400 MW @ 60 Hz 6 UNITS ARE HRSG UNITS 1 UNIT 64 MW @ 60 Hz EX STOCK THESE ARE BRAND NEW UNITS, WARRANTY TRANSFERRABLE MUST BE SOLD AS A PACKAGE ONLY, NOT AVAILABLE INDIVIDUALLY PACKAGE IS COMPLETE WITH CONTROL SYSTEMS, ETC. QUANTITY: 7 Learn More

J-5082 7 SIEMENS SGT 800 UNITS, TOTALING 400 MW, 60 Hz – PACKAGE DEAL ONLY TOTAL: 400 MEGAWATTSJ-5082 7 SIEMENS SGT 800 UNITS, TOTALING 400 MW, 60 Hz – PACKAGE DEAL ONLY TOTAL: 400 MEGAWATTS MAKE: SIEMENS MODEL: SGT 800 TOTALLING 400 MW @ 60 Hz 6 UNITS ARE HRSG UNITS 1 UNIT 64 MW @ 60 Hz EX STOCK THESE ARE BRAND NEW UNITS, WARRANTY TRANSFERRABLE MUST BE SOLD AS A PACKAGE ONLY, NOT AVAILABLE INDIVIDUALLY PACKAGE IS COMPLETE WITH CONTROL SYSTEMS, ETC. QUANTITY: 7 Learn More -

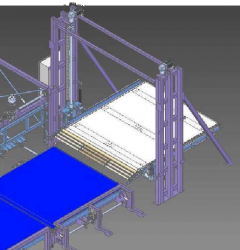

YY-2748 AUTOMATIC UNSTACKER FOR FOAM LAYERS MOTORIZED 2 WAY, INTEGRATED BELT FOR FAST ALIGNMENT, MACHINE N. 1, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES)YY-2748 AUTOMATIC UNSTACKER FOR FOAM LAYERS MOTORIZED 2 WAY, INTEGRATED BELT FOR FAST ALIGNMENT, MACHINE N. 1, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES) AUTOMATIC UNLOADER FOR FOAM LAYERS MODEL: G220PRO QUANTITY: 1 Learn More

YY-2748 AUTOMATIC UNSTACKER FOR FOAM LAYERS MOTORIZED 2 WAY, INTEGRATED BELT FOR FAST ALIGNMENT, MACHINE N. 1, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES)YY-2748 AUTOMATIC UNSTACKER FOR FOAM LAYERS MOTORIZED 2 WAY, INTEGRATED BELT FOR FAST ALIGNMENT, MACHINE N. 1, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES) AUTOMATIC UNLOADER FOR FOAM LAYERS MODEL: G220PRO QUANTITY: 1 Learn More -

YY-2090 CROSSLAPPER, MAXIMUM LAPPING WIDTH UP TO 4500mm DELIVERY WIDTH – 60 M/MINYY-2090 CROSSLAPPER, MAXIMUM LAPPING WIDTH UP TO 4500mm DELIVERY WIDTH – 60 M/MIN POWER: 7.75KW LAYING WIDTH: UP TO 4500mm QUANTITY: 1 Learn More

YY-2090 CROSSLAPPER, MAXIMUM LAPPING WIDTH UP TO 4500mm DELIVERY WIDTH – 60 M/MINYY-2090 CROSSLAPPER, MAXIMUM LAPPING WIDTH UP TO 4500mm DELIVERY WIDTH – 60 M/MIN POWER: 7.75KW LAYING WIDTH: UP TO 4500mm QUANTITY: 1 Learn More -

T-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINET-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINE CONTENT OF LINE HOT MELT SITATION UNIT - WITH HOT MELT UNIT (CORNER AND CENTER GLUING) TRANSPORTATION CONVEYOR WITH ANTISTATIC SILICON BELT (2 SETS) MATTRESS FLIPPING CONVEYOR (1 SET) AUTOMATIC PRESSING SYSTEM (1 SET) Learn More

T-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINET-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINE CONTENT OF LINE HOT MELT SITATION UNIT - WITH HOT MELT UNIT (CORNER AND CENTER GLUING) TRANSPORTATION CONVEYOR WITH ANTISTATIC SILICON BELT (2 SETS) MATTRESS FLIPPING CONVEYOR (1 SET) AUTOMATIC PRESSING SYSTEM (1 SET) Learn More