Search results for: 'Parts for'

- Related search terms

- parts for T

- forma

- parts f

- parts for c

- For in

-

TT-1995 HASSIA THL 24/28 & WRAP AROUND CARDBOARD PACKER, CAPACITY 37,000 PIECES PER HOUR, YEAR 1986TT-1995 HASSIA THL 24/28 & WRAP AROUND CARDBOARD PACKER, CAPACITY 37,000 PIECES PER HOUR, YEAR 1986 BRAND: HASSIA MODEL: THL 24/28 STATIONS: PLASTIC ROLL INSERT - PRE HEAT - FORMING TO CUPS – FILLING – SEALING - CUTTING IN PIECES - ROBOT PICK AND PLACE - WRAP AROUND CARTON PACKER QUANTITY: 1 Learn More

TT-1995 HASSIA THL 24/28 & WRAP AROUND CARDBOARD PACKER, CAPACITY 37,000 PIECES PER HOUR, YEAR 1986TT-1995 HASSIA THL 24/28 & WRAP AROUND CARDBOARD PACKER, CAPACITY 37,000 PIECES PER HOUR, YEAR 1986 BRAND: HASSIA MODEL: THL 24/28 STATIONS: PLASTIC ROLL INSERT - PRE HEAT - FORMING TO CUPS – FILLING – SEALING - CUTTING IN PIECES - ROBOT PICK AND PLACE - WRAP AROUND CARTON PACKER QUANTITY: 1 Learn More -

TT-1963 OMNI PLUS (800) LENO, WIDTH 3400mm, FOUR AND FIVE CAMS PER LOOM, TWO COLOR SELECTORSTT-1963 OMNI PLUS (800) LENO, WIDTH 3400mm, FOUR AND FIVE CAMS PER LOOM, TWO COLOR SELECTORS BASIC MACHINE MONITORING: INTEGRATED MICROPROCESSOR, MONITORING AND CONTROLLING ALL MAJOR MECHANICAL AND ELECTRONIC FUNCTIONS. WITH KEYBOARD AND DISPLAY. SENSITIVITY OF DETECTION AND CONTROL THROUGH MICROPROCESSOR WITH 4 COLOR LIGHT COLUMN FOR STOP INDICATIONS. QUANTITY: 24 Learn More

TT-1963 OMNI PLUS (800) LENO, WIDTH 3400mm, FOUR AND FIVE CAMS PER LOOM, TWO COLOR SELECTORSTT-1963 OMNI PLUS (800) LENO, WIDTH 3400mm, FOUR AND FIVE CAMS PER LOOM, TWO COLOR SELECTORS BASIC MACHINE MONITORING: INTEGRATED MICROPROCESSOR, MONITORING AND CONTROLLING ALL MAJOR MECHANICAL AND ELECTRONIC FUNCTIONS. WITH KEYBOARD AND DISPLAY. SENSITIVITY OF DETECTION AND CONTROL THROUGH MICROPROCESSOR WITH 4 COLOR LIGHT COLUMN FOR STOP INDICATIONS. QUANTITY: 24 Learn More -

TT-1886 KAWASAKI PU4000B-ER GAS TURBINE POWER PLANT 51.2MW 60Hz, (16 X 3.2MW), YEAR 2008TT-1886 KAWASAKI PU4000B-ER GAS TURBINE POWER PLANT 51.2MW 60Hz, (16 X 3.2MW), YEAR 2008 KAWASAKI PU4000B-ER GAS TURBINE POWER PLANT 51.2MW 60Hz (16 X 3.2MW) MAIN SPECIFICATIONS GAS TURBINE MODEL: M1T-23 BRAND: KAWASAKI POWER OUTPUT: 3,200KWE FREQUENCY & VOLTAGE: 60Hz & 6600V YEAR OF PRODUCTION: 2008 RUNNING HOURS: ABOUT 60 HOURS FUEL OIL: NATURAL GAS PLANT AUXILIARY EQUIPMENT: 1 SET Learn More

TT-1886 KAWASAKI PU4000B-ER GAS TURBINE POWER PLANT 51.2MW 60Hz, (16 X 3.2MW), YEAR 2008TT-1886 KAWASAKI PU4000B-ER GAS TURBINE POWER PLANT 51.2MW 60Hz, (16 X 3.2MW), YEAR 2008 KAWASAKI PU4000B-ER GAS TURBINE POWER PLANT 51.2MW 60Hz (16 X 3.2MW) MAIN SPECIFICATIONS GAS TURBINE MODEL: M1T-23 BRAND: KAWASAKI POWER OUTPUT: 3,200KWE FREQUENCY & VOLTAGE: 60Hz & 6600V YEAR OF PRODUCTION: 2008 RUNNING HOURS: ABOUT 60 HOURS FUEL OIL: NATURAL GAS PLANT AUXILIARY EQUIPMENT: 1 SET Learn More -

J-4684 DIGITAL KNIFE CUTTING MACHINE, WORKING AREA 2500mm x 1600mm, FOR SINGLE PLY FILM CUTTINGJ-4684 DIGITAL KNIFE CUTTING MACHINE, WORKING AREA 2500mm x 1600mm, FOR SINGLE PLY FILM CUTTING WORKING AREA: LENGTH 2500 x WIDTH 1600mm MAIN CUTTING CONFIGURATION: 1) AUTO FEEDING TABLE 2) BELT DRIVE SYSTEM 3) 8 INDEPENDENT SUCTION ZONES (UNDERNEATH THE MACHINE TABLE THERE ARE 8 TUBES CONNECTING TO THE VACUUM PUMP. THERE IS ONE SOLENOID VALVE WHICH CONTROLS THE OPENING AND CLOSING) 4) 7.5 KW VACUUM PUMP 5) ONE KNIFE HOLDER 6) OSCILLATING KNIFE QUANTITY: 1 Learn More

J-4684 DIGITAL KNIFE CUTTING MACHINE, WORKING AREA 2500mm x 1600mm, FOR SINGLE PLY FILM CUTTINGJ-4684 DIGITAL KNIFE CUTTING MACHINE, WORKING AREA 2500mm x 1600mm, FOR SINGLE PLY FILM CUTTING WORKING AREA: LENGTH 2500 x WIDTH 1600mm MAIN CUTTING CONFIGURATION: 1) AUTO FEEDING TABLE 2) BELT DRIVE SYSTEM 3) 8 INDEPENDENT SUCTION ZONES (UNDERNEATH THE MACHINE TABLE THERE ARE 8 TUBES CONNECTING TO THE VACUUM PUMP. THERE IS ONE SOLENOID VALVE WHICH CONTROLS THE OPENING AND CLOSING) 4) 7.5 KW VACUUM PUMP 5) ONE KNIFE HOLDER 6) OSCILLATING KNIFE QUANTITY: 1 Learn More -

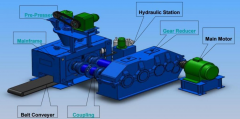

YY-2223 BRIQUETTING MACHINESYY-2223 BRIQUETTING MACHINES ASK FOR MORE DETAILS! Learn More

YY-2223 BRIQUETTING MACHINESYY-2223 BRIQUETTING MACHINES ASK FOR MORE DETAILS! Learn More -

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More -

V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW -480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS)V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW-480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS) FULLY AUTOMATIC PET PAD MAKING MACHINE THE MACHINE OPERATORS JOB IS ONLY TO ADD THE RAW MATERIALS AND VERIFY THAT THE MACHINE IS RUNNING PROPERLY. ABSORBENT CORE CRUSH, MIX AND MAKE THE CORE. TOP SHEET, ABSORBENT CORE, BACK SHEET (PE FILM), LAMINATED. FINAL PRODUCTS ARE FOLDED HORIZONTALLY CUTS PAD INTO FINAL SIZE CREATES VERTICAL FOLD MAIN TECHNICAL PARAMETERS: DESIGN SPEED: 300 METERS PER MINUTE (60mm x 90mm) WORKING SPEED: 250 METERS PER MINUTE (60mm x 90mm) QUALIFIED RATE: >98% EFFICIENCY: >85% INSTALLED POWER: 300 KW (MAIN MACHINE) ELECTRICITY: 480 VOLTS, 60 Hz AIR PRESSURE: 0.6 MPA, 2.6 m3 PER MINUTE TOTAL WEIGHT: 65 TONS PRODUCT SIZE: 400mm x 600mm, 600mm x 600mm, 900mm x 600mm, 560mm x 560mm, 4 SIZES, ACCORDING TO ORDER QUANTITY: 1 Learn More

V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW -480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS)V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW-480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS) FULLY AUTOMATIC PET PAD MAKING MACHINE THE MACHINE OPERATORS JOB IS ONLY TO ADD THE RAW MATERIALS AND VERIFY THAT THE MACHINE IS RUNNING PROPERLY. ABSORBENT CORE CRUSH, MIX AND MAKE THE CORE. TOP SHEET, ABSORBENT CORE, BACK SHEET (PE FILM), LAMINATED. FINAL PRODUCTS ARE FOLDED HORIZONTALLY CUTS PAD INTO FINAL SIZE CREATES VERTICAL FOLD MAIN TECHNICAL PARAMETERS: DESIGN SPEED: 300 METERS PER MINUTE (60mm x 90mm) WORKING SPEED: 250 METERS PER MINUTE (60mm x 90mm) QUALIFIED RATE: >98% EFFICIENCY: >85% INSTALLED POWER: 300 KW (MAIN MACHINE) ELECTRICITY: 480 VOLTS, 60 Hz AIR PRESSURE: 0.6 MPA, 2.6 m3 PER MINUTE TOTAL WEIGHT: 65 TONS PRODUCT SIZE: 400mm x 600mm, 600mm x 600mm, 900mm x 600mm, 560mm x 560mm, 4 SIZES, ACCORDING TO ORDER QUANTITY: 1 Learn More -

J-3540 ITALIANA RIGENERAZIONE TEARING PLANT, WORKING WIDTH 2000mmJ-3540 ITALIANA RIGENERAZIONE TEARING PLANT, WORKING WIDTH 2000mm VARIOUS SPARE PARTS SPLIT SALE POSSIBLE Learn More

J-3540 ITALIANA RIGENERAZIONE TEARING PLANT, WORKING WIDTH 2000mmJ-3540 ITALIANA RIGENERAZIONE TEARING PLANT, WORKING WIDTH 2000mm VARIOUS SPARE PARTS SPLIT SALE POSSIBLE Learn More -

T-7933 4 SIDE SEAL GAUZE SWAB PACKING MACHINE - NEWT-7933 4 SIDE SEAL GAUZE SWAB PACKING MACHINE - NEW MAIN STRUCTURE SYSTEM: 1. FEEDING SYSTEM 2. DRAG SYSTEM 3. SEAL AND FORMING SYSTEM 4. CUTTING SYSTEM 5. OUTPUT AND CONVEYO 6. PNEUMATIC AND PRESSURIZATION SYSTEM 7. ELECTRICAL CONTROL SYSTEM 8. EQUIPMENT FRAME AND ACCESSORY Learn More

T-7933 4 SIDE SEAL GAUZE SWAB PACKING MACHINE - NEWT-7933 4 SIDE SEAL GAUZE SWAB PACKING MACHINE - NEW MAIN STRUCTURE SYSTEM: 1. FEEDING SYSTEM 2. DRAG SYSTEM 3. SEAL AND FORMING SYSTEM 4. CUTTING SYSTEM 5. OUTPUT AND CONVEYO 6. PNEUMATIC AND PRESSURIZATION SYSTEM 7. ELECTRICAL CONTROL SYSTEM 8. EQUIPMENT FRAME AND ACCESSORY Learn More -

Z-1613 AUTOMATIC CARTON PACKAGING MACHINEZ-1613 AUTOMATIC CARTON PACKAGING MACHINE CARTONING FORM: HORIZONTAL CARTONING CARTONING SPEED: 30 TO 40 BOXES PER MINUTE (DEPENDING ON CARTON DIMENSIONS) PROCESS REQUIREMENTS: -AUTOMATIC BOX OPENING, CARTONING -GLUE SPRAYING -BOX SEALING VOLTAGE: 220 VOLTS, 60Hz PLC MICRO COMPUTER FULL AUTOMATIC CONTROL MAN-MACHINE INTERFACE OPERATION SYSTEM (HMI), AUTOMATICALLY DISPLAYS THE PACKING SPEED, QUANTITY, FAULT REASON AND OTHER PERFORMANCE PARAMETERS. THE INDENTATION OF THE CARTON IS GENERALLY: 0.4mm DEEP QUANTITY: 1 Learn More

Z-1613 AUTOMATIC CARTON PACKAGING MACHINEZ-1613 AUTOMATIC CARTON PACKAGING MACHINE CARTONING FORM: HORIZONTAL CARTONING CARTONING SPEED: 30 TO 40 BOXES PER MINUTE (DEPENDING ON CARTON DIMENSIONS) PROCESS REQUIREMENTS: -AUTOMATIC BOX OPENING, CARTONING -GLUE SPRAYING -BOX SEALING VOLTAGE: 220 VOLTS, 60Hz PLC MICRO COMPUTER FULL AUTOMATIC CONTROL MAN-MACHINE INTERFACE OPERATION SYSTEM (HMI), AUTOMATICALLY DISPLAYS THE PACKING SPEED, QUANTITY, FAULT REASON AND OTHER PERFORMANCE PARAMETERS. THE INDENTATION OF THE CARTON IS GENERALLY: 0.4mm DEEP QUANTITY: 1 Learn More