Search results for: 'cas'

- Related search terms

- Cash k10

- Casing

- Casing equipments

- cash machin

- cast o

-

R-3266 SIROCCO SR 35 ROASTER - 35 KILOS

R-3266 SIROCCO SR 35 ROASTER - 35 KILOSR-3266 SIROCCO SR 35 ROASTER - 35 KILOS

SEVEN “MACHINES” IN ONE BODY. THAT SAVES YOU PRECIOUS SPACE, EXPENSIVE ENERGY, REDUCES WASTE AND TOTALLY QUIET. WHEN COMPARING, REMEMBER THAT YOU WILL NEVER NEED TO BUY OXIDIZER, AND A AFTERBURNER, SINCE IT IS ALL INCLUDED.

AFTERBURNER

INCINERATOR

CHAFF COLLECTOR

MANUALLY & PROGRAMMED PROFILE CONTROLLER

VARIABLE AIR SPEED CONTROLLER

SEPARATE HEAT CONTROLLER

GAS MODULATING CONTROLLERCOMPLETE ROASTING PROCESS WITH ALL FEATURES BUILT INSIDE ONE MACHINE

GENTLE CAST IRON ROASTING ENVIRONMENT

MECHANICALLY FLUIDIZED BEAN MOVEMENT

INTEGRATED AFTERBURNER AND INCINERATOR

TO ELIMINATE SMOKE, ODOR AND CHAFF

GRAPHICAL TOUCH SCREEN WITH PROFILE MEMORY

OVERSIZED INSPECTION PORTS

STIRFLEX COOLING TRAY

QUICK-RELEASE COOLER WITH REMOVABLE SCREEN

MAINTENANCE FREE SEALED ROASTING DRUM

BUILT-IN STONER BOOT

LOW PROFILE INFEED HOPPER

WEB-ENABLED FOR FACTORY ASSISTANCE AND DIAGNOSTICS

AUTOMATIC OR SEMI-AUTOMATIC OPERATION FOR CONSISTENT BATCHES

CLEAR PROCESS INFORMATION INCLUDES BEAN TEMP., ELAPSED TIME,

TEMPERATURE CHANGE AND STATUSSPECIFICATIONS:

MODEL #: SR 35

BATCH CAPACITY: 35 KGS

DIMENSIONS: 35" W X 112" L X 84" H

COOLER DIAMETER: 40

HEAT SPECIFICATIONS: GAS & 380K-760K

WEIGHT: 3600 LBSQUANTITY: 1

Learn More -

V-1041 AIRLAY- FELT LINE 2400mmINDEX 1. Technical specification pag.2 2. Line composition pag.3 3. Machines description pag.4 4. Total price of the turn-key plant pag.25 5. Sale terms pag.26 6. Payment terms pag.28 7. General selling terms and conditions pag.29 Learn More

V-1041 AIRLAY- FELT LINE 2400mmINDEX 1. Technical specification pag.2 2. Line composition pag.3 3. Machines description pag.4 4. Total price of the turn-key plant pag.25 5. Sale terms pag.26 6. Payment terms pag.28 7. General selling terms and conditions pag.29 Learn More -

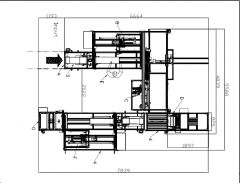

M-1456 COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATEDREFERENCE NUMBER: M-1456 (660211BTC5R) COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATED QUANTITY AVAILABLE: 1 Learn More

M-1456 COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATEDREFERENCE NUMBER: M-1456 (660211BTC5R) COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATED QUANTITY AVAILABLE: 1 Learn More -

TT-8223 VERSA-DRILL V100NG DRILLING RIG, YEAR 2009TT-8223 VERSA-DRILL V100NG DRILLING RIG, YEAR 2009 1. VERSA-DRILL V100NG DRILLING RIG 2. YEAR 2009 3. BRAND: VERSA-DRILL 4. MODEL: V100NG 5. YEAR: 2009 6. CONDITION: USED QUANTITY: 1 Learn More

TT-8223 VERSA-DRILL V100NG DRILLING RIG, YEAR 2009TT-8223 VERSA-DRILL V100NG DRILLING RIG, YEAR 2009 1. VERSA-DRILL V100NG DRILLING RIG 2. YEAR 2009 3. BRAND: VERSA-DRILL 4. MODEL: V100NG 5. YEAR: 2009 6. CONDITION: USED QUANTITY: 1 Learn More -

YY-3559 13 MW SIEMENS SGT-400 NATURAL GAS TURBINE GENSET 22 PICES 2022 NEW – UNUSEDYY-3559 13 MW SIEMENS SGT-400 NATURAL GAS TURBINE GENSET 22 PICES 2022 NEW – UNUSED DETAILS: 1. MANUFACTURER SIEMENS 2. MODEL SGT-400 3. YEAR 2022 4. CONDITION NEW 5. CATEGORY NATURAL GAS TURBINES 6. SUBCATEGORIES 10 - 99 MW 7. WATTAGE 13 MW 8. HOURS ZERO 9. FREQUENCY 50 Hz 10. FUEL TYPE NATURAL GAS 11. VOLTAGE 230 V 12. SIZE (L X W X H) 14.0 X 3.1 X 4.3 M 13. WEIGHT APPROX. 84 TON Learn More

YY-3559 13 MW SIEMENS SGT-400 NATURAL GAS TURBINE GENSET 22 PICES 2022 NEW – UNUSEDYY-3559 13 MW SIEMENS SGT-400 NATURAL GAS TURBINE GENSET 22 PICES 2022 NEW – UNUSED DETAILS: 1. MANUFACTURER SIEMENS 2. MODEL SGT-400 3. YEAR 2022 4. CONDITION NEW 5. CATEGORY NATURAL GAS TURBINES 6. SUBCATEGORIES 10 - 99 MW 7. WATTAGE 13 MW 8. HOURS ZERO 9. FREQUENCY 50 Hz 10. FUEL TYPE NATURAL GAS 11. VOLTAGE 230 V 12. SIZE (L X W X H) 14.0 X 3.1 X 4.3 M 13. WEIGHT APPROX. 84 TON Learn More -

YY-3558 13 MW SIEMENS SGT-400 NATURAL GAS TURBINE GENSET 12 PICES 2022 NEW UNUSEDYY-3558 13 MW SIEMENS SGT-400 NATURAL GAS TURBINE GENSET 12 PICES 2022 NEW UNUSED DETAILS: 1. MANUFACTURER SIEMENS 2. MODEL SGT-400 3. YEAR 2022 4. CONDITION NEW 5. CATEGORY NATURAL GAS TURBINES 6. SUBCATEGORIES 10 - 99 MW 7. WATTAGE 13 MW 8. HOURS ZERO 9. FREQUENCY 50 Hz 10. FUEL TYPE NATURAL GAS 11. VOLTAGE 230 V 12. SIZE (L X W X H) 14.0 X 3.1 X 4.3 M 13. WEIGHT APPROX. 84 TON Learn More

YY-3558 13 MW SIEMENS SGT-400 NATURAL GAS TURBINE GENSET 12 PICES 2022 NEW UNUSEDYY-3558 13 MW SIEMENS SGT-400 NATURAL GAS TURBINE GENSET 12 PICES 2022 NEW UNUSED DETAILS: 1. MANUFACTURER SIEMENS 2. MODEL SGT-400 3. YEAR 2022 4. CONDITION NEW 5. CATEGORY NATURAL GAS TURBINES 6. SUBCATEGORIES 10 - 99 MW 7. WATTAGE 13 MW 8. HOURS ZERO 9. FREQUENCY 50 Hz 10. FUEL TYPE NATURAL GAS 11. VOLTAGE 230 V 12. SIZE (L X W X H) 14.0 X 3.1 X 4.3 M 13. WEIGHT APPROX. 84 TON Learn More -

TT-7680 SIEMENS SST 400 CONDENSING STEAM TURBINE, YEAR 2011, 50/60Hz, 30 MWTT-7680 SIEMENS SST 400 CONDENSING STEAM TURBINE, YEAR 2011, 50/60Hz, 30 MW SIEMENS SST 400 YEAR 2011 TYPE: SST 400 CONDENSING STEAM TURBINE WITH FOUR BLEEDS AND ONE EXTRACTION TURBOSE OUTPUT: (AT GENERATOR TERMINALS) NORMAL 30 MW MAXIMAL 31.88 MW MINIMAL 4.5 MW QUANTITY: 4 Learn More

TT-7680 SIEMENS SST 400 CONDENSING STEAM TURBINE, YEAR 2011, 50/60Hz, 30 MWTT-7680 SIEMENS SST 400 CONDENSING STEAM TURBINE, YEAR 2011, 50/60Hz, 30 MW SIEMENS SST 400 YEAR 2011 TYPE: SST 400 CONDENSING STEAM TURBINE WITH FOUR BLEEDS AND ONE EXTRACTION TURBOSE OUTPUT: (AT GENERATOR TERMINALS) NORMAL 30 MW MAXIMAL 31.88 MW MINIMAL 4.5 MW QUANTITY: 4 Learn More -

TT-7562 CATERPILLAR 816B, YEAR 1989, RECONDITIONED, 17,330 HOURSTT-7562 CATERPILLAR 816B, YEAR 1989, RECONDITIONED, 17,330 HOURS 1. MACHINE HOURS: 17,330 2. CATERPILLAR DEALER REBUILT THE COMPLETE DRIVE TRAIN AT 15,384 HOURS 3. ENGINE, TORQUE, TRANSMISSION, TRANSFER CASE, BOTH DIFFERENTIALS, 4. ALL FINAL DRIVES, REAR AXLE OSCILLATION & HYDRAULIC PUMPS ETC. 5. REBUILD / REPAIR RECORDS ARE AVAILABLE. 6. ALL NEEDED REPAIRS & SERVICING HAS BEEN COMPLETED BY MARCEL EQUIPMENT SINCE ARRIVING IN OUR YARD. QUANTITY: 1 Learn More

TT-7562 CATERPILLAR 816B, YEAR 1989, RECONDITIONED, 17,330 HOURSTT-7562 CATERPILLAR 816B, YEAR 1989, RECONDITIONED, 17,330 HOURS 1. MACHINE HOURS: 17,330 2. CATERPILLAR DEALER REBUILT THE COMPLETE DRIVE TRAIN AT 15,384 HOURS 3. ENGINE, TORQUE, TRANSMISSION, TRANSFER CASE, BOTH DIFFERENTIALS, 4. ALL FINAL DRIVES, REAR AXLE OSCILLATION & HYDRAULIC PUMPS ETC. 5. REBUILD / REPAIR RECORDS ARE AVAILABLE. 6. ALL NEEDED REPAIRS & SERVICING HAS BEEN COMPLETED BY MARCEL EQUIPMENT SINCE ARRIVING IN OUR YARD. QUANTITY: 1 Learn More -

TT-4775 SCHRAMM T130XD DUAL ROTARY RIG, YEAR 2005TT-4775 SCHRAMM T130XD DUAL ROTARY RIG, YEAR 2005 CONDITION USED YEAR 2005 1350/500 SULLAIR COMPRESSOR QUANTITY: 1 Learn More

TT-4775 SCHRAMM T130XD DUAL ROTARY RIG, YEAR 2005TT-4775 SCHRAMM T130XD DUAL ROTARY RIG, YEAR 2005 CONDITION USED YEAR 2005 1350/500 SULLAIR COMPRESSOR QUANTITY: 1 Learn More -

TT-4126 WOOL CARDING MACHINETT-4126 WOOL CARDING MACHINE CONDITION: NEW WARRANTY OF CORE COMPONENTS: 1 YEAR MACHINE IS FOR SHEEP WOOL, CAMEL HAIR, CASHMERE, YAK DOWN AND OTHER ANIMAL FIBERS THIS MACHINE REMOVES COARSE HAIR, DANDRUFF AND OTHER IMPURITIES FROM SHEEP WOOL, SO NORMALLY THIS MACHINE CAN NOT BE EQUIPPED WITH A COILER FOR SHEEP WOOL TOPS. QUANTITY: 1 Learn More

TT-4126 WOOL CARDING MACHINETT-4126 WOOL CARDING MACHINE CONDITION: NEW WARRANTY OF CORE COMPONENTS: 1 YEAR MACHINE IS FOR SHEEP WOOL, CAMEL HAIR, CASHMERE, YAK DOWN AND OTHER ANIMAL FIBERS THIS MACHINE REMOVES COARSE HAIR, DANDRUFF AND OTHER IMPURITIES FROM SHEEP WOOL, SO NORMALLY THIS MACHINE CAN NOT BE EQUIPPED WITH A COILER FOR SHEEP WOOL TOPS. QUANTITY: 1 Learn More